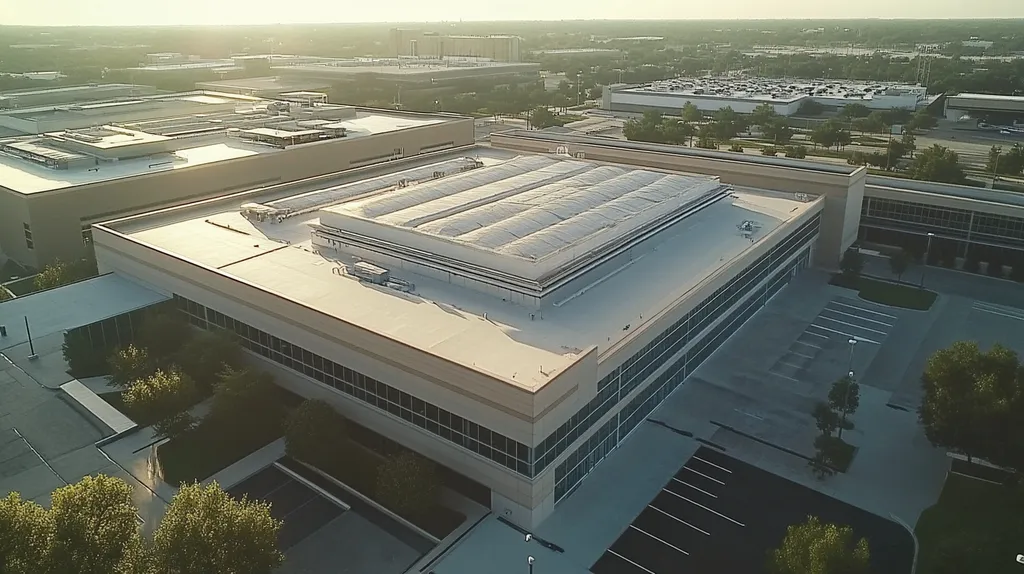

For commercial property owners and facility managers, the stakes couldn’t be higher when it comes to roof coating costs. Industry data shows that poor coating decisions can increase maintenance expenses by up to 40% over a building’s lifetime.

From material selection to application methods, every choice impacts the bottom line. With coating projects ranging from $1.50 to $4.00 per square foot, understanding the true costs is critical for protecting both the building and the budget.

This comprehensive guide breaks down the essential cost factors, compliance requirements, and best practices that every property professional needs to consider before embarking on a roof coating project.

SECTION 1: PERFORMANCE FACTORS

For commercial and industrial property owners, understanding performance factors in roof coating projects is vital. A smart investment in roof coating can lead to notable savings by extending the life of the roof and slashing energy costs. For example, choosing the wrong material can balloon maintenance expenses, potentially costing thousands. Therefore, it’s essential for property owners to grasp the nuances of material selection, surface preparation, and the overall durability of coatings.

Coating Material Selection

Selecting the right coating material is a pivotal step in any roof coating project. Various materials offer distinct advantages in terms of protection and durability. For instance, silicone coatings excel at water resistance, while acrylic types shine in providing UV protection.

This choice isn’t just about longevity; it also impacts energy efficiency. Some coatings reflect sunlight more effectively, leading to lower cooling bills. Tailoring the material to your roof’s specific needs can translate into substantial savings over the years.

Compatibility with existing roofing materials is equally important. A mismatch can lead to underperformance and issues that might require costly repairs. Each roofing system has its unique characteristics, necessitating a custom approach for best results.

While high-quality coatings might come with a larger upfront investment, they can save money in the long run by reducing the need for repairs and minimizing energy waste. Conducting thorough research and collaborating with a seasoned contractor can streamline this decision-making process.

Key Action Items

Roof Surface Preparation

The significance of thorough roof surface preparation is paramount. The success of a coating system heavily relies on the meticulous cleaning, repairing, and priming of the surface before application. Inadequate preparation can ruin adhesion, leading to a coating that fails prematurely.

Take, for instance, the cleaning stage: if not done properly, dirt and grime can prevent the coating from adhering effectively. This oversight can shorten the coating’s lifespan and potentially create leaks or structural problems.

Additionally, addressing existing issues such as cracks or blisters is critical prior to applying a new coating. Skipping these repairs can worsen underlying problems, resulting in more extensive and expensive repairs later. Conducting a thorough inspection before application is essential to catch any potential issues early on.

Weather conditions also play a role in successful surface preparation. Factors like humidity and temperature can significantly influence the coating’s application outcome. Contractors must account for these variables to ensure the best possible results.

Key Action Items

Durability and Lifespan

The durability and projected lifespan of a roof coating play a significant role in the overall cost-effectiveness of the investment. Quality coatings can last from 10 to 20 years or even longer, depending on their material and how well they are installed. Property owners should evaluate their long-term goals and how choosing a coating aligns with these objectives.

Many coatings also come with warranties that promise certain performance standards for specific periods. These warranties can differ significantly based on the type of material chosen and the manufacturer’s policies, with some coatings providing extensive protection against weathering and wear.

It’s crucial to assess local climate conditions when considering durability. Areas that experience extreme weather may need coatings specifically designed for harsh UV rays or torrential rain.

Ultimately, opting for a coating with superior durability doesn’t just enhance the lifespan of the roof; it also boosts the property’s overall value. A well-maintained roof contributes to the building’s appeal, transforming it into a valuable asset instead of a potential liability.

Key Action Items

SECTION 2: FINANCIAL CONSIDERATIONS

Navigating the financial landscape of roof coating projects is essential for property owners and facility managers. Establishing a detailed budget not only minimizes unforeseen expenses but also empowers stakeholders to make informed decisions. Did you know that unexpected costs can eat up to 40% of roofing budgets? This section will guide you through key financial aspects, including cost per square foot, labor and material expenses, and other potential costs that may arise during the project.

Cost per Square Foot Analysis

Understanding the cost per square foot is fundamental to any roofing project. For commercial roof coatings, prices generally range from $1.50 to $4.00 per square foot, influenced by factors like coating type, roofing area size, and the current state of the roof.

Before pinning down exact costs, conducting a thorough assessment of the roof’s needs can be beneficial. A well-prepared, clean roof means less coating material and labor, ultimately reducing costs.

Different materials come at different price points too. Acrylic coatings tend to be the most budget-friendly, while silicone and polyurethane can vary. Knowing these distinctions will help you make savvy selections.

Buying materials in bulk can further reduce costs, and working with contractors who offer comprehensive quotes will help you refine your budget and identify potential savings.

Key Action Items

Labor and Material Costs

Labor and material costs significantly contribute to the overall budget of any roofing endeavor. Labor can constitute 50% to 70% of total expenses, highlighting the importance of skilled professionals for proper application.

The choice of materials also plays a pivotal role. While high-quality coatings may have a higher upfront cost, their durability and energy efficiency can yield long-term savings. Balancing immediate expenses with future returns is key.

Moreover, labor costs can change based on the complexity of the project. Roof characteristics, such as unique slopes or existing HVAC units, may require specialized skilled labor, affecting the overall budget. Carefully evaluating the incomplete work scope provides clarity on labor requirements.

Engaging experienced contractors might result in higher labor costs initially, but their expertise may ultimately save money by avoiding costly repairs later.

Key Action Items

Additional Expenses and Permits

In addition to typical labor and material costs, other expenses may emerge in roof coating projects. Many areas necessitate permits, which can elevate initial project costs. These permits are vital for compliance with local building regulations.

Don’t overlook potential costs for pre-coating inspections. These evaluations can uncover underlying issues that must be resolved before coating, shielding you from future expenses.

Equipment rentals and scaffolding may also surface as unanticipated costs, especially for intricate or high roofs. Planning for these expenses at the onset can help maintain budget integrity.

Furthermore, considering maintenance and warranty stipulations in your financial planning is vital. Regular maintenance may prevent costly repairs stemming from premature coating failures.

Key Action Items

SECTION 3: COMPLIANCE REQUIREMENTS

Neglecting compliance requirements during commercial roof coating projects can lead to costly consequences and serious project delays. Each property owner faces potential financial strain from hefty fines, unexpected penalties, and even halted operations due to non-compliance with local building codes, manufacturer specifications, or environmental regulations. Understanding these requirements upfront is essential to ensuring a seamless roofing experience.

Local Building Codes and Regulations

Local building codes are a foundational directive in commercial roofing ventures, governing everything from approved materials to structural integrity and fire safety measures. Adhering to these codes is not just best practice; it guarantees the safety and longevity of the building.

Neglecting these codes can quickly lead to unexpected work stoppages and fines. For instance, a facility in an urban area faced heavy penalties after falling short of fire resistance mandates in their roof coating project.

Before starting any work, property owners should connect with local regulatory agencies to grasp specific roof coating requirements and avoid future compliance hurdles. Staying updated on changes to building codes is also wise, as these standards evolve to reflect newer safety measures and environmental concerns.

Key Action Items

Manufacturer Specifications and Warranties

Manufacturer specifications are critical for ensuring the longevity and effectiveness of roof coatings. Each product comes with specific application conditions and material compatibility guidelines that must be strictly followed.

Ignoring these specifications can void warranties, leading to unexpected repair expenses and liability challenges. A facility once incurred substantial costs when their roof failed prematurely, as they neglected to adhere to the manufacturer’s advised application temperature.

To mitigate risks, property owners should deeply familiarize themselves with manufacturer literature and need to ensure compliance throughout the installation process. Engaging experienced contractors will further maximize warranty advantages while ensuring proper application of the coating.

Key Action Items

Environmental and Safety Standards

In today’s roofing industry, adhering to environmental and safety standards is paramount. Both state and federal regulations focus on minimizing environmental impact and requiring sustainable practices.

Failing to meet these environmental standards can lead to severe legal repercussions and harm a facility’s reputation. One contractor faced litigation for using potentially harmful roofing materials without proper disclosure, damaging their credibility and operational standing.

Property managers must ensure compliance with certifications such as LEED and local green building mandates, enhancing both marketability and attractiveness to eco-conscious tenants. Additionally, prioritizing safety regulations protects workers and reinforces the project’s integrity.

Key Action Items

SECTION 4: RISK MANAGEMENT

In the world of commercial roofing, effective risk management is paramount, especially when it comes to coatings. Property owners and facility managers must navigate the potential pitfalls of leaks, structural damage, and unwanted downtime. With leaks accounting for as much as 40% of all roofing issues, according to the National Roofing Contractors Association, the stakes couldn’t be higher. By proactively identifying potential problems, assessing the current state of the roof, and mitigating environmental risks, decision-makers can protect their valuable investments.

Identifying Potential Leaks and Damage

Spotting potential leaks early can lead to major cost savings. Inspections should focus on seams, flashings, and penetrations, which are common culprits for leaks. Utilizing infrared technology can reveal hidden moisture lurking beneath existing roofing materials.

Additionally, conducting visual inspections during severe weather is vital. Conditions can change rapidly during rain and storms, highlighting vulnerabilities that may not be apparent otherwise. Documenting these inspections is essential for timely repairs.

Regular maintenance is your best friend in preventing leaks. Allocating funds for ongoing assessments keeps properties safeguarded, ensuring minor issues don’t morph into expensive repairs.

Key Action Items

Assessing Roof Condition and Needed Repairs

Knowing your roof’s current condition is vital for successful coating projects. A comprehensive assessment needs to check for membrane wear, punctures, and blistering, as these issues can complicate the application of new coatings.

It’s crucial to address any minor repairs before applying a new coating. Ignoring these repairs not only jeopardizes the new coating but can also lead to expensive maintenance issues down the road. Property owners should factor these repair costs into their overall project budget.

Bringing in roofing professionals for evaluations can uncover hidden issues that the untrained eye might miss. Their expert input ensures a thorough understanding of your roof’s health.

Key Action Items

Mitigating Weather and Environmental Risks

Weather poses a significant challenge to the success of roof coating projects. Environmental conditions like extreme heat and heavy rain can disrupt the curing process of coatings. Therefore, scheduling applications during milder weather is essential to avoid premature failures.

Facility managers should keep an eye on meteorological forecasts to select the most opportune times for application. This proactive approach helps reduce application problems and enhances the coating’s lifespan.

Other factors, including UV exposure and temperature fluctuations, can lead to material degradation over time. Opting for high-quality, UV-resistant coatings can help mitigate these risks.

Key Action Items

SECTION 5: OPERATIONAL PROCEDURES

Proper operational procedures are crucial for achieving a successful roof coating project. Neglecting these steps can not only result in costly mistakes but also shorten the lifespan of coatings by a staggering 50%. Focusing on pre-coating inspections, careful application practices, and diligent post-coating maintenance helps ensure your roofing solution is durable and effective.

Pre-Coating Inspections and Cleaning

The foundation of a successful coating application lies in a thorough pre-coating inspection. Property owners need to scout for structural damage, existing leaks, and moisture retention areas. Addressing these issues promptly is vital to avoiding complications down the line.

Next up is cleaning! Removing dirt, debris, and biological growth such as moss or algae is essential. A poorly cleaned surface can hinder adhesion, resulting in bubbling or peeling of the coating—no one wants that!

Cleaning methods will likely include pressure washing or chemical treatments tailored to your roof type. The last step is a final inspection after cleaning but before coating, ensuring any lingering issues have been resolved for optimal adhesion.

Key Action Items

Application Process and Best Practices

When it comes to applying roof coatings, attention to detail is key. Following manufacturer guidelines, especially regarding temperature and humidity, is crucial to success. Extreme temperatures can lead to bubbling or improper curing, and no one wants to deal with that headache!

Equipping yourself with the right tools and techniques makes a world of difference. Professional applicators typically utilize rollers or sprays specifically suited for the coating type, ensuring an even and consistent thickness for maximum protection.

Consider layering your application. Applying several thin coats instead of one thick coat can significantly enhance durability and resistance to environmental challenges. Furthermore, maintaining clear communication among team members is essential for seamless coverage—no gaps or overlaps allowed!

Key Action Items

Post-Coating Maintenance and Monitoring

Once the coating is in place, ongoing maintenance becomes essential to extend the roof’s life. Regular inspections are a must, with experts advocating for checks at least twice a year and following significant weather events.

Monitoring the coating’s condition is equally vital. Check for signs of wear, peeling, or discoloration—these can indicate underlying problems that need addressing quickly. A proactive approach saves time and money in the long run.

Additionally, incorporating periodic cleaning into the maintenance schedule keeps dirt and debris at bay, ensuring the coating’s effectiveness while enhancing the roof’s appearance. Keeping accurate records of inspections and repairs will also help in managing warranties and budgeting for future roof care.

Key Action Items

SECTION 5: OPERATIONAL PROCEDURES

Ignoring proper operational procedures in a roof coating project can lead to costly mistakes and premature coating failure. Astonishingly, improper preparation can cut the lifespan of coatings by up to 50%. Ensuring thorough pre-coating inspections, meticulous application practices, and diligent post-coating maintenance is essential for a roofing solution that stands the test of time.

Pre-Coating Inspections and Cleaning

Before any coating application, conducting a thorough inspection of the roof is a must. Property owners should check for structural damage, existing leaks, and potential moisture retention hotspots. Promptly addressing these issues is crucial to avoiding complications later.

Cleaning the roof surface is equally critical. It’s vital to remove dirt, debris, and biological growth like moss or algae. Neglecting this step can hinder adhesion, leading to bubbling or peeling of the coating—an outcome no one wants!

Various cleaning methods are available, including pressure washing or chemical treatments, tailored to the roof type and contamination level. Finally, a last inspection should occur post-cleaning but pre-coating, ensuring any lingering issues are resolved for optimal performance.

Key Action Items

Application Process and Best Practices

The process of applying roof coatings demands meticulous attention to detail. It’s essential to follow manufacturer guidelines about temperature and humidity since extreme conditions can cause bubbling or improper curing. Nobody wants to deal with those headaches!

Equipping yourself with the right tools makes all the difference. Professional applicators typically use rollers or spray equipment designed specifically for the type of coating, ensuring an even and consistent thickness across the roof.

Layering the application can provide added durability. Applying multiple thin coats instead of one thick layer helps build a robust finish, improving resistance to environmental factors. Clear communication among team members is key to ensuring no gaps or overlaps in coverage.

Key Action Items

Post-Coating Maintenance and Monitoring

Once the coating is applied, ongoing maintenance is key to extending the roof’s lifespan. Regular inspections are essential, and experts suggest checking the roof at least twice a year, especially after significant weather events.

Monitoring the coating for signs of wear, peeling, or discoloration is also vital. These issues can signal underlying problems that require prompt attention, allowing for a proactive approach that ultimately saves time and money.

Additionally, property managers should plan periodic cleaning to prevent dirt and debris buildup. Regular cleaning not only improves appearance but also ensures that the coating effectively protects the roof substrate. Keeping detailed records of inspections and repairs will aid in warranty management and future budgeting for roof care.

Key Action Items

Looking Ahead

With commercial roof coating costs ranging from $1.50 to $4.00 per square foot and potential maintenance savings of up to 40%, making informed decisions about coating projects has never been more critical.

Industry data shows that proper material selection, thorough surface preparation, and strict compliance with manufacturer specifications can extend a roof’s lifespan by 10-20 years.

Environmental regulations continue to tighten, making it essential for property owners to choose sustainable coating solutions that meet both current and anticipated standards.

The most successful coating projects combine detailed planning, professional application, and systematic maintenance protocols to maximize return on investment while protecting valuable building assets.

By following established best practices and staying ahead of emerging industry trends, facility managers can ensure their roof coating investments deliver optimal performance and value.

FREQUENTLY ASKED QUESTIONS

Q. What performance factors should I consider for my commercial roof?

A. The right coating material, proper surface preparation, and durability are crucial. Each material offers unique advantages in protection and energy efficiency, so it’s essential to match them to your specific roof needs to avoid costly future repairs.

Q. How do I analyze costs per square foot for industrial roof coatings?

A. Costs typically range from $1.50 to $4.00 per square foot. Factors like coating type and roof condition affect pricing, so conducting an assessment helps refine your budget and guide material choices.

Q. What compliance requirements should I be aware of for my commercial roof?

A. Be aware of local building codes, manufacturer specifications, and environmental regulations. Non-compliance can lead to fines and project delays. Ensure all standards are met to avoid costly setbacks.

Q. How can I identify potential leaks and damage on my commercial roof?

A. Regular inspections focusing on seams, flashings, and surface condition are key. Utilizing infrared technology can help detect hidden moisture, ensuring prompt repairs and preventing costly leaks.

Q. What operational procedures should I follow for roof coating projects?

A. Conduct thorough inspections and cleanings before application. Follow manufacturer guidelines during the coating process, and prioritize regular maintenance post-application to extend the roof’s lifespan and effectiveness.

Q. How do I ensure a successful application process for my roof coating?

A. Follow guidelines based on temperature and humidity, and use appropriate application tools. Applying multiple thin coats rather than one thick layer enhances durability, ensuring even coverage and improved results.

Q. How often should I inspect and maintain my commercial roof?

A. Schedule inspections at least twice a year, especially after major weather events. Monitoring for signs of wear and maintaining cleanliness are essential for prolonging the life and effectiveness of the coating.