Welcome to today’s Battle Royale featuring two roofing heavyweights: “Passive Ventilation” in the east corner versus “Mechanical Ventilation” in the west!

Tonight’s showdown pits these contenders against each other across six punishing rounds designed to test every aspect of their performance for Commercial Roof Effectiveness.

At stake? Millions in potential costs, decades of building protection, and the critical performance demands of modern commercial and industrial facilities.

Our professional judging panel will evaluate each round on technical merit, real-world performance, and value delivery. After all six rounds, we’ll declare our ultimate champion.

Ladies and gentlemen, facility managers and building owners… it’s time to rumble!

ROUND 1: INITIAL COSTS & INSTALLATION

In commercial roofing, ventilation system selection can make or break your building’s performance and long-term cost structure. Poor ventilation choices often lead to premature roof failure, increased energy costs, and uncomfortable indoor conditions. Understanding the initial investment and installation requirements of both passive and mechanical systems is crucial for making an informed decision that aligns with your building’s needs and budget constraints.

Material Expenses

Material costs represent one of the most significant differences between passive and mechanical ventilation systems. Passive systems utilize basic components like ridge vents, soffit vents, and air chambers, typically costing $2-4 per square foot for materials.

Mechanical ventilation systems require more sophisticated components, including powered fans, electrical systems, and digital controls. These materials generally cost $5-8 per square foot, not including backup systems and monitoring equipment.

While both systems offer different benefits, passive ventilation clearly provides a substantial cost advantage in terms of materials, often saving 40-60% compared to mechanical alternatives.

Installation Complexity

Installation complexity directly impacts both project timeline and labor costs. Passive ventilation systems require minimal specialized tools and can often be installed by general roofing crews, reducing the need for multiple specialized contractors.

Mechanical systems demand extensive electrical work, control system programming, and specialized technicians. These requirements often necessitate coordination between multiple trades and can create scheduling conflicts that extend installation time.

The straightforward nature of passive system installation provides a clear advantage, reducing both labor costs and potential complications during the installation process.

Project Timeline

Project duration significantly affects business operations and overall costs. Passive ventilation installations typically complete in 25-40% less time than mechanical systems, allowing businesses to resume normal operations more quickly.

Mechanical ventilation installations require additional time for electrical work, system testing, and commissioning. These steps can extend project timelines by several weeks and often require multiple inspection phases.

The efficiency of passive system installation presents another clear advantage, minimizing disruption to building operations and reducing overall project costs.

ROUND 1 WINNER: PASSIVE VENTILATION

ROUND 2: DURABILITY & LIFESPAN

When evaluating commercial roofing ventilation systems, durability and lifespan considerations can make the difference between a 30-year roof and one that fails in under a decade. Poor ventilation choices often lead to moisture accumulation, thermal stress, and material degradation that can cut a roof’s functional life in half.

Component Longevity

Passive ventilation systems rely on natural airflow and static components like ridge vents, soffit vents, and air chambers. These components typically last 25-30 years with minimal maintenance requirements due to their lack of moving parts.

The simplicity of passive systems means fewer points of potential failure. When properly designed and installed, these components often outlast the roofing materials themselves, requiring replacement only during complete roof system renovations.

Mechanical ventilation systems depend on powered fans, motors, and electronic controls that typically need replacement every 7-10 years. These components face continuous wear and can fail unexpectedly, potentially compromising the entire ventilation system.

The durability advantage clearly goes to passive ventilation systems in this category due to their superior component longevity and reduced maintenance requirements.

Weather Resistance

Passive ventilation systems demonstrate exceptional resilience during severe weather events. Their fixed components remain functional even during power outages and can withstand high winds when properly installed.

These systems continue working effectively through most environmental challenges, maintaining their protective function without external power or intervention. The lack of electrical components eliminates the risk of weather-related system failures.

Mechanical systems often struggle during extreme weather conditions. Power outages can render them completely ineffective, while electrical components are vulnerable to lightning strikes and water damage.

For weather resistance, passive ventilation systems hold a clear advantage due to their consistent performance regardless of external conditions.

Maintenance Requirements

Passive ventilation systems typically require only annual inspections and occasional cleaning to maintain peak performance. Their maintenance needs focus on ensuring vents remain unobstructed and checking for physical damage.

The minimal maintenance requirements of passive systems translate to lower long-term costs and reduced risk of system failure. Most maintenance tasks can be performed during routine roof inspections without specialized technicians.

Mechanical ventilation systems demand quarterly maintenance checks, regular part replacements, and ongoing system adjustments. These requirements increase both maintenance costs and the likelihood of system downtime.

In terms of maintenance demands and associated costs, passive ventilation systems demonstrate a clear advantage over their mechanical counterparts.

ROUND 2 WINNER: Passive Ventilation

ROUND 3: PERFORMANCE FACTORS

Performance factors can make the difference between a thriving facility and one plagued by high operating costs and tenant complaints. With energy costs rising 15-25% annually in many regions, ventilation choices directly impact both building efficiency and occupant comfort. Understanding these performance factors is essential for making informed decisions that will affect your facility for decades.

Energy Efficiency

Energy efficiency has become a critical factor in commercial building operations, with ventilation systems accounting for up to 30% of a building’s energy consumption. Proper ventilation design can significantly reduce HVAC loads and associated costs.

Passive ventilation systems harness natural air movement and thermal dynamics to regulate building temperature. These systems require no external power source and can reduce cooling costs by 25-35% in properly designed installations.

Mechanical ventilation systems consume substantial electricity to operate fans and controls. While modern systems incorporate energy-saving features, they still require continuous power input for operation.

With no operating costs and proven effectiveness, passive ventilation claims the “ADVANTAGE” in energy efficiency.

Indoor Air Quality

Indoor air quality directly impacts occupant health, productivity, and satisfaction. Poor ventilation can lead to sick building syndrome, increased absenteeism, and potential liability issues.

Passive ventilation systems provide continuous air exchange without mechanical intervention. Natural airflow patterns help remove pollutants and maintain consistent fresh air distribution throughout the building.

Mechanical systems offer precise control over air movement and filtration. However, they can create pressure imbalances and may circulate contaminants if not properly maintained.

While both systems can perform effectively, mechanical ventilation earns the “ADVANTAGE” through superior control and filtration capabilities.

System Longevity

The longevity of ventilation systems directly affects maintenance budgets and replacement schedules. A well-designed system should maintain peak performance for 15-20 years.

Passive ventilation systems have minimal components that can fail or degrade. Their simplicity and lack of moving parts typically result in lifespans exceeding 25 years with minimal maintenance.

Mechanical systems face regular wear on motors, bearings, and control systems. Even with proper maintenance, major components often require replacement every 7-10 years.

Due to their inherent durability and minimal maintenance requirements, passive ventilation systems claim the “ADVANTAGE” in longevity.

ROUND 3 WINNER: PASSIVE VENTILATION

ROUND 4: MAINTENANCE REQUIREMENTS

Maintenance decisions can make or break a commercial roof’s performance and lifespan. Industry data shows that 85% of premature roof failures stem from inadequate maintenance protocols, while proper maintenance can extend roof life by up to 40%. For ventilation systems specifically, maintenance oversights can transform a well-designed system into a liability within 2-3 years.

Regular Inspection Requirements

Regular inspections form the foundation of effective ventilation maintenance. Passive systems typically require bi-annual professional inspections, focusing on vent blockages, seal integrity, and structural alignment.

These inspections can usually be completed in a single day, with minimal disruption to building operations. Most issues identified during passive system inspections can be resolved through basic cleaning and minor repairs.

Mechanical systems demand monthly or quarterly inspections of motors, bearings, and electrical components. These specialized inspections often require shutdown periods and multiple technicians to complete properly.

The straightforward nature and reduced frequency of passive system inspections earns them the ADVANTAGE in this category.

Repair Frequency

Repair frequency directly impacts both maintenance budgets and system reliability. Passive ventilation systems typically require repairs every 3-5 years, mainly focusing on weather seal replacement and vent realignment.

Most passive system repairs can be completed within a single day using standard roofing materials. The simplicity of these repairs reduces both cost and complexity.

Mechanical systems face more frequent repair needs, often requiring attention every 6-12 months. Component failures can cascade into larger issues, necessitating emergency repairs and system downtime.

Based on lower repair frequency and complexity, passive ventilation claims the ADVANTAGE.

Maintenance Costs

Annual maintenance costs significantly impact long-term facility budgets. Passive systems typically require $0.15-0.25 per square foot annually for maintenance, including inspection and routine cleaning.

These costs remain relatively stable over time, with minimal inflation impact. Emergency repairs are rare, making maintenance expenses predictable and manageable.

Mechanical systems average $0.45-0.75 per square foot annually, excluding emergency repairs and component replacements. These costs tend to increase as systems age, particularly after the 5-year mark.

The substantial cost difference gives passive ventilation the clear ADVANTAGE in maintenance expenses.

ROUND 4 WINNER: PASSIVE VENTILATION

ROUND 5: SUSTAINABILITY CREDENTIALS

As building codes tighten and environmental regulations intensify, sustainable roofing solutions have moved from optional features to critical requirements. With commercial buildings accounting for 35% of total energy consumption in developed nations, ventilation choices can dramatically impact both environmental footprint and operating costs.

Property owners face increasing pressure to demonstrate environmental leadership while maintaining profitable operations. The right ventilation strategy can reduce energy usage by up to 40% while helping buildings achieve crucial sustainability certifications.

Energy Consumption Impact

Energy consumption represents the most significant environmental impact of commercial building operations. Passive ventilation systems harness natural air movement and thermal dynamics, requiring zero operational energy while maintaining consistent air exchange rates.

These systems work continuously without power input, reducing building cooling loads by 25-40% through strategic placement of vents and air chambers. Their effectiveness increases with building height and proper integration with overall envelope design.

Mechanical ventilation systems require constant electrical input for fans, motors, and control systems. While modern units incorporate energy-saving features, they still consume substantial power during operation.

For minimizing energy consumption and associated environmental impact, passive ventilation claims the ADVANTAGE.

Carbon Footprint Assessment

The total carbon footprint of ventilation systems extends beyond operational impacts. Passive systems utilize simple components with minimal embedded carbon, typically requiring replacement only during major renovations.

Their straightforward design and long service life reduce manufacturing impacts and transportation requirements. Most components can be locally sourced, further reducing environmental impact.

Mechanical systems require complex manufacturing processes and frequent component replacements. The production and disposal of electronic controls, motors, and specialized parts contribute significantly to their lifetime carbon footprint.

In terms of total carbon impact, passive ventilation demonstrates clear ADVANTAGE.

Green Building Certification

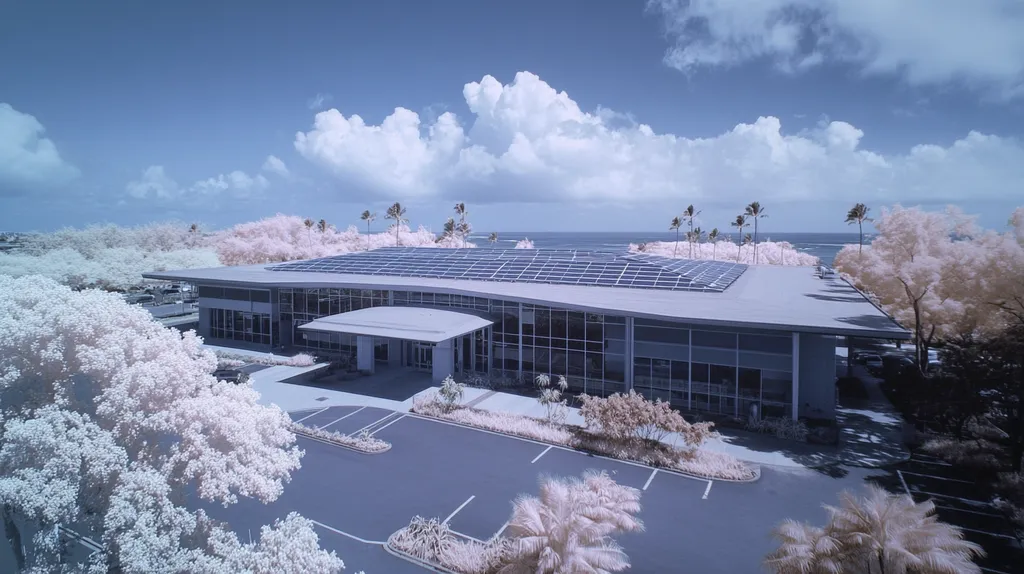

Sustainable building certifications increasingly influence property values and tenant decisions. Passive ventilation systems contribute significant points toward LEED, BREEAM, and other green building certifications through their energy efficiency and natural operation.

These systems align perfectly with biophilic design principles and zero-energy building goals. Their simplicity and effectiveness make them ideal for projects targeting the highest levels of certification.

While mechanical systems can contribute to certification goals through advanced controls and monitoring, their energy consumption often offsets these benefits. The complexity of these systems can also complicate certification documentation.

For maximizing green building certification potential, passive ventilation earns the ADVANTAGE.

ROUND 5 WINNER: PASSIVE VENTILATION

ROUND 6: SPECIALIZED APPLICATIONS

Specialized commercial environments present unique ventilation challenges that can make or break building performance. With indoor air quality regulations tightening and energy costs rising 20-30% annually, choosing the wrong ventilation strategy for these applications can lead to compliance violations, operational inefficiencies, and tenant dissatisfaction.

Different building types demand distinct approaches to air movement, temperature control, and humidity management. Understanding these specific requirements helps property owners avoid costly retrofits and system failures.

Industrial Processing Facilities

Industrial processing facilities face unique challenges with heat generation, particulate control, and moisture management. These environments often produce significant thermal loads and airborne contaminants that must be actively managed to protect equipment and workers.

Passive ventilation systems struggle to maintain consistent air quality in these demanding environments. While they can provide basic air exchange, they lack the power to overcome heavy process loads and cannot guarantee specific air change rates required by many manufacturing operations.

Mechanical ventilation systems excel in these environments by providing precise control over air movement and filtration. Their ability to respond to changing conditions and maintain specific environmental parameters makes them essential for industrial processing applications.

For industrial processing facilities, mechanical ventilation claims the clear ADVANTAGE.

Cold Storage Facilities

Temperature-controlled storage facilities require exceptionally reliable ventilation systems to maintain product integrity. These environments must balance air exchange requirements with strict temperature control while preventing condensation and ice formation.

Passive ventilation systems present significant risks in cold storage applications. Their reliance on natural air movement can create temperature fluctuations and moisture problems that compromise storage conditions.

Mechanical systems provide the precise control needed for cold storage environments. Their ability to manage air movement while maintaining temperature and humidity setpoints makes them essential for these specialized applications.

In cold storage facilities, mechanical ventilation demonstrates clear ADVANTAGE.

Research Laboratories

Research facilities demand extremely precise environmental control to maintain experiment validity and ensure safety. These spaces require specific air pressure relationships, filtration levels, and air change rates that directly impact research outcomes.

Passive ventilation systems cannot meet the stringent requirements of laboratory environments. Their inability to maintain consistent pressure differentials and air change rates makes them unsuitable for these critical applications.

Mechanical ventilation systems provide the exact control and monitoring capabilities required in laboratory settings. Their ability to maintain specific environmental parameters and respond to changing conditions makes them essential for research applications.

For research laboratories, mechanical ventilation earns the clear ADVANTAGE.

ROUND 6 WINNER: MECHANICAL VENTILATION

AND THE WINNER IS…

After six grueling rounds of technical analysis, with decisive victories in five categories, we have our undisputed Commercial Roof Ventilation Champion: PASSIVE VENTILATION!

This natural powerhouse dominated the competition with knockout performances in cost efficiency, durability, energy consumption, maintenance requirements, and sustainability credentials. Its ability to deliver reliable performance without power consumption while maintaining building integrity proved virtually unstoppable.

But don’t count Mechanical Ventilation out completely! This technical specialist proved its worth in Round 6, demonstrating superior capabilities in specialized applications like industrial processing, cold storage, and research facilities where precise environmental control is non-negotiable.

Remember, folks: Every building represents its own unique challenge. Local climate conditions, property characteristics, and specific use requirements can dramatically impact ventilation system performance. This analysis provides general guidance but cannot account for all variables. Building owners should always consult with qualified roofing professionals who can evaluate their specific situation.

In the high-stakes arena of commercial roofing, there’s no substitute for making an informed choice. The true victory comes not from blindly following the champion, but from selecting the ventilation system that best matches your facility’s specific requirements and performance demands. Now that’s what we call a knockout decision!

FREQUENTLY ASKED QUESTIONS

Q. What are the initial costs of a commercial roof ventilation system?

A. The initial costs vary significantly between passive and mechanical systems. Passive systems typically cost $2-4 per square foot, while mechanical systems can run from $5-8 per square foot for materials. Installation complexity also affects overall expenses, with passive systems being less labor-intensive and quicker to install.

Q. How does durability affect an industrial roof’s ventilation choice?

A. Durability is critical; passive systems can last 25-30 years with minimal upkeep due to fewer moving parts. In contrast, mechanical systems might require significant repairs and part replacements every 7-10 years, which affects long-term costs and reliability.

Q. How does a commercial roof ventilation system affect energy costs?

A. The choice of ventilation significantly impacts energy efficiency. Passive systems use natural airflow, reducing energy consumption by as much as 30%. Mechanical systems, however, require continuous power to operate, leading to higher energy bills over time.

Q. What are the maintenance requirements of a commercial roof ventilation system?

A. Maintenance varies greatly; passive systems usually need inspections twice a year, focusing on simple cleaning. Mechanical systems require frequent checks and repairs, leading to higher maintenance costs and potential system downtime, especially as they age.

Q. How does sustainability influence the choice of ventilation in commercial roofing?

A. Sustainability is increasingly important as it affects certifications and operational costs. Passive systems significantly reduce energy consumption and carbon footprint compared to mechanical systems, making them a preferred choice for environmentally-conscious buildings aiming for green certifications.

Q. Are there specialized applications where mechanical ventilation is necessary?

A. Yes, specialized applications like industrial processing or research laboratories require precise environmental control that passive systems can’t provide. Mechanical ventilation excels in such environments, ensuring proper air quality and meeting strict regulatory standards.

Q. How can I determine the best ventilation system for my commercial roof?

A. Assess your facility’s specific needs by considering factors such as building type, climate, and usage patterns. Consulting with a roofing professional can also help align your ventilation choice with long-term goals, including durability, cost, and sustainability.