Commercial roof failures cost businesses over $2.5 billion annually in repairs, inventory damage, and operational disruptions. Yet studies show that 90% of these failures stem from preventable design flaws.

Modern commercial roofs must balance multiple competing demands: extreme weather resilience, energy efficiency, equipment support, and long-term durability. With replacement costs averaging $10-15 per square foot, the stakes for getting roof design right have never been higher.

This comprehensive guide examines the essential elements of commercial roof design, from material selection to preventive maintenance, helping facility managers make informed decisions that maximize protection while minimizing lifetime costs.

SECTION 1: THE BASICS EXPLAINED

Commercial roof design demands precision and expertise, as even minor oversights can lead to catastrophic failures. Studies show that 40% of all commercial building energy loss occurs through poorly designed roofing systems. With replacement costs averaging $10-15 per square foot, the stakes for getting roof design right have never been higher.

What It Is (In Plain Language)

Commercial roof design is the strategic planning of a building’s topmost protective layer. It combines material selection, structural engineering, and environmental considerations to create a lasting shield for the structure below.

Modern roof designs must balance multiple functions: weather protection, thermal regulation, and equipment support. Each component, from the deck to the membrane, plays a specific role in the system’s overall performance.

The Insurance Institute for Business & Home Safety emphasizes using industry-standard materials and detailed installation protocols to enhance durability across different climate zones. (source: IBHS)

Success depends on considering local weather patterns, building use patterns, and long-term maintenance requirements. These factors determine everything from slope angles to material thickness.

Why It Matters (To Your Building)

A well-designed roof serves as your building’s first line of defense against environmental threats. It prevents water infiltration, manages thermal loads, and protects expensive interior assets.

Financial implications are significant. While premium roof designs may cost 15-20% more initially, they typically reduce annual operating costs by 25-30% through improved energy efficiency.

Proper design also extends roof lifespan significantly. A strategically planned roof can last 20-30 years, while poorly designed systems often require replacement within 10 years.

Beyond protection, modern roof designs can support additional functionality like solar panels or green roof systems, increasing property value and sustainability credentials.

How It Works

Effective roof design starts with a comprehensive site analysis. This includes evaluating local climate data, building orientation, and internal use patterns to determine optimal materials and configurations.

The design process incorporates multiple layers, each serving specific functions. The deck provides structural support, while underlayment creates a water-resistant barrier. The top membrane or covering delivers weather protection and UV resistance.

Drainage systems require careful engineering to prevent water pooling. This includes calculating proper slopes, sizing gutters, and positioning downspouts to handle maximum anticipated rainfall.

Modern designs also factor in future maintenance access and potential equipment installation. This forward-thinking approach ensures the roof can adapt to changing building needs while maintaining its protective integrity.

SECTION 2: PRACTICAL APPLICATIONS

Commercial roof design has evolved beyond simple weather protection into a critical system that impacts building performance, energy efficiency, and operational costs. Industry data shows that properly designed roofs can reduce energy consumption by up to 30% while extending service life by decades. However, most existing commercial roofs fall short of current performance standards, leading to unnecessary expenses and premature failures.

Common Uses & Examples

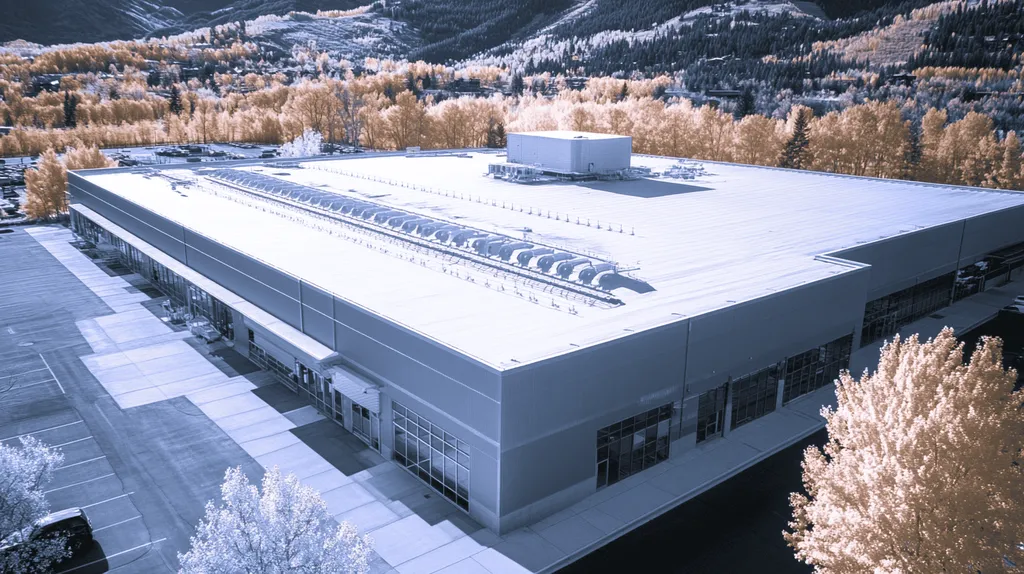

Modern commercial roofs must accommodate diverse functions while maintaining structural integrity. The most common applications include equipment mounting platforms, solar panel arrays, and green roof installations that transform unused space into functional assets.

Cover the entire roof deck with proper underlayment and flashing systems that comply with ASTM D1970 standards to ensure maximum protection. This includes careful attention to wall intersections and proper layering of materials for optimal performance. (source: IBHS)

High-traffic areas require specialized walking paths and equipment pads to prevent membrane damage. These protective elements must integrate seamlessly with the roof’s waterproofing system while maintaining accessibility for maintenance.

Drainage solutions have become increasingly sophisticated, incorporating tapered insulation systems and enhanced water management features that prevent ponding while protecting the building envelope.

When You Need It Most

Roof design becomes particularly critical during extreme weather events when system failures can lead to catastrophic damage. Buildings in hurricane-prone regions require enhanced attachment methods and impact-resistant materials.

Facilities undergoing renovation or equipment upgrades must carefully evaluate their roof’s load-bearing capacity. This assessment ensures new installations don’t compromise the existing structure.

Emergency situations often reveal design weaknesses that require immediate attention. Quick response capabilities depend on having access points and repair zones clearly identified in the original design.

Buildings with sensitive operations, such as data centers or healthcare facilities, require redundant protection systems and backup drainage to prevent any possibility of water intrusion.

Interactions With Other Systems

Roof design significantly impacts HVAC efficiency through thermal performance and equipment placement. Proper integration of mechanical systems requires careful coordination of penetrations and support structures.

Electrical systems must be protected while remaining accessible for maintenance. This includes proper conduit placement and weather-tight penetration details that prevent moisture infiltration.

Building automation systems increasingly rely on roof-mounted sensors and monitoring equipment. These components require secure mounting solutions that don’t compromise the roof’s integrity.

Fire suppression systems and emergency access routes need clear pathways and appropriate support. These essential services must remain functional without creating vulnerabilities in the roof system.

SECTION 3: KEY TERMINOLOGY DECODED

Commercial roofing terminology can make or break a project’s success. Studies show that terminology misunderstandings contribute to over 30% of roofing project disputes and delays. For facility managers and property owners, mastering essential roofing terms isn’t just about communication – it’s about protecting their investment and making informed decisions that impact building performance for decades.

Essential Terms Explained

The membrane serves as your roof’s primary weather barrier. Single-ply membranes like TPO and EPDM dominate commercial applications, each offering distinct advantages in durability, energy efficiency, and chemical resistance.

Insulation R-value measures thermal resistance, with higher numbers indicating better temperature control. Modern commercial roofs typically require R-values between 20 and 35, depending on climate zone and building use.

Roof assemblies consist of multiple components working together. The deck provides structural support, while the vapor barrier prevents moisture from compromising insulation performance.

Proper flashing details protect vulnerable areas where different roof components meet. These critical transition points require careful design and premium materials to prevent water infiltration.

Industry Jargon Translated

Built-up roofing (BUR) refers to traditional tar-and-gravel systems using multiple layers. While labor-intensive, these systems offer excellent durability and puncture resistance.

Modified bitumen combines asphalt with polymer reinforcement for enhanced flexibility. These systems excel in extreme temperature variations and high-traffic applications.

Parapet walls extend above the roof level to create a protective barrier. These extensions require careful waterproofing and often incorporate through-wall flashing systems.

Crickets and saddles are raised triangular structures that direct water around rooftop obstacles. These essential drainage components prevent ponding water behind equipment or other penetrations.

Measurement & Units Simplified

Roof slope is expressed as rise over run, typically in inches per foot. A 1/4:12 slope means the roof rises 1/4 inch for every 12 inches of horizontal distance.

Live loads refer to temporary weight from maintenance activities, equipment, or snow. Dead loads account for permanent weight from the roof system itself and mounted equipment.

Wind uplift resistance is measured in pounds per square foot (psf). Different zones of the roof require varying levels of resistance, with corners and perimeters needing the highest values.

Material thickness is often measured in mils (thousandths of an inch). Common membrane thicknesses range from 45 to 80 mils, with thicker materials generally offering better durability and puncture resistance.

SECTION 4: DECISION FACTORS

Selecting the right commercial roofing system represents a critical business decision with far-reaching implications. Research shows that poor roofing choices can increase energy costs by up to 40% while reducing building asset value. Modern commercial roofs must balance multiple competing factors including initial investment, long-term performance, and sustainability requirements.

Cost Considerations

Initial costs vary dramatically between roofing systems, with material selection driving much of the variance. Premium materials may cost 20-30% more upfront but can deliver superior protection and energy efficiency.

Installation quality significantly impacts total cost of ownership. Professional installation using appropriate techniques and proper detailing often prevents expensive repairs later.

TPO roofing systems offer an excellent balance of cost-effectiveness and energy efficiency through their highly reflective surface and straightforward installation process. (source: Heidler Roofing)

Life-cycle cost analysis should include factors like maintenance requirements, energy savings, and potential insurance premium reductions. These elements often justify higher upfront investments in superior materials.

Performance Trade-offs

Every roofing system presents distinct advantages and limitations that must align with specific building requirements. Climate conditions, building use patterns, and maintenance capabilities all influence optimal material selection.

Energy efficiency often competes with durability in material selection. While some materials excel at heat reflection, they may require more frequent maintenance or offer less impact resistance.

Structural limitations may restrict material choices. Heavy materials like concrete tiles provide excellent durability but require substantial structural support that many buildings cannot accommodate.

Future adaptability should factor into performance evaluations. Systems that can accommodate later modifications or equipment installations often prove more valuable long-term.

Lifespan & Durability Factors

Expected service life varies significantly between roofing systems, ranging from 15 to 40 years under optimal conditions. Material quality and installation expertise directly impact longevity.

Environmental stressors dramatically affect durability. UV exposure, temperature fluctuations, and chemical exposure can accelerate deterioration of certain materials while leaving others unaffected.

Maintenance requirements correlate strongly with system longevity. Regular inspections and prompt repairs can extend roof life by 25% or more, regardless of material choice.

Warranty terms should align with expected lifespan. comprehensive warranties covering both materials and workmanship provide valuable protection against premature failure.

SECTION 5: COMMON CHALLENGES

Commercial roof failures cost businesses billions annually in repairs, damaged inventory, and operational disruptions. Industry data shows that 90% of premature roof failures stem from preventable issues that could have been identified during regular inspections. Understanding and addressing common roofing challenges has become critical as extreme weather events increase and building systems grow more complex.

Frequent Problems & Solutions

Water intrusion remains the leading cause of commercial roof failures, with faulty flashing details accounting for over 60% of leak-related issues. Proper component integration, including deck preparation, insulation placement, and membrane attachment, creates a robust defense against moisture infiltration.

Each roof system component plays a specific role in protecting the building and extending service life. Quality flashing and drainage systems prevent structural water damage while proper insulation and vapor barriers regulate indoor temperature and prevent moisture buildup.

Expert installation of all components ensures system integrity and effective long-term performance. Professional detailing around penetrations, proper membrane seaming, and correct drainage slopes are essential for preventing common failure points. (source: Reimagine Roofing)

Poor ventilation and inadequate insulation lead to condensation issues that deteriorate roofing materials from the inside out. Installing proper ventilation systems and maintaining appropriate insulation levels helps prevent these moisture-related failures.

Warning Signs To Watch For

Surface blistering and membrane ridging indicate trapped moisture or air within the roofing system. These deformations compromise membrane integrity and require immediate investigation to prevent spreading.

Ponding water that remains for more than 48 hours signals drainage problems that can lead to membrane degradation and eventual leaks. Areas of standing water should be addressed through tapered insulation or drain installation.

Seam failures at membrane joints often appear as separations or gaps in the material. Regular inspection of these critical connection points helps identify potential failures before water intrusion occurs.

Excessive granule loss on modified bitumen roofs or cracking in single-ply membranes indicates material degradation. These signs of aging require prompt attention to prevent system failure.

Preventative Approaches

Implementing a documented maintenance program with scheduled inspections forms the foundation of roof preservation. These programs should include detailed checklists, photo documentation, and clear repair protocols.

Training maintenance staff to recognize early warning signs enables quick response to developing issues. This includes understanding proper inspection techniques and knowing when to call in professional assistance.

Maintaining detailed records of all roof-related activities helps track problem patterns and predict maintenance needs. Documentation should include inspection reports, repair histories, and warranty information.

Creating designated roof access paths and equipment maintenance zones helps prevent membrane damage from foot traffic and service activities. These protected areas preserve roof integrity while enabling necessary maintenance work.

SECTION 6: NEXT STEPS & RESOURCES

The commercial roofing industry faces unprecedented challenges, with material costs rising 20-30% annually and increasingly extreme weather events testing system integrity. Studies show that 75% of roof failures stem from inadequate planning and resource allocation during the initial design phase. Understanding available resources and asking the right questions can mean the difference between a roof that lasts 25 years and one that fails prematurely.

Questions To Ask Providers

Start by verifying the provider’s experience with your specific building type and roofing system. Request detailed case studies of similar projects, including performance data and long-term maintenance records.

Understand their quality control processes and documentation methods. Professional contractors should offer comprehensive installation documentation, including moisture surveys, adhesion tests, and seam inspections.

Cover the entire roof deck with proper underlayment and flashing systems that comply with ASTM D1970 standards to ensure maximum protection. This includes careful attention to wall intersections and proper layering of materials for optimal performance. (source: IBHS)

Discuss emergency response capabilities and warranty coverage details. Leading providers maintain 24/7 response teams and offer comprehensive warranties covering both materials and workmanship.

Industry Standards & Guidelines

Reference current ASTM and ANSI standards for material performance requirements. These guidelines establish minimum criteria for durability, weather resistance, and fire safety.

Familiarize yourself with local building codes and energy efficiency requirements. Many jurisdictions now mandate specific R-values and reflectivity ratings for commercial roofs.

Review FM Global and UL requirements for wind uplift resistance and fire ratings. These standards help ensure your roof system meets insurance requirements and safety regulations.

Consider LEED and other sustainability guidelines that may impact material selection. Green building standards increasingly influence roofing specifications and can affect building certification status.

Further Learning Simplified

Access online training modules through professional organizations like NRCA and RCI. These resources offer self-paced learning on topics from basic maintenance to advanced design principles.

Attend manufacturer training sessions and certification programs. These hands-on experiences provide valuable insights into proper installation techniques and system capabilities.

Subscribe to industry publications that track emerging technologies and best practices. Regular updates help you stay informed about innovations that could benefit your facility.

Join professional networks and attend industry conferences. These connections provide opportunities to learn from peers and discover solutions to common challenges.

The Bottom Line

With commercial roof replacements costing upwards of $1 million for large facilities, proper design has never been more critical to building performance and operational success.

Industry data shows that well-designed roofing systems can reduce energy costs by 30% while extending service life by decades, yet 75% of commercial roofs fail prematurely due to preventable design flaws.

The integration of advanced materials, proper drainage engineering, and strategic preventive maintenance protocols represents the new standard for commercial roof design excellence.

As extreme weather events increase and building systems grow more complex, investing in proper roof design isn’t just about protection – it’s about ensuring business continuity and maximizing facility ROI for decades to come.

FREQUENTLY ASKED QUESTIONS

Q. What is commercial roof design in simple terms?

A. It refers to planning the protective layer of a commercial building, integrating materials, structure, and environmental factors for long-lasting performance.

Q. How can commercial roofs improve energy efficiency?

A. Proper design reduces energy consumption by optimizing materials that reflect heat and improve insulation, potentially cutting energy costs by 30%.

Q. What are essential terms in commercial roofing?

A. Key terms include membrane, R-value, roof assemblies, and flashing—all crucial for understanding roofing performance and materials.

Q. What factors should I consider when selecting an industrial roof?

A. Consider initial costs, required performance, environmental sustainability, and long-term maintenance needs to ensure effective investment.

Q. What are common challenges with commercial roofing?

A. Frequent challenges include water intrusion, poor ventilation, and inadequate drainage, which can lead to significant repair costs if ignored.

Q. What steps should I take for my commercial roof maintenance?

A. Establish a regular inspection schedule, train maintenance staff to recognize issues early, and document all maintenance activities thoroughly.

Q. How can I assess the lifespan of my commercial roof?

A. Evaluate the material quality, installation craftsmanship, and perform regular inspections to identify any damage that may shorten its lifespan.