Every year, commercial building owners lose millions of dollars to premature roof deterioration, with over 80% of these failures linked to inadequate protective coatings. In an era of rising energy costs and increasingly extreme weather, proper roof coating selection and maintenance have become critical to building longevity.

From extending roof life by up to 15 years to reducing cooling costs by 30%, modern coating systems offer compelling solutions for property owners and facility managers. However, navigating the complex landscape of coating options, application methods, and maintenance requirements can be overwhelming.

This comprehensive guide breaks down everything decision-makers need to know about commercial roof coatings, from fundamental concepts to advanced optimization strategies.

SECTION 1: FUNDAMENTAL CONCEPTS

Choosing the right roofing materials can dramatically affect both operational expenses and the lifespan of a building. With about 60% of commercial roofs being flat—an area that’s prone to wear—investing in high-quality coatings is crucial. These coatings not only extend the roof’s life but can also significantly lower maintenance costs. This section unpacks the different types of coatings available, their numerous benefits, and how they can be effectively applied, empowering property owners and facility managers to make informed decisions.

Types of Commercial Roof Coatings

Grasping the various types of commercial roof coatings is key to effective maintenance planning. Common choices include acrylic, silicone, and polyurethane coatings. Each of these options offers unique qualities, such as ultraviolet (UV) resistance or waterproofing, which can impact how well they perform over time.

Acrylic coatings are a favorite due to their versatility and reflectivity. They can help lower energy bills by keeping buildings cooler during summer months. On the other hand, silicone coatings excel at water resistance, making them perfect for roofs that experience frequent standing water, as they create a seamless protective layer.

If durability is a priority, polyurethane coatings stand out. They are tougher than acrylics and silicones, making them ideal for high-traffic roofs where wear and tear are common. The selection of the right coating type should hinge on the specific needs of the facility, underlining the importance of professional assessments for optimal outcomes.

Ultimately, the decision should consider factors like local climate, the existing condition of the roof, and the desired longevity of the coating, ensuring that the property is well-protected against the elements.

Benefits and Advantages

The advantages of applying coatings to commercial roofs are both significant and wide-ranging. One of the most compelling benefits is cost savings; roof coatings can lead to drastic reductions in energy bills. Reflective coatings, in particular, minimize heat absorption, allowing for more stable interior temperatures.

Moreover, these coatings provide outstanding protection against harsh weather conditions. They play a crucial role in preventing leaks, structural damage, and mold, effectively extending the roof’s lifespan. Remarkably, a well-maintained roof coating can add up to 15 years of life to a roof.

The ease of application is another considerable advantage. Most coatings can be applied without extensive roof repair or replacement, resulting in minimal disruption to business operations. This flexibility makes coatings an appealing option for facilities that are undergoing renovations or expansions.

Additionally, many coatings support environmental goals. Reflective roof coatings can significantly reduce energy consumption and mitigate the heat island effect found in urban settings, enabling buildings to showcase their commitment to sustainable practices. This environmental consciousness can be an attractive feature for many businesses.

Common Applications and Uses

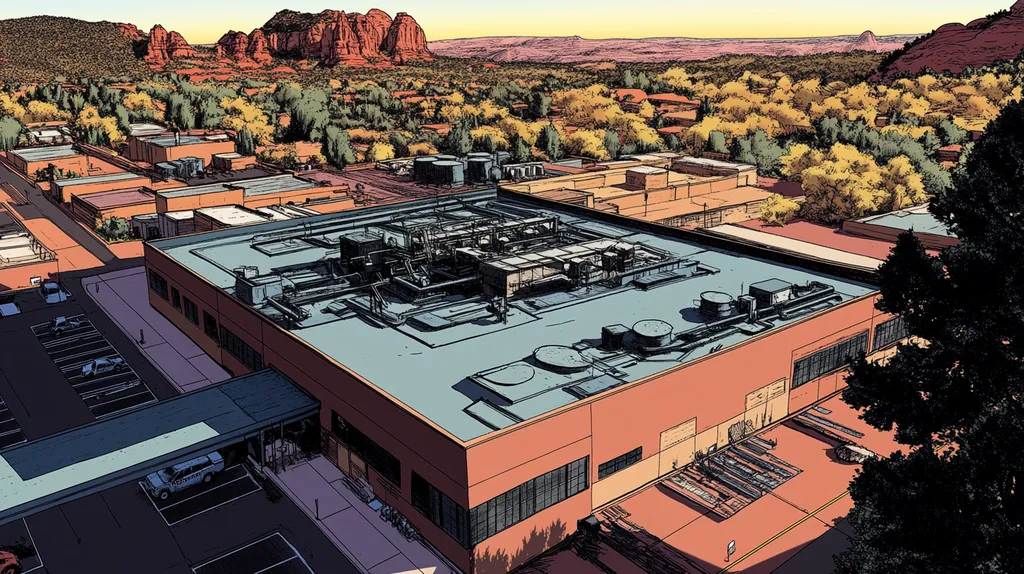

Commercial roof coatings find applications across a multitude of industries and building types. Their versatility makes them particularly suitable for school districts, warehouses, shopping centers, and industrial facilities where flat or low-slope roofs are prevalent.

In warehouse environments, where roof wear can accelerate due to equipment movement, a durable coating can shield against physical damage while boosting energy efficiency. Furthermore, coatings can seal minor leaks, preventing them from escalating into expensive repairs that can disrupt business.

In the retail space, where customer comfort is essential, reflective coatings can maintain cooler indoor temperatures and offer significant energy savings. Additionally, these coatings can enhance the overall aesthetics of a building, making it more inviting for customers.

In summary, the ability to tailor roofing coatings to accommodate the specific operational needs of a business underscores their vital role in modern roof management strategies. This adaptability makes them an indispensable investment for any commercial property owner.

SECTION 2: SYSTEM COMPONENTS

Choosing the right coating for a commercial roof is not just a matter of preference; it’s a critical decision that can significantly impact a building’s safety and financial health. Many property owners underestimate the importance of understanding the essential components of roof coatings. The materials chosen have a profound effect on durability, performance, and cost efficiency. According to the National Roofing Contractors Association (NRCA), poor coating choices can lead to premature roof failures, costing businesses thousands in repairs and replacements. This section will explore the fundamental components that make up roof coatings.

Materials and Formulations

The materials used in roof coatings play a crucial role in determining their longevity and protective capabilities. Common formulations include acrylic, silicone, and polyurethane, each offering unique benefits. For example, acrylic coatings are water-based and easy to apply, making them a popular choice for a variety of settings. On the other hand, silicone coatings deliver exceptional water resistance, making them particularly suited for wet climates where water pooling is a concern.

It’s essential to grasp the characteristics of these materials, as the formulation can influence not only the application process but also the ongoing maintenance needs. For instance, polyurethane coatings typically provide better chemical resistance, making them ideal for industrial environments where exposure to harsh substances is common.

Moreover, each formulation has specific cleaning and preparation requirements before application. Skipping these crucial pre-application steps can undermine the effectiveness of the coating. Thus, selecting a formulation that aligns with the existing roof material and its intended use is vital.

Additionally, application method matters significantly. Different types of coatings may require particular thicknesses and layering techniques, ultimately affecting the roof’s overall durability and performance. Understanding these details is key to ensuring a successful coat.

Adhesion and Compatibility

Proper adhesion is one of the most vital factors impacting the performance of roof coatings. If a coating fails to stick appropriately, moisture can sneak in and cause significant damage. This makes compatibility between the existing roof and the new coating paramount.

For instance, applying a silicone coating on a substrate not designed for it could result in peeling or bubbling. This incompatibility often stems from the chemical properties of the materials in question. Consulting with roofing specialists can help identify the best material combinations to ensure a solid bond.

Furthermore, surface preparation is critically important. Contaminants like oil, grease, and dirt can severely hinder adhesion, so thorough cleaning is essential. An improperly prepared surface can lead to costly failures and unexpected repairs, which could have been avoided.

In a competitive marketplace, strong adhesion can offer a significant advantage. Roofs with high adhesion rates are likely to outlast their poorly adhered counterparts and require less frequent maintenance, translating into substantial cost savings for property managers.

Thickness and Coverage Requirements

The thickness of the coating and the coverage requirements are crucial for ensuring the effectiveness of roof coatings. Each product comes with specific recommendations regarding the number of coats and total mil thickness required for optimal results. Ignoring these recommendations can lead to underperformance.

For example, a coating that is too thin may not provide adequate UV protection, leading to deterioration and possible leaks. Conversely, applying an excessive thickness can cause cracking and peeling. Achieving a balanced application requires careful attention to detail.

Environmental factors also influence the necessary thickness for coatings. Roofs situated in areas subject to extreme weather may need thicker applications to withstand severe conditions. This underscores the necessity for a customized approach in selecting coatings.

Ultimately, understanding these coverage requirements empowers property owners to make choices that prolong the lifespan of their roofing systems. Proper application thickness ensures the roof can endure environmental stress while delivering top-notch performance.

SECTION 3: IMPLEMENTATION METHODS

Effectively applying roof coatings is essential for safeguarding commercial properties and maximizing roof longevity. Neglecting proper surface preparation can lead to coating failures, resulting in expensive repairs and potential interruptions in business operations. In fact, inadequate surface prep ranks among the top causes of coating-related issues, according to the Roofing Contractors Association. This section will delve into critical surface preparation techniques, optimal application methods, and vital safety considerations to ensure a successful coating project.

Surface Preparation Techniques

Surface preparation sets the stage for a successful roofing project. Proper cleaning is crucial to ensure that coatings adhere effectively to the roof. Often, this involves power washing to eliminate dirt, debris, and old coatings. For instance, if a factory roof is coated with a layer of grime, it will prevent new coatings from bonding adequately.

In some cases, surface repairs must be addressed before applying a new coating. Patching leaks or sealing gaps can stop moisture from entering, which would compromise the integrity of the coating. Utilizing moisture surveys can help identify hidden issues that should be resolved prior to application.

Choosing the right primer is also key; various coatings need specific primers to achieve optimal adhesion. Using incompatible products could lead to delamination, which can jeopardize the entire roofing system.

Finally, verifying that the surface is dry and free from contaminants is essential to enhance coating performance. A surface that successfully passes the “water bead test”—where water beads up and doesn’t soak in—indicates it’s ready for the next steps.

Application Methods and Tools

The methods of application greatly affect how well roofing coatings perform. Spray application is often favored for its speed and overall coverage, while rollers and brushes are better for reaching edges and corners. Each method has its own advantages, depending on the roofing material and type of coating being used.

Temperature and humidity are also crucial factors to consider. Most coatings require specific climate conditions for proper curing, so applying them in extreme heat or cold can lead to issues during drying and overall application failure.

Using the right tools is essential for achieving a polished final product. High-quality sprayers, rollers, and brushes can significantly impact the uniformity of the finish. It’s important to adhere to manufacturer guidelines regarding application rates and techniques for the chosen coating.

Moreover, layering coatings can provide enhanced performance. Multiple thin layers generally outperform a single thick coat, as they help to reduce the risk of bubbling or cracking.

Safety and Environmental Considerations

Safety should always be a top priority during the application process. Many roofing coatings contain volatile organic compounds (VOCs), which can pose health risks if proper precautions aren’t taken. Employing appropriate personal protective equipment (PPE) for workers is crucial to minimize exposure.

It is also essential to adhere to environmental regulations regarding the handling and disposal of roofing materials. Opting for low-VOC coatings can significantly lower environmental impact while improving air quality around the building.

Furthermore, ensuring proper ventilation during application is vital. Adequate airflow helps disperse potentially harmful fumes, maintaining a safe working environment for both workers and building occupants.

Lastly, involving trained professionals in the application process can further mitigate risks. Their experience ensures compliance with safety guidelines and environmental standards, protecting both employees and the facility from potential hazards.

SECTION 4: MAINTENANCE REQUIREMENTS

Neglecting the maintenance of coatings on commercial roofs can lead to significant damage and costly repairs. In fact, research indicates that regular inspections can extend a roof’s lifespan by up to 25%. This section highlights the critical need for routine inspections, timely repairs, and well-structured maintenance schedules to protect roofing investments and avoid potential losses.

Inspection and Monitoring

Regular inspections are essential for maintaining the integrity of coated roofs. Experts suggest performing assessments at least twice a year, especially following significant weather events. These proactive check-ups help catch potential problems before they escalate into major issues.

Facility managers should keep an eye out for signs of wear during inspections, such as cracks, peeling, or blistering in the coating. Spotting these issues early enables quick action, preventing moisture from infiltrating and causing more severe structural problems.

Drones and infrared technology can greatly enhance monitoring accuracy, ensuring comprehensive assessment of the entire roof surface. These advanced tools offer detailed insights on roof conditions, allowing for well-informed maintenance decisions.

Additionally, keeping detailed records of inspections is invaluable for tracking deterioration over time. This documentation assists in budgeting future maintenance or repairs, ultimately prolonging the roof’s lifespan and performance.

Repair and Touch-Up Procedures

Timely repairs are crucial to maintaining the effectiveness of roof coatings. Addressing small cracks and blisters promptly can prevent further damage and save thousands in future repair costs. Think of these quick fixes as preventive medicine for commercial roofs.

When conducting repairs, it’s important to select patching materials that match the existing coating. Using incompatible products can lead to more damage, compromising the protective layer you worked so hard to maintain.

Facility managers should establish straightforward procedures for reporting damages discovered during inspections. Addressing these issues quickly enhances safety and helps protect the roofing investment.

Training maintenance staff on basic repair techniques can also be beneficial. This empowers teams to respond rapidly to issues, reducing reliance on external contractors and streamlining the repair process.

Preventative Maintenance Schedules

A well-organized preventative maintenance schedule can significantly enhance a roof’s longevity. This involves outlining routine tasks, like cleaning surfaces, addressing minor repairs, and monitoring the health of the coatings.

The frequency of these tasks can depend on environmental factors. For instance, roofs in regions that experience heavy rain or snowfall may require more frequent maintenance checks compared to those in drier climates.

Integrating preventative maintenance into the overall facility management plan emphasizes its importance. Utilizing software for scheduling and reminders can simplify the process, ensuring that essential maintenance tasks aren’t overlooked.

Investing in a structured maintenance approach not only safeguards the physical integrity of the roof but also boosts the overall property value. Preventative measures help reduce the need for emergency repairs, saving time and resources in the long run.

SECTION 5: PERFORMANCE METRICS

When it comes to selecting coatings for commercial roofs, performance metrics are far more than just numbers—they are the indicators of longevity and efficiency that can affect a building’s bottom line. Poor water resistance can lead to leaks, causing damage that could run into thousands of dollars. Likewise, inadequate UV and weather resistance shortens the lifespan of your roof, driving up maintenance expenses and lowering the overall value of the property. This section dives into the essential performance metrics that should be top of mind when choosing roof coatings.

Water Resistance and Durability

A roof coating’s ability to resist water is one of the most crucial performance metrics. If a coating fails to seal properly, it can allow water infiltration, jeopardizing the roof’s structural integrity. The cost associated with repairing leaks can be substantial, so investing in a reliable coating is vital.

Durability is another key factor; coatings must endure various environmental conditions over time without losing functionality. For instance, coatings suited for areas with heavy rainfall or snow must remain intact, performing effectively for years before needing replacement.

Opting for high-quality materials enhances both waterproofing and durability. This means choosing products specifically engineered to resist the wear and tear of ever-changing weather conditions while serving as a reliable barrier against water ingress.

To maintain effective water resistance, it’s essential to schedule regular roof maintenance and inspections. Property owners should conduct routine checks to identify potential vulnerabilities and address them before they develop into more significant issues.

UV and Weather Resistance

Ultraviolet (UV) radiation can significantly diminish the lifespan of roof coatings if not adequately addressed. Coatings lacking sufficient UV protection risk fading, peeling, or cracking, which leads to faster deterioration. This degradation not only affects the coating but can also result in increased energy costs due to reduced reflective properties that allow heat absorption.

Weather resistance is equally critical, especially for roofs exposed to extreme conditions. A coating should not only withstand UV radiation but also be resilient against high winds, hail, and temperature fluctuations. High-quality coatings are formulated to retain their protective qualities even in the harshest environments.

Modern coatings feature advanced formulations that offer enhanced UV and weather protection compared to older products. Selecting coatings with these advanced features can lead to substantial long-term savings while reducing the environmental footprint.

Regular assessments and timely reapplication of coatings are necessary to maximize protection against UV rays and weather-related damage. Taking this proactive approach helps maintain a robust and durable roof over time.

Energy Efficiency and Reflectivity

Energy efficiency is increasingly vital to commercial properties, impacting operational costs and environmental sustainability. Roof coatings designed to reflect sunlight significantly reduce heat absorbed by buildings, thus lowering energy consumption for cooling. This is particularly important in urban areas facing heat island effects.

Reflectivity serves as a key performance metric influencing energy efficiency. Coatings with high reflectivity can lower the temperature of roofs by up to 20% when compared to darker surfaces, translating directly into decreased reliance on air conditioning and substantial energy savings.

Moreover, certain coatings meet or exceed energy efficiency standards. Such products not only provide immediate financial savings but can also help earn credits under green building certifications.

Investing in energy-efficient coatings not only boosts property value but also enhances marketability, attracting eco-conscious tenants and buyers looking for sustainable features.

SECTION 5: PERFORMANCE METRICS

The effectiveness of coatings on commercial roofs plays a vital role in determining not only the roof’s lifespan but also the overall functionality of the building. Insufficient water resistance can lead to leaks, resulting in expensive interior damage and disruptions. Similarly, coatings that fail to withstand UV rays and harsh weather can quickly degrade, leading to increased maintenance costs and lower property values. This section highlights the essential performance metrics that should always be considered when selecting roof coatings.

Water Resistance and Durability

Water resistance stands out as a crucial performance metric for roof coatings. Coatings that fail to provide a watertight seal can invite moisture infiltration, jeopardizing the roof’s structural integrity and resulting in costly repairs. A well-sealed roof successfully prevents water damage, helping property owners avoid excessive expenses related to unforeseen leaks.

Durability is equally important. Coatings need to withstand a variety of environmental conditions without losing effectiveness. For example, roofs in regions prone to heavy rain or snowfall must maintain their integrity for years without frequent replacements, which can otherwise inflate long-term costs.

Choosing high-quality materials that prioritize both waterproofing and durability is essential. Investing in well-engineered coatings safeguards roofs against wear and tear while providing reliable protection from water ingress.

Routine maintenance and inspections play a critical role in ensuring ongoing water resistance. Property owners should schedule regular checks to spot vulnerabilities early on, ultimately prolonging the roof’s life.

UV and Weather Resistance

UV radiation can dramatically cut short the lifespan of roof coatings if not addressed properly. Coatings lacking adequate UV protection risk fading, peeling, or cracking, leading to rapid deterioration. This deterioration not only impacts the protective coating but also increases energy costs due to raised heat absorption from a loss of reflective properties.

Weather resistance is just as vital, particularly for roofs exposed to severe storms. Coatings should be engineered to endure not only UV rays but also high winds and extreme temperature fluctuations. Quality coatings maintain their protective properties and performance even in tough conditions.

Modern coatings often feature advanced formulations that provide superior UV and weather resistance. Opting for these enhanced coatings can yield significant long-term savings and minimize the environmental footprint.

Regular assessments and timely reapplications of coatings maximize their effectiveness against UV damage and severe weather. A proactive maintenance strategy helps keep a roof strong and resilient for the long haul.

Energy Efficiency and Reflectivity

Energy efficiency has become a top priority for commercial properties, affecting both operating costs and sustainability initiatives. Roof coatings designed to reflect sunlight can help reduce the heat absorbed by buildings, leading to lower cooling energy consumption. This is particularly crucial in urban environments suffering from heat island effects.

Reflectivity is a pivotal performance metric that directly influences energy efficiency. Coatings with high reflectivity can lower roof temperatures by up to 20% compared to darker materials, translating directly to reduced reliance on air conditioning and substantial savings on energy bills.

Additionally, certain coatings are engineered to meet or exceed specific energy efficiency standards, offering immediate financial rewards and contributing to green building certifications.

Investing in energy-efficient coatings not only enhances property value but also improves marketability. Buildings with sustainable features tend to attract environmentally aware tenants and buyers, further amplifying their appeal.

Looking Ahead

With commercial roof failures costing businesses over $2.5 billion annually, selecting and maintaining proper protective coatings has never been more critical.

Modern coating technologies offer building owners unprecedented opportunities to extend roof life, reduce energy costs, and protect their investments against increasingly extreme weather patterns.

However, success requires a systematic approach – from careful material selection and professional application to consistent monitoring and maintenance.

The future of commercial roofing lies in these advanced coating systems, which continue to evolve with improved durability, enhanced energy efficiency, and reduced environmental impact.

By implementing the strategies outlined in this guide, property owners and facility managers can maximize their roof’s performance while minimizing long-term costs.

FREQUENTLY ASKED QUESTIONS

Q. What types of coatings are best for a commercial roof?

A. The best coatings for a commercial roof include acrylic, silicone, and polyurethane. Each type offers unique benefits, such as UV resistance or waterproofing, which can significantly affect their performance over time. It’s essential to choose based on your facility’s specific needs and local climate for optimal protection.

Q. How do I know if my industrial roof coating is compatible with my roof?

A. To determine compatibility, consider both the existing roof material and the new coating’s specifications. Consulting with a roofing specialist can help identify the best material combinations, ensuring proper adhesion and performance. Proper surface preparation is also critical to the coating’s effectiveness.

Q. What surface preparation is needed for a commercial roof coating?

A. Surface preparation involves thorough cleaning, often including power washing to remove dirt and debris. Any existing damage, like leaks or cracks, should be addressed before application. Additionally, confirming the surface is dry and free from contaminants ensures strong adhesion of the new coating.

Q. How often should I inspect my commercial roof for maintenance?

A. It’s advisable to inspect your commercial roof at least twice a year, especially after significant weather events. Regular inspections help identify wear and potential issues early, allowing for timely repairs that can prevent extensive damage and costly repairs in the future.

Q. What performance metrics should I consider for a commercial roof coating?

A. Key performance metrics include water resistance, UV resistance, and weather durability. These factors influence the effectiveness and longevity of the coating, impacting your roof’s protection and maintenance costs. Investing in high- quality coatings can lead to substantial long-term savings and improved property value.

Q. What are the best safety practices during roof coating application?

A. Safety practices include using personal protective equipment (PPE) and ensuring proper ventilation. It is crucial to follow environmental regulations concerning material disposal. Training employees on application methods further enhances safety while reducing the risk of accidents and exposure to harmful substances.

Q. What’s the impact of reflective coatings on energy efficiency in commercial roofs?

A. Reflective coatings significantly improve energy efficiency by reducing heat absorption, which lowers cooling costs. This is especially beneficial in urban areas facing heat island effects. Additionally, these coatings can contribute to green building certifications, enhancing property appeal and marketability.