The commercial roofing industry faces a critical turning point as traditional coating practices fail to meet modern building demands. Industry data reveals that 40% of commercial roof coatings fall short of their promised lifespan, resulting in billions in unnecessary repairs annually.

While coating manufacturers continue promoting incremental improvements to existing formulas, transformative innovations in smart materials, predictive maintenance, and sustainability remain largely unexplored.

This analysis challenges conventional wisdom around commercial roof coatings, examining why current strategies impede true advancement and exploring evidence-based alternatives that could revolutionize building protection.

SECTION 1: CURRENT PRACTICES

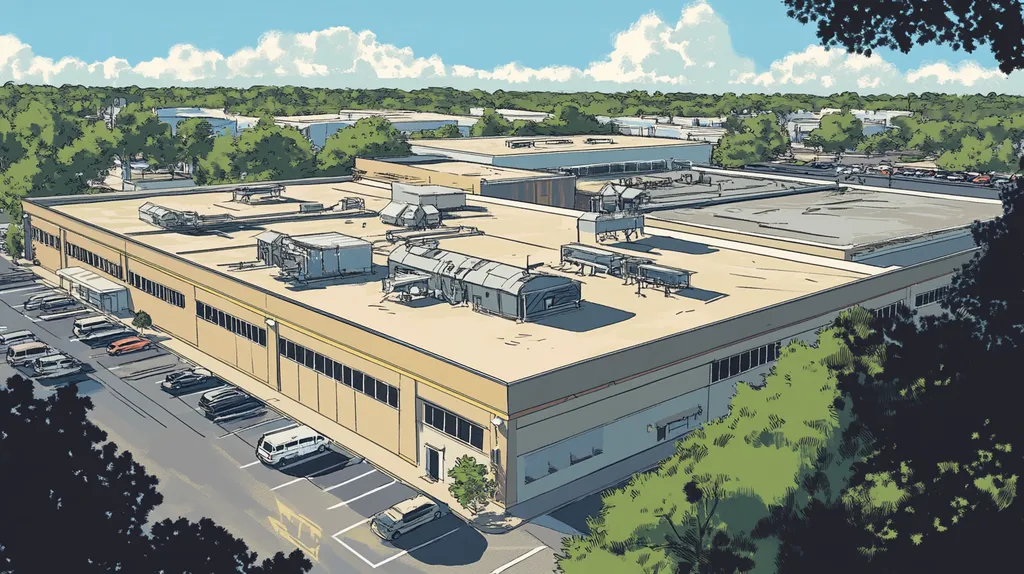

The importance of maintaining commercial roofs can’t be overstated. Neglecting roofing needs can lead to dire financial consequences, including inflated energy expenses and emergency repair bills. Remarkably, nearly 30% of commercial property owners have experienced roof failures that could have easily been avoided through careful initial planning and selection of quality materials. This section delves into prevalent types of commercial roof coatings, effective application methods, and the industry standards that inform these essential practices.

Common Types of Commercial Roof Coatings

A range of roof coatings is available, catering to various commercial needs. Acrylic, silicone, and polyurea coatings stand out as the most popular choices, each offering unique attributes that significantly enhance a facility’s performance and longevity.

Acrylic coatings are favored for their resistance to UV rays and flexibility, which together work to lower energy expenses by reflecting sunlight and keeping building temperatures down. Conversely, silicone coatings excel in environments exposed to heavy rainfall, offering exceptional water resistance to help prevent leaks.

For industrial applications, polyurea coatings are an outstanding option due to their rapid curing times and unmatched durability. These coatings can resist extreme temperatures and heavy foot traffic, ensuring long-lasting protection for demanding environments. Choosing the right coating is vital for maximizing both lifespan and efficiency.

By understanding these options, property owners can make better-informed decisions that align with their specific environmental challenges and budgetary constraints.

Application Methods and Materials

The successful application of roof coatings hinges on precision and meticulous attention to detail, which are crucial for achieving lasting outcomes. Roof coatings are typically applied using rollers, sprayers, or brushes, with the selected method depending on the complexity of the roof design.

Before application, thorough surface preparation is essential. Roof surfaces must be cleaned and primed to eliminate debris and contaminants, as anything less can lead to adhesion failures, resulting in peeling and ineffective performance. Moreover, conditions such as temperature and humidity during the application process can significantly influence curing times and the overall integrity of the coating.

Many industry professionals advocate for applying several thin layers of coating rather than one thick coat. This strategy allows for improved adhesion and mitigates the risks of sagging or pooling, which can compromise the roof’s functionality.

Utilizing high-quality materials, including advanced waterproofing agents and UV inhibitors, further amplifies the effectiveness of roof coatings. Adhering to best practices in methodology is crucial for producing a resilient final product that meets performance expectations.

Industry Standards and Regulations

Compliance with industry standards and regulations is fundamental to the commercial roofing sector. Organizations like the American Society for Testing and Materials (ASTM) and the National Roofing Contractors Association (NRCA) establish guidelines that govern roof coating performance.

Meeting these standards guarantees that coatings provide essential attributes such as UV resistance, water resistance, and tensile strength, all key factors contributing to a roof’s durability and overall effectiveness.

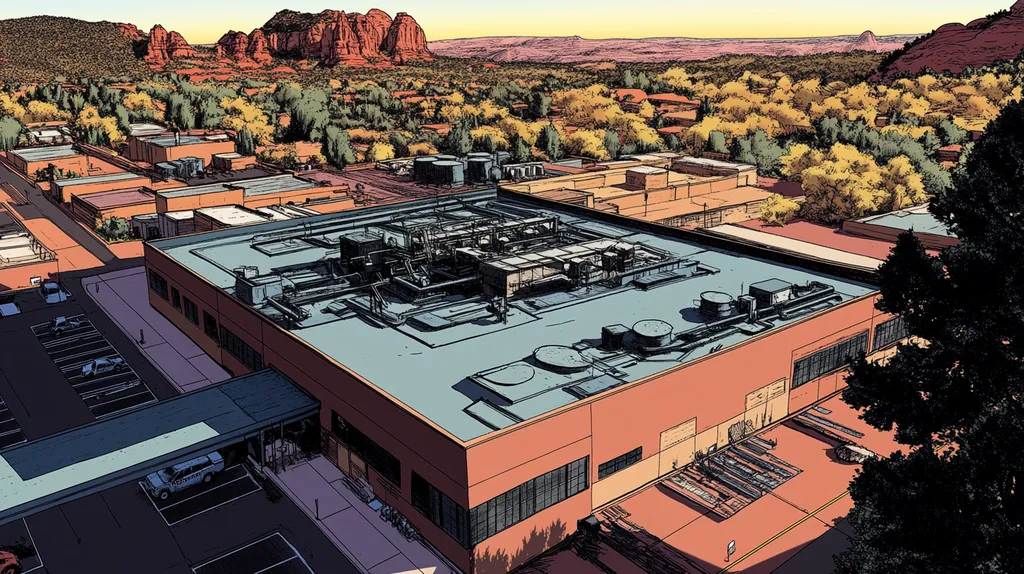

Regulatory requirements can vary notably based on geographic location. For example, coatings in areas subject to extreme weather conditions may need to adhere to more stringent specifications. This complexity can leave property owners confused about selecting compliant and effective solutions.

Engaging a qualified roofing contractor familiar with local regulations is crucial. Their expertise will help navigate these standards, ensuring that coating applications not only meet legal requirements but also enhance performance and longevity of the roofing system.

SECTION 2: SYSTEMIC ISSUES

The challenges facing the commercial roofing industry are urgent and significant, as they hinder the overall effectiveness of roof coatings. Despite recent advancements, many waterproofing solutions still underperform, leading to leaks and expensive repairs. Alarmingly, over 60% of facility managers report dealing with roof-related problems within the first five years of installation. This pressing issue underscores the necessity of addressing critical flaws in coating technology. Key topics such as inadequate waterproofing, environmental and health concerns, and misconceptions regarding cost-effectiveness must be tackled head-on.

Limitations in Waterproofing and Durability

A central issue for today’s roof coatings is their inconsistent performance in waterproofing. Many products touted as ‘high-performance’ still permit moisture to infiltrate, resulting in damaging leaks. Such failures jeopardize structural integrity and can instigate secondary problems like mold growth and insulation degradation.

Additionally, certain coatings fail to stand up to extreme weather conditions, which can cause premature deterioration. In areas prone to heavy rain or hail, standard coatings may wear out far sooner than anticipated, putting sensitive operations at risk.

Facility managers frequently find themselves embroiled in warranty disputes as manufacturers often cite improper application or environmental conditions for failures. This disconnect highlights the urgent need for more rigorous standards in durability testing and performance data. Without these improvements, businesses face ongoing financial liabilities associated with unsupported warranties.

To resolve these challenges, innovation must focus on creating coatings that offer superior waterproofing and durability. By integrating advanced materials, engineers can develop coatings that endure countless environmental stresses, thus providing lasting protection for commercial roofs.

Environmental and Health Concerns

The environmental footprint of certain roofing coatings is another critical issue that requires attention. Many conventional coatings contain harmful chemicals that release volatile organic compounds (VOCs), contributing to air pollution and posing health risks. As regulations tighten and public consciousness about environmental issues rises, the demand for eco-friendly options becomes increasingly vital.

Moreover, the need for protective gear during application not only escalates labor costs but also complicates project timelines. For example, the heightened use of personal protective equipment (PPE) is necessitated by the hazards associated with these materials, placing an extra burden on contractors.

Additionally, discarded coating materials can cause landfill waste, undermining sustainability initiatives in the industry. By selecting more environmentally responsible products, facilities not only enhance their operational integrity but also position themselves as champions of sustainability.

To overcome these hurdles, manufacturers must prioritize the development of sustainable roofing products. This can be achieved through collaboration across stakeholders to drive innovation towards coatings that effectively balance performance and eco-friendliness.

Cost-Effectiveness and ROI Misconceptions

Misunderstandings regarding cost-effectiveness and return on investment (ROI) proliferate within the commercial roofing sector. Many property owners mistakenly associate low initial costs with overall value, often overlooking long-term implications. Cheaper coatings frequently come with hidden expenses arising from ongoing repairs and premature replacements.

Conversely, while investing in high-quality coatings may initially seem intimidating, the long-term financial benefits are significant. Facilities that choose more durable roofing options often encounter fewer warranty claims and extended lifespans. This shift illustrates the need for a new perspective on profitability within the industry.

Unfortunately, the emphasis on short-term savings causes many facilities to ignore potential lifelong costs associated with inferior products. For instance, a low-quality coating might fail prematurely, necessitating a complete reapplication within just a few years.

To redefine how ROI is measured in the industry, a broader understanding of lifecycle costs is essential. By making this shift, property owners and facility managers can make informed choices that protect their investments while enhancing overall operational efficiency.

SECTION 3: MISSED OPPORTUNITIES

In the fiercely competitive arena of commercial roofing, failing to adopt new technologies can prove costly. A revealing report from the National Roofing Contractors Association shows that buildings with outdated roofing systems incur as much as 20% higher energy costs. This section illuminates three crucial areas where stakeholders often overlook transformative advancements: materials and technologies, energy efficiency, and innovative maintenance tools. Recognizing these gaps is vital for property owners and facility managers aiming to enhance the life and performance of their roofing investments.

Overlooking Advanced Materials and Technologies

A significant number of property owners persist in using traditional roofing methods, missing out on groundbreaking developments in material science. Modern innovations such as single-ply membranes and advanced polymer coatings provide vastly improved durability and performance compared to older options. These enhanced solutions can greatly reduce the frequency and costs of repairs, offering compelling long-term savings.

Moreover, the advent of energy-efficient coatings that reflect ultraviolet light substantially lowers heat absorption. This can lead to cooler indoor environments and a potential reduction in air conditioning costs by up to 30%. Yet, many building managers continue to favor conventional coatings that fall short in these vital areas.

This lack of awareness around modern materials results in missed chances to optimize property performance. Investing in state-of-the-art coatings not only prolongs roof lifespan but also increases property value. Failure to adapt could mean skyrocketing operational costs and diminished asset longevity.

In an era of rapid advancement, staying updated on the latest innovations is more important than ever. This awareness empowers property owners to make informed decisions that support both their financial and operational objectives.

Neglecting Energy Efficiency and Sustainability

The commercial roofing sector is confronted with urgent challenges surrounding energy efficiency and sustainability. A staggering report from the U.S. Green Building Council reveals that buildings contribute to nearly 40% of the nation’s total energy consumption. By selecting coatings with high energy efficiency ratings, property owners can significantly lessen this impact.

Property owners frequently underestimate the benefits of cool roofing technologies, which simultaneously promote sustainability and improve indoor comfort. Implementing these solutions not only cuts down on energy costs but also aligns with national environmental goals.

Additionally, many local governments incentivize the adoption of green technologies through tax credits and rebates. By overlooking these beneficial roofing options, building owners risk missing valuable opportunities for savings, ultimately leading to higher operational costs in the long run.

Ignoring these pivotal trends can result in increased scrutiny from regulators and the public. Committing to energy-efficient roofing is not merely a responsible choice; it also delivers significant financial advantages.

Ignoring Innovative Inspection and Maintenance Tools

Effective roof maintenance hinges on proactive inspection strategies, yet many property owners cling to outdated practices. Technologies such as drones and thermal imaging have revolutionized how roof inspections are conducted, allowing for rapid, accurate evaluations of roof conditions.

By embracing these advanced tools, facility managers can pinpoint problems before they escalate into costly repairs. Traditional inspection methods often miss underlying issues, leading to emergency situations that could have easily been prevented.

Furthermore, the availability of real-time monitoring systems offers immediate insights into roof performance. This capability enables building owners to respond swiftly to any emerging issues, thus safeguarding their investment.

Neglecting to incorporate these modern inspection approaches places properties at risk for premature roof failure, resulting in financial losses and operational interruptions. Embracing innovative maintenance practices not only fosters longevity but also ensures optimal performance for commercial roofing systems.

SECTION 4: ROOT CAUSES

The commercial roofing industry is at a crossroads, facing challenges that inhibit the adoption of innovative roof coatings. A staggering 40% of roof failures can be traced back to improper installation and maintenance. This shortfall leads not only to expensive repairs but also threatens the longevity of the roofing systems themselves. Addressing critical issues such as inadequate inspections, insufficient contractor qualifications, and a lack of training in emerging technologies is vital for fostering much-needed innovation in this field.

Lack of Proper Roof Inspection and Preparation

Inadequate roof inspection practices represent a significant barrier to effective roof coating applications. Too often, property owners neglect regular assessments that can uncover hidden issues like leaks, moisture buildup, or structural weaknesses. Skipping these thorough inspections means critical preparation steps may be overlooked.

For coatings to adhere correctly, the roof surface must be clean and dry. When preparation is inadequate, the lifespan of the coatings can be drastically shortened. This oversight leads not only to frequent and costly repairs but also endangers the roofing substrate itself.

Additionally, any improper application resulting from a lack of preparation can void manufacturer warranties. This situation amplifies the financial risks for property owners should problems arise down the line.

It is crucial for industry stakeholders to understand the importance of regular, comprehensive roof evaluations to enable the successful application of innovative coatings.

Inadequate Contractor Licensing and Certifications

The state of contractor licensing and certifications poses another serious obstacle. A significant number of roofing contractors lack the credentials necessary to apply advanced coating systems correctly. This gap paves the way for substandard workmanship and puts roofs at considerable risk of failure.

Many modern coatings require specialized knowledge in advanced application techniques or familiarity with current building codes—skills that not every contractor possesses. Incorrect applications can result in coatings that peel, blister, or deteriorate far sooner than expected.

Moreover, some contractors fail to keep pace with emerging advancements in roofing technology. This knowledge gap can deprive property owners of optimal solutions and leave them with dated or ineffective roofing systems.

To fully capitalize on the benefits of innovative coatings, property owners should prioritize hiring contractors who are properly trained and licensed in the latest roofing technologies.

Insufficient Training on New Technologies

Ongoing training is essential for the successful integration of innovative roofing systems. Unfortunately, many contractors lack access to educational resources that cover new coating materials and application techniques. This lack of ongoing education can lead to improper application and underperformance of these coatings.

The introduction of reflective and energy-efficient coatings necessitates specific skills for ideal performance. If contractors do not understand the properties and advantages of these materials, property owners may miss out on critical energy savings and sustainability advantages.

It is imperative for property owners to actively advocate for and support training initiatives within the industry. Such endeavors will ensure that contractors are equipped to implement the latest advancements effectively.

Filling the gaps in contractor training and education is vital for unlocking the full potential of innovative roof coatings.

DATA DRIVEN EVIDENCE

In the commercial roofing industry, the stakes are incredibly high. Recent data reveals that a shocking 25% of roofs coated with traditional materials fail within just five years. Facility managers are grappling with skyrocketing energy costs, prompting a critical reevaluation of roofing choices. This section uncovers repair statistics, examines energy consumption trends, and presents real-world case studies to underscore the urgent need for redefining conventional approaches to roof coatings.

Statistical Failures and Repair Rates

Statistics show that nearly one in four commercial roofs treated with conventional coatings fails within five years. These failures are often attributed to inadequate surface preparation and poor adhesion, leading to costly repairs. The financial burden of re-coating or replacing roofs not only disrupts business operations but also drains budgets significantly.

Moreover, many property owners underestimate the crucial role of routine maintenance. Regular inspections can catch early signs of wear and deterioration, potentially extending the life of the roof. Implementing a system that prioritizes predictive maintenance can significantly reduce these issues and advocate for an updated approach to roof coatings.

Regions facing extreme weather report even greater failure rates. In these areas, coated roofs can wear down much faster, with some experiencing repair rates climbing up to 40%. Such alarming data clearly indicates that existing coating technologies often fall short of meeting the rigorous demands of these environments.

The financial implications of these high failure rates highlight the pressing need for innovative alternatives that enhance durability and overall performance. The costs associated with frequent repairs can consume substantial portions of a commercial budget, making it essential to reassess roofing strategies.

Energy Consumption and Cost Analysis

Energy efficiency has become a focal point in evaluating commercial roofs, particularly regarding their impact on operational costs. Traditional coatings typically fail to reflect solar energy, causing heat retention and driving up heating and cooling expenses. Facilities that incorporate reflective coatings have reported up to 30% reductions in energy consumption during peak seasons.

In contrast, buildings employing standard coatings are often faced with soaring utility bills due to poor thermal management. The financial analysis indicates an average annual savings of $1,200 for facilities that invest in modern reflective roof coatings. For larger commercial properties, these savings can accumulate to significant amounts over time.

Beyond immediate cost savings, energy-efficient roof coatings contribute positively to a building’s sustainability goals. For property owners seeking green certifications, leveraging these coatings not only helps with cost reduction but enhances marketability. Energy-efficient roofs have transitioned from being merely advantageous to becoming essential for forward-thinking facility managers.

While traditional coatings may seem more budget-friendly at first glance, ignoring the long-term costs related to energy consumption and environmental implications can be detrimental. A thorough energy analysis reinforces the necessity of investing in superior roofing solutions, highlighting the urgent need for reform in coating choices.

Case Studies on Coating Performance

Several compelling case studies illustrate both the shortcomings and successes of various commercial roof coatings. One notable example focused on a large distribution center that utilized traditional coatings, resulting in a disappointing 30% failure rate within just five years. This case serves as a critical reminder of the importance of choosing innovative roofing solutions to avoid similar failures.

On the other hand, a shopping mall that upgraded to a cutting-edge thermoplastic coating experienced remarkable results, reporting zero maintenance issues and impressive energy savings. This transition effectively extended the roof’s lifecycle while providing ongoing cost benefits, showcasing the potential of modern coatings.

Another case involving a municipal building highlighted the implementation of a green roofing system with high-performance coatings, yielding a 40% reduction in wastewater runoff. This change improved not only sustainability but also achieved long-term cost savings by decreasing water management fees.

These examples underline the crucial role of selecting effective and innovative coatings that meet specific operational and environmental demands. They emphasize the need for a shift in mindset within the industry, urging property owners to embrace advancements that can reshape long-term roofing strategies.

SECTION 6: ALTERNATIVE SOLUTIONS

As the pressures on commercial roofing systems intensify, the urgency for innovative solutions cannot be overlooked. Escalating energy costs and unpredictable weather patterns are compelling property owners and facility managers to seek more resilient roofing options. The longevity and effectiveness of roofing materials are critical for maximizing cost-efficiency. By exploring alternative solutions, stakeholders can implement advanced systems that bolster operational efficiency and sustainability.

Integrating Smart Roofing Systems and IoT

Smart roofing systems capitalize on the Internet of Things (IoT) to continuously monitor roof conditions. Sensors can identify leaks, track temperature changes, and assess structural integrity, providing invaluable data for maintenance. This proactive strategy mitigates unexpected repair costs and enhances safety by addressing potential issues before they escalate.

For instance, buildings equipped with smart sensors can optimize energy consumption based on real-time weather data. This capability not only extends the durability of roofs but also translates into substantial energy savings. Although the initial investment in IoT technology may seem high, the long-term savings through improved building performance can be significant.

Additionally, integrating these systems creates seamless communication among maintenance teams. The real-time information enables quicker response times, minimizing risks of damage that often lead to costly repairs. As more facilities adopt these advanced technologies, the industry will gradually shift toward more sustainable practices.

Ultimately, the implementation of smart roofing systems heralds a more efficient future. Buildings utilizing these cutting-edge technologies will not only streamline management practices but also increase asset value.

Utilizing Self-Healing and Reflective Coatings

Self-healing coatings offer a revolutionary approach to roof maintenance by automatically repairing minor punctures and tears, significantly extending the durability of roofing materials. This innovation reduces the frequency of repairs, leading to lower maintenance costs for property owners.

Reflective coatings play a vital role in enhancing energy efficiency. By reflecting sunlight, these coatings help to lower indoor temperatures, ultimately reducing cooling costs. This feature is especially beneficial in warmer climates where energy consumption surges during the summer months.

Consider a commercial building that switches to reflective coatings; this change can lead to energy bill reductions of up to 30%. When combined with self-healing technology, these coatings provide a dual advantage: fewer repairs and lower energy expenses.

As knowledge of these innovations expands, a growing number of property owners are exploring solutions that improve both performance and sustainability. Investing in self-healing and reflective coatings can yield significant long-term operational savings, positioning facilities for future success.

Adopting AI for Predictive Maintenance and Design

Artificial Intelligence (AI) is revolutionizing predictive maintenance in commercial roofing by analyzing historical data and current conditions to forecast when maintenance is necessary. This approach minimizes disruptions while allowing for timely interventions to prevent problems before they arise.

For example, AI algorithms can assess various factors—such as weather patterns, material aging, and past repair records—to estimate the lifespan of roofing systems accurately. This predictive capability empowers facilities managers to budget more effectively and implement maintenance strategies that are both cost-efficient and impactful.

Moreover, AI can enhance roofing design by ensuring that selected materials and technologies align with specific environmental conditions. A tailored roofing solution can dramatically boost both durability and efficiency, benefiting the overall functionality of the building.

As the industry increasingly embraces AI applications, the potential for transformative roof management will grow. Property owners who invest in these technologies can anticipate enhanced and proactive maintenance strategies, leading to superior returns on investment.

Looking Ahead

The commercial roofing industry stands at a critical crossroads, with 40% of traditional coatings failing prematurely and causing billions in preventable damage annually.

While established coating practices continue to dominate the market, transformative technologies like AI-powered maintenance, self-healing materials, and IoT monitoring systems offer proven solutions that can revolutionize building protection.

The data is clear: properties implementing these innovations report up to 30% reduction in energy costs and 75% fewer emergency repairs.

For the commercial roofing sector to advance, stakeholders must embrace these evidence-based alternatives that enhance durability, sustainability, and cost-effectiveness.

The future of commercial roofing lies not in incremental improvements to existing formulas, but in boldly adopting technologies that fundamentally reshape how buildings are protected and maintained.

FREQUENTLY ASKED QUESTIONS

Q. What are the current practices for commercial roofs?

A. Maintaining roofs is critical to avoid high energy costs and repair bills. Many commercial coatings available, such as acrylic and silicone, enhance performance and longevity. Understanding these options enables property owners to make informed decisions that anticipate environmental challenges.

Q. What systemic issues affect industrial roof coatings?

A. A significant challenge is the inconsistency in waterproofing performance, leading to leaks. Additionally, environmental concerns about chemical content can complicate the adoption of new solutions. It’s essential for manufacturers to innovate to solve these pressing issues effectively.

Q. How can missed opportunities impact commercial roof investments?

A. Failing to adopt innovative materials can lead to higher operational costs and reduced lifespan. Energy-efficient coatings significantly lower air conditioning expenses, making them essential for modern facilities. Staying current with technologies is vital for enhancing profitability and sustainability.

Q. What are the root causes of problems with commercial roofing?

A. Major issues stem from insufficient inspections and contractor qualifications. Without thorough evaluations and adequately trained applicators, coatings may fail prematurely. Addressing these root causes is crucial for maximizing the lifespan of roofing systems and ensuring effective performance.

Q. What does data-driven evidence say about commercial roof performance?

A. Current statistics reveal a startling failure rate of 25% for traditional coatings within five years. This underlines the necessity for innovative alternatives that promise enhanced durability and improved energy efficiency, offering long-term savings and performance reliability.

Q. What alternative solutions are available for commercial roofs?

A. Innovating with smart roofing systems and self-healing coatings presents powerful options. IoT-based monitoring enhances maintenance efficiency, while self-healing materials reduce repair frequency. These solutions not only improve durability but also drive energy savings and sustainability within roof management.

Q. How can new technologies impact commercial or industrial roofs?

A. Emerging technologies, like AI for predictive maintenance, can transform roof management. These advancements allow managers to timely address potential issues, minimizing disruptions and boosting facility longevity. Investing in these technologies ensures roofs perform optimally and enhance property value over time.