Picture this: a million-dollar roof coating project transforms into a peeling, bubbling disaster within six months—all because Mother Nature crashed the application party uninvited.

Weather conditions during coating application can make or break commercial roof investments faster than facility managers can say “emergency repair budget.”

When temperature swings, humidity spikes, or contractors rush to beat incoming storms, protective coatings become expensive lessons in environmental physics rather than long-lasting building shields.

Understanding how weather sabotages coating success—and more importantly, how to prevent it—separates smart property investments from recurring maintenance nightmares that drain operational budgets for years.

SECTION 1: THE BASICS EXPLAINED

Picture this: your million-dollar roof coating project transforms into a peeling, bubbling disaster within six months—all because Mother Nature wasn’t invited to the planning party. Weather conditions during coating application can make or break your investment faster than you can say “emergency repair budget.”

The stakes couldn’t be higher when your building’s protective shield depends on perfect timing. One poorly timed application can turn a cost-saving roof restoration into an expensive lesson in meteorology.

What It Is (In Plain Language)

Think of roof coating application as giving your building a superhero cape—but only if the cape actually sticks and stays put. This process involves spreading a protective liquid layer over your commercial roof surface to extend its life and boost performance.

Here’s where it gets tricky: weather conditions act like invisible saboteurs during application. Rain, humidity, temperature swings, and wind can all crash the coating party uninvited.

Imagine trying to paint your house while someone sprays a garden hose nearby—that’s essentially what happens when moisture interferes with coating adhesion. The result? Bubbles, peeling, and premature failure that’ll have you reaching for the aspirin.

Weather-sensitive coating application simply means becoming a weather detective before breaking out the coating equipment. Smart timing and environmental control ensure your coating forms the rock-solid bond your roof deserves.

Why It Matters (To Your Building)

Your roof doesn’t just sit there looking pretty—it’s working overtime as your building’s ultimate bodyguard against nature’s daily assault. When coatings fail due to weather mishaps, that protection crumbles faster than a cookie in a toddler’s hands.

Failed coatings can turn a 10-year investment into a 10-month headache, complete with leaks that disrupt operations and damage expensive equipment below. Nobody wants to explain to the boss why the server room is taking an unexpected shower.

Energy costs start climbing when reflective coatings lose their superpowers prematurely. Your HVAC system works harder, utility bills spike, and sustainability goals take a nosedive.

Choosing a coating suited to local climate conditions—whether dealing with Seattle’s persistent drizzle or Phoenix’s blazing summers—can mean the difference between energy savings and coating catastrophe. Proper weather-conscious application protects your building’s integrity while keeping maintenance budgets happy.

How It Works

Coating curing is like watching a magical transformation—liquid material undergoes chemical and physical changes to become your roof’s new best friend. But this magic show requires perfect environmental conditions to pull off the grand finale.

Temperature plays the role of master conductor in this symphony. Too cold, and the coating moves slower than molasses, refusing to cure properly.

Too hot, and it races to dry so fast that cracks appear like lightning bolts across the surface. Humidity acts like an uninvited moisture crasher, preventing proper adhesion and creating bubble parties under the coating.

Wind speed matters more than you’d think—strong gusts can turn your pristine coating application into a debris collection project or cause uneven drying that leads to surface imperfections. Professional applicators become weather wizards, monitoring all these factors to identify those perfect application windows.

(source: FacilitiesNet)

SECTION 2: PRACTICAL APPLICATIONS

When coating projects go sideways, they don’t just fail—they fail spectacularly, taking budgets and building integrity down with them. The difference between coating success and disaster often comes down to understanding exactly when, where, and how weather turns friendly applications into expensive nightmares.

Smart facility managers know that coating applications aren’t one-size-fits-all solutions. Each situation demands weather-conscious strategies that turn environmental challenges into competitive advantages.

Common Uses & Examples

Silicone coatings reign supreme on flat commercial roofs where ponding water likes to throw pool parties. These weather warriors laugh in the face of standing water and UV bombardment, making them perfect for warehouse and retail spaces that can’t afford leak-related shutdowns.

Acrylic coatings become energy-saving superstars on metal roofs in blazing hot climates, reflecting heat like mirrors bouncing sunlight back to space. But here’s the catch—applying acrylics during high humidity creates cloudy, weak films that peel faster than sunburn skin.

Elastomeric coatings stretch and flex with temperature swings, preventing the thermal expansion cracks that turn roofs into geological fault lines. These flexible heroes work overtime on buildings where HVAC units create hot spots and temperature variations.

Maintenance coatings step in as emergency responders, sealing minor damage before it becomes major catastrophe. Heavy rainfall can expose weaknesses in your roofing system, with water seeping into small cracks and seams, leading to leaks and water damage that compromise structural integrity.

Each coating type throws different tantrums when weather conditions go rogue. Understanding these personality quirks helps property managers dodge the coating application landmines that destroy budgets and reputations.

When You Need It Most

Spring and fall weather act like coating application minefields, with morning dew, surprise showers, and temperature roller coasters that sabotage even the best-planned projects. These transitional seasons demand extra vigilance and flexible scheduling to catch those perfect application windows.

Summer heat waves turn coating application into a race against time—materials cure so fast they barely have time to level properly before hardening into cracked, thin disasters. Winter cold creates the opposite problem, with coatings moving like frozen molasses and refusing to cure completely.

The golden rule? Never trust yesterday’s weather forecast when today’s coating application hangs in the balance. Monitoring real-time temperature, humidity, and wind conditions separates successful projects from expensive do-overs.

Storm season becomes coating enemy number one, where a surprise downpour can trap moisture under freshly applied materials. This creates blistering and bubbling that makes roofs look like they’ve contracted a serious case of architectural acne.

Smart timing turns weather from foe to friend, with stable, dry conditions providing the perfect stage for coatings to cure into long-lasting protective shields.

Interactions With Other Systems

Roof coatings don’t operate as lone wolves—they’re team players that must integrate seamlessly with existing roofing components or risk spectacular failure. Applying coatings over poorly prepared or damaged substrates creates weak links that snap under weather pressure.

Moisture trapped beneath coatings becomes a ticking time bomb, especially when applied over wet insulation. This hidden enemy promotes mold growth and material degradation that can compromise entire roofing systems from the inside out.

Ventilation systems must pull double duty, allowing moisture escape both before and after coating application. Blocked or inadequate ventilation turns coating projects into moisture traps that breed expensive problems.

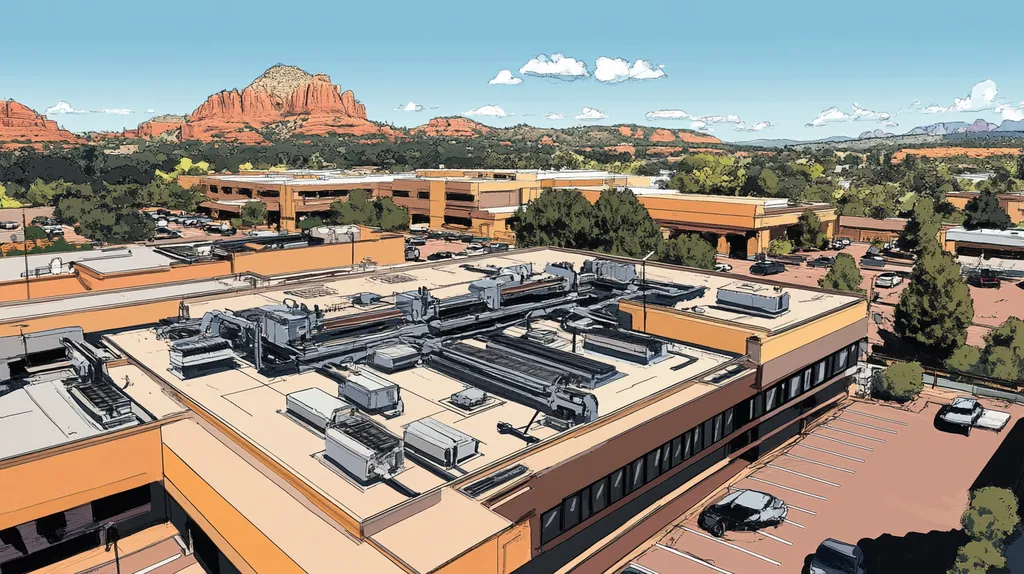

Rooftop equipment creates its own weather microclimate, with HVAC units generating heat islands and creating challenging application conditions. Reflective coatings can reduce equipment heat load but require precise sealing around penetrations to prevent weather infiltration.

Drainage systems become critical partners in coating success, ensuring water moves off surfaces quickly rather than pooling and testing coating durability. Proper coordination ensures coatings enhance overall system performance instead of creating new vulnerabilities. (source: Castagra)

SECTION 3: KEY TERMINOLOGY DECODED

Weather-related coating failures often start with a single misunderstood term that sends entire projects sideways. When facility managers confuse “dew point” with “temperature” or think “relative humidity” is just a weather report detail, they’re setting up expensive coating disasters.

The roofing industry loves its jargon, but these aren’t just fancy words—they’re the difference between protective coatings that last decades and expensive re-dos that drain maintenance budgets. Understanding these terms transforms weather from a mysterious enemy into a predictable partner in coating success.

Essential Terms Explained

Dew point acts like nature’s invisible tripwire for coating applications. This critical temperature marks when air moisture transforms into water droplets on surfaces—and coating disaster begins.

When roof surface temperature drops at or below the dew point during application, condensation crashes the party uninvited. The result? Coatings that bubble, blister, and peel like sunburned skin within months instead of protecting for years.

Relative humidity measures how much moisture air carries compared to its maximum capacity at current temperature. High humidity doesn’t just make humans uncomfortable—it turns coating applications into slow-motion nightmares where materials refuse to cure properly.

Surface temperature often plays hide-and-seek with air temperature, creating dangerous application traps. A sunny 80-degree day can still feature cold roof surfaces that invite condensation disasters during early morning applications.

Smart contractors become weather detectives, monitoring these invisible factors that determine whether coatings bond permanently or fail spectacularly.

Industry Jargon Translated

Flash point sounds dramatic because it is—this temperature marks when coating materials become fire hazards through vapor ignition. Understanding flash points protects both application crews and buildings from turning coating projects into emergency situations.

Storage and handling procedures revolve around flash point safety, especially during hot weather when temperatures can push materials toward dangerous thresholds. Proper precautions keep coating applications productive rather than perilous.

VOCs (Volatile Organic Compounds) determine which coatings pass environmental regulations in different regions. Low-VOC formulations aren’t just environmentally friendly—they’re legally required in many urban areas where air quality matters.

Recoat windows create narrow timing opportunities for multi-layer applications. Miss this window by applying too soon, and layers won’t bond properly—wait too long, and adhesion fails just as catastrophically.

These terms aren’t roofing trivia—they’re operational guidelines that separate successful coating projects from expensive lessons in material science. Roof coatings need to stand up to moisture laying on the roof and UV rays from the sun, making proper terminology understanding crucial for long-term performance. (source: FacilitiesNet)

Measurement & Units Simplified

Temperature confusion creates expensive miscommunications when contractors work in Fahrenheit while specifications call for Celsius. A 20-degree difference in temperature units can mean the difference between perfect application conditions and coating catastrophe.

Smart facility managers always confirm measurement units during project planning to avoid weather-related disasters. Double-checking units prevents contractors from applying coatings during inappropriate temperature ranges.

Mil thickness measurements determine coating performance and longevity—one mil equals one-thousandth of an inch. Too thin, and coatings fail prematurely; too thick, and they crack under thermal stress like overloaded bridges.

Wind speed measurements in mph or km/h directly impact drying patterns and contamination risks. Strong winds can deposit debris onto wet coatings or create uneven curing that leads to performance variations across roof surfaces.

Accurate measurement interpretation transforms coating applications from guesswork into precision operations that deliver decades of reliable protection instead of recurring maintenance headaches.

SECTION 4: DECISION FACTORS

Weather conditions during coating application don’t just affect immediate results—they determine whether your investment delivers decades of protection or becomes a recurring budget nightmare. Smart facility managers know that choosing the wrong coating system or ignoring environmental factors can turn a $50,000 restoration into a $200,000 replacement disaster.

The decision-making process becomes a high-stakes balancing act where upfront costs, performance expectations, and durability requirements must align with local climate realities. Getting this equation wrong transforms protective investments into expensive lessons in roofing physics.

Cost Considerations

Budget constraints love to whisper sweet lies about cheaper coatings, but these bargain-basement solutions often demand perfect weather conditions that Mother Nature rarely provides. Low-cost water-based coatings might save money upfront but throw tantrums when humidity climbs above 80%, creating bubbling disasters that cost triple the original investment to fix.

Weather delays turn coating projects into expensive waiting games where labor crews burn through budgets while monitoring humidity gauges and temperature readings. Rushing applications during marginal conditions to avoid delay costs typically backfires spectacularly, with failed coatings demanding complete removal and reapplication within months.

Premium coatings with wider environmental tolerance windows often cost 20-30% more initially but slash weather-related failure risks that destroy maintenance budgets. These weather-forgiving formulations allow application during broader temperature and humidity ranges, reducing project delays and eliminating costly rework cycles.

Smart budgeting factors potential weather delays into project timelines, recognizing that patience during application pays dividends through extended coating life. Temperature and humidity during roof coating application affect drying times, adhesion, and performance, making environmental monitoring a critical cost control strategy.

Performance Trade-offs

Coating performance becomes a weather-dependent chess match where each material type brings different strengths and vulnerabilities to environmental challenges. Silicone coatings laugh at ponding water and UV bombardment but demand bone-dry surfaces during application—one moisture mishap creates adhesion failures that compromise entire roof sections.

Acrylic coatings offer excellent UV reflection and energy savings but turn into prima donnas when humidity exceeds manufacturer specifications. These temperature-sensitive materials cure beautifully in desert climates but struggle in humid coastal environments where moisture creates cloudy, weak films.

Fast-curing formulations promise quick project completion but punish contractors who encounter unexpected weather changes during application. High humidity slows drying and increases moisture entrapment, causing premature coating failure that forces expensive emergency repairs during peak operational seasons.

Elastomeric coatings provide superior flexibility for thermal expansion but require precise temperature control during curing to achieve maximum performance. Understanding these performance trade-offs helps facility managers select systems that thrive in local climate conditions rather than fighting environmental realities. (source: Armour Roof Co.)

Lifespan & Durability Factors

Coating longevity directly correlates with application weather conditions, where perfect environmental timing can extend service life from 10 years to 20 years or more. Coatings applied during optimal temperature and humidity ranges form stronger molecular bonds that resist cracking, chalking, and water intrusion throughout their service life.

Freeze-thaw cycles become coating endurance tests that separate properly applied systems from weather-compromised disasters. Buildings in northern climates require coatings designed for thermal shock resistance, while southern facilities need UV-stable formulations that won’t degrade under relentless solar bombardment.

Wind exposure during application creates hidden durability killers through dust contamination and uneven drying patterns that compromise coating integrity. These surface imperfections become stress concentration points where premature failures begin, shortening expected service life and increasing maintenance frequency.

Ignoring local weather patterns during coating selection transforms 15-year protection investments into 5-year maintenance cycles that drain operational budgets. Proper environmental assessment combined with weather-appropriate coating selection ensures maximum durability while minimizing lifecycle costs.

SECTION 5: COMMON CHALLENGES

Weather-related coating disasters don’t announce themselves with sirens and flashing lights—they sneak up quietly, turning million-dollar roof investments into maintenance money pits that drain budgets for years. When temperatures swing wildly, humidity spikes unexpectedly, or contractors rush applications to beat incoming storms, coating failures become inevitable mathematical equations rather than unfortunate accidents.

The most expensive coating challenges aren’t the obvious ones like applying materials during thunderstorms. They’re the sneaky environmental saboteurs that create perfect storms of failure conditions while appearing manageable to untrained eyes.

Frequent Problems & Solutions

Moisture contamination acts like a coating vampire, sucking the life out of adhesion bonds before property managers even realize they’ve been bitten. Morning dew, surface condensation, and trapped humidity create invisible barriers between coating and substrate that guarantee spectacular peeling disasters within months.

Temperature shock syndrome strikes when coatings experience wild swings between scorching days and freezing nights. These thermal roller coasters create expansion-contraction stress cycles that crack coatings like eggshells, turning seamless protective barriers into water highway systems.

Flash curing nightmares occur when blazing sun and low humidity team up to dry coatings faster than race cars hitting the finish line. Materials cure so quickly they can’t level properly, creating thin spots, pinholes, and surface defects that compromise long-term performance.

Smart solutions start with weather station monitoring that tracks real-time conditions rather than relying on yesterday’s forecasts. Moisture meters become essential tools for detecting hidden dampness that visual inspections miss completely.

Flexible scheduling windows allow contractors to shift application timing when environmental conditions turn hostile. Building buffer days into project timelines prevents rushed applications that create expensive long-term problems.

Warning Signs To Watch For

Bubbling and blistering transform smooth coating surfaces into lunar landscapes dotted with moisture-filled craters. These telltale bumps signal trapped water vapor that’s pushing coating layers away from substrates like tiny hydraulic jacks working in slow motion.

Chalking surfaces start shedding powdery residue that comes off on hands like sidewalk chalk, indicating UV degradation accelerated by improper curing conditions. This coating sunburn weakens protective barriers and shortens service life dramatically.

Color variations across roof surfaces reveal uneven drying patterns caused by wind exposure, temperature differences, or application timing issues. These rainbow effects aren’t just cosmetic problems—they indicate performance variations that create weak spots.

Edge lifting and peeling typically begin at seams, penetrations, and detail areas where weather stresses concentrate most intensely. These vulnerable zones become early warning systems for broader coating adhesion problems.

Pinhole formations create microscopic leak pathways that allow water infiltration despite apparently intact coating surfaces. Weather conditions that can deliver these benefits must be carefully managed to prevent compromising roof coating applications.

Preventative Approaches

Environmental monitoring systems transform weather guessing games into data-driven application decisions. Digital hygrometers, surface thermometers, and wind speed meters provide real-time feedback that prevents contractors from applying coatings during dangerous conditions.

Coating selection strategies must match local climate personalities rather than fighting environmental realities. Desert installations demand UV-stable formulations while coastal facilities need moisture-resistant systems that thrive in humid conditions.

Application timing windows become strategic weapons against weather-related failures when properly planned. Early morning starts avoid afternoon heat spikes, while fall and spring scheduling dodges temperature extremes that stress coating performance.

Quality control protocols should include mandatory environmental checks before, during, and after application phases. These checkpoints catch dangerous condition changes before they sabotage entire coating installations.

Proper coating selection depends on local climate conditions and weather factors like rain, humidity, and high winds must be considered throughout the application process. (source: FacilitiesNet)

SECTION 6: NEXT STEPS & RESOURCES

Weather-related coating disasters don’t discriminate—they’ll happily destroy million-dollar investments while facility managers scramble to explain budget overruns to executives. The good news? Armed with the right questions, industry standards, and ongoing education, you can transform weather from coating enemy into predictable partner.

Smart property managers know that knowledge is their best defense against environmental sabotage. This section provides the roadmap for turning weather awareness into coating success stories that protect buildings and budgets for decades.

Questions To Ask Providers

Don’t let contractors treat weather monitoring like optional homework—demand detailed environmental protocols before signing contracts. Ask how they measure surface temperature, humidity levels, and dew point during application windows.

Dig deeper into their weather contingency plans when Mother Nature throws curveballs. What happens when unexpected humidity spikes crash the coating party, or surprise temperature drops threaten adhesion quality?

Request specific examples of how they’ve handled challenging weather conditions on similar projects. Generic answers about “monitoring conditions” won’t cut it when your roof’s protection hangs in the balance.

Smart questions reveal whether contractors understand local climate personalities or treat every project like cookie-cutter installations. The right provider becomes your weather-savvy partner rather than another vendor crossing fingers and hoping for sunny skies.

Confirm their equipment arsenal includes digital hygrometers, infrared thermometers, and moisture detection tools—not just eyeball assessments that miss invisible environmental landmines.

Industry Standards & Guidelines

ASTM International and NRCA guidelines aren’t suggestions—they’re your insurance policy against weather-related coating catastrophes. These organizations have decoded the environmental mysteries that turn protective coatings into expensive lessons in roofing physics.

ASTM D6083 specifications provide temperature ranges and moisture limits that separate successful applications from bubbling disasters. These aren’t arbitrary numbers—they’re battle-tested thresholds that prevent environmental sabotage.

NRCA standards emphasize moisture testing protocols that catch hidden dampness before it destroys adhesion bonds. Following these guidelines transforms guesswork applications into precision installations with predictable outcomes.

Choosing a roof coating best suited to a facility’s local climate—whether that involves the rain and humidity of Seattle or the oppressive heat of a Phoenix summer—can be the difference between a failed application and one that delivers energy savings and prolongs a roof’s performance life. (source: FacilitiesNet)

Building these standards into contractor specifications creates accountability benchmarks that prevent weather-rushed applications from destroying long-term performance expectations.

Further Learning Simplified

Weather patterns and coating technology evolve faster than facility managers can track, making continuous education essential for protecting roofing investments. The National Roofing Contractors Association offers digestible webinars that decode complex environmental impacts without requiring meteorology degrees.

Elastomeric Roof Coatings Association resources break down climate-specific challenges into actionable strategies that busy property managers can implement immediately. These aren’t academic exercises—they’re practical tools for preventing expensive coating failures.

Industry white papers and video tutorials transform confusing weather science into straightforward application guidelines. Smart facility managers treat these resources like maintenance manuals that prevent problems rather than repair disasters.

Attending periodic workshops connects property managers with coating experts who share real-world solutions to environmental challenges. These networking opportunities often reveal innovative approaches that textbooks haven’t discovered yet.

Staying current with weather-resistant coating developments ensures your facility benefits from technological advances that extend service life while reducing maintenance frequency and costs.

The Bottom Line

Weather conditions separate successful coating investments from million-dollar maintenance disasters that drain operational budgets for decades.

Property managers who treat environmental factors as afterthoughts create predictable failure cycles where protective coatings become expensive lessons in roofing physics. Temperature swings, humidity spikes, and rushed applications transform decade-long investments into recurring repair nightmares.

Smart facility managers know that weather monitoring isn’t optional—it’s the difference between coatings that protect buildings for twenty years versus systems that fail within twenty months.

The stakes couldn’t be higher when building integrity hangs in the balance. Weather-conscious coating decisions protect both facilities and budgets while weather-blind applications guarantee spectacular failures that destroy reputations and drain resources.

Don’t let Mother Nature crash your next coating project uninvited—make environmental control your competitive advantage in the battle for long-lasting roof protection.

FREQUENTLY ASKED QUESTIONS

Q. How do weather conditions impact commercial roof coating applications?

A. Weather conditions like rain, humidity, temperature, and wind act as sneaky saboteurs during coating application. Moisture can cause bubbling and peeling, while extreme temperatures lead to cracking or slow curing. Timing your project around ideal weather is like setting the stage for a perfect superhero cape to stick and protect your roof for years.

Q. What weather factors should industrial roof managers monitor during coating?

A. Industrial roof managers must keep an eye on temperature swings, humidity levels, rainfall, and wind speed. Seasonal changes often bring dew and surprise showers that can sabotage applications. Staying flexible with schedules and monitoring real-time data helps turn tricky weather into a reliable partner instead of a costly foe.

Q. What key weather terms affect commercial roof coating success?

A. Understanding terms like dew point, relative humidity, surface temperature, and flash point is vital. Dew point signals when condensation forms, wrecking coatings; relative humidity influences drying speed; surface temperature may differ from air temperature, causing hidden moisture risks. Knowing this jargon turns guesswork into smart decisions for lasting protection.

Q. How do weather conditions influence coating choices for commercial roofs?

A. Weather drives whether coatings perform or flop—silicone handles ponding water elegantly but needs dry surfaces, acrylics shine in sunny climes yet hate humidity, and elastomeric coatings flex with temperature changes but crave stable curing conditions. Picking the right system tailored to your climate keeps budgets intact and roofs happy.

Q. What common weather-related problems cause commercial roof coating failures?

A. Sneaky foes like moisture barriers create peeling, temperature shocks crack coatings, and flash curing shrinks protective films prematurely. Warning signs include bubbling, chalking, color changes, and peeling edges. Tackling these issues means monitoring conditions closely and scheduling work within tight weather windows.

Q. What should commercial roof owners ask coating contractors about weather protocols?

A. Demand details on how they track surface temperature, humidity, dew point, and wind during application. Probe their contingency plans for sudden weather changes and ask for proven examples managing tough environments. Confirm they use digital monitoring tools, not just eyeball estimates—your roof deserves a weather-savvy partner, not guesswork.

Q. How can real-time weather monitoring prevent coating failures on industrial roofs?

A. Real-time monitoring transforms coating projects from weather roulette to calculated science. Instruments like hygrometers and infrared thermometers detect moisture, temperature swings, and wind gusts that jeopardize adhesion. This data empowers managers to pause or proceed smartly, avoiding costly failures and extending roof lifespan with precision timing.