In commercial buildings across hot climate regions, roof surface temperatures now routinely exceed 180°F, accelerating material breakdown and driving cooling costs to unprecedented levels. Studies indicate unprotected roofing systems in these environments deteriorate 40% faster than their projected lifespan.

Modern coating technologies offer a critical defense against these extreme conditions, with advanced formulations capable of reducing surface temperatures by up to 60°F while extending roof longevity by 15-20 years.

This comprehensive guide examines the essential elements of commercial roof coatings for hot climates, from material selection and application considerations to long-term performance metrics and maintenance requirements.

SECTION 1: THE BASICS EXPLAINED

Commercial roofing systems in hot climates face unprecedented challenges, with surface temperatures routinely exceeding 150°F during peak summer months. These extreme conditions accelerate material degradation, increase cooling costs, and reduce roof lifespans by up to 45%. Protective coatings represent a critical defense against these challenges, offering both immediate and long-term benefits for commercial property owners.

What It Is (In Plain Language)

Roof coatings are engineered liquid compounds that create a seamless, protective membrane when applied to commercial roofing surfaces. These specialized formulations contain advanced polymers, reflective pigments, and UV-resistant compounds designed specifically for extreme heat conditions.

Modern coating systems come in several categories, including acrylic, silicone, and polyurethane variants. Each type offers distinct advantages, from superior waterproofing to exceptional UV reflection, allowing property managers to select solutions tailored to their specific climate challenges.

The application process transforms these liquid materials into a durable, monolithic barrier that adheres firmly to the existing roof surface. This seamless membrane eliminates weak points and provides comprehensive protection against thermal stress.

Unlike traditional roofing materials, these coatings can be applied without disrupting building operations, making them an efficient solution for maintaining commercial properties.

Why It Matters (To Your Building)

Thermal loading represents one of the most significant threats to commercial roofing systems in hot climates. Without proper protection, intense heat causes progressive material breakdown, leading to premature aging and structural compromise.

Heat-resistant coatings directly address this challenge by reflecting up to 85% of solar radiation. This dramatic reduction in heat absorption helps maintain stable roof temperatures, preventing thermal expansion and contraction cycles that cause material fatigue.

The financial implications are substantial, as properly coated roofs typically reduce cooling costs by 20-30% during peak summer months. This efficiency improvement translates to immediate operational savings and enhanced building value.

Protected roofing systems also require fewer repairs and extend replacement intervals by 10-15 years, generating significant long-term cost benefits for property owners.

How It Works

Protective coatings function through multiple mechanisms to shield commercial roofs from heat damage. The primary defense comes from specialized reflective pigments that scatter incoming solar radiation before it can be absorbed into the roofing structure.

These systems also incorporate advanced polymer technologies that maintain flexibility across extreme temperature ranges. This elasticity prevents coating failure during thermal cycling, ensuring continuous protection throughout the year.

The molecular structure of quality coatings creates a moisture-resistant barrier while allowing trapped vapor to escape. This balance prevents both water infiltration and pressure buildup beneath the coating surface.

Chemical stabilizers within the coating matrix actively resist UV degradation, maintaining protective properties even after years of sun exposure. This durability ensures consistent performance throughout the coating’s service life.

SECTION 2: PRACTICAL APPLICATIONS

Commercial roofing in hot climates faces unprecedented challenges, with surface temperatures routinely exceeding 180°F. Modern coating technologies have emerged as a critical solution, offering substantial protection against extreme heat while reducing energy costs. Understanding the practical applications of these systems is essential for property managers seeking to optimize their building performance and protect their investments.

Common Uses & Examples

Cool roof coatings serve as specialized protective layers that reflect sunlight and absorb less heat compared to traditional roofing materials. These advanced systems can reduce surface temperatures by up to 50-60°F while protecting against UV degradation and thermal expansion. (source: CES Roofing)

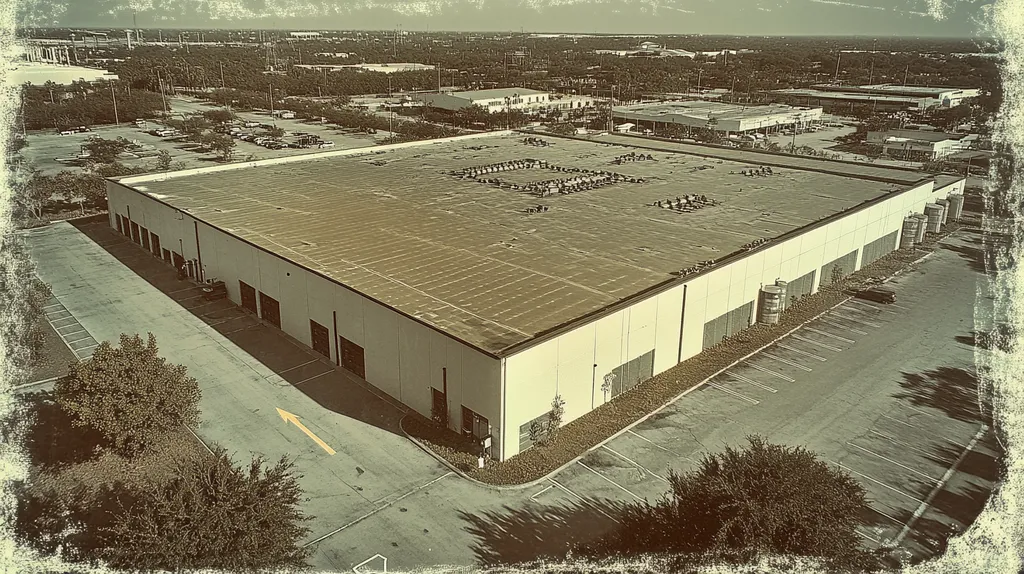

Large commercial facilities, particularly distribution centers and manufacturing plants, frequently implement these coatings to combat excessive heat load. The seamless membrane creates an uninterrupted barrier against thermal stress while maintaining flexibility under extreme conditions.

Retail complexes and office buildings utilize reflective coatings to enhance energy efficiency and extend roof lifespans. These applications often target aging roof systems, providing renewed protection while avoiding costly replacement.

Healthcare facilities and data centers employ specialized coating formulations that offer both thermal protection and bacterial resistance. These dual-purpose systems help maintain critical internal environments while reducing operational costs.

When You Need It Most

Strategic timing of coating applications maximizes their effectiveness and return on investment. Early intervention, typically at the first signs of roof aging or before extreme weather seasons, provides optimal protection and cost efficiency.

New construction projects benefit from immediate coating application, as integration with fresh roofing systems ensures maximum adhesion and performance. This proactive approach establishes robust protection from day one.

Buildings experiencing significant cooling costs or showing early signs of heat-related deterioration require immediate coating consideration. These indicators often emerge 5-7 years into a roof’s service life, marking the ideal intervention window.

Seasonal transitions, particularly before peak summer months, present optimal application periods. This timing allows proper curing and ensures maximum protection during intense heat conditions.

Interactions With Other Systems

Coating systems must integrate effectively with existing roofing components to achieve optimal performance. The interaction between coatings and underlying materials directly impacts system longevity and effectiveness.

HVAC efficiency improves significantly when coupled with properly applied roof coatings. Reduced thermal load translates to decreased mechanical strain and extended equipment life cycles.

Building envelope systems benefit from the additional moisture protection provided by quality coatings. This synergy enhances overall building performance and reduces interior condensation risks.

Solar panel installations perform more efficiently when combined with reflective coating systems. The reduced ambient roof temperature helps maintain optimal panel efficiency while protecting underlying materials.

SECTION 3: KEY TERMINOLOGY DECODED

Commercial roofing terminology presents a significant challenge for property owners and facility managers, with misunderstandings leading to costly installation errors and premature system failures. Technical specifications directly impact energy efficiency, with proper material selection potentially reducing cooling costs by up to 40%. Understanding these key terms enables informed decision-making and optimal system performance in extreme heat conditions.

Essential Terms Explained

Solar reflectance represents the most critical performance metric for hot climate applications, measuring the percentage of solar energy reflected rather than absorbed. Higher reflectance values, typically ranging from 0.60 to 0.85, indicate superior heat resistance and reduced thermal loading.

Thermal emittance quantifies a material’s ability to release absorbed heat back into the atmosphere. This property works in conjunction with reflectance to determine overall cooling efficiency and becomes particularly crucial during extended heat exposure.

Tensile strength indicates a coating’s resistance to physical stress and thermal expansion. This measurement becomes essential in hot climates where dramatic temperature fluctuations create significant material strain.

Permeability ratings determine how effectively coatings balance water resistance with vapor transmission. Optimal permeability prevents both moisture infiltration and trapped condensation, protecting underlying roof structures.

Industry Jargon Translated

Cool roof systems encompass specialized coating formulations engineered specifically for thermal management. These systems utilize advanced polymer technology to maintain performance under extreme temperature conditions.

Mil thickness refers to the coating’s applied depth, measured in thousandths of an inch. Proper mil thickness ensures adequate protection while avoiding material waste or application defects.

Substrate compatibility describes how effectively coatings bond with existing roof surfaces. This factor determines both initial adhesion and long-term performance under thermal stress.

Service life indicators predict coating durability based on environmental exposure and material properties. These metrics help facility managers plan maintenance schedules and replacement intervals.

Measurement & Units Simplified

Solar Reflectance Index (SRI) combines reflectance and emittance into a single value ranging from 0 to 100. Higher numbers indicate better thermal performance, with premium coatings achieving SRI values above 100 in laboratory testing.

Volume solids percentage indicates the amount of useful coating material remaining after curing. This measurement helps calculate coverage rates and determine actual material costs for project planning.

Elongation capacity measures a coating’s ability to stretch without breaking, expressed as a percentage of original length. Hot climate applications typically require minimum elongation values of 180% to accommodate thermal movement.

Adhesion strength quantifies the bond between coating and substrate in pounds per square inch (psi). Higher values indicate better resistance to thermal stress and mechanical damage, with quality systems exceeding 400 psi.

SECTION 4: DECISION FACTORS

Commercial property owners face critical decisions when selecting roofing coatings for hot climates, with choices directly impacting both immediate operations and long-term facility costs. Surface temperatures in these environments regularly exceed 180°F, accelerating material degradation and increasing cooling demands by up to 40%. Making informed coating decisions becomes essential when considering that proper selection can reduce internal temperatures by up to 50°F while extending roof lifespans by 15-20 years.

Cost Considerations

Initial coating investments typically range from $2-8 per square foot, varying significantly based on material quality and application requirements. Premium materials often command higher upfront costs but deliver superior performance metrics and extended service life.

Installation expenses encompass surface preparation, primer application, and final coating procedures. These costs can increase by 25-40% when addressing existing surface damage or requiring specialized application techniques.

Maintenance requirements significantly impact total ownership costs, with high-quality systems typically requiring inspection and maintenance every 3-5 years versus annual attention for standard coatings. This differential can represent a 30-40% variance in long-term maintenance expenses.

Energy savings potential must factor into cost analysis, as reflective coatings in hot climates can reduce cooling costs by up to 30%. In regions with intense UV exposure, these savings can offset premium material costs within 2-3 years. (source: Solaria Solar and Roofing)

Performance Trade-offs

Coating performance characteristics vary significantly across product categories, with each type offering distinct advantages and limitations. Silicone coatings provide superior UV resistance but may accumulate surface dirt more readily than alternative materials.

Durability often correlates directly with coating thickness, typically measured in dry mils. While thicker applications offer enhanced protection, they increase material costs and may impact application procedures.

Chemical resistance becomes crucial in industrial environments where roof surfaces encounter various pollutants. Enhanced chemical protection often requires specialized formulations that may reduce other performance attributes.

Weather resistance capabilities differ among coating types, with some excelling in extreme heat but showing reduced performance in areas with frequent rainfall or high humidity. This variance necessitates careful climate-specific selection.

Lifespan & Durability Factors

Environmental exposure represents the primary determinant of coating longevity, with UV radiation and thermal cycling causing progressive material degradation. Quality systems maintain protective properties for 15-20 years, while standard materials may require replacement within 7-10 years.

Surface preparation quality directly influences coating adhesion and long-term performance. Proper cleaning and priming can extend service life by 30-40% compared to installations with minimal preparation.

Application conditions significantly impact coating durability, with temperature and humidity during installation affecting cure rates and final membrane characteristics. Optimal conditions ensure maximum service life and performance.

Maintenance protocols play a crucial role in system longevity, with regular inspections and prompt repairs preventing minor issues from escalating into significant problems. Established maintenance programs can extend coating life by 25-35%.

SECTION 5: COMMON CHALLENGES

Commercial roofing systems in hot climates face unprecedented stress, with surface temperatures frequently exceeding 180°F during peak periods. These extreme conditions accelerate material degradation, compromise structural integrity, and drive excessive cooling costs that can exceed $100,000 annually for large facilities. Understanding and addressing these challenges becomes critical as global temperatures continue rising, with proper management strategies potentially extending roof lifespans by 15-20 years while reducing energy consumption by up to 40%.

Frequent Problems & Solutions

Thermal cycling represents the primary threat to coating integrity, as daily temperature fluctuations create expansion and contraction that stresses material bonds. These cycles can reduce coating adhesion by up to 40% within the first three years of installation.

UV degradation accelerates coating breakdown, particularly in poorly formulated or improperly applied systems. This deterioration manifests through surface chalking, color fading, and progressive loss of protective properties.

A cooler roof translates directly to reduced structural stress and lower operational costs. Premium coating systems can decrease surface temperatures by up to 60°F while significantly reducing the load on HVAC systems. (source: Polo International)

Moisture entrapment beneath coating surfaces leads to blistering and delamination. Proper surface preparation and coating selection can eliminate 90% of these moisture-related failures.

Warning Signs To Watch For

Surface crazing and micro-cracking indicate early stages of coating stress. These minute imperfections create entry points for moisture and accelerate system deterioration if left unaddressed.

Reflectivity loss manifests through darkening or discoloration of coating surfaces. This degradation reduces thermal performance and increases building cooling demands.

Edge lifting and separation along seams signal adhesion failures that require immediate attention. These defects typically emerge at roof transitions and penetrations where thermal stress concentrates.

Increasing energy costs, particularly during peak summer months, often indicate declining coating performance. Monthly utility tracking can identify these trends before visible damage occurs.

Preventative Approaches

Systematic inspection protocols must include thermal imaging and adhesion testing at quarterly intervals. This rigorous monitoring enables early detection of coating degradation before substantial damage occurs.

Surface cleaning requirements increase in environments with high dust or industrial pollution. Establishing monthly cleaning schedules prevents contaminant accumulation that degrades coating performance.

Strategic recoating intervals, typically every 7-10 years, maintain optimal protection. This proactive approach prevents the cascading failures that occur when coatings exceed their service life.

Detailed documentation of coating performance metrics, including reflectivity measurements and thermal readings, enables data-driven maintenance decisions. This analytical approach optimizes both timing and scope of preventative measures.

SECTION 6: NEXT STEPS & RESOURCES

Commercial property owners face critical decisions regarding roofing solutions as surface temperatures continue breaking records nationwide. With cooling costs representing up to 40% of building energy consumption, selecting appropriate coating systems becomes increasingly vital. Current market conditions demand thorough evaluation of providers, compliance with evolving standards, and ongoing education to protect substantial roofing investments.

Questions To Ask Providers

Quality assurance verification represents the first critical inquiry when evaluating coating providers. Request detailed documentation of their quality control processes, application procedures, and post-installation inspection protocols.

Performance metrics demand thorough examination, including specific data on thermal resistance, UV protection, and expected service life. Providers should supply comprehensive test results demonstrating coating effectiveness under extreme conditions.

Material compatibility testing procedures must be clearly defined and documented. Professional providers conduct systematic evaluations to ensure coating adhesion and performance with existing roof substrates.

Project timelines and disruption mitigation strategies require detailed discussion. Experienced providers present clear schedules that minimize impact on building operations while ensuring proper installation conditions.

Industry Standards & Guidelines

The specific performance requirements for cool roof retrofitting vary significantly based on building type, occupancy patterns, and geographic location. Coating selections must align with these variables to maximize energy efficiency and operational benefits. (source: Greater London Authority)

ASTM D6083 establishes minimum requirements for acrylic coating performance, including elongation capacity, tensile strength, and adhesion characteristics. These standards provide essential benchmarks for material selection.

Cool Roof Rating Council (CRRC) ratings offer standardized metrics for comparing coating reflectivity and emissivity. These measurements enable objective evaluation of thermal performance potential.

FM Global and UL requirements define safety and durability standards for coated roof assemblies. Compliance with these guidelines ensures proper system integration and long-term reliability.

Further Learning Simplified

Professional certification programs provide structured education on coating technologies and application methods. These courses offer detailed insights into material science and installation best practices.

Technical bulletins from major coating manufacturers deliver regular updates on product innovations and application techniques. These resources help maintain current knowledge of evolving solutions.

Industry associations conduct regional seminars focused on climate-specific challenges and solutions. These events facilitate direct interaction with technical experts and experienced practitioners.

Online learning platforms offer on-demand access to detailed case studies and performance data. These resources enable comprehensive analysis of coating applications in similar environments.

The Bottom Line

With commercial roof temperatures now routinely exceeding 180°F in hot climates, protective coatings have become critical infrastructure investments rather than optional upgrades.

Studies demonstrate that properly selected and maintained coating systems can reduce surface temperatures by up to 60°F while extending roof lifespans by 15-20 years.

The financial implications are substantial, with quality coating systems delivering 20-40% reductions in cooling costs and up to 300% returns on investment over their service life.

As global temperatures continue rising, implementing appropriate coating solutions represents a fundamental requirement for protecting commercial building assets and ensuring operational sustainability.

Property owners who delay coating implementation face accelerated material degradation, excessive energy costs, and premature roof replacement – challenges that grow more costly with each passing season.

FREQUENTLY ASKED QUESTIONS

Q. What are commercial roofing coatings for hot climates?

A. Roof coatings are liquid compounds that form a seamless protective membrane when applied. They are designed to combat extreme heat, providing essential waterproofing, reflection of UV rays, and thermal protection, thereby enhancing the roof’s performance and longevity.

Q. How do coatings benefit commercial roofs in hot weather?

A. Coatings protect roofs from high temperatures by reflecting solar radiation and minimizing heat absorption. This helps reduce cooling costs significantly, prolongs the roof’s lifespan, and mitigates material degradation, ultimately leading to lower maintenance and replacement costs.

Q. What should I know about commercial roof coatings ingredients?

A. Common ingredients in these coatings include reflective pigments, advanced polymers, and UV stabilizers. These components work together to enhance the roof’s thermal performance, ensure flexibility under temperature variations, and provide durability against UV degradation and moisture infiltration.

Q. What factors influence the choice of coatings for industrial roofs?

A. Factors include the roof’s age, existing material condition, local climate, and the specific performance needs of the facility. Additionally, considerations around cost, maintenance frequency, and expected service life are critical in selecting the optimal coating solution for industrial roofs.

Q. How often should commercial roof coatings be maintained?

A. Maintenance schedules typically recommend inspections every 3-5 years. Regular check-ups ensure the coatings remain effective, addressing any potential issues early and maximizing the protection and longevity of the roofing system against the harsh climate.

Q. What challenges do coatings face in hot climates?

A. Coatings confront challenges like thermal expansion, UV degradation, and moisture infiltration. High temperatures can stress materials, leading to adhesion failure and necessitating proactive measures to maintain the roof’s integrity and performance under severe conditions.

Q. Why are reflective coatings advantageous for commercial roofs?

A. Reflective coatings significantly reduce heat absorption, leading to lower interior temperatures and decreased energy costs for cooling. This technology enhances occupant comfort and imprisons energy expenditure while prolonging the lifespan of the roofing system, making it a valuable investment.