In industrial roofing, up to 75% of premature coating failures stem from improper application sequence, leading to millions in avoidable repair costs annually across commercial facilities.

The systematic application of protective coatings represents a critical factor in extending roof longevity and maintaining building integrity, yet many facility managers lack clear guidance on optimal coating processes.

This comprehensive guide examines the essential elements of successful coating applications, from surface preparation to final curing, providing property owners with actionable strategies to maximize their roofing investments and prevent costly failures.

SECTION 1: THE BASICS EXPLAINED

Grasping the fundamentals of coating applications on industrial roofs is essential for ensuring their longevity and performance. Properly applied coatings can protect roofs from severe weather and harmful UV exposure, ultimately slashing repair costs by as much as 50%. For property owners and facility managers, understanding these key concepts allows for informed decisions that shield their investments and improve operational efficiency.

What It Is (In Plain Language)

Coating applications involve the addition of a protective layer to industrial roofs, enhancing their durability and extending their lifespan. Various materials are used for these coatings—such as silicone, acrylic, or polyurethane—each providing specific advantages. Essentially, the coating serves as a shield, defending the underlying roof structure against the damaging effects of the environment.

For example, silicone coatings excel at reflecting sunlight, which helps reduce cooling costs, while acrylic coatings offer strong UV protection. The selection of the appropriate coating is influenced by the type of roof and the specific environmental conditions it endures.

Mastering these basics is crucial for property owners as it helps shape their maintenance strategies and cost-saving measures. Regularly applying coatings optimizes the roof’s protective capabilities, thereby prolonging its service life.

In summary, a well-executed coating application not only maintains the roof’s integrity but also enhances its overall performance, making it a vital component of effective roof management.

Why It Matters (To Your Building)

The condition of a roof is fundamental to the functionality and value of any building. Coatings play a critical role in preventing water intrusion, a primary cause of structural damage and mold proliferation. By offering a robust protective barrier, coatings help ensure a safe and dry environment within the building.

A well-maintained roof also contributes to energy efficiency. Reflective coatings mitigate heat absorption, lowering cooling expenses during warmer months. The resulting energy savings can yield substantial returns on investment over time.

Moreover, in some cases, applying these coatings may qualify buildings for energy-efficiency certifications and financial rebates, making it a smart fiscal decision. Therefore, knowing when and what type of coating to use is essential for any property owner.

Overall, a strategic approach to coating applications not only safeguards the roof but also drives significant operational savings, establishing it as a crucial consideration for facility management.

How It Works

The coating application process begins with a thorough cleaning of the roof surface to facilitate proper adhesion. This may involve removing dirt, debris, and any existing coatings. Ensuring a clean surface is critical, as contaminants can compromise the bond strength of the new coating.

Once the surface is prepped, the coating is applied using methods such as spraying, rolling, or brushing, depending on the roof size and material. Each method is designed to achieve even coverage and optimal performance in protecting the roof.

After application, the coating typically requires a curing period during which it bonds effectively with the roof material. This cure time, which varies by the type of coating used, is essential for realizing its protective properties.

Regular inspections and maintenance of the coating are necessary to extend its lifespan, allowing for timely reapplications when needed. This proactive strategy not only protects the roof but also helps avoid larger, more expensive repairs in the future.

SECTION 2: PRACTICAL APPLICATIONS

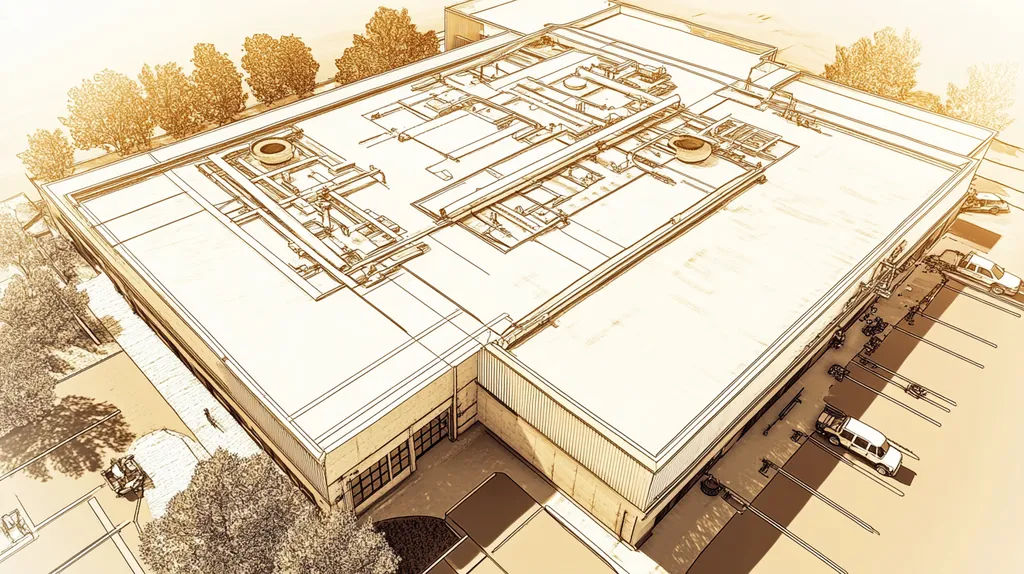

The durability of an industrial roof is essential for safeguarding valuable assets and ensuring seamless operations. With around 30% of a facility’s maintenance budget often devoted to roofing, the importance of effective coating application cannot be overstated. Choosing the right coating can lead to substantial cost savings by preventing leaks, extending the roof’s service life, and improving energy efficiency. This section delves into the common uses of roofing coatings, specifies when they are most needed, and examines their interactions with other roofing systems.

Common Uses & Examples

Roof coatings play a vital role in various industrial applications. They enhance waterproofing, provide UV protection, and improve energy efficiency. For instance, applying a reflective coating on a metal roof can cut cooling costs by up to 30% during the hot summer months.

Elastomeric coatings, which have great flexibility, can effectively seal small cracks and leaks, allowing aging roofs to remain functional longer. For example, using a polyurethane coating on an EPDM rubber roof enhances its flexibility and resilience against extreme weather.

Coatings also serve to restore aging roofs, presenting a cost-effective alternative to full replacements. By carefully assessing the condition of the roof, facility managers can select coatings tailored to their specific challenges.

Ultimately, selecting the appropriate coating is crucial. It should address factors like climate, building type, and the existing condition of the roof to maximize both functionality and lifespan.

When You Need It Most

Knowing when to apply coatings is crucial for prolonging roof life. Severe weather regions, marked by extreme heat or frequent rain, necessitate timely coating applications. Facilities in hail-prone areas should invest in reinforced coatings for enhanced protection.

Roofs over critical operations or those housing high-value equipment should receive coatings at the first signs of wear. Promptly treating small leaks with the right sealant can prevent more serious damage from occurring.

Annual inspections are another key timing factor. Incorporating coating applications during these assessments can help to preemptively address issues, reinforcing roofs before enduring harsh weather conditions.

By routinely monitoring the roof’s condition and strategically applying coatings, facility managers can achieve considerable savings over time, minimize emergency repairs, and extend roof longevity.

Interactions With Other Systems

Coatings do not exist in isolation; they significantly interact with other roofing systems. Understanding these interactions is vital for maintaining both roofing performance and longevity. For example, when applying a new coating over existing membranes, compatibility is essential. Using incompatible products can lead to adhesion failures that undermine the effectiveness of the coating.

Additionally, coatings must coordinate with insulation systems and drainage components. Properly applied coatings can enhance drainage efficiency, promoting effective water runoff and preventing pooling, which can compromise roofing materials.

Integrating the coatings with roof-mounted equipment, such as HVAC systems, is also critical. While coatings can protect the areas around roof penetrations, care must be taken to ensure that access for maintenance is not obstructed.

Ultimately, effective coating application should be part of a comprehensive roofing strategy that aligns with all existing systems. Ensuring that coatings function harmoniously with other roofing components is essential for preserving the overall integrity of the roof system.

SECTION 3: KEY TERMINOLOGY DECODED

Understanding the terminology in industrial roofing is crucial for making well-informed decisions that impact both budget and building integrity. Misunderstandings around key terms can lead to inappropriate material choices and costly applications, ultimately risking the roof’s durability. This section clarifies essential terms, translates industry jargon, and simplifies measurement units that are vital for roofing projects. By becoming fluent in this specialized language, property owners and facility managers can make informed choices that enhance the lifespan and efficiency of their roofs.

Essential Terms Explained

Coatings are specialized materials applied to roofs to provide protection and enhance performance. These can come in liquid or solid forms, designed to safeguard against UV rays, chemicals, and moisture. Familiarity with different types of coatings—such as elastomeric and reflective—is essential for their effective use.

The term substrate refers to the underlying material of the roof that will support the coating. Common substrates include metal, concrete, and single-ply membranes. Recognizing the type of substrate helps ensure that the selected coating is compatible and effective.

Adhesion plays a significant role in the performance of coatings, determining how well they bond to the substrate. If adhesion is poor, coatings may peel or flake off, which can lead to roof failure. Understanding adhesion characteristics is vital to prevent premature coating deterioration.

Additionally, the re-coating interval is an important concept. This term indicates how often a roof should receive a new layer of coating. Regular monitoring and adherence to this schedule can significantly extend the roof’s service life.

Industry Jargon Translated

Terms such as “weathering” and “film thickness” can be confusing for individuals outside the roofing industry. Weathering describes how environmental elements affect roof surfaces over time, potentially weakening coatings, thus making its understanding vital for long-term maintenance strategies.

Film thickness measures the coating’s layer once applied. It’s essential because if a coating is too thin, it may not offer sufficient protection, while an overly thick layer could result in stress and cracking.

Flexibility is another critical term; it indicates how well a coating can expand and contract with temperature changes, ultimately prolonging its lifespan. However, varying levels of flexibility exist among coatings, making careful selection based on local climate conditions essential.

Lastly, “VOC” stands for volatile organic compounds, which are chemicals released as gases from certain roofing products. Opting for low-VOC coatings can improve indoor air quality and comply with environmental regulations.

Measurement & Units Simplified

Understanding measurement units is essential to ensure proper coating application. The mil, defined as one-thousandth of an inch, is a common unit used to discuss film thickness. For optimal performance, the desired thickness for coatings typically ranges from 15 to 30 mils.

Square footage is another critical metric, representing the area needing coverage. Accurate square footage calculations ensure that enough material is ordered, reducing waste and preventing additional costs. Careful measurement of the roof’s dimensions is necessary for informed purchasing decisions.

Additionally, temperature and humidity levels during coating application are measured in degrees Fahrenheit and percent, respectively. These factors can significantly affect drying times and adhesion quality, influencing the success of the application.

Finally, the coverage rate indicates how far one gallon of coating can spread. Familiarity with coverage rates aids in budgeting and resource planning, ensuring that projects are completed efficiently and cost-effectively.

SECTION 4: DECISION FACTORS

Selecting the right coatings for industrial roofs is more than just a maintenance task; it’s a strategic decision that can dramatically influence a facility’s operational expenses and lifespan. A subpar coating choice can lead to leaks, skyrocketing maintenance costs, and disruptions in business continuity. Therefore, property owners and facility managers must navigate critical factors such as cost, performance trade-offs, and durability to make informed, impactful decisions that enhance roofing system efficiency.

Cost Considerations

Cost invariably holds primacy in decision-making for property owners and facility managers. Yet, initial price should not overshadow long-term financial implications. Some coatings may present a lower upfront cost but fall short in durability, leading to frequent replacements.

Investing in robust coatings, although seemingly pricier at first glance, often proves more economical over time. A high-quality elastomeric coating may command a heftier initial cost but significantly outlast a budget option, translating into reduced repair and replacement expenses.

Additionally, potential downtime due to roofing issues should be evaluated. Operational interruptions can result in substantial financial losses for businesses, emphasizing the importance of quality over initial savings. Conducting a comprehensive cost-benefit analysis when selecting coatings will help ensure optimal long-term investment.

By focusing on the total cost of ownership rather than just the sticker price, facility managers can make decisions that pay dividends for years to come.

Performance Trade-offs

Performance trade-offs represent a critical aspect of the roofing coating selection process. Each coating provides unique protective attributes while presenting its own strengths and weaknesses. For instance, while some coatings may offer superior UV resistance, they may falter under extreme temperature variations.

Understanding the specific environmental challenges faced by the roof is vital. Facilities in regions prone to heavy rainfall might necessitate a more water-resistant coating, while roofs in sun-drenched climates should prioritize UV protection. Failing to match the coating to the roofing environment can lead to premature failure.

Moreover, factors such as adhesion, flexibility, and durability against chemicals must be assessed. An informed evaluation of how each coating performs across various metrics will lead to better decisions and, ultimately, extended roof life.

This balance between performance criteria and the operational needs of the facility is essential for optimizing the roofing system in every unique context.

Lifespan & Durability Factors

Durability and lifespan are pivotal variables that directly affect the total cost of roof ownership. Coatings engineered for extreme environmental conditions tend to have longer life spans compared to less resilient products. Choosing roof coatings with a verified history of durability can yield cost efficiencies over time.

As an example, a coating that offers a 10-year manufacturer warranty might only endure five years under harsh conditions. Therefore, a thorough examination of warranty terms and expected performance in specific environments is imperative to ascertain true value.

Additionally, the thickness of the coating is instrumental in determining its durability. Thicker coatings typically enhance protection against damage and wear, assuming they adhere correctly. Property owners should favor products that promise long-lasting performance and that have been tested in environments similar to their own.

By prioritizing durability, facility managers can mitigate future repair demands, ensuring uninterrupted operations and safety in their facilities.

SECTION 5: COMMON CHALLENGES

Coating application on industrial roofs is fraught with challenges that can significantly undermine their durability and performance. Ignoring these issues can result in costly repairs, shortened roofing material lifespan, and potential safety hazards. Alarmingly, research indicates that 25% of roof failures stem from improper application techniques. Recognizing common challenges and understanding their solutions is crucial for property owners and facility managers alike.

Frequent Problems & Solutions

Inadequate surface preparation stands out as a prevalent challenge in the coating application process. Without thorough cleaning, contaminants can block adhesion, leading to coating failure. High-pressure washing and adherence to manufacturer guidelines can effectively remedy this issue.

Another common hurdle is improper mixing of coating materials. Inconsistent mixing often results in uneven coverage and quicker wear. Facility managers should utilize calibrated mixers and ensure that all crew members are well-trained in proper mixing methods.

Temperature fluctuations during the application phase can detrimentally affect the curing process. If temperatures are too high or low, coatings may fail to adhere properly. Monitoring weather conditions and scheduling installations during optimal temperatures—generally above 50°F (10°C)—is essential for success (source: SmartSeal).

Lastly, excessively thick application of coatings can trap moisture, leading to blisters and bubbles. Adhering to the manufacturer’s recommended thickness is crucial for ensuring even application and long-term performance of the roof coating.

Warning Signs To Watch For

Property owners need to stay alert for early signs of coating failure. Discoloration or peeling may indicate moisture intrusion or application errors. Prompt inspection and remediation can prevent further degradation and costly repairs.

Another warning sign is the presence of bubbles or blisters on the roof’s surface. This condition often points to trapped moisture, necessitating immediate action to avert structural issues.

A decline in roof performance, such as leaks during rain events, signifies potential coating inefficiency. Regular inspections should be conducted to assess the condition of the roof and execute timely interventions when problems arise.

If cleaning and maintenance activities do not yield improvements, it may suggest a need to re-evaluate the existing coating application entirely.

Preventative Approaches

Implementing a proactive maintenance strategy is crucial for averting common challenges associated with roof coatings. Regular inspections can help identify issues before they escalate into major problems. Scheduling these evaluations biannually, ideally during different weather seasons, provides comprehensive insights into the roof’s health.

Training staff on correct coating application techniques is another essential preventative measure. A knowledgeable crew can significantly minimize application errors that lead to premature coating failure.

Utilizing high-quality materials plays a vital role in achieving long-term durability. Investing in premium coatings formulated for specific industrial conditions can enhance resilience against harsh environments, thereby extending the roof’s lifespan.

Finally, establishing clear communication channels with coating manufacturers ensures that property owners remain informed about best practices and product advancements. Such partnerships can enhance performance and lead to reduced long-term costs.

SECTION 6: NEXT STEPS & RESOURCES

In the rapidly evolving landscape of industrial roofing, making informed choices has never been more critical for property owners and facility managers. The right coating application can dramatically enhance a roof’s durability and overall performance. Navigating this complexities requires asking the right questions, adhering to established standards, and committing to ongoing education. This section outlines crucial steps and resources to empower well-informed roofing decisions.

Questions To Ask Providers

Starting with the right inquiries sets the foundation for sound coating applications. Property owners should first assess the provider’s expertise with various coating types. Different coatings have unique compatibilities with roofing materials, significantly impacting their durability and efficiency.

Next, it’s important to understand the application process. How will the provider monitor weather conditions during application? As temperature and humidity are key to the coating’s performance, this inquiry is indispensable.

Discuss warranties and their coverage areas as well. A comprehensive warranty often signifies the provider’s confidence in their products and services, giving peace of mind to property owners.

Lastly, explore available maintenance plans. Regular inspections and upkeep are essential to maximizing the lifespan of a coated roof, ultimately saving substantial costs in the long run.

Industry Standards & Guidelines

Adhering to industry standards is critical for achieving a successful coating application. The American Society for Testing and Materials (ASTM) offers valuable guidelines on surface preparation and application techniques, which help ensure coatings bond correctly and perform optimally.

Additionally, the National Roofing Contractors Association (NRCA) provides comprehensive guidelines that cover best practices specific to roofing, including application processes for coatings.

Facility managers should remain informed about local building codes related to roofing materials and coatings. Compliance with these codes safeguards safety and helps avoid costly fines.

Regularly reviewing updates to these standards can provide insights into new technologies and methods, ultimately improving the performance of industrial roofing systems.

Further Learning Simplified

Continued education is essential in keeping pace with advancements in roofing technologies. Workshops and webinars presented by industry organizations like the Roofing Contractors Association offer hands-on experiences and expert knowledge on the latest coating application techniques.

Online courses from roofing manufacturers are also beneficial. These can deepen understanding of specific products and their uses, enhancing decision-making capabilities for property owners.

Industry publications and newsletters serve as excellent sources for updates on best practices and innovative coating technologies. Subscribing to these resources is crucial for staying informed in an ever-changing industry.

Lastly, engaging with professional networks facilitates knowledge sharing and keeps facility managers updated on evolving trends and emerging solutions in the roofing sector.

The Bottom Line

With over $3.5 billion spent annually on industrial roof repairs, proper coating application sequence remains a critical factor in extending roof life and protecting facility investments.

Research demonstrates that facilities following standardized coating protocols experience 40% fewer leaks and achieve up to twice the service life compared to those with improper applications.

The increasing complexity of modern coating systems, combined with rising material and labor costs, makes adherence to optimal application sequences more crucial than ever for property owners.

By implementing the guidelines outlined in this article, facility managers can significantly reduce maintenance costs while maximizing roof performance and durability.

Regular monitoring, proper documentation, and ongoing education about coating applications will continue to be essential elements of successful industrial roofing management.

FREQUENTLY ASKED QUESTIONS

Q. What are the basics of coatings for industrial roofs?

A. Coating applications provide protective layers that enhance the durability and extend the lifespan of industrial roofs. They defend against UV rays and severe weather, potentially reducing maintenance costs significantly. Understanding different materials like silicone and acrylic is essential for selecting the right coating for specific environmental conditions.

Q. How can coatings benefit my commercial roof?

A. Coatings improve waterproofing, UV protection, and energy efficiency, which are crucial for industrial roofs. Applications of certain coatings, like reflective types on metal roofs, can dramatically reduce cooling costs. Choosing the right type enhances the roof’s functionality and prolongs its service life, thereby yielding cost savings.

Q. What terminology should I know about industrial roofs?

A. Familiarity with terms such as substrate, adhesion, and re-coating interval is essential for effective roof management. The substrate is the underlying material, while adhesion speaks to how well coatings bond. Understanding these concepts enables better decision-making relating to coatings and maintenance approaches.

Q. What factors should influence my coating decisions?

A. Critical factors include cost, performance trade-offs, and durability. While cheaper coatings may offer initial savings, they can lead to frequent replacements and repairs. Evaluating the environmental conditions unique to your facility ensures the selected coating meets specific operational needs, enhancing overall efficiency.

Q. What are common challenges in coating applications?

A. Common issues include inadequate surface preparation, improper mixing, and temperature fluctuations during application. Each can lead to coating failure and increased maintenance costs. Regular inspections and adherence to manufacturer guidelines can help identify these challenges early, ensuring effective application.

Q. How can I ensure successful coating application?

A. To ensure success, engage providers with demonstrated expertise and ask pertinent questions about their processes. Verify adherence to industry standards and guidelines for surface preparation and application techniques. Regular training and utilizing high-quality materials also help enhance the coating’s performance and lifespan.

Q. What is the best way to maintain a coated roof?

A. Regular inspections and maintenance are critical for prolonging the lifespan of a coated roof. Establish a routine schedule for biannual assessments and keep communication open with your coating provider regarding best practices. Prompt action on maintenance can prevent costly repairs and ensure ongoing roof integrity.