Time takes a hefty toll on commercial roofs, with studies showing that 90% experience significant performance degradation by their 15th year. For facility managers, this aging process threatens both operational continuity and bottom lines.

Each passing year brings new challenges: deteriorating materials, shifting regulatory requirements, and escalating maintenance costs. Without proper oversight, these issues can spiral into catastrophic failures and budget-breaking repairs.

This comprehensive guide examines critical age-related factors affecting roof performance, providing facility managers with actionable strategies for assessment, maintenance, and strategic planning.

SECTION 1: PERFORMANCE FACTORS

The age of a commercial roof is like its personal diary, revealing a lot about its life story and ongoing performance. If left unchecked, age-related issues can snowball into major headaches and hefty repair bills. Did you know that about 30% of commercial roofs develop significant leaks by their 15th year without proper upkeep? This section will delve into critical performance factors such as uneven aging, material deterioration, and the impact of weather and climate.

Uneven Aging and Micro-Climates

Aging isn’t a one-size-fits-all process for roofs. Factors like surrounding buildings and landscaping create micro-climates that can speed up wear in certain areas. For example, roofs tucked away in the shadows of nearby structures may trap moisture longer, accelerating deterioration. Meanwhile, sections bathed in sunlight can become brittle, making them more vulnerable to cracks.

For facility managers, recognizing these differences is essential. Conducting regular inspections that take micro-climate effects into account can help expose hidden problems before they escalate. A manager might discover blistering on shaded parts of the roof, signaling a need for targeted intervention.

It’s important to note that materials respond uniquely to localized temperature and humidity levels. To gain deeper insights, managers could consider installing sensors to monitor varying conditions across different roof sections. By adopting this nuanced approach, facility managers can effectively extend their roofs’ lifespans.

Key Action Items

Material Deterioration Over Time

Over time, all roofing materials face an uphill battle against degradation. Influences such as chemical exposure and harsh UV rays can wear them down. Take EPDM membranes, for instance; they might lose elasticity after just ten years, making them prone to tears and leaks. By catching these issues early, facility managers can sidestep major inconveniences.

Each roofing material has its own lifespan and deterioration pattern. Asphalt shingles may develop warping, while thermoplastic membranes can become brittle as they age. This variation underscores the importance of customized maintenance plans based on the unique materials in use.

Proactivity is key here; regular assessments empower managers to make timely interventions. For example, catching granule loss in asphalt shingles can prompt quick action, such as re-coating or section replacement. Understanding how materials deteriorate goes beyond just prevention; it’s also about planning strategically for replacements. Ongoing education about material performance will aid facility managers in making the best decisions.

Key Action Items

Impact of Weather and Climate

The weather isn’t just a daily conversation starter; it’s a significant player in a roof’s performance. Frequent heavy rains can lead to water pooling, which sets the stage for leaks over time. Similarly, roofs in regions facing extreme temperature variations often expand and contract, leading to accelerated wear and tear.

Long-term climate trends can also affect how roofs are designed and maintained. For example, facilities located in hurricane-prone areas may benefit from specialized fastening systems, while those in arid climates might prioritize UV-resistant coatings. Adapting roofing strategies to local weather patterns is critical for longevity.

Facility managers need to stay alert regarding how current climate changes impact their roofs. For instance, rising average temperatures could lead to quicker degradation of certain materials. Regular reviews of weather-related impacts provide a foundation for proactive measures.

Key Action Items

SECTION 2: FINANCIAL CONSIDERATIONS

The financial stakes surrounding aging commercial roofs are high and cannot be ignored. As these roofs wear with time, maintenance and repair expenses tend to climb steeply. Industry research indicates that once roofs hit the 15-year mark, repair costs can soar by up to 40% compared to newer installations. This creates a pivotal choice for property owners and facility managers: should they invest in ongoing repairs or transition to a complete roof replacement? Grasping these financial factors is crucial for effective budgeting and strategic long-term planning.

Increasing Maintenance and Repair Costs

As roofs age, exposure to weather elements, UV rays, and general wear-and-tear causes them to deteriorate. This wear necessitates more frequent maintenance and repairs. For instance, a commercial roof at the ten-year mark may require annual upkeep costing around 2% of its total value.

However, by the time the roof clocks 20 years, the maintenance percentage can swoop up to nearly double. Aging materials and outdated systems often lead to unexpected failures, resulting in bigger expenses. These escalating repair costs can rapidly thin out facility budgets.

Furthermore, these repair expenditures can trigger a domino effect, impacting other areas like increased energy bills due to inadequate insulation or additional repairs caused by water damage elsewhere.

Key Action Items

Economic Viability of Repairs vs. Replacement

When a roof ages, facility managers face a clear dilemma: should they pursue repairs or consider a full replacement? Repairs can offer short-term fixes, but they often yield diminishing returns as the roof nears the end of its life. For instance, patching leaks in a 25-year-old roof may extend its utility by just a few more years.

The economic wisdom of repairs becomes questionable when the costs edge towards or surpass 50% of the expense of a new roof. In such scenarios, replacing the roof might emerge as the smarter financial move. A new roof not only brings superior warranties but also enhances energy efficiency, resulting in long-term savings.

Performing a comprehensive cost-benefit analysis can equip facility managers with the insights needed for sound roofing decisions. Neglecting age-related performance considerations can lead to urgent crises that might have been averted with strategic foresight.

Key Action Items

Budgeting for Roof Lifecycle

Facility managers should embrace a budgeting approach that fully encompasses the entire lifecycle of the roof. This strategy involves planning for all expenses from installation to maintenance and eventual replacement. Experts suggest setting aside 1-3% of a roof’s value each year specifically for maintenance.

Moreover, cultivating a capital reserve dedicated to roof replacements can ease the financial burden of unexpected costs down the road. This proactive savings strategy allows property owners to sidestep the stress of sudden major expenses.

A lifecycle budgeting perspective aligns roofing decisions with broader property management objectives. It cultivates foresight and encourages informed choices based on anticipated future expenses rather than reactive fixes.

Ultimately, grasping financial implications equips facility managers to tackle the challenges posed by aging roofs, thereby protecting their investments for the long haul.

Key Action Items

SECTION 3: COMPLIANCE REQUIREMENTS

The age of a commercial roof isn’t just about appearances; it holds significant weight in the world of compliance. An aging roof can fall short of up-to-date regulatory standards, leading to potential legal troubles and financial burdens. Research indicates that over 70% of commercial roofs are beyond their expected lifespan, creating gaps that could jeopardize safety and budgets. Facility managers must grasp compliance requirements to safeguard their operations, ensuring both safety and efficiency.

Regulatory Standards for Roofing Materials

Staying compliant with regulatory standards is fundamental for effective roof management. Guidelines from the International Building Code (IBC) and local ordinances outline key specifications, such as fire resistance, reflectivity, and insulation capabilities. As roofs age, they risk not meeting these criteria, placing property owners at financial and liability crossroads.

Additionally, certain materials might fall under environmental regulations governing their usage and disposal. Non-compliance can result in hefty fines. This underscores the importance of vigilance in regularly assessing roofing materials for compliance with evolving standards.

To follow regulations, facility managers should assess their roofing systems periodically. This proactive approach not only mitigates risks but also aids in budgeting for necessary updates. Collaborating with certified roofing professionals helps ensure compliance with industry standards as regulations change.

Key Action Items

Safety Codes and Inspections

Safety codes are a cornerstone of commercial roof management. The Occupational Safety and Health Administration (OSHA) enforces specific safety standards critical for roof work. For aging roofs, these codes become increasingly relevant as deteriorating structures can pose serious risks during inspections and repairs.

Facility managers should prioritize regular safety inspections to pinpoint hazards associated with their roofs. For instance, weakened structural elements can lead to accidents, elevating liability and repair costs. Identifying these risks early is essential for maintaining safe work conditions.

As roofs age, specialized inspection strategies may be necessary. Techniques like infrared thermography can identify moisture issues that standard inspections might overlook, ensuring a higher level of protection for both property and personnel.

Ultimately, maintaining adherence to safety codes safeguards both assets and individual well-being. Integrating robust safety measures into roof practices bolsters operational integrity across the board.

Key Action Items

Environmental Compliance

Environmental compliance is more crucial than ever for facility managers governing aging roofs. Regulations from the Environmental Protection Agency (EPA) regarding hazardous materials can affect roofing materials, especially for older roofs that may contain substances like asbestos or lead.

With rising environmental concerns, transitioning to eco-friendly materials is top of mind. Facility managers must verify that any repairs or replacements comply with these evolving standards to prevent harmful substances from contaminating the environment. Non-compliance can lead to steep penalties and tarnished reputations.

Exploring sustainable roofing options like cool roofs or green roofs is a worthy consideration. These solutions not only adhere to compliance requirements but also enhance energy efficiency and building performance.

Regular evaluations of environmental compliance align facilities with changing regulations. By keeping informed, property managers can adapt their roofing strategies to promote sustainability along with compliance.

Key Action Items

SECTION 4: RISK MANAGEMENT

As commercial roofs age, the risk of leaks and structural failures escalates dramatically. Research shows that nearly half of all roofing failures can be traced back to neglected maintenance and assessments. For facility managers, proactively identifying and addressing these risks is vital to protect investments and maintain smooth operations. This section explores critical risk management areas, including leak sources, structural integrity, and weather-related challenges.

Identifying Potential Leak Sources

When it comes to aging roofs, pinpointing potential leak sources is paramount. Common leak suspects include seams, flashing, and penetrations. Each roof type, whether TPO, EPDM, or built-up, has distinct weaknesses that demand careful examination.

Routine inspections, particularly after severe weather, are essential. Neglecting this step can allow small leaks to morph into significant problems. For example, a minor seam failure can cause extensive water damage, jeopardizing interior spaces.

Using infrared inspections can further help detect concealed moisture accumulation. This proactive strategy allows for early intervention, stopping small leaks from evolving into extensive repairs. Documenting previous leaks and their causes provides invaluable insights for future maintenance planning.

Key Action Items

Assessing Structural Integrity

Evaluating structural integrity is crucial as roofs age, as it impacts load-bearing capacity and resilience against environmental factors. Regular assessments should encompass not only roofing materials but also underlying structures like decking and support beams.

Facility managers should enlist qualified professionals for periodic evaluations. Any compromised structures—whether from water intrusion or natural wear—can present significant safety hazards.

Inadequate drainage systems can worsen structural problems. Aging roofs often fail to effectively manage water, leading to pooling that strains structural components. Addressing these drainage inefficiencies is vital for prolonging roof life.

Key Action Items

Mitigating Weather-Related Risks

With weather events becoming more severe, the strain on aging roofs is intensifying. Rising temperatures, heavy rainfall, and hail can exacerbate existing vulnerabilities.

Regularly assessing insulation and waterproofing measures is essential, particularly in regions prone to extreme conditions. Keeping these components up to date can drastically reduce leak occurrences during heavy storms.

Facility managers should implement maintenance plans that incorporate seasonal assessments and evaluations after severe weather. Prompt repairs can mean the difference between minor fixes and costly roof replacements. Investing in weather-resistant materials and protective coatings can bolster overall roof resilience, yielding long-term benefits.

Key Action Items

SECTION 5: OPERATIONAL PROCEDURES

As commercial roofs age, their stability and performance take a hit, potentially leading to costly damages and operational hiccups. Routine oversight becomes essential to maintain roof health and thwart unexpected failures. Did you know that proactive maintenance can extend a roof’s lifespan by a remarkable 30%? This section highlights vital operational procedures, focusing on regular inspections, strategic maintenance scheduling, and swift emergency protocols.

Regular Inspection Checklists

Conducting regular inspections is critical for identifying roofing issues before they escalate. A thorough inspection checklist should cover crucial aspects such as membrane integrity, flashing condition, and drainage systems. For instance, assessing seam integrity can prevent leaks from becoming major headaches.

Ideally, facility managers should carry out inspections at least twice a year, aligning with the spring and fall seasons. This timing takes advantage of weather patterns, helping to reveal vulnerabilities that seasonal changes can exacerbate. Moreover, meticulous documentation during inspections is vital to track wear patterns and enhance future evaluations.

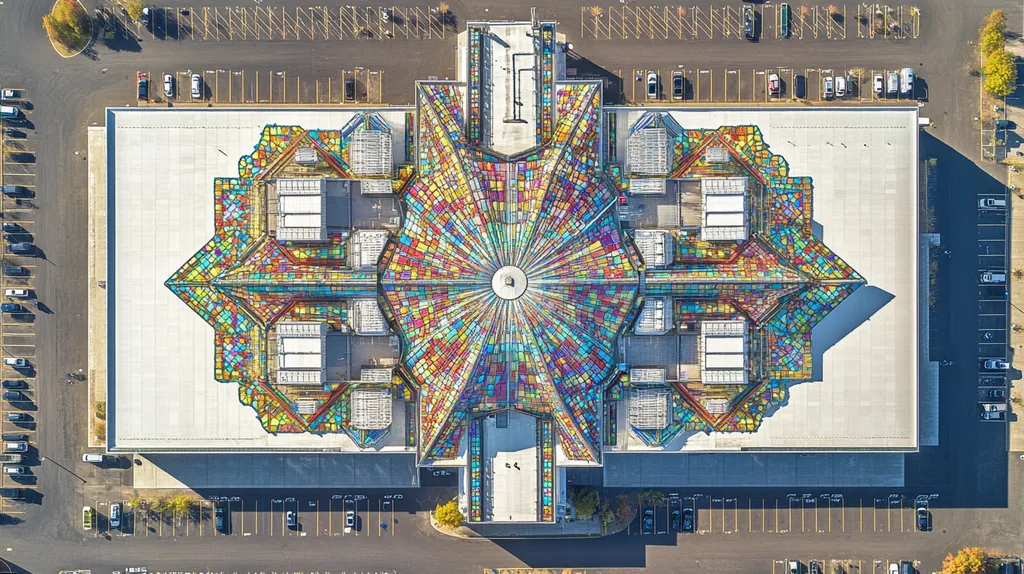

Employing knowledgeable professionals for these inspections is key. Their expertise ensures that even the slightest signs of damage, like blisters or areas of ponding water, are not missed. Utilizing drone technology for inspections can provide a bird’s-eye view, allowing for comprehensive assessments that maintain safety while offering detailed insights.

Key Action Items

Maintenance Scheduling and Tracking

Establishing a maintenance schedule is paramount for extending roof durability and enhancing overall performance. Facility managers should create a comprehensive calendar outlining essential tasks such as gutter cleaning, debris removal, and HVAC servicing on the roof. Regular maintenance can dramatically reduce risks of leaks and other complications.

Utilizing a maintenance tracking system is equally important to ensure tasks are completed efficiently. Digital tools, like facility management software, offer reminders for upcoming services and maintain a detailed record of all activities, aiding in budget planning.

Furthermore, systematic assessments during maintenance allow for consistent evaluation of the roof’s condition. Integrating inspection findings helps foster improved communication between maintenance teams and management, leading to a proactive approach in roof care.

Key Action Items

Emergency Repair Protocols

Developing an effective emergency repair protocol is crucial for managing unexpected roofing issues efficiently. Facility managers should craft a clear plan that delineates steps to take when problems arise, including immediate actions, notification procedures, and essential contractor contact information.

Establishing a priority system for response can significantly minimize damages during emergencies. For example, leaks that occur during torrential rain might necessitate urgent attention to prevent further complications, while less severe damage might require more measured responses. This organized approach facilitates swift allocation of resources when emergencies strike.

It’s also essential for facility managers to maintain an up-to-date list of trusted roofing contractors. Building relationships with these professionals ahead of time expedites response times during crises, significantly reducing potential downtime. Regular training for facility staff on emergency procedures enhances overall preparedness.

Key Action Items

SECTION 5: OPERATIONAL PROCEDURES

As commercial roofs age, their structural integrity and performance can significantly decline, leading to costly damage and disruptions. Routine oversight is essential for maintaining roof health and preventing unexpected failures. Statistics show that proactive maintenance can extend a roof’s lifespan by up to 30%. This section outlines operational procedures, focusing on regular inspections, scheduled maintenance, and emergency protocols.

Regular Inspection Checklists

Regular inspections are essential to identify potential roofing issues before they escalate. An effective inspection checklist should cover critical areas such as membrane integrity, flashing condition, and drainage systems. Evaluating seam integrity can prevent leaks that may not surface until extensive damage occurs.

Facility managers should conduct inspections at least biannually, ideally in spring and fall. This schedule aligns well with weather patterns, which can uncover vulnerabilities exacerbated by seasonal changes. Thorough documentation during inspections is also key to tracking wear patterns and refining future evaluations.

Engaging knowledgeable professionals for these inspections enhances safety and effectiveness. Their expertise ensures that even subtle signs of wear or damage, such as blisters or ponding water, are identified. Additionally, utilizing drone technology can provide a comprehensive view of the roof without compromising safety while offering detailed insights.

Key Action Items

Maintenance Scheduling and Tracking

Establishing a maintenance schedule is vital for prolonging roof life and optimizing performance. Facility managers should create a calendar outlining routine maintenance tasks like cleaning gutters, removing debris, and servicing HVAC units on the roof. Consistent maintenance significantly reduces the risk of leaks and potential complications.

Implementing a maintenance tracking system helps ensure these tasks are completed efficiently. Digital solutions, such as facility management software, provide reminders for upcoming services and maintain comprehensive records of all activities. This data is essential for budgeting and planning future expenditures.

Additionally, routine maintenance offers opportunities to evaluate the roof’s condition systematically. Integrating findings from inspections into the maintenance schedule fosters improved communication between maintenance teams and management, leading to a proactive approach in roof care.

Key Action Items

Emergency Repair Protocols

Developing an effective emergency repair protocol is crucial for efficiently managing unexpected roofing issues. Facility managers should create a clear plan that outlines steps to take when a problem arises, such as immediate actions, notification procedures, and contact details for trusted roofing contractors.

Establishing a priority system for response can minimize damages during critical situations. For example, leaks during heavy storms may require immediate attention to prevent further complications, while less severe damage might be addressed later. This organized approach allows for efficient allocation of resources when emergencies strike.

Facility managers should maintain readily accessible contact information for reliable roofing contractors. Building relationships with these professionals ahead of time can expedite response times during emergencies, leading to reduced downtime. Regular training for facility staff on emergency procedures enhances overall preparedness.

Key Action Items

The Bottom Line

With 90% of commercial roofs showing significant deterioration by year 15, facility managers cannot afford to ignore the effects of aging on roofing performance.

Proactive maintenance and monitoring can extend a roof’s functional lifespan by up to 30%, delivering substantial cost savings and operational benefits.

Regular inspections, coupled with documented maintenance procedures and emergency protocols, form the foundation of effective age-related risk management.

Staying compliant with evolving regulations while balancing repair costs against replacement timing requires strategic planning and consistent oversight.

By implementing the actionable strategies outlined in this guide, facility managers can better protect their roofing assets and optimize long-term performance through every stage of the aging process.

FREQUENTLY ASKED QUESTIONS

Q. How does the age of a commercial roof affect its performance?

A. The age can lead to deterioration, uneven wear, and increased leaks if not monitored. Regular inspections tailored to micro-climates can identify issues early, helping to maintain roof performance.

Q. What financial concerns should I consider for my aging commercial roof?

A. Maintenance costs typically rise significantly after the 15-year mark. Performing a cost-benefit analysis can reveal whether repairs are viable or if a replacement is a better investment for long-term savings.

Q. Are there compliance requirements for commercial roofs based on age?

A. Yes, older roofs may not meet current building codes or environmental standards. Regular reviews ensure compliance and mitigate legal risks associated with outdated materials and safety requirements.

Q. How can I manage risks associated with an aging industrial roof?

A. Identify and address potential leak sources, assess structural integrity regularly, and prepare for weather-related challenges through proactive maintenance to minimize risks.

Q. What operational procedures should I follow for my commercial roof?

A. Implement regular inspection schedules, set maintenance tasks, and have clear emergency repair protocols in place to ensure the roof remains in top condition and operational incidents are minimized.

Q. What types of roofing materials are best for commercial roofs?

A. Materials like TPO, EPDM, and modified bitumen are popular due to their durability. Each type has unique longevity and performance characteristics, so understanding specific needs is crucial in selecting the right material.

Q. How can I ensure the longevity of my aging commercial roof?

A. Regular inspections, maintenance scheduling, and timely repairs significantly extend roof life. Additionally, adopting weather-resistant technologies and considering material upgrades tailored to your climate can enhance durability.