In an era where a single roof leak can spiral into $10,000+ in repairs, understanding commercial roof coating proposals isn’t just paperwork—it’s protection for your bottom line. Studies show that 35% of commercial roofs fail prematurely due to inadequate maintenance and poor coating choices.

From reflective coatings that slash cooling costs to elastomeric solutions that prevent water damage, today’s coating options offer powerful protection—when specified correctly.

This comprehensive guide cuts through the marketing hype to deliver actionable insights on proposal evaluation, material selection, and long-term performance optimization for commercial property stakeholders.

SECTION 1: THE BASICS EXPLAINED

Grasping the ins and outs of commercial roof coating proposals is essential for property owners and facility managers alike. Failing to invest in high-quality coatings could spell disaster, leading to roofs that crumble before their time and surprise expenses that could drain budgets. Studies have shown that a well-maintained roof can live up to 50% longer! In this section, we’ll break down the nitty-gritty of roof coatings, why they are vital for your building’s well-being, and how they accomplish their impressive feats.

What It Is (In Plain Language)

Think of a commercial roof coating as a magic elixir for your roof: it’s a liquid applied to the roof’s surface that creates a waterproof barrier. This product turns into a seamless membrane that protects against leaks, pesky UV rays, and the expansion and contraction that occurs with temperature swings. Coatings come in various flavors—acrylic, silicone, urethane—to suit different roof types just like choosing the right tool for a job.

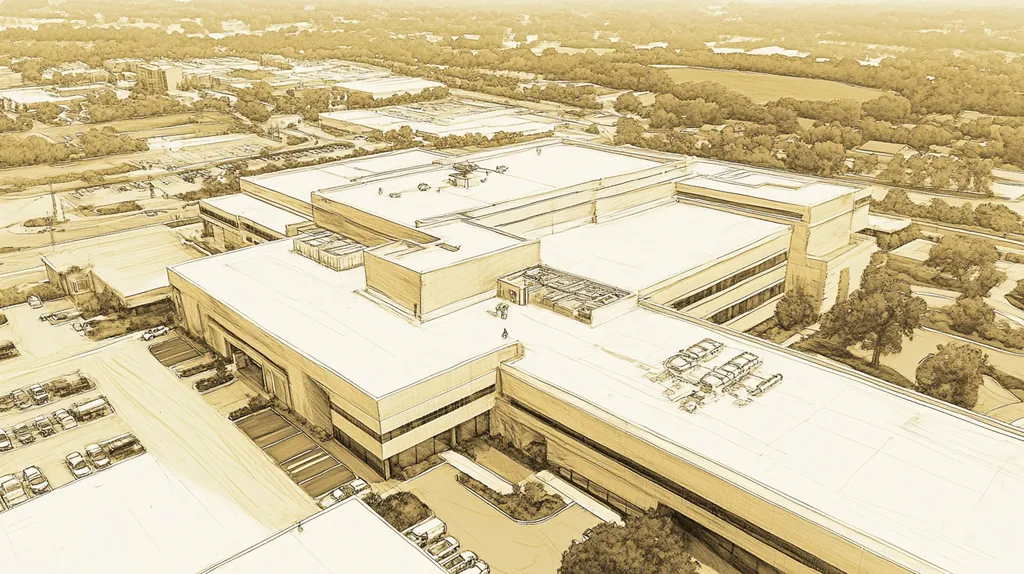

These coatings work best on flat or low-slope roofs, which are the bread and butter of commercial buildings. Instead of committing to a full roof replacement that could disrupt operations and drain your wallet, applying a coating is a less invasive and budget-friendly option. Plus, it not only ramps up the roof’s efficiency but also spruces up its appearance.

Roof coatings are designed to cling to existing roofing materials, making them an attractive choice for property owners wary of the maintenance battle. They often demand little surface prep while delivering substantial protective advantages.

In summary, commercial roof coatings are like insurance for your roof: they extend its lifespan and are a shrewd investment for preserving the integrity of your building.

Why It Matters (To Your Building)

The effectiveness of a commercial roof coating impacts the overall health of your building. A failing roof can usher in water intrusion, opening the floodgates to structural damage, mold infestations, and skyrocketing energy costs. Roof coatings act as a formidable barrier against these threats, keeping the elements at bay.

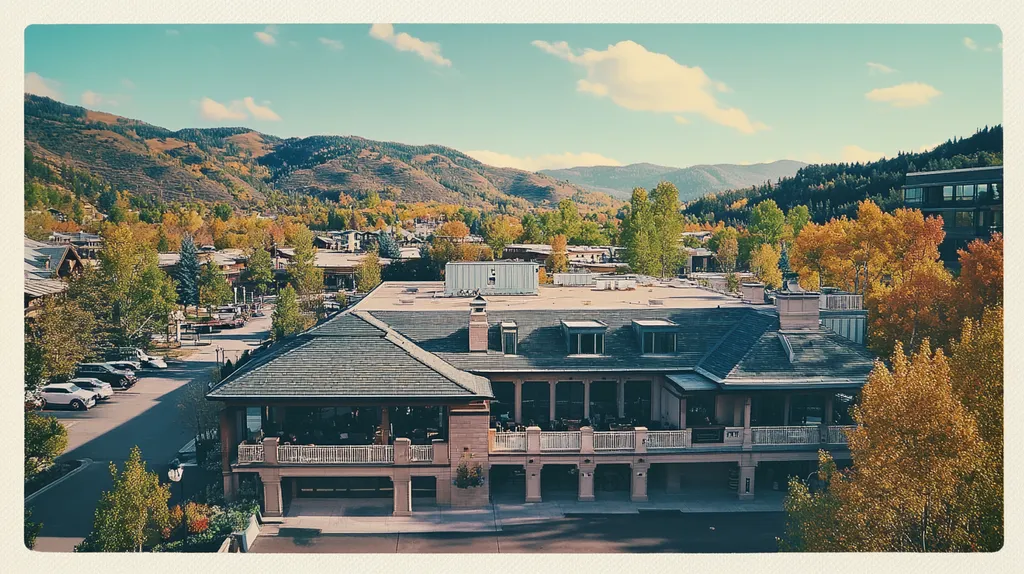

On top of that, these systems can turbocharge your building’s energy efficiency. Reflective coatings, for instance, can slash cooling costs by reducing heat absorption. Not only does this create a cozier indoor atmosphere, but it also aligns with environmental sustainability goals.

Ignoring roof maintenance can haunt property owners with long-term financial headaches. Water damage repairs can balloon quickly, and you might find yourself staring down a complete roof replacement sooner than anticipated. Shelling out for coatings can keep those risks in check while maximizing your existing roof’s lifespan.

Ultimately, effective roof coatings are about protecting assets and boosting operational efficiency. They play a crucial role in safeguarding property value and ensuring that buildings function as they should.

How It Works

Deciphering how commercial roof coatings do their thing can equip property owners to make savvy decisions. When applied, these coatings form a strong bond with the existing substrate, creating a unified surface designed to withstand external pressures. This bond is what transforms the roof into a waterproof fortress.

The application starts with a clean slate: the roof surface is cleared of debris and contaminants. Next, the coating gets evenly applied—whether by spraying, rolling, or brushing—based on the product and roof type. Once applied, the coating cures to forge a protective shell.

These coatings often come packed with protective additives that fend off UV radiation and resist degradation from harsh weather. This is paramount for maintaining not just the coating itself but the entire roofing system’s integrity.

At the end of the day, commercial roof coatings function as a preventative ally. They act as shields against wear and tear, promoting sustainability by prolonging roof life and minimizing extensive repairs or replacements.

SECTION 2: PRACTICAL APPLICATIONS

The importance of effective roof maintenance can’t be stressed enough. A staggering 35% of commercial roofing failures arise from neglect. For property owners, this grim statistic serves as a wake-up call. Investing in roof coatings is not just smart; it’s crucial for extending the lifespan of your roof and enhancing energy efficiency, ultimately saving substantial amounts on operational costs. In this section, we’ll explore the practical applications of roof coatings, from common uses to timing and integration with existing systems.

Common Uses & Examples

Roof coatings are versatile tools tailored to a range of roofing types and environmental conditions. For flat roofs, silicone or acrylic coatings shine by reflecting sunlight, cooling down the surface and slashing energy bills. Metal roofs, too, can benefit, as specialized coatings prevent rust and prolong their lifespan.

A standout application is the restoration of aging roofs. Instead of shelling out for an entire replacement, savvy property owners can rejuvenate their roof with a high-quality coating, an economical and efficient solution. Take, for example, elastomeric coatings. They’re known for creating seamless barriers that effectively thwart leaks.

Moreover, roof coatings act as proactive protectors. Regular application forms a resilient layer that shields the substrate from harsh weather. This forward-thinking strategy not only preserves the roof’s health but maximizes durability, reducing the need for extensive repairs.

When You Need It Most

Timing is everything when it comes to roof coatings. Property owners should watch for signs after severe weather events, like heavy rains or hail, which can jeopardize roof integrity. A prompt application of protective coatings in these instances can prevent extensive damage and significantly prolong the roof’s lifespan.

New construction projects also offer an optimal window for coating applications. Sprucing up new roofs right after installation adds an immediate layer of protection and enhances energy efficiency. In a world where heating and cooling costs can cripple budgets, this early intervention pays dividends.

Routine inspections are another pivotal moment. Spotting the early signs of wear and applying a coating at this stage can save property owners from facing larger, costlier issues later. This proactive approach helps protect investments while ensuring the building continues to function seamlessly.

Interactions With Other Systems

Roof coatings don’t exist in a vacuum; they can significantly interact with other building systems. Before applying a coating, it’s crucial to consider the existing insulation systems, as using incompatible materials can lead to performance failures. A little miscalculation here can dramatically impact roof durability and energy efficiency.

Drainage systems, too, play a vital role in roof performance. Outdated or poorly designed drainage can cause water pooling, undermining the effectiveness of the coating. Ensuring optimal drainage before applying a coating will amplify the roof’s performance.

Lastly, the choice of coating may also depend on the HVAC systems installed on the rooftop. Reflective coatings can help manage rooftop temperatures, benefitting equipment below. However, considerations like access points for maintenance crews must not be overlooked when planning applications—thoroughness here pays off.

SECTION 3: KEY TERMINOLOGY DECODED

In the complex world of commercial roofing, understanding key terminology isn’t just helpful—it’s essential. Misunderstanding roofing jargon can lead to costly blunders, whether it’s miscalculating your budget or misjudging the longevity of your roof. Take, for instance, the distinction between “restoration” and “replacement.” Choosing the wrong option can ripple through timelines and ultimately impact long-term performance. This section breaks down the crucial vocabulary and measurement units that empower property owners and facility managers to make informed decisions.

Essential Terms Explained

When delving into commercial roof coatings, certain terms pop up frequently. For starters, “elastomeric” refers to flexible, rubber-like coatings that stretch and compress with temperature changes. This adaptiveness is vital for preventing cracks and prolonging the roof’s lifespan.

Another term to familiarize yourself with is “reflectivity,” which gauges how much sunlight a roofing system can bounce away. Higher reflectivity ratings not only save on energy costs but also contribute to a more comfortable indoor environment.

Don’t overlook “adhesion,” essential for coating longevity. This term describes how well a coating sticks to the existing rooftop surface. Strong adhesion ensures lasting performance and reduces the headache of frequent maintenance.

Getting comfortable with these key terms helps property owners negotiate and assess proposals, ensuring they choose the best options for their roofs.

Industry Jargon Translated

Roofing lingo can be daunting, so let’s decode a few favorites. The term “substrate” designates the underlying layer of a roofing system. Understanding your substrate is key to selecting compatible roofing products. Mismatching can spell trouble!

“Thermoplastic” and “thermoset” are also important terms describing roofing membranes. Thermoplastic membranes can be re-shaped when heated—think of them as the playdough of roofing. In contrast, thermoset membranes undergo a chemical change, forming a rigid structure that’s generally more durable. Each type has strengths and weaknesses that should align with specific building needs.

Lastly, “spalling” indicates when the surface layer of a substrate begins to fracture. Spotting this early protects against far more significant issues down the line, emphasizing why decoding jargon is crucial for smart maintenance decisions.

Translating this terminology into everyday language paves the way for clearer communication between property managers and roofing professionals, fostering informed choices.

Measurement & Units Simplified

Measurements play a critical role in roofing projects, so knowing the standard units is essential. A key measurement is the “square,” equivalent to 100 square feet. This unit simplifies estimating the materials needed for a job.

Another critical unit is “mils,” which measures coating thickness. One mil is one-thousandth of an inch. The thickness of your coating can significantly impact its durability and effectiveness, making it vital to specify this accurately in your proposals.

Then there’s “RTU,” or “Ready to Use,” referring to products that are pre-measured and ready for application. This means no guesswork, taking the hassle out of some of the more tedious aspects of roofing work.

Grasping these measurements streamlines the decision-making process, helping facility managers quickly analyze proposals to ensure they positively impact the roof’s longevity and performance.

SECTION 4: DECISION FACTORS

When it comes to commercial roof coating proposals, making savvy choices can mean the difference between a smooth operation and a financial sinkhole. With ever-increasing material costs and unpredictable weather wreaking havoc, it’s vital to grasp the nuances of cost, performance, and lifespan. Each decision can reshape long-term roofing health, thus paving the way for more informed and strategic investments. This section breaks down these pivotal factors.

Cost Considerations

Cost stands as a primary concern for property owners and facility managers. The initial investment in roof coatings can vary based on material choices, installation complexity, and warranty features. However, focusing solely on the upfront cost might obscure long-term savings on maintenance and energy efficiency.

For example, investing in a high-quality reflective roof coating may come with a hefty price tag initially, but it can slice cooling costs in the long run, especially in warmer climates. These coatings help lower energy expenses by reflecting sunlight away from buildings. Furthermore, a durable coating often translates to reduced maintenance costs, as they resist environmental wear.

In essence, property owners should consider the total cost of ownership. A cheaper coating could lure you in but may lead to frequent repairs, negating any initial savings. Evaluating the full financial landscape is crucial for making an investment that truly benefits the bottom line.

Performance Trade-offs

Choosing a roof coating isn’t just a straightforward decision; it involves performance trade-offs that can significantly influence effectiveness. Each coating type serves specific conditions and purposes, coming with its own unique strengths and weaknesses. For instance, some coatings excel in waterproofing, while others focus on UV protection or reflective properties.

When selecting a coating, consider factors like local weather conditions and specific building functions. A coating that shines in UV protection may effectively minimize thermal expansion, a major culprit behind roof damage during temperature extremes. Balancing these different performance attributes with costs helps property owners make astute decisions.

Although high-performance coatings might dent the budget initially, their resilience against harsh conditions often pays off by prolonging roof lifespan. This results in fewer repairs and longer intervals between recoating, all while enhancing overall efficiency.

Lifespan & Durability Factors

Lifespan and durability are non-negotiable when it comes to selecting a roof coating for any commercial property. Coatings that last longer provide substantial protection and can lead to significant cost savings over time. Yet, all coatings are not created equal when it comes to longevity.

Premium-grade coatings often come with warranties ranging from 15 to 20 years, while lower-quality options may start deteriorating within just a few years, leading to premature failures. Understanding and evaluating the expected lifespan is crucial for effective budget planning and maintenance scheduling.

Durability also hinges on resistance to foot traffic, extreme weather conditions, and chemical exposure. High-performance coatings stand strong against the elements, helping to prevent premature damage. Recognizing these durability factors empowers property owners to select the right products for their roofs.

With the right coating choice, property owners can not only extend the life of their roofs but also bolster overall building integrity, making this decision a cornerstone of effective property management.

SECTION 5: COMMON CHALLENGES

Commercial roof coatings are a powerful solution for extending a roof’s lifespan and boosting energy efficiency. However, property owners and facility managers often encounter challenges that can undermine these benefits. Issues like inadequate surface preparation, improper application techniques, and environmental factors can significantly impact performance. Understanding these challenges is crucial for making informed decisions and optimizing roof coating proposals.

Frequent Problems & Solutions

A leading culprit in roof coating failures is inadequate surface preparation. Without a clean surface, coatings can bubble and peel, losing effectiveness faster than you can say “leak.” It’s critical to ensure the roof is thoroughly cleaned to promote proper adhesion between the coating and the substrate.

Property owners should invest time in cleaning and inspecting the roof before diving into coating applications. Using a pressure washer or heavy-duty cleaners can clear away dirt, grime, and any residual coatings. Inspections should also reveal underlying issues, like blisters or structural damage, which need to be remedied before proceeding.

Weather is another player in the roof coating game. Applying coatings during rain, high humidity, or excessive heat can derail the curing process. If the coating doesn’t dry correctly, it may lead to poor performance and necessitate costly reapplications.

To dodge these pitfalls, keep a close eye on the weather. Schedule installations during mild, dry conditions to ensure the coating cures properly and performs effectively.

Lastly, improper application techniques can result in uneven coverage. This not only detracts from the roof’s appearance but also leaves it vulnerable to the elements.

Working with professional applicators experienced in roof coatings ensures proper application thickness and uniform coverage across the surface, enhancing performance and aesthetics.

Warning Signs To Watch For

Identifying warning signs early can save property managers from larger headaches down the road. The first red flag is visible peeling or bubbling of the coating. If spotted, it’s essential to conduct an inspection immediately—addressing these issues quickly can prevent significant, costly repairs.

Discoloration or fading is another sign that the coating may be losing its reflective properties. This not only impacts aesthetics but can also contribute to higher energy costs as it fails to keep heat at bay.

Regular inspections can help catch these issues before they escalate. Establishing a maintenance schedule ensures that problems are identified early, allowing the roof to maintain its protective capabilities.

It’s also wise to keep an eye on surrounding features like flashings, seams, and drainage systems. Wear and tear in these areas can hint at an underperforming coating, signaling that attention is needed.

By staying vigilant and addressing issues promptly, property managers can significantly extend the life of their roofing systems.

Preventative Approaches

Preventative maintenance is an essential strategy that can save both time and money. Regular inspections should focus on identifying vulnerabilities like cracks or thinning coatings. Scheduling professional assessments will reveal problems that may not be visible to the untrained eye, ensuring a proactive approach.

Establishing a cleaning routine is another key preventative measure. Debris buildup can lead to trapped moisture and ultimately degrade the coating. A clean roof is a happy roof!

Property owners should develop a comprehensive maintenance checklist that includes visual inspections and cleaning schedules. This proactive strategy helps extend the life of roof coatings while maintaining energy efficiency.

Also, choosing high-quality materials makes a significant difference in roof performance. Premium coatings often come with robust warranties, which can lessen maintenance needs and encourage longevity.

Implementing a complete roof maintenance plan that encompasses cleaning, inspections, and timely repairs can be a game-changer. By prioritizing preventative strategies, property managers can maximize their investment in roofing systems.

SECTION 6: NEXT STEPS & RESOURCES

The stakes couldn’t be higher when selecting a roofing solution for commercial properties. With a small leak costing over $10,000 in repairs if left unattended, property owners and facility managers must act strategically to protect their investments. Understanding the right questions to pose to providers is essential for making informed choices and ensuring optimal performance from coating solutions.

Questions To Ask Providers

Asking the right questions to roofing providers can lead to significant advantages. Start by probing into their experience specifically with roof coatings applicable to your building type. Understanding their past projects will illuminate their expertise and offer peace of mind.

Don’t shy away from discussing warranties and guarantees. A reputable provider should offer robust warranties that secure both materials and workmanship, shielding you from unexpected out-of-pocket expenses down the line.

Dig into the application process and tools they use. Adhering to industry best practices is crucial for the long-term success of your roof coating. Request references or case studies from past clients to gauge reliability.

Finally, don’t forget to ask about maintenance requirements post-application. Knowing how to care for your newly coated roof will be invaluable in extending its lifespan.

Industry Standards & Guidelines

Being familiar with industry standards is essential for making sound roofing decisions. The American Society for Testing and Materials (ASTM) sets forth guidelines to ensure quality and performance in roof coatings. Adhering to these benchmarks safeguards property owners against inferior materials and shoddy workmanship.

The Cool Roof Rating Council (CRRC) provides tests for measuring the reflectivity and emissivity of roofing products. Opting for coatings that comply with CRRC guidelines can significantly enhance energy efficiency, leading to lower cooling costs.

Additionally, facilities managers should align with the National Roofing Contractors Association (NRCA) guidelines, which offer access to best practice manuals that assist in making astute coating selections.

Lastly, staying compliant with local building codes and regulations is paramount. This diligence can prevent delays and legal hurdles during the coating process, securing your investment.

Further Learning Simplified

Continuously expanding roofing knowledge is a winning strategy for property owners and facility managers. A wealth of online resources is available, offering easy access to crucial information about roof coatings and maintenance. Roofing associations and government agencies often host educational materials that simplify complex topics.

Engaging in webinars and workshops provides deeper insights into industry trends and innovations. These events frequently feature expert speakers sharing case studies and practical advice aimed at maximizing roof performance.

Subscribing to industry publications is another way to stay informed. Keeping up with the latest articles and research can enhance understanding of new technologies and strategies that fortify roofing choices.

Lastly, building a network with other industry professionals promotes knowledge-sharing. Conversations with peers can spark discussions that illuminate best practices and emerging solutions.

The Bottom Line

With commercial roof failures costing businesses over $5 billion annually, the stakes for proper coating selection and application couldn’t be higher.

Today’s market offers an overwhelming array of coating solutions, each promising to be the ultimate fix for your roofing challenges.

Yet the data is clear: successful roof coating projects hinge not on flashy marketing promises, but on thorough proposal evaluation, proper material selection, and meticulous installation oversight.

By focusing on proven performance metrics, warranty terms, and application standards while steering clear of unproven “breakthrough” technologies, property owners can secure lasting protection for their roofing investments.

The future of commercial roofing lies not in gimmicks, but in time-tested solutions properly specified and expertly applied.

FREQUENTLY ASKED QUESTIONS

Q. What is a commercial roof coating?

A. A commercial roof coating is a liquid layer applied to the roof’s surface to create a waterproof barrier. It transforms into a seamless membrane that protects against leaks and UV rays while extending your roof’s lifespan and improving energy efficiency.

Q. How can a commercial roof coating save money?

A. Investing in roof coatings may reduce energy costs significantly as they reflect sunlight, keeping your building cooler. They also minimize maintenance needs and the risk of costly replacements, creating savings that add up over time.

Q. What does reflectivity mean in industrial roofs?

A. Reflectivity measures how much sunlight a roofing surface can reflect away. Higher reflectivity ratings lead to cooler buildings, reduced energy costs, and a more comfortable indoor environment, especially in warm climates.

Q. When should I coat my commercial roof?

A. Coat your roof after significant weather events or during inspections when early signs of wear are noticed. New roofs also benefit from coatings applied right after installation to enhance protection and energy efficiency from the get-go.

Q. What are common pitfalls in applying coatings?

A. Common pitfalls include inadequate surface preparation, poor application techniques, and inappropriate weather conditions during the application process. Each of these can negatively impact the coating’s performance and lead to costly failures down the line.

Q. How can I ensure a quality roof coating application?

A. To ensure quality, ask providers about their experience with roof coatings and inspect their past work. Also, inquire about warranties and necessary maintenance practices after application to maintain performance and protect your investment.

Q. What resources can help me learn more about roof coatings?

A. Various online resources are available, including roofing association websites and educational webinars. Industry publications also provide valuable insights into trends, technologies, and best practices to help you make informed decisions.