Every year, over 50 facility managers face severe penalties and legal action due to preventable roofing accidents and safety violations. The financial impact of these incidents averages $150,000 per case, not including potential loss of life.

For commercial properties, maintaining roof safety compliance involves a complex web of regulations, performance factors, and risk management protocols. Recent industry studies show that 73% of roof-related incidents stem from inadequate safety measures and compliance oversights.

This comprehensive guide provides facility managers with actionable solutions for ensuring roof safety, from structural assessments to emergency protocols, helping protect both personnel and property investments.

SECTION 1: PERFORMANCE FACTORS

For facility managers, the safety of a commercial roof is a fundamental concern. Inadequate attention to performance factors can contribute to structural failures and significant financial consequences. Studies reveal that 20% of commercial roofs face critical issues due to insufficient evaluations. Therefore, assessing structural integrity, evaluating the roof’s condition and age, and understanding load capacity limits are essential for maintaining safety and regulatory compliance.

Assessing Roof Structural Integrity

Ensuring the structural integrity of a roof is vital for safety and effectiveness. Routine assessments help pinpoint vulnerabilities that could endanger the roof’s ability to support various loads. Key factors include the condition of decking materials, the spacing of supports, and the overall integrity of the roofing system.

Professional evaluations typically check for sagging or uneven surfaces, which may signal deeper issues. Catching these problems early can save building owners from facing larger, costly repairs in the future.

Moreover, it’s important to consider environmental factors unique to specific locations. Areas with harsh weather conditions might require more frequent inspections to maintain structural integrity.

Utilizing advanced technologies, such as infrared scanning, can significantly enhance the evaluation process, providing facility managers with a more comprehensive view of the roof’s condition.

Key Action Items

Evaluating Roof Condition and Age

The age of a roof plays a significant role in its safety and performance. Over time, roofing materials deteriorate, reducing their effectiveness. Facility managers need to continuously evaluate not only visible wear but also hidden problems that can cause premature failure.

Focus on areas such as seams, flashing, and drainage systems, which often reveal the earliest signs of wear. Even roofs that seem structurally sound may conceal deeper issues beneath the surface.

Implementing a roof management plan that prioritizes regular inspections can greatly extend the lifespan of the roof. Tracking age-related benchmarks will assist in planning for repairs or replacements.

Maintaining a detailed record of inspections and repairs is also beneficial, as it contributes to a better understanding of the roof’s health and informs future decisions.

Key Action Items

Determining Load Capacity Limits

Recognizing the load capacity limits of a roof is essential for maintaining safety and ensuring compliance. Roofs are specifically engineered to bear certain weights, which include snow loads, equipment, and potential maintenance activities. Surpassing these limits can result in severe failures.

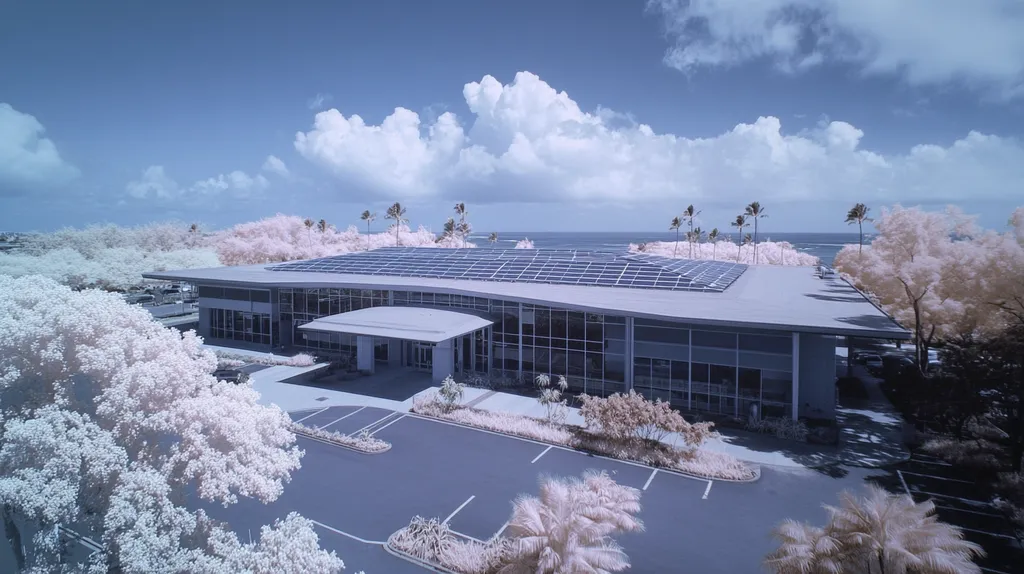

Facility managers should familiarize themselves with the maximum load ratings specified in roof designs and conduct routine assessments of any added installations. Heavy HVAC units or solar panels can alter load distribution significantly.

Furthermore, factoring in seasonal weight changes, such as snow accumulation, requires ongoing monitoring to prevent overloading. Establishing a clear strategy for managing these loads is crucial to keeping roofs within safe operational parameters.

In summary, regular evaluations of load capacities, coupled with an understanding of roof construction, can avert dangerous failures and enhance overall roof safety.

Key Action Items

SECTION 2: FINANCIAL CONSIDERATIONS

For facility managers, the costs associated with complying with roof safety regulations are not just numbers on a spreadsheet; they can have serious real-world implications. Ignoring safety compliance can lead to costly repairs, fines, and heightened liability risks. Research has shown that businesses committed to roofing safety can save as much as 35% on unexpected repair costs. This section will dive into the financial dimensions of safety compliance, the need for regular maintenance budgeting, and how these elements can lead to substantial long-term savings.

Cost of Safety Compliance Measures

Investing in safety compliance measures may seem daunting, but these initial costs are vital for safeguarding both property and personnel. Equipment like safety harnesses, guardrails, and inspection tools require upfront spending, yet the expenses are minor compared to the potential costs of workplace accidents and associated liabilities.

Providing certified training for maintenance staff is another essential step that enhances safety compliance. Trained personnel are better equipped to recognize and mitigate risks, which ultimately reduces operational hazards. These precautions not only fulfill legal requirements but also contribute to the roofing system’s performance and durability.

Additionally, using roofing materials that meet industry standards helps prevent premature wear and tear, leading to healthier roofs in the long run. Viewing safety compliance as a strategic investment rather than merely an expense helps managers protect their financial assets.

Key Action Items

Budgeting for Regular Maintenance

Regular maintenance is the cornerstone of ensuring roof safety and longevity. By setting aside a budget for routine inspections and upkeep, facility managers significantly reduce the risk of major repairs. Facilities that prioritize maintenance often handle minor issues before they evolve into costly problems.

Allocating funds for maintenance aligns organizational priorities with safety goals. For instance, regular roofing inspections can highlight vulnerabilities and hazardous conditions that need immediate attention, thus fostering a culture of accountability and safety in the workplace.

Moreover, the financial burden of neglecting maintenance far exceeds that of routine upkeep. While emergency repairs can soar into tens of thousands of dollars, planned maintenance costs remain manageable. Common industry practice suggests allocating 1-3% of the roof’s total value annually for effective maintenance to safeguard investments.

Key Action Items

Projecting Long-Term Cost Savings

Although the initial expenses of safety compliance may seem overwhelming, the long-term benefits can be substantial. Proper investment in safety measures and regular maintenance can yield significant savings. Research indicates that proactive roof maintenance can extend the lifespan of a roof by as much as 50%.

Additionally, minimizing accidents and ensuring compliance can lead to lower insurance premiums. Facilities that consistently demonstrate a commitment to safety often enjoy favorable insurance rates, translating to noteworthy savings over time. Improved safety records also significantly reduce the risk of costly lawsuits.

Furthermore, maintaining a well-optimized roof enhances energy efficiency, contributing to reduced utility bills. A well-insulated roof can lower heating and cooling expenses by up to 20%, benefiting both the bottom line and the environment. Ultimately, understanding safety and compliance from a long-term perspective provides a robust financial rationale for investing in these critical areas.

Key Action Items

SECTION 3: COMPLIANCE REQUIREMENTS

Ensuring commercial roof safety is not just important; it is essential. With the Bureau of Labor Statistics reporting that falls are among the leading causes of fatalities in the construction industry, understanding compliance regulations is crucial. Facility managers must skillfully navigate the complexities of OSHA regulations and local building codes to maintain safety and prevent liabilities.

Understanding OSHA Regulations

The Occupational Safety and Health Administration (OSHA) establishes vital guidelines to safeguard workers, particularly regarding roof safety. Facility managers must be familiar with regulations that mandate proper fall protection measures, such as using guardrails and safety harnesses during maintenance and repair work. Noncompliance can result in fines that add up quickly, straining budgets significantly.

OSHA also specifies necessary training and safety practices for workers. Hazards related to commercial roofs, including exposure to harsh weather and working from heights, need to be addressed through comprehensive safety training. Neglecting these training sessions can expose facility managers to substantial liabilities.

Regular reviews of applicable OSHA regulations are essential to prevent compliance lapses. Staying informed about updates and changes fosters a culture of safety that protects employees and corporate assets. A robust safety program that aligns with OSHA standards not only enhances worker safety but also promotes operational efficiency.

Key Action Items

Meeting Local Building Codes

Local building codes are established to ensure that roofing systems are designed and installed correctly and safely. These codes often stipulate specific materials and construction practices that cater to the region’s climate and potential hazards. Understanding these local regulations is essential for facility managers to ensure that roofs meet required safety and performance standards.

Noncompliance with local codes can lead to significant consequences, including fines, project delays, and unsafe roof conditions. For example, overlooking a local requirement for specific fire safety roofing materials could have disastrous effects, both in physical safety and organizational reputation.

Maintaining regular communication with local building authorities can help stay informed about code updates. Additionally, partnering with licensed roofing contractors who are familiar with these codes can streamline compliance efforts and enhance safety while building valuable relationships with key regulatory bodies.

Key Action Items

Ensuring Compliance Documentation

Maintaining meticulous compliance documentation is vital for every facility manager. This includes keeping thorough records of inspections, safety training sessions, and maintenance activities. Organized documentation demonstrates a commitment to safety and due diligence.

In case of an accident or audit, comprehensive records can profoundly affect outcomes. Showing adherence to safety protocols through well-maintained documents can mitigate liability issues during legal situations. Without adequate documentation, facility managers expose themselves to potential penalties and allegations of negligence.

Establishing a consistent process for documenting compliance can simplify this task. Utilizing digital tools and management software can streamline tracking inspections and training, facilitating easy access to necessary information when required. Prioritizing accurate documentation fosters a culture of accountability and safety within the organization.

Key Action Items

SECTION 4: RISK MANAGEMENT

Risk management in commercial roofing is essential for ensuring employee safety and maintaining operational efficiency. With falls accounting for nearly 40% of all construction-related fatalities, facility managers must prioritize identifying hazards and implementing strategies to mitigate risks. This section addresses the critical aspects of fall hazards, electrical and chemical risks, and the need for effective emergency response plans.

Identifying Potential Fall Hazards

Recognizing potential fall hazards is the cornerstone of effective risk management. Roofs pose various risks, including unprotected edges, skylights, and openings left during maintenance. Regular inspections are crucial to identify these hazards before any work begins.

Creating a detailed inventory of identified hazards aids in planning safety measures. Collaborating with roofing professionals ensures a thorough assessment of risks that may be missed during routine checks.

Installing guardrails and safety netting can substantially lower the fall risks. Additionally, clear signage alerting workers to potential hazards is vital. Training employees to recognize and respond to risks promotes a safer work environment.

Key Action Items

Mitigating Electrical and Chemical Risks

Electrical and chemical risks warrant serious attention during roofing maintenance. Roofs may contain electrical components, such as wiring for HVAC systems, which can lead to severe electrical shocks without proper precautions.

Routine inspections of electrical systems enable the detection of frayed wires or exposed parts. Employing lockout/tagout procedures during maintenance prevents accidental activation of systems.

Some roofing materials can pose health hazards due to their chemicals. Proper handling and storage are essential, and Safety Data Sheets (SDS) should be accessible to inform workers of potential dangers and safety practices.

Key Action Items

Developing Emergency Response Plans

Establishing effective emergency response plans is crucial for minimizing risks and ensuring safety during unexpected incidents. Facility managers should customize plans to address specific roofing dangers and potential emergencies.

The first task involves conducting a risk assessment to identify likely emergency scenarios, such as falls or hazardous material spills. This assessment guides the formulation of actionable response protocols.

Employees must be clear about their roles in emergencies. Regular drills reinforce essential actions, including evacuation routes and reporting procedures. Partnering with local emergency services enhances the plan’s overall effectiveness.

Key Action Items

SECTION 5: OPERATIONAL PROCEDURES

Ensuring safety on commercial roofs is paramount to preventing accidents and minimizing liability. With falls cited as the leading cause of death in the construction sector by the Occupational Safety and Health Administration (OSHA), rigorous operational procedures are essential. This section focuses on key practices, including effective training in fall protection, the establishment of safe access protocols, and the importance of conducting regular safety inspections.

Training Staff in Fall Protection

Successful fall protection training is critical for maintaining roof safety. It’s vital that employees are well-versed in potential hazards and proficient in using protective equipment. Regular training refreshers can make the difference between safety and disaster.

Training sessions should incorporate specific scenarios relevant to the workplace, using real-world examples to illustrate common pitfalls. This approach helps maintain awareness of safety protocols.

Hands-on training is particularly effective, allowing workers to practice using harnesses and fall protection systems. This helps reinforce memory and familiarity with procedures when they are on the roof.

Key Action Items

Implementing Safe Access Protocols

Developing safe access protocols is essential for preventing falls during roof maintenance. Clear guidelines should dictate how staff can safely ascend and descend from the roof, including the proper use of ladders, scaffolds, and safety gates.

Utilizing fixed ladders equipped with handrails enhances safety for rooftop access. Designating specific entry points can also minimize risks in busy areas.

Regular inspections of access points should be standard. Any wear or hazardous conditions need prompt attention to maintain a safe work environment.

Key Action Items

Conducting Regular Safety Inspections

Regular safety inspections are crucial for identifying and addressing potential hazards before they result in incidents. Establishing a systematic inspection schedule allows for routine evaluation of the roof’s condition and compliance with safety protocols.

During these inspections, look for signs of wear, water pooling, or loose materials that may pose risks. These evaluations are fundamental in preserving both the roof’s integrity and worker safety.

Engaging trained personnel or safety inspectors can provide a deeper assessment. Their expertise is beneficial for uncovering hidden hazards that staff might overlook.

Key Action Items

SECTION 5: OPERATIONAL PROCEDURES

Ensuring safety on commercial roofs is crucial for preventing accidents and protecting liability. With falls identified as the leading cause of fatalities in the construction industry, effective operational procedures are vital. This section highlights essential practices, including staff training in fall protection, implementing safe access protocols, and conducting thorough safety inspections.

Training Staff in Fall Protection

Effective training in fall protection is essential to uphold roof safety. Employees must have a solid understanding of potential hazards and be skilled in using protective equipment. Regular refresher training sessions significantly contribute to maintaining safety standards.

Consider integrating training scenarios directly applicable to your facility. Using real-world examples drives home the relevance and importance of adhering to safety protocols.

Incorporating hands-on practice with harnesses and fall protection systems enhances retention. Workers who engage in practical training are more prepared to follow safety procedures when on the roof.

Documenting all training sessions and certifications confirms compliance with safety requirements and supports a culture of safety in the workplace.

Key Action Items

Implementing Safe Access Protocols

Establishing safe access protocols is critical to preventing falls during roof maintenance. Clear procedures should outline how staff safely ascend and descend, including ladder, scaffold, and safety gate usage.

Utilizing fixed ladders with handrails enhances safety for rooftop access. Designating specific entry points also helps reduce risk exposure in busy areas.

Regular inspections of access points should be standard practice, promptly addressing any wear or hazardous conditions. Clear signage indicating safe access paths is essential for reinforcing these protocols among employees.

Key Action Items

Conducting Regular Safety Inspections

Regular safety inspections are crucial for identifying and addressing potential hazards before incidents occur. Establish a structured schedule for evaluating the roof’s condition and safety protocol adherence.

During inspections, identify signs of wear, pooling water, or loose materials that could pose risks. Regular evaluations help maintain both the roof’s integrity and the safety of personnel.

Involving trained safety inspectors can provide deeper insights during evaluations, revealing hidden dangers that may go unnoticed. Documenting findings and actions taken fosters continuous improvement and accountability.

Key Action Items

The Bottom Line

With workplace accidents from roof safety violations costing businesses over $1.5 billion annually, the stakes for proper compliance have never been higher.

Success in commercial roof safety hinges on three critical factors: comprehensive staff training, rigorous inspection protocols, and meticulous documentation of all safety measures.

Facilities that implement the strategies outlined in this guide consistently report up to 70% fewer safety incidents and realize significant cost savings through reduced insurance premiums and avoided penalties.

Moving forward, facility managers must prioritize proactive safety measures over reactive responses, as OSHA continues to strengthen enforcement and increase violation penalties.

The investment in proper roof safety protocols today prevents catastrophic costs tomorrow, both in human and financial terms.

FREQUENTLY ASKED QUESTIONS

Q. What are essential performance factors for a commercial roof?

A. Assessing structural integrity, roof condition, and load capacities is vital for safety. Regular inspections help identify potential vulnerabilities before they lead to costly failures.

Q. How can I budget for industrial roof maintenance?

A. Set aside 1-3% of the roof’s total value annually for maintenance. Regular inspections and proactive planning prevent expensive emergency repairs and extend the roof’s lifespan.

Q. What compliance requirements must I follow for commercial roofs?

A. Familiarize yourself with OSHA regulations and local building codes. Regular compliance audits will help ensure safety and avoid penalties related to noncompliance.

Q. How can I identify fall hazards on my commercial roof?

A. Conduct regular inspections for hazards such as unprotected edges and skylights. Documenting identified risks helps in planning safety measures and training workers on safe practices.

Q. Why is fall protection training important for staff?

A. Regular training ensures employees understand hazards and proper equipment usage. Knowledgeable workers are more likely to follow safety protocols, reducing the likelihood of accidents.

Q. What are safe access protocols for a commercial roof?

A. Implement clear protocols for using ladders and scaffolding. Regularly inspect access points and ensure they are safe for staff to minimize fall risks during roof maintenance.

Q. How can I improve energy efficiency with my commercial roof?

A. Invest in well-insulated roofing materials and consider reflective coatings. This can lower heating and cooling costs while extending the lifespan of the roof.