Industry research reveals that over 85% of commercial roof failures stem from inadequate inspection and delayed maintenance, leading to an average repair cost of $15 per square foot when issues escalate.

For facility managers, implementing a systematic roof inspection program isn’t merely about preventing leaks – it’s about protecting substantial business investments and avoiding catastrophic structural failures.

This comprehensive guide provides actionable solutions across six critical areas: performance assessment, financial planning, compliance verification, risk management, operational procedures, and long-term strategic considerations.

SECTION 1: PERFORMANCE FACTORS

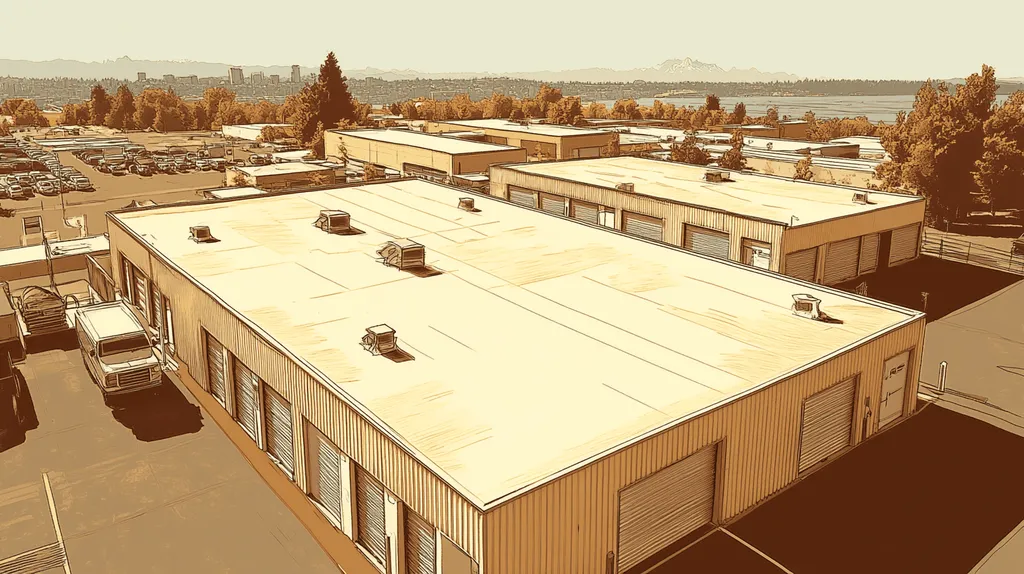

Regular maintenance of commercial roofs is not merely advisable; it’s essential for effective property management. Research indicates that over 30% of commercial roofs fail primarily due to insufficient maintenance. Such failures can result in expensive repairs, safety threats, and significant operational interruptions. Therefore, facility managers must make it a priority to conduct roof inspections that emphasize surface integrity, drainage efficiency, and critical features like flashing to secure long-term roof performance.

Assessing Roof Surface Integrity and Membrane Condition

The initial stage of a roof inspection involves assessing the membrane’s surface integrity. Watch for signs of wear, such as cracks, blisters, or bubbles, which may signal underlying vulnerabilities. Conducting routine inspections can catch these issues at an early stage, preventing minor problems from transforming into significant leaks.

Using a visual inspection approach, facility managers can identify these areas of concern. While roof systems are generally designed to last 20 years or more, allowing minor damage to go unchecked can dramatically shorten their lifespan. Timely attention to these findings is critical to maintaining the roof’s protective capacity.

Additionally, evaluating the impact of UV exposure and severe weather is imperative, as both can accelerate the deterioration of roofing materials. During inspections, be on the lookout for discoloration or unusual wear that might indicate that the membrane has been compromised.

Key Action Items

Evaluating Drainage Efficiency and Water Management

Proper drainage is vital for maximizing the lifespan of any commercial roof. Stagnant water can contribute to structural damage and foster mold growth. During inspections, it’s essential to check drains, gutters, and downspouts for any clogs.

Facility managers should verify that the drainage system functions correctly and directs water away from the structure. It’s crucial to check for proper slope and possible ponding areas during evaluations to pinpoint potential trouble spots. All components of the water management system should be clean and well-maintained.

If drainage issues are discovered, swift action is necessary to avert further water-related problems. Regular maintenance not only mitigates risks linked to standing water but also strengthens the overall integrity of the building.

Key Action Items

Inspecting Flashing, Penetrations, and Edge Details

Flashing and roof penetrations are often critical spots where leaks can develop. These elements protect vulnerable roof edges and transitions such as vents and pipes. It’s vital to inspect flashing for gaps, corrosion, or deterioration to maintain waterproofing effectiveness.

Facility managers should closely examine connections between different roofing materials, particularly at junctions around walls, chimneys, and skylights. These areas are common failure points that require diligent maintenance. Sealing any gaps identified during inspections with the appropriate materials can yield significant cost savings over time.

Edge details are equally important for moisture management; unsealed edges can allow wind-driven rain to infiltrate the roofing system. Hence, taking a good look at edge conditions during inspections is essential.

Key Action Items

SECTION 2: FINANCIAL CONSIDERATIONS

Understanding the financial implications of commercial roofing is vital for facility managers aiming to avoid costly blunders. With research indicating that up to 80% of roof failures stem from insufficient maintenance, proactive management is critical. Unplanned repairs can lead to significant strain on budgets, underscoring the importance of knowing when to repair or replace roofing systems. This section highlights three important financial considerations that directly influence roofing decisions.

Calculating Repair Costs Versus Replacement Options

Facility managers must determine when repairs are sensible and when it’s time for a full replacement. While many roofs can be repaired to extend their lifespan, poorly executed fixes or outdated materials can lead back to underlying problems. Thorough inspections can clarify the roof’s condition, facilitating informed choices.

If the costs of repairs exceed 30% of the replacement price, opting for a new roof may be the smarter long-term investment. It’s also essential to evaluate the materials’ lifespans; more durable materials, though pricier initially, often save money over time.

Additionally, tracking historical repair data can reveal patterns and forecast when a replacement may be necessary, further aiding financial planning.

Key Action Items

Budgeting for Routine and Emergency Maintenance

Effective budgeting for both routine and emergency maintenance is essential in financial planning. By implementing a proactive maintenance plan, facility managers can avoid unexpected repair costs that might arise from sudden roof failures. Setting aside funds specifically for emergencies can significantly alleviate fiscal pressures.

Scheduling at least two inspections annually helps catch minor issues before they escalate into major financial burdens. This investment in routine maintenance pays off by preventing costly emergency repairs in the future.

Seasonal weather impacts also need to be factored into budgeting. Preparing for possible weather-related repairs can shield budgets from surprises during extreme weather events.

Key Action Items

Analyzing Impact on Energy Efficiency and Utility Expenses

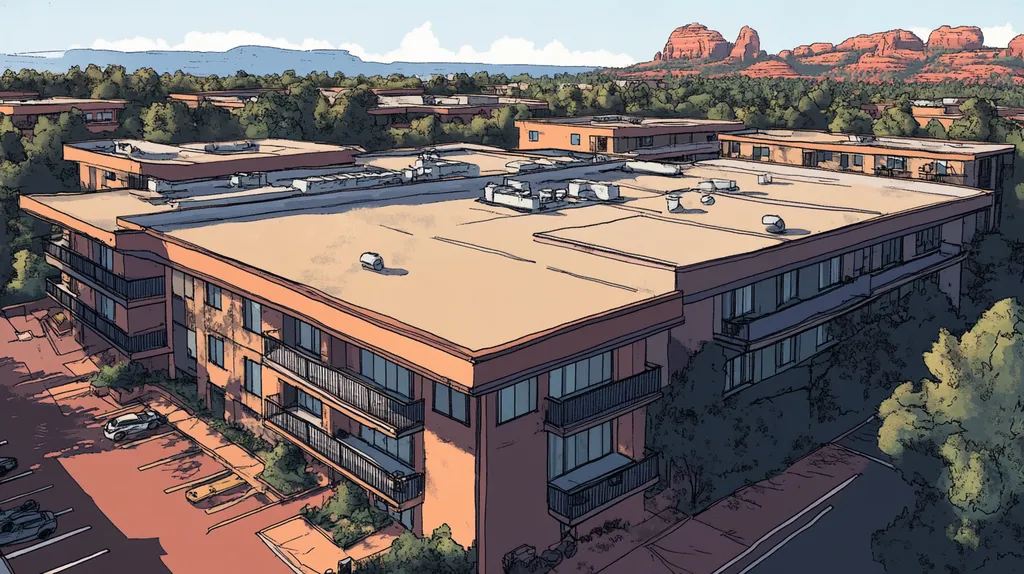

The roof’s condition can significantly influence energy efficiency, directly affecting utility costs. A compromised roof that allows air leakage can drive up heating and cooling expenditures. By conducting an energy audit, managers can understand how the roofing system impacts overall energy consumption.

Investing in modern, energy-efficient roofing materials can lead to substantial utility cost reductions. Upgrading to energy-efficient systems not only enhances operational efficiency but may also alleviate initial investment costs through long-term savings.

A well-maintained roof optimizes insulation effectiveness, further reducing energy consumption and prolonging the life of HVAC systems. Facility managers should evaluate energy savings as a key metric when considering roofing projects.

Key Action Items

SECTION 3: COMPLIANCE REQUIREMENTS

Neglecting compliance requirements can have serious financial consequences for facility managers and property owners. Building codes and industry standards exist to guarantee safety and long-term durability. A report from the National Roofing Contractors Association reveals that non-compliance can lead to an average of $70,000 in repair costs per incident. Understanding these requirements is essential not just for regulatory compliance but also for protecting investments and maintaining the structural integrity of buildings.

Verifying Compliance with Building Codes and Standards

Building codes and industry standards outline essential guidelines for roofing installations and maintenance. Facility managers must familiarize themselves with local regulations, as these can differ significantly depending on the area. For instance, some regions mandate the use of specific materials that can withstand high winds, which will influence roofing selection.

A comprehensive roof inspection should verify that all materials and installations meet these regulations. Failing to comply can create safety hazards, insurance issues, and substantial fines. Continuous monitoring throughout the roof’s life helps ensure that any modifications align with current code requirements.

Staying compliant not only safeguards the building’s structural integrity but also enhances its market value. A roof that adheres to relevant codes becomes a strong selling point, particularly for organizations focused on sustainability. Regular updates on local codes should be integrated into the facility manager’s routine responsibilities.

Key Action Items

Documenting Warranty Conditions and Manufacturer Specifications

Warranties issued by roofing manufacturers often depend on strict adherence to specified installation and maintenance practices. It is vital for facility managers to understand these conditions, as failures to comply can void warranties, placing repair costs solely on the property owner.

Documentation must include manufacturer specifications that outline proper maintenance and inspection procedures. For example, some materials require regular cleaning or specific sealants to maintain their effectiveness. A well-documented maintenance plan aligning with these specifications is crucial for retaining warranty coverage.

Moreover, it’s wise to keep thorough records of all inspections and repairs conducted. This documentation serves as evidence of due diligence, which can be vital for any warranty claims. Collaborating with experienced roofing contractors can streamline this process, ensuring maintenance actions meet both compliance and warranty standards.

Key Action Items

Meeting Insurance Requirements and Risk Assessment Protocols

Insurance policies for commercial properties often hinge on compliance with safety standards and effective maintenance protocols. Facility managers must ensure that roofing systems comply with insurers’ requirements and are regularly assessed for potential risks. Any gaps in compliance can lead to increased premiums or denied claims in the event of damage.

Regular inspections and risk assessments can help identify vulnerabilities in the roofing system, such as leaks or material wear that could compromise safety and insurance status. For example, stagnant water accumulation can significantly impair roofing materials; early detection is key to mitigating these risks.

Engaging with insurance providers to clarify specific roofing requirements can be beneficial. Some insurers may even offer discounts for documented compliance with maintenance protocols, making a proactive approach financially advantageous.

Key Action Items

SECTION 4: RISK MANAGEMENT

Effective risk management in commercial roofing is crucial for protecting property value and ensuring safety. A report indicates that about 70% of commercial roofs sustain weather-related damage due to a lack of maintenance. Facility managers must proactively address vulnerabilities to mitigate financial losses and avoid operational disruptions. This section covers essential aspects of risk management, including how to identify weather vulnerabilities, address safety hazards, and emphasize the importance of regular inspections.

Identifying and Mitigating Weather-Related Vulnerabilities

Severe weather poses significant risks to commercial roofs. High winds, hail, and heavy storms can inflict immediate damage, resulting in expensive repairs and business interruptions. Understanding the specific climate vulnerabilities of a building’s roof type is essential for effective management.

For instance, flat roofs are particularly prone to ponding water and subsequent leaks during heavy rain. Regular maintenance should include reinforcing seams and ensuring efficient drainage systems are in place to combat these issues.

Additionally, using weather-resistant materials can enhance the roof’s longevity. Evaluating the roof’s exposure to UV radiation can lead to preventive measures such as applying reflective coatings or improving insulation. This proactive approach safeguards property assets and extends roof lifespan.

Key Action Items

Addressing Safety Hazards for Personnel and Rooftop Equipment

Ensuring safety for both personnel and equipment on the roof is paramount. Inspectors need to identify hazardous conditions such as loose debris, exposed edges, or unstable structures that could lead to accidents and injuries.

For rooftop equipment, keeping pathways and access points clear and well-marked is crucial. Safety hazards can lead to liability claims if accidents occur, underscoring the need for routine safety assessments.

Employing safety harnesses and guardrails during maintenance can significantly reduce the risk of falls. Regular safety training for staff fosters a culture of vigilance and accountability, further reinforcing safety protocols.

Key Action Items

Preventing Liabilities Through Regular Inspection Intervals

Conducting regular roof inspections is a key element of effective risk management. Many facility managers overlook this essential practice, yet it can help prevent liabilities associated with neglect. Inspections should ideally occur at least twice a year, in spring and fall, to maintain ongoing oversight.

Infrequent inspections can allow minor issues to escalate into major problems, leading to significant financial repercussions. For instance, a small, undetected leak could cause extensive water damage and promote mold growth, leading to costly repairs.

Keeping a detailed log of each inspection is critical for accountability, providing a historical reference for future evaluations. This documentation can also protect property owners against liability claims by demonstrating due diligence in maintaining the roof.

Key Action Items

SECTION 5: OPERATIONAL PROCEDURES

The integrity of a commercial roof plays a crucial role in managing both maintenance costs and safety risks. Without a structured inspection schedule, property owners and facility managers risk exposing their assets to water damage, structural problems, and expensive repairs. Research shows that timely inspections can extend a roof’s lifespan by as much as 25%. This section emphasizes the importance of implementing systematic operational procedures: bi-annual inspections, staff training, and established repair protocols.

Implementing Bi-Annual and Post-Event Inspection Schedules

Establishing a routine inspection schedule is essential for identifying potential issues before they worsen. Conducting bi-annual roof inspections in spring and fall allows facility managers to evaluate the roof’s integrity after extreme weather. Additionally, performing post-event inspections following storms or heavy snowfall is critical for promptly assessing any damage.

For instance, hailstorms can cause hidden cracks or punctures in roofing materials that lead to persistent leaks. Inspections conducted after such events help uncover these issues right away. Utilizing drones for aerial inspections can enhance this process, offering a comprehensive view of the roof’s condition while ensuring personnel safety.

Thorough documentation from these inspections should be maintained to track trends over time, aiding future maintenance strategies. By implementing these inspection schedules, managers can prevent unexpected deterioration and ensure timely maintenance interventions.

Key Action Items

Training Staff on Safe Access and Inspection Techniques

Training staff on safety protocols is vital for effective roof inspection and maintenance. Facility managers should prioritize safety training programs that instruct team members on safe access methods and inspection techniques, covering ladder safety, harness use, and appropriate footwear.

Employees also need to learn how to identify safety hazards such as roof edges, slippery surfaces, and electrical obstructions. Incorporating hands-on training with experienced roofers can enhance staff preparedness, ensuring they are equipped to address issues as they arise.

Additionally, staff should be trained in using safety technologies, including harnesses and drones, for secure inspections. Investing in comprehensive training not only protects workers but also decreases the likelihood of costly accidents due to improper safety measures.

Key Action Items

Establishing Protocols for Immediate Repairs and Debris Removal

A rapid response to identified issues can significantly minimize damage and repair costs. Protocols for immediate repairs should be established to ensure that minor problems do not escalate. For example, if a small leak is found during an inspection, having a system in place for immediate patching can prevent further water damage.

At the same time, protocols for debris removal must be prioritized. Accumulations of leaves, branches, or trash can obstruct drainage systems, causing ponding and deterioration. Scheduling regular debris removal helps keep both drainage and the overall roof condition in check.

A checklist for post-inspection repairs can facilitate this process, including tasks like sealing cracks, replacing detached flashings, and clearing debris. These protocols will enable facility managers to act swiftly, preserving the roof’s integrity and extending its lifespan.

Key Action Items

SECTION 5: OPERATIONAL PROCEDURES

The integrity of a commercial roof is crucial for maintaining a building’s safety and managing maintenance costs. Without a regular inspection schedule, property owners and facility managers risk facing water damage, structural issues, and costly repairs. Studies indicate that timely inspections can extend a roof’s lifespan by up to 25%. This section highlights the importance of systematic operational procedures: bi-annual inspections, staff training on safety protocols, and established repair procedures.

Implementing Bi-Annual and Post-Event Inspection Schedules

Establishing a routine inspection schedule is vital for detecting potential issues before they escalate. Conducting bi-annual inspections, ideally during spring and fall, enables facility managers to assess the roof’s integrity after extreme weather. Additionally, post-event inspections following storms or heavy snowfall are essential for promptly identifying any damage.

For example, hailstorms can create hidden cracks or punctures in roofing materials, leading to ongoing leaks. Inspections after such events help pinpoint these issues swiftly. Utilizing drone technology for aerial inspections can enhance the process, allowing for a comprehensive view of the roof’s condition without risking personnel safety.

Meticulous documentation of inspection findings is necessary to track trends over time, guiding future maintenance strategies. By adhering to these inspection schedules, managers can prevent unexpected deterioration and ensure timely interventions.

Key Action Items

Training Staff on Safe Access and Inspection Techniques

Equipping staff with proper training in safety protocols is essential for effective roof inspection and maintenance. Facility managers should prioritize safety training programs that cover safe access methods and inspection techniques, including ladder safety, harness usage, and appropriate footwear for roof access.

Staff should be trained to recognize hazards such as roof edges, slippery surfaces, and electrical obstructions. Incorporating hands-on training with experienced roofers can significantly improve staff preparedness, ensuring they are ready to handle issues as they arise.

Moreover, staff should learn to utilize safety technologies, such as harnesses and drones, for secure inspections. This investment in training not only protects workers but also mitigates the risk of costly accidents stemming from improper safety measures.

Key Action Items

Establishing Protocols for Immediate Repairs and Debris Removal

A rapid response to identified issues can significantly reduce damage and repair costs. Establishing protocols for immediate repairs after inspections ensures that minor problems do not escalate. For example, if a small leak is discovered during an inspection, implementing an immediate patching system can prevent further water damage.

In addition, prioritizing debris removal is essential. Accumulations of leaves, branches, or trash can obstruct drainage systems, leading to ponding and deterioration. Scheduling regular debris removal helps maintain both drainage systems and the overall roof condition.

A checklist for post-inspection repairs can streamline the process, including tasks such as sealing cracks, replacing detached flashings, and removing debris. These protocols empower facility managers to take swift action, preserving the roof’s integrity and prolonging its lifespan.

Key Action Items

The Bottom Line

Industry data shows that 85% of commercial roof failures stem from inadequate inspection and delayed maintenance, costing businesses an average of $15 per square foot in emergency repairs.

A systematic inspection program represents the difference between proactive maintenance and catastrophic failure that can shut down operations.

By implementing the comprehensive inspection protocols outlined in this guide—from surface integrity checks to financial planning and compliance verification—facility managers can extend roof lifespans by up to 25% while avoiding emergency repairs.

The stakes are clear: regular inspections, documented maintenance, and swift response to identified issues protect not just the roof, but the entire building investment and operations beneath it.

Moving forward, successful facility management depends on turning these inspection guidelines into consistent, documented action.

FREQUENTLY ASKED QUESTIONS

Q. Why is regular maintenance crucial for a commercial roof?

A. Routine maintenance is essential as it prevents costly failures. Neglect can lead to leaks and structural damage, which ultimately result in increased repair costs. Regular inspections help identify issues early, thereby extending the roof’s lifespan and ensuring its protective capabilities.

Q. How do I budget for maintaining an industrial roof?

A. Budgeting for an industrial roof entails setting aside funds for both routine and emergency maintenance. Prioritize regular inspections, which can identify minor issues before they escalate. Ensure you allocate a specific amount for emergencies while considering the impact of seasonal weather on your overall costs.

Q. What are compliance requirements for commercial roofs?

A. Compliance requirements include adherence to building codes and industry standards regarding materials and installations. Facility managers must stay informed on local regulations and ensure roofs meet safety guidelines to avoid legal issues and potential fines.

Q. How can I manage weather-related risks for commercial roofs?

A. Managing weather-related risks requires identifying vulnerabilities and implementing preventive measures. Regular maintenance, such as checking for drainage issues and reinforcing vulnerable areas, can mitigate potential damage from storms and extreme weather conditions. Utilizing weather-resistant materials also enhances roof resilience.

Q. What operational procedures should I follow for a commercial roof?

A. Operational procedures should include establishing a bi-annual inspection schedule, training staff on safety protocols, and implementing immediate repair protocols. These procedures enhance roof management and safety, ensuring that any issues are promptly addressed to avoid costly repairs later.

Q. How often should I perform inspections on my commercial roof?

A. Inspections should be conducted at least twice a year, ideally in spring and fall. Additionally, post-event inspections should follow any major weather events to promptly assess and address any damage to the roof, ensuring ongoing protection and integrity.

Q. What immediate actions should I take if I find roofing issues?

A. If roofing issues are identified, immediately document the findings and implement repair protocols. Swiftly address minor problems such as leaks or debris to prevent further damage. Ensure that any repairs are logged for future reference and ongoing maintenance planning.