Poorly designed commercial roofs cost U.S. businesses over $2.5 billion annually in premature failures, repairs, and energy waste. Yet many facility managers lack access to comprehensive design guidance that integrates modern materials with proven engineering principles.

This handbook provides a systematic approach to commercial roof design from initial concept through long-term maintenance. Drawing from decades of field experience and current building science, it delivers actionable insights for protecting valuable building assets.

Through six detailed sections, readers will master essential concepts in structural design, system components, installation methods, maintenance protocols, performance metrics, and optimization strategies.

SECTION 1: FUNDAMENTAL CONCEPTS

Every commercial roofing project begins with critical design decisions that determine decades of performance. Industry data shows that over 40% of premature roof failures stem from inadequate initial design rather than material defects or installation issues. Understanding core roofing concepts isn’t just about technical compliance – it’s about protecting millions in property value and preventing catastrophic failures that can halt business operations.

Key Roof Design Principles and Terminology

The foundation of effective commercial roofing lies in understanding how different components work together as a system. Every element, from the deck to the membrane, plays a specific role in protecting the building envelope.

Modern roofing systems incorporate multiple layers: structural deck, vapor barrier, insulation, cover board, and weatherproofing membrane. Each layer must be properly specified and integrated to create a cohesive system.

Material selection requires careful consideration of building use, local climate, and budget constraints. Single-ply membranes like TPO offer excellent UV resistance, while modified bitumen provides superior puncture resistance.

Design decisions must also account for mechanical equipment, roof penetrations, and future maintenance access. These elements significantly impact the roof’s long-term performance and serviceability.

Understanding Wind Uplift and Load Parameters

Wind uplift forces can compromise even the most robust roofing systems. The interaction between wind and building geometry creates complex pressure patterns that must be carefully analyzed during design.

The DuPont Technical Manual emphasizes that wind uplift resistance must be calculated using geographic wind zones and design pressures specific to each project’s location. These calculations must account for roof pitch, ridge height, site altitude, and local topography. (source: DuPont Technical Manual)

Load calculations must also consider dead loads from equipment and materials, plus live loads from maintenance activities, snow accumulation, and rainfall. These combined forces influence structural requirements and attachment methods.

Corner and perimeter zones require enhanced attachment patterns and stronger materials due to increased wind forces in these areas. Proper detailing at these critical zones prevents progressive system failure.

Roof Slope and Drainage Considerations

Effective drainage design begins with proper slope calculations. Even minimal ponding can accelerate membrane degradation and lead to structural concerns.

Primary drainage systems must be sized to handle peak rainfall events while secondary (emergency) drainage prevents overloading. The placement of drains, scuppers, and overflow devices requires careful coordination with structural elements.

Tapered insulation systems can create positive drainage on structural decks with minimal slope. These systems must be designed to prevent thermal bridging while maintaining adequate water flow.

Regular maintenance of drainage systems is essential for long-term performance. Blocked drains can cause rapid accumulation of weight far exceeding design loads, potentially leading to structural failure.

Climate change considerations now require drainage systems designed for more intense rainfall events. This often means larger drain sizes and more robust overflow provisions than traditional specifications.

SECTION 2: SYSTEM COMPONENTS

A commercial roof represents a complex system where each component plays a vital role in protecting valuable assets. Studies show that 35% of premature roof failures stem from improper component selection or integration. Understanding these critical elements helps facility managers make informed decisions that can extend roof life by 10-15 years while reducing maintenance costs.

Structural Decks and Insulation Materials

The structural deck forms the foundation of every commercial roofing system, providing essential support for all other components. Most commercial buildings utilize steel, concrete, or wood decks, each offering distinct advantages in terms of cost, span capability, and fire resistance.

Insulation selection dramatically impacts both energy efficiency and system longevity. Modern polyisocyanurate and expanded polystyrene materials offer superior R-values while contributing to the roof’s structural integrity.

The first layer of any commercial roof is the deck, followed by carefully selected insulation to maintain thermal efficiency. The integration of these components creates the base for subsequent waterproofing layers. (source: NASI Roofing)

Proper deck and insulation combinations must account for local climate conditions, building use patterns, and energy code requirements. These factors determine the optimal assembly for long-term performance.

Membrane Types and Layering Configurations

Modern roofing membranes offer varying degrees of weather resistance, durability, and installation flexibility. Single-ply options like TPO and PVC provide excellent UV resistance, while modified bitumen excels in puncture protection.

The configuration of membrane layers significantly affects system performance. Fully-adhered systems typically offer superior wind resistance compared to mechanically fastened alternatives.

Material thickness and reinforcement types must align with expected roof traffic and environmental stresses. Premium membranes often incorporate additional reinforcement layers for enhanced durability.

Chemical compatibility between different membrane components requires careful consideration. Incompatible materials can lead to premature degradation and system failure.

Flashing, Edge Details, and Roof Penetrations

Flashing details represent the most vulnerable points in any roofing system. These critical transitions require precise material selection and installation techniques to prevent water infiltration.

Edge metal systems must meet ANSI/SPRI ES-1 standards for wind resistance. Proper edge detail design prevents membrane billowing and potential system detachment during high winds.

Roof penetrations demand careful coordination between trades to ensure proper installation. Each penetration requires specific flashing methods based on size, shape, and function.

Regular inspection of flashing and penetration details helps identify potential issues before they lead to significant damage. Proactive maintenance of these components extends overall system longevity.

SECTION 3: IMPLEMENTATION METHODS

Proper implementation methods can mean the difference between a roof that lasts decades and one that fails prematurely. Industry data shows that installation-related issues account for nearly 40% of commercial roof failures, leading to millions in repair costs and business disruptions. Understanding and executing correct implementation techniques is crucial for protecting valuable building assets and ensuring long-term performance.

Attachment Techniques and Fastening Patterns

Mechanically attached roofing systems secure directly to the structural deck, while fully adhered systems use specialized adhesives for complete surface bonding. The choice between these methods significantly impacts wind resistance and long-term durability. (source: IKO Industries Ltd.)

Wind uplift calculations determine precise fastening patterns, especially critical in corner and perimeter zones. These high-stress areas require additional mechanical reinforcement to prevent membrane separation during severe weather events.

Different deck materials demand specific fastener types and installation patterns. Steel decks typically require corrosion-resistant screws, while concrete substrates may need specialized anchors or adhesive systems.

Regular inspection of attachment points helps identify potential weaknesses before they lead to system failure. This proactive approach prevents costly emergency repairs and extends roof lifespan.

Vapor Barrier and Moisture Control Practices

Effective moisture control begins with proper vapor barrier placement and integration. These barriers must create continuous protection against water vapor migration, which can compromise insulation performance and accelerate material degradation.

Climate zones influence vapor barrier specifications and installation methods. Buildings in humid regions require more robust moisture control systems than those in arid environments.

Penetrations and terminations present critical points for vapor control. These areas demand careful detailing and proper material selection to maintain the vapor barrier’s integrity.

Regular monitoring of interior humidity levels helps identify potential vapor barrier failures. Early detection of moisture issues prevents extensive damage to roofing components and building contents.

Sequencing Installation and Quality Assurance

Proper installation sequencing ensures each component performs as designed. This includes coordinating material deliveries, managing weather constraints, and maintaining appropriate temperature conditions during installation.

Quality control checkpoints must occur at critical stages throughout the installation process. These inspections verify proper attachment, seam integrity, and flashing details before proceeding to subsequent layers.

Documentation of installation procedures provides valuable reference for future maintenance and repairs. This includes photographing concealed components and recording specific material lots used.

Weather monitoring and material storage practices significantly impact installation quality. Proper protection of materials and careful timing of weather-sensitive operations prevents installation defects.

SECTION 4: MAINTENANCE REQUIREMENTS

Proactive maintenance represents the difference between a roof lasting its full service life and premature failure. Industry data shows that over 80% of commercial roofs fail before their warranty expiration, with inadequate maintenance being the leading cause. A well-executed maintenance program can double a roof’s functional lifespan while protecting millions in building assets and preventing business interruptions.

Routine Inspection Protocols and Timing

Semi-annual inspections form the foundation of effective roof maintenance, with additional assessments required after severe weather events. Spring inspections identify winter damage, while fall inspections ensure readiness for upcoming cold weather stresses.

Professional roof surveys must include detailed membrane examination, seam testing, and drainage system evaluation. These assessments help identify potential issues before they develop into major failures.

Documentation through high-resolution photography and detailed checklists creates an invaluable maintenance history. This record helps track degradation patterns and justifies proactive repairs.

Modern inspection tools like infrared scanning can detect hidden moisture issues not visible during visual surveys. Early detection of subsurface problems prevents extensive damage to insulation and deck components.

Identifying and Addressing Common Roof Failures

Membrane separations and punctures account for nearly 40% of commercial roof leaks. Regular surface evaluations can identify these issues before water infiltration damages underlying components.

Modified bitumen systems require specific inspection protocols, focusing on seam integrity and membrane adhesion. Regular checks of mechanical fasteners and plate systems help prevent wind uplift failures in attached systems. (source: IKO Complete Guide to Commercial Flat Roofing Systems)

Flashing failures at penetrations and perimeters create vulnerable entry points for water. Systematic evaluation of these critical areas helps prevent costly interior damage.

Blocked drainage systems can rapidly overload structural capacity during heavy rainfall. Regular cleaning and testing of drains prevents catastrophic ponding failures.

Repair Materials and Techniques for Longevity

Material selection for repairs must match the existing roof system while incorporating current technology improvements. Compatible sealants and reinforcement materials extend repair durability.

Emergency temporary repairs require specific materials designed for adverse conditions. These products bridge the gap until permanent repairs can be properly implemented.

Proper surface preparation dramatically impacts repair effectiveness. Thorough cleaning and proper drying of repair areas ensures optimal adhesion and longevity.

Quality control measures during repairs prevent callback issues. Temperature monitoring, adhesive testing, and seam probing help verify repair integrity.

SECTION 5: PERFORMANCE METRICS

Modern commercial roofing demands rigorous performance evaluation to protect substantial facility investments. Industry studies reveal that roofs lacking proper performance monitoring experience 60% more failures and cost nearly three times more to maintain over their lifespan. By establishing clear metrics for wind resistance, thermal efficiency, and water intrusion, facility managers can prevent catastrophic failures while optimizing their roof’s longevity and return on investment.

Measuring Wind Uplift Resistance and Durability

Wind uplift testing must conform to ASTM D6381 standards, providing quantifiable data on membrane and fastener performance under simulated storm conditions. These measurements establish baseline performance metrics for ongoing system evaluation.

Corner and perimeter zones require enhanced testing protocols due to increased wind forces. Regular monitoring of these high-stress areas helps prevent progressive system failure that often begins at these critical points.

Dynamic pull testing of mechanical fasteners provides crucial data on attachment strength. This information guides maintenance scheduling and helps predict potential failure points before they compromise system integrity.

Periodic uplift resistance verification ensures continued compliance with design specifications. This ongoing assessment protects both the roofing investment and building contents from wind-related damage.

Thermal Performance and Energy Efficiency Standards

Commercial roofing systems are typically flat or low slope, significantly impacting energy efficiency through heat absorption and reflection. Single-ply membranes like PVC, TPO, or EPDM offer varying degrees of thermal performance based on color and surface properties. (source: Roofing Academy X)

R-value testing of insulation systems must occur regularly to verify continued thermal resistance. Degraded insulation can reduce energy efficiency by up to 40%, dramatically increasing HVAC operating costs.

Infrared scanning provides detailed mapping of thermal performance across the entire roof surface. This technology identifies areas of compromised insulation and thermal bridging that traditional inspections might miss.

Solar reflectance index (SRI) measurements help optimize membrane selection for specific climate conditions. Higher SRI values reduce cooling loads in warm climates, while lower values may benefit heating-dominated regions.

Leak Detection and Water Infiltration Monitoring

Electronic leak detection (ELD) systems provide precise location data for membrane breaches. This technology can identify potential leaks before water penetration causes significant damage to underlying components.

Moisture mapping through capacitance testing reveals subsurface water accumulation patterns. Early detection of moisture intrusion prevents insulation degradation and helps maintain thermal performance.

Core sampling at strategic locations verifies system composition and moisture content. These physical tests complement electronic monitoring to provide comprehensive water infiltration data.

Integration of real-time moisture sensors with building automation systems enables immediate leak response. This proactive approach minimizes water damage and reduces repair costs through early intervention.

SECTION 6: OPTIMIZATION STRATEGIES

Modern commercial roofing faces unprecedented challenges from extreme weather events, rising energy costs, and evolving building codes. Industry data shows that optimized roof systems can reduce energy costs by up to 30% while extending service life by 10-15 years. Yet many commercial properties continue operating with outdated designs that leave them vulnerable to failures and excessive operating costs. Understanding and implementing key optimization strategies has become critical for protecting building assets and maintaining competitive operating expenses.

Enhancing Roof System Resilience to Weathering

Built-up roofing systems with embedded gravel provide superior protection against extreme weather conditions when properly designed and installed. Structural roof deck attachments must account for specific wind pressures across field, perimeter, and corner zones to prevent system failure.

Edge flashing, coping, and counterflashing installations demand strict compliance with ANSI/SPRI/FM4435/ES-1 standards based on site-specific design pressures. Proper installation of starter strips and drip edges on sealed roof decks creates critical water barriers at vulnerable transition points. (source: Insurance Institute for Business & Home Safety)

Reinforced membrane systems offer enhanced puncture resistance and dimensional stability. These premium materials provide superior protection against hail damage and foot traffic while maintaining long-term weathering performance.

Strategic placement of expansion joints and control gaps allows the roof system to accommodate building movement. This flexibility prevents membrane tears and separation that often lead to water infiltration.

Integrating Reflective and Cool Roof Technologies

Modern reflective membranes can reduce peak roof temperatures by up to 50°F compared to traditional dark surfaces. This dramatic temperature reduction decreases thermal stress on roofing components while lowering cooling costs.

White and light-colored membranes maintain higher solar reflectance indices (SRI) throughout their service life. Regular cleaning and maintenance of these surfaces preserves their reflective properties and energy-saving benefits.

Cool roof coatings provide cost-effective options for upgrading existing dark membranes. These field-applied solutions can restore weathered surfaces while adding reflective properties to older roofing systems.

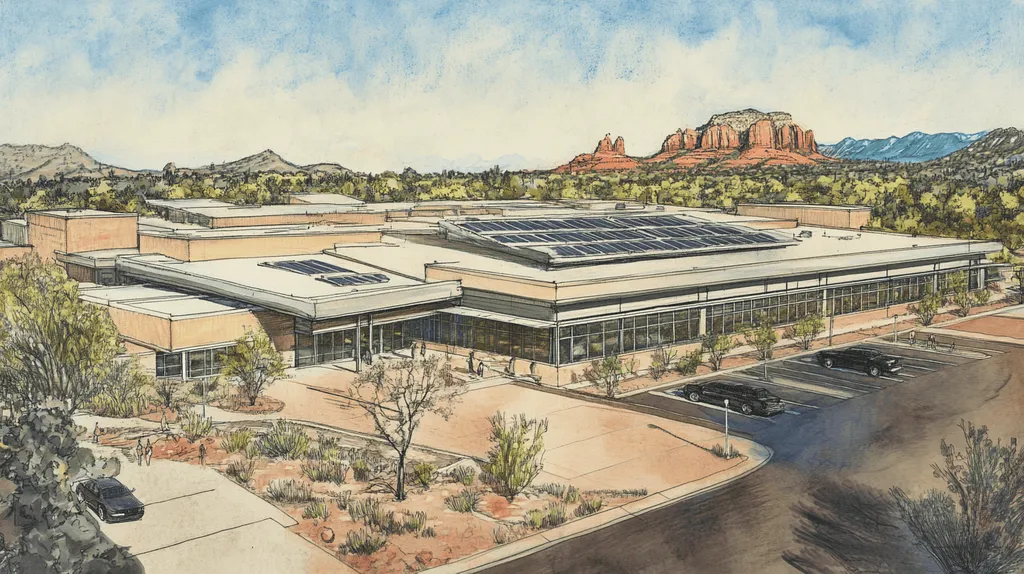

Integration of photovoltaic systems with reflective membranes creates synergistic benefits. The cooler operating temperatures improve solar panel efficiency while the panels provide additional protection for the roof surface.

Design Adjustments for Cost-Effectiveness and Longevity

Strategic placement of roof-mounted equipment minimizes penetrations through critical waterproofing layers. Consolidating mechanical systems into designated areas reduces potential leak points while simplifying maintenance access.

Enhanced insulation systems with staggered joints prevent thermal bridging and condensation issues. Proper thermal design extends membrane life by reducing temperature fluctuations and associated stress.

Walkway systems protect high-traffic areas while providing safe access for maintenance personnel. These sacrificial wear layers prevent membrane damage without compromising system integrity.

Integration of leak detection systems enables early identification of moisture infiltration. This technology allows targeted repairs before minor issues develop into major problems requiring extensive reconstruction.

Looking Ahead

Commercial roofing failures cost U.S. businesses over $2.5 billion annually, with 80% of roofs failing before their intended lifespan due to preventable design and maintenance issues.

As extreme weather events increase and energy costs rise, proper roof design has become more critical than ever for protecting valuable building assets.

The integration of modern materials, advanced monitoring systems, and optimization strategies can extend roof life by 10-15 years while reducing energy costs by up to 30%.

By implementing the comprehensive design principles, component selection criteria, and maintenance protocols outlined in this handbook, facility managers can significantly reduce their risk of catastrophic failures while maximizing their return on investment.

The future of commercial roofing lies in proactive design that anticipates challenges rather than reacting to failures.

FREQUENTLY ASKED QUESTIONS

Q. What are fundamental concepts of a commercial roof?

A. Understanding the core components of a commercial roof is critical for longevity and performance. Proper design choices and material selection play major roles in preventing premature failures and ensuring effective protection for your building’s assets.

Q. How do system components affect an industrial roof’s lifespan?

A. Each component of an industrial roof, from the structural deck to the waterproofing layers, interacts to determine overall durability. Proper selection and integration of these parts can extend lifespan significantly while minimizing maintenance costs and potential failures.

Q. What are the best implementation methods for a commercial roof?

A. Following proper installation techniques is crucial in ensuring a commercial roof’s reliability. Correct attachment methods and effective moisture control practices, including sequencing and quality assurance, contribute to a roof’s long-term performance and durability.

Q. What maintenance requirements are essential for a commercial roof?

A. Regular inspections and maintenance are vital to extend the functional life of a commercial roof. Establishing routine protocols to identify and address potential issues can significantly reduce repair costs and help avoid premature failures.

Q. How can performance metrics assess my industrial roof?

A. Establishing metrics for wind resistance, thermal efficiency, and water intrusion can optimize your industrial roof’s performance. Regular evaluations will help identify potential issues early, ultimately protecting your investment and reducing maintenance costs.

Q. What optimization strategies can enhance commercial roofs?

A. Implementing optimization strategies such as reflective technologies and better insulation can enhance roof performance. These changes can significantly reduce energy costs while extending the overall life span of the roofing system.

Q. What are the benefits of integrating cool roof technologies?

A. Integrating cool roof technologies reduces energy consumption by lowering peak roof temperatures. This lowers cooling costs and extends the life of roofing materials while improving indoor comfort for occupants.