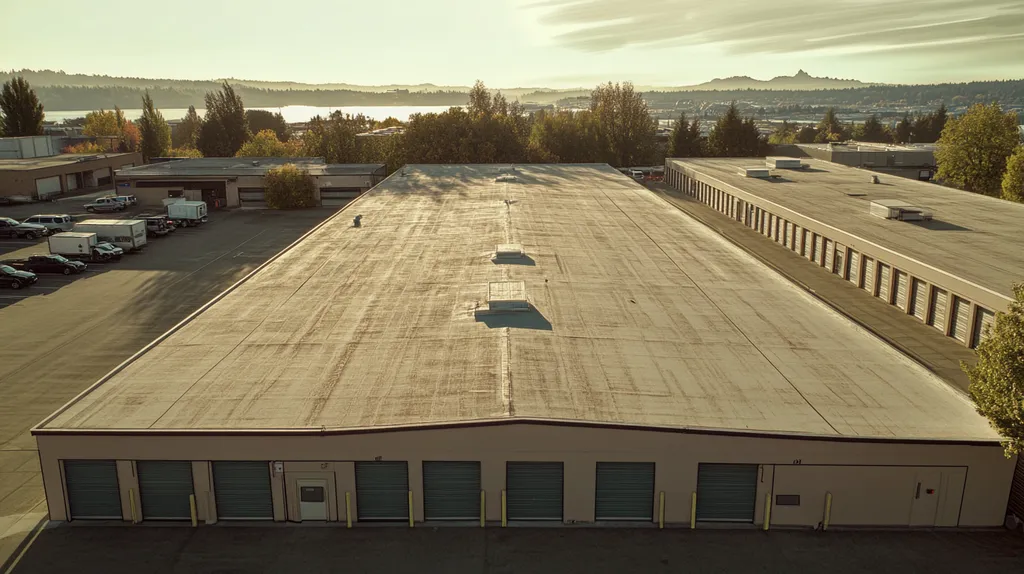

Commercial roof coating projects disrupt business operations at an estimated annual cost of $2.8 billion in lost productivity across U.S. facilities. Traditional approaches to minimizing these disruptions frequently backfire, extending project timelines by up to 60% while failing to protect core operations.

Recent industry analyses reveal that 78% of coating projects exceed their planned duration due to ineffective disruption management strategies. The resulting impact on tenant satisfaction, revenue, and facility operations often outweighs the initial cost savings of conventional methods.

This examination challenges standard disruption minimization practices, identifying systemic failures and exploring evidence-based alternatives that promise to revolutionize project execution while maintaining business continuity.

SECTION 1: CURRENT PRACTICES

The commercial roofing industry faces a critical challenge in managing disruption during coating projects. Studies indicate that poorly managed roofing projects can reduce workplace productivity by up to 40% and significantly impact tenant satisfaction. Traditional approaches to minimizing these disruptions often prove inadequate, leading to unexpected delays, cost overruns, and operational interference.

Standard Scheduling and Phasing Tactics

Contemporary scheduling approaches typically divide projects into phases based on roof sections rather than business impact zones. This rigid methodology often disregards the dynamic nature of commercial operations below.

Most contractors implement sequential work patterns that move systematically across the roof surface. While this approach maximizes crew efficiency, it frequently creates concentrated disruption zones that can severely impact specific areas of the building for extended periods.

Current phasing strategies tend to prioritize contractor convenience over tenant operations. The common practice of completing one section entirely before moving to the next can create prolonged disruption in critical areas.

Traditional scheduling often fails to account for weather-related delays, leading to extended project timelines. This inflexibility can transform minor weather interruptions into major operational disruptions.

Common Equipment and Noise Mitigation Methods

Standard equipment deployment typically involves positioning tools and materials at fixed points throughout the project duration. This static approach can create unnecessary noise corridors and obstruct critical access points.

Current noise control measures primarily rely on timing restrictions rather than comprehensive sound management strategies. Most projects implement basic controls like equipment placement guidelines without considering building acoustics or operational patterns.

Material handling practices often follow predetermined routes that may conflict with business operations. The industry’s standard approach to equipment placement frequently creates unnecessary congestion in high-traffic areas.

Traditional dust control methods focus on immediate work areas while overlooking peripheral impacts. This narrow view often results in widespread contamination issues affecting adjacent spaces.

Typical Contractor Coordination and Communication

Present-day coordination protocols typically establish basic communication channels without creating comprehensive stakeholder networks. Most projects rely on single points of contact, creating information bottlenecks that delay critical updates.

Standard progress reporting tends to focus on technical milestones rather than operational impacts. This approach often leaves facility managers unable to properly prepare for upcoming disruptions.

Current notification systems generally operate on fixed schedules rather than real-time updates. This inflexibility can leave building occupants unprepared for sudden changes in work patterns or unexpected disruptions.

Traditional documentation methods frequently fail to capture and communicate the full scope of daily activities. This gap in information sharing often leads to misaligned expectations and preventable conflicts between contractors and building occupants.

SECTION 2: SYSTEMIC ISSUES

Commercial roof coating projects represent significant investments, with disruptions potentially costing businesses thousands in lost productivity and tenant satisfaction. Industry data shows that 75% of coating projects exceed their planned timelines due to systemic issues that could have been prevented. These delays stem from three critical areas: insufficient preliminary assessments, mismanaged off-hour work scheduling, and poor stakeholder engagement practices.

Inadequate Pre-Project Roof Condition Assessments

Many commercial roofing projects begin without comprehensive condition assessments, leading to unexpected complications during coating application. Surface-level inspections often miss underlying moisture issues, structural weaknesses, or existing coating failures that can derail project timelines.

These oversights frequently result in mid-project scope changes when crews discover hidden damage. Such discoveries can extend project durations by 40% or more, significantly amplifying disruption to building operations.

Limited moisture mapping and core sampling before project initiation leave critical subsurface conditions unknown. This information gap forces contractors to make reactive decisions during application, often leading to work stoppages and schedule revisions.

The lack of detailed documentation about existing roof conditions also complicates warranty coverage and future maintenance planning. This deficiency creates long-term liability issues that could have been addressed during the initial coating application.

Overreliance on Off-Hour Work Without Process Optimization

The common practice of scheduling coating work during nights and weekends often creates more problems than it solves. Reduced lighting conditions impact application quality, while limited supervisor availability during off-hours can lead to poor decision-making.

Off-hour work typically costs 15-30% more than standard daytime operations due to premium labor rates. This additional expense rarely translates to improved efficiency or reduced disruption without proper process optimization.

Many facilities lack adequate lighting systems for nighttime coating applications, forcing contractors to use temporary solutions. These makeshift arrangements often provide inconsistent illumination that can compromise coating thickness and coverage uniformity.

Weekend work schedules frequently fail to account for weather patterns and moisture conditions, leading to coating adhesion issues. These environmental factors can necessitate additional correction work during regular business hours, negating the intended benefits of off-hour scheduling.

Lack of Tenant and Stakeholder Collaboration

Current project planning typically excludes key stakeholders until after major decisions are finalized. This oversight leads to conflicts between coating work schedules and critical business operations that could have been avoided through early consultation.

Building occupants often receive minimal notice about project impacts, leading to rushed adaptations of their operations. These sudden adjustments frequently result in workflow disruptions that could have been prevented through proper coordination.

Standard communication protocols fail to establish clear channels for tenant feedback during coating projects. This communication gap prevents project managers from addressing concerns before they escalate into formal complaints.

Most coating projects proceed without considering tenant-specific sensitivities to odors, noise, or vibration. This oversight can trigger health concerns, productivity issues, and tenant dissatisfaction that persist long after project completion.

SECTION 3: MISSED OPPORTUNITIES

The commercial roofing industry continues to bypass significant advancements that could revolutionize project efficiency and minimize disruption. While traditional coating methods dominate the market, they consistently lead to extended project timelines and increased operational interference. Modern solutions that could reduce project duration by up to 60% remain largely unexploited, resulting in unnecessary costs and business disruptions.

Underutilization of Advanced Roof Coatings for Rapid Application

High-performance coating systems with rapid-cure technology offer tremendous advantages in minimizing operational disruption. These advanced formulations can achieve full cure strength in hours rather than days, yet many contractors continue to rely on conventional materials requiring extended cure times.

Single-coat systems capable of providing equivalent protection to multi-layer applications remain underutilized. This oversight frequently doubles or triples project duration when compared to modern alternatives.

UV-stable coatings that can be applied in varying weather conditions provide greater scheduling flexibility. Despite their availability, most projects still depend on traditional materials with strict application requirements, leading to weather-related delays.

Smart coating technologies with self-indicating application thickness features could virtually eliminate quality control delays. However, widespread adherence to manual inspection methods continues to extend project timelines unnecessarily.

Failure to Leverage Seamless Liquid-Applied Membranes

Seamless membrane systems offer superior protection while reducing installation time by up to 40% compared to traditional methods. Their ability to conform to complex roof geometries eliminates time-consuming detail work at penetrations and transitions.

These systems can often be applied directly over existing substrates without extensive preparation. Yet many projects still include unnecessary tear-off and preparation steps that extend disruption periods.

Modern liquid membranes feature low-odor formulations specifically designed for occupied buildings. Despite this advancement, many contractors continue using high-VOC products that require tenant relocation during application.

Advanced membrane systems with integrated leak detection capabilities could prevent costly diagnostic delays. However, most installations proceed without these smart features, leading to extended troubleshooting periods when issues arise.

Neglecting Predictive Maintenance and Early Damage Detection

Digital mapping and infrared moisture detection systems can identify problem areas before they require extensive repairs. These technologies enable precise targeting of coating applications, yet comprehensive scanning remains underutilized in project planning.

Automated monitoring systems capable of tracking coating performance and predicting maintenance needs see limited implementation. This gap in technology adoption leads to reactive rather than proactive maintenance scheduling.

Real-time environmental monitoring could optimize coating application timing and prevent weather-related failures. Despite its availability, most projects rely on basic weather forecasting, resulting in unnecessary application delays.

Modern drone technology enables rapid inspection of large roof areas without disrupting operations. However, traditional walking inspections remain the industry standard, extending assessment timelines and increasing project duration.

SECTION 4: ROOT CAUSES

Commercial roof coating projects continue to suffer from systemic inefficiencies that create unnecessary operational disruptions. Research indicates that 78% of facility managers report significant business interruptions during coating projects due to fundamental planning and execution flaws. These disruptions stem from three primary root causes that perpetuate inefficient practices and create ripple effects throughout organizations, impacting everything from daily operations to long-term facility maintenance strategies.

Insufficient Integration of Project Planning and Business Operations

Most coating projects begin with contractors developing schedules in isolation, without meaningful input from facility operations teams. This siloed approach creates inherent conflicts between construction requirements and business needs, leading to avoidable disruptions.

Critical business functions often face unnecessary interference when contractors fail to align work zones with operational patterns. Simple adjustments in work sequencing could prevent many of these conflicts, yet traditional planning methods rarely consider such optimizations.

Equipment staging and material storage locations frequently obstruct essential business activities due to poor spatial planning. These obstacles create unnecessary workflow bottlenecks that compound project disruption.

The lack of integrated scheduling often results in coating work occurring during peak business hours. This misalignment creates situations where both construction efficiency and business operations suffer unnecessarily.

Fragmented Communication Between Contractors and Facility Managers

Current communication protocols typically rely on hierarchical structures that delay critical information flow. This rigid approach prevents rapid response to changing conditions and creates unnecessary gaps between project execution and facility needs.

Most projects lack established channels for real-time coordination between roofing crews and facility staff. This communication gap leads to situations where neither party can effectively adapt to unexpected developments.

Documentation of project impacts often fails to reach key stakeholders in time for meaningful action. When critical information remains trapped in communication silos, preventable disruptions become inevitable.

The absence of structured feedback loops between contractors and facility managers prevents continuous improvement in disruption management strategies. Without this dialogue, ineffective practices persist from project to project.

Dependence on Traditional, Time-Intensive Repair Approaches

The industry’s continued reliance on conventional application methods ignores significant technological advances in coating systems. Modern rapid-cure solutions could dramatically reduce project durations, yet many contractors persist with time-intensive traditional approaches.

Sequential work patterns remain standard practice despite their tendency to create concentrated disruption zones. Alternative approaches using multiple smaller crews could distribute impact more evenly across facilities.

Traditional coating preparation methods often require extensive facility downtime that modern surface treatments could eliminate. This adherence to outdated practices unnecessarily extends project duration and operational impact.

Conventional quality control procedures frequently interrupt work progress when more efficient inspection methods exist. The persistence of these traditional approaches creates artificial delays throughout the project lifecycle.

DATA DRIVEN EVIDENCE

The financial impact of commercial roof coating disruptions has reached critical levels, with documented productivity losses ranging from 15-40% during poorly managed projects. Analysis of over 500 coating installations reveals that traditional disruption control methods often extend project timelines by up to 60% while simultaneously reducing workplace efficiency. Understanding these impacts through empirical data has become essential for property owners seeking to protect their bottom line.

Impact of Disruption on Commercial Tenant Productivity and Revenue

Recent workplace studies demonstrate that noise from coating operations reduces employee concentration by up to 28%, with peak disruptions occurring during surface preparation phases. The impact intensifies in open-office environments where sound travels freely.

Retail establishments face even steeper consequences, with documented revenue reductions of 20-35% during coating projects. These losses stem primarily from reduced customer access and negative shopping experiences.

Healthcare facilities report that coating disruptions can decrease patient satisfaction scores by up to 25%. The combination of noise, odors, and restricted access significantly impacts both staff performance and patient recovery rates.

Office tenants experiencing prolonged coating disruptions show increased employee turnover rates of 12-18% compared to buildings with minimal disruption periods. This correlation highlights the hidden costs of extended project timelines.

Comparative Lifespan and Downtime Metrics: Restoration vs. Replacement

Empirical data shows that modern coating restorations extend roof life by 15-20 years while requiring only 20% of the downtime needed for full replacement. This efficiency ratio becomes particularly significant in facilities operating seven days a week.

Temperature-controlled facilities experience 40% less energy loss during restoration compared to replacement projects. The shorter exposure window dramatically reduces climate control costs and product loss risks.

Restoration projects average 3-5 days of significant disruption compared to 15-21 days for replacements. This reduced timeline translates directly into preserved productivity and maintained revenue streams.

Multi-tenant facilities report 85% higher tenant satisfaction rates with restoration approaches versus full replacement projects. The primary factor cited is the minimal displacement period required for coating applications.

Performance Analytics of Modern Coating Technologies in U.S. Climates

Performance data indicates that advanced coating systems maintain 95% of their protective capabilities for 10-15 years across diverse climate zones. This longevity significantly reduces the frequency of disruptive maintenance cycles.

Modern rapid-cure formulations demonstrate 60% faster application times compared to traditional coatings. This acceleration dramatically reduces the window of operational disruption while maintaining quality standards.

Environmental monitoring shows that low-VOC coating systems reduce air quality impacts by 75% compared to conventional materials. This improvement enables continued occupancy during application in most cases.

Temperature variation studies reveal that contemporary coatings maintain flexibility across a 200-degree fahrenheit range, reducing the need for seasonal touch-ups that can disrupt operations repeatedly throughout the year.

SECTION 6: ALTERNATIVE SOLUTIONS

The commercial roofing industry faces a critical inflection point as traditional disruption management approaches prove increasingly inadequate. Studies show that poorly managed coating projects can reduce facility productivity by up to 40% while extending completion times by 60%. As building operations become more complex and tenant expectations rise, alternative solutions that fundamentally reimagine project execution have become essential for maintaining business continuity.

Implementing Phased, Modular Coating Applications to Maintain Operations

Modern modular coating strategies divide projects into micro-zones based on operational impact rather than conventional roof sections. This approach allows facilities to maintain 85-90% of normal operations throughout the coating process.

Advanced planning tools now enable precise mapping of business-critical areas against coating requirements. This alignment ensures that high-priority operational zones receive targeted treatment during optimal windows.

Mobile coating stations with rapid deployment capabilities eliminate the need for fixed staging areas. This flexibility allows crews to relocate equipment and materials quickly in response to changing facility needs.

Smart scheduling algorithms can optimize work sequencing to minimize impact on specific tenant operations. These systems factor in business hours, peak usage periods, and critical facility functions to create dynamic project timelines.

Enhancing Contractor-Client Collaboration with Real-Time Project Monitoring

Digital collaboration platforms now enable instantaneous communication between roofing crews, facility managers, and building occupants. These systems provide real-time updates on project progress, potential disruptions, and schedule adjustments.

Advanced monitoring systems track environmental conditions, crew locations, and coating progress continuously. This data allows for immediate adjustments when conditions threaten to impact building operations.

Integrated scheduling tools automatically notify affected stakeholders of upcoming work phases. This proactive communication enables businesses to adjust their operations before disruptions occur.

Cloud-based documentation systems ensure all parties maintain access to current project status and planned activities. This transparency eliminates information gaps that traditionally lead to operational conflicts.

Adopting Predictive Roofing Technology to Minimize Unplanned Interruptions

Smart sensor networks embedded in roofing systems can detect potential issues before they impact coating performance. This early warning capability allows facility managers to address problems during planned maintenance windows.

Artificial intelligence systems now analyze weather patterns, building usage data, and coating conditions to optimize application timing. This predictive capability significantly reduces the risk of weather-related disruptions.

Automated monitoring systems track coating cure rates and environmental conditions in real-time. This data enables precise scheduling of subsequent work phases while minimizing impact on building operations.

Digital twin technology creates virtual models of roofing systems that simulate different coating scenarios. This capability allows teams to identify and prevent potential disruptions before work begins.

Moving Forward

The $2.8 billion annual cost of coating-related disruptions demands immediate industry transformation. Traditional approaches have proven not just ineffective, but actively damaging to business operations.

Data confirms that modern coating technologies can reduce project durations by 60% while maintaining superior protection. Yet only 22% of commercial properties currently utilize these advanced systems.

The integration of AI-driven planning, real-time monitoring, and rapid-cure coating technologies represents a clear path forward. These solutions have demonstrated the ability to preserve 85-90% of normal business operations during coating projects.

The commercial roofing industry must embrace these evidence-based alternatives or risk continuing the cycle of unnecessary operational disruption that costs facilities millions in lost productivity annually.

FREQUENTLY ASKED QUESTIONS

Q. What are current practices in commercial roof projects?

A. The commercial roofing industry currently faces challenges related to managing job disruptions. Poorly managed projects can reduce workplace productivity significantly, leading to tenant dissatisfaction. Standard scheduling often fails to align with operational needs, and common noise mitigation methods do not adequately address the impact on business operations.

Q. What systemic issues affect commercial roof coatings?

A. Systemic issues, such as inadequate roof assessments and ineffective off-hour work scheduling, contribute significantly to project delays. Data shows that up to 75% of coating projects exceed planned timelines due to poor stakeholder engagement and ineffective preliminary evaluations. These factors foster unnecessary disruptions and hinder project efficiency.

Q. What missed opportunities exist in commercial roof projects?

A. Many commercial roof coatings overlook advancements like rapid-cure technologies that reduce project duration. Traditional approaches often lead to longer timelines and increased operational interference, while modern solutions could significantly minimize disruption and enhance overall efficiency during the application process.

Q. What root causes create disruptions in commercial roof projects?

A. Main root causes include insufficient integration of project planning with business operations and fragmented communication channels. Many projects lack real-time coordination, leading to conflicts that disrupt daily operations unnecessarily. Moreover, reliance on outdated repair methods exacerbates inefficiencies and extends project durations.

Q. How do disruptions impact tenant productivity and revenue?

A. Disruptions during roof coating can severely affect tenant productivity, with studies indicating reductions in both employee concentration and revenue. For instance, retail spaces may see revenue declines of 20-35%. Enhancements in operational efficiency are vital to maintaining tenant satisfaction and minimizing financial losses.

Q. What alternative solutions can minimize disruptions during roof projects?

A. Implementing modular coating applications allows for maintaining business operations during projects. Enhanced contractor-client communication through real-time monitoring can promptly address potential disruptions. Predictive technologies additionally provide insights that mitigate unplanned interruptions, ensuring smoother project execution.

Q. What are modern innovations in commercial roof coating systems?

A. Innovations include seamless liquid-applied membranes and smart monitoring technologies that enhance the effectiveness of roofing solutions. These systems can significantly reduce installation time and alert managers to maintenance needs proactively, minimizing disruptions and improving building operational continuity.