Ever watched a commercial building transform from profitable operation to emergency disaster zone in a single winter storm? While facility managers across the country battle freeze-thaw cycles that turn minor roof vulnerabilities into catastrophic leaks, one critical decision separates the prepared from the panicked: proper roof coating selection and application.

Winter doesn’t just challenge commercial roofs—it wages all-out war through relentless temperature swings, ice dams, and thermal shock that can destroy unprotected surfaces overnight. The difference between bulletproof winter performance and budget-busting emergency repairs often comes down to understanding what roof coatings are, when they’re needed most, and how to deploy them strategically before Mother Nature’s worst tantrums arrive.

SECTION 1: THE BASICS EXPLAINED

Picture this: while your commercial roof silently battles winter’s fury above, one tiny crack can turn into a catastrophic leak that shuts down operations and drains budgets faster than melting snow disappears down a storm drain. Winter doesn’t just challenge roofs—it wages war on them through relentless freeze-thaw cycles, ice dams, and thermal shock that can transform a perfectly good roof into a liability overnight.

The secret weapon in this seasonal showdown? Roof coatings—the unsung heroes that can mean the difference between smooth sailing through winter and emergency repair crews camping out on your property. Understanding what these protective powerhouses are, why they’re mission-critical for your building, and how they work their magic sets the stage for winter-proofing success.

What It Is (In Plain Language)

Think of roof coating as your building’s winter armor—a liquid-applied protective layer that transforms into a seamless shield over your existing commercial roof. Unlike the massive disruption of a full roof replacement, coating application is like giving your roof a superhero makeover without the construction chaos.

These coatings come in three main flavors: acrylic (the budget-friendly workhorse), silicone (the waterproofing champion), and polyurethane (the durability titan). Each brings its own superpowers to the table, but they all share one mission: creating an impenetrable, waterproof barrier that laughs in the face of weather extremes.

When winter arrives with its bag of nasty tricks—ice dams, snow overload, and those brutal freeze-thaw cycles that crack even the toughest materials—your coating stands guard. It’s like having a bouncer at the door of your building, keeping trouble out while your business operations stay warm and dry inside.

The beauty lies in the simplicity: liquid goes on, cures into a protective film, and suddenly your roof has the winter-fighting power it needs. No major construction, no extended downtime, just enhanced protection that gets the job done.

Why It Matters (To Your Building)

Here’s the winter reality check: every freeze-thaw cycle is like a tiny demolition crew working overtime on your roof. Water sneaks into microscopic cracks, freezes overnight, expands with the force of a hydraulic jack, and creates bigger cracks for the next round of destruction.

Without proper coating protection, this cycle accelerates faster than a runaway freight train, turning small maintenance issues into budget-busting emergencies. One major leak can shut down entire facility sections, damage expensive equipment, and create safety hazards that put operations at risk.

Smart facility managers know that coating investment pays dividends through improved energy efficiency too. Reflective coatings bounce heat away during sunny winter days, reducing the thermal stress that causes roof materials to expand and contract like an accordion.

The bottom line hits where it counts: coated roofs maintain their integrity season after season, while unprotected roofs become liability time bombs waiting to explode during the worst possible weather conditions.

How It Works

The magic happens at the molecular level, where roof coatings create a continuous, elastic film that bonds tighter to your roof than a best friend bonds to free pizza. This seamless membrane seals every tiny crack, gap, and vulnerable spot where water might try to stage a sneak attack.

When temperatures fluctuate like a yo-yo championship, the coating moves with your roof, expanding and contracting in perfect harmony. This flexibility prevents the dreaded crack formation that turns roofs into sieves during winter storms.

Ecodur Roof Coatings protect commercial roofs from extreme weather by expanding and contracting with the roof, preventing cracks and leaks caused by thermal movement. They provide excellent UV resistance and can be applied to various roofing materials (source: Castagra).

The waterproofing performance really shines when winter unleashes its worst. Melting snow and ice meet an impenetrable barrier that redirects water away from vulnerable areas, stopping the freeze-thaw destruction cycle before it can gain momentum.

Many coatings also serve as thermal regulators, moderating the wild temperature swings that stress roof materials beyond their limits. It’s like giving your roof a climate-controlled environment that keeps it happy and healthy through winter’s wildest mood swings.

SECTION 2: PRACTICAL APPLICATIONS

Picture a sprawling warehouse district on a February morning—while most facilities hum along normally, one building sits empty with yellow caution tape blocking the entrance. The culprit? A coating failure that turned a minor roof weakness into a catastrophic leak during last week’s ice storm.

This scenario plays out across commercial districts every winter, separating the prepared from the caught-off-guard. Smart facility managers don’t just slap coatings on roofs and hope for the best—they strategically deploy these protective systems where they pack the biggest punch, time applications for maximum effectiveness, and ensure every building component works together like a well-oiled machine.

Common Uses & Examples

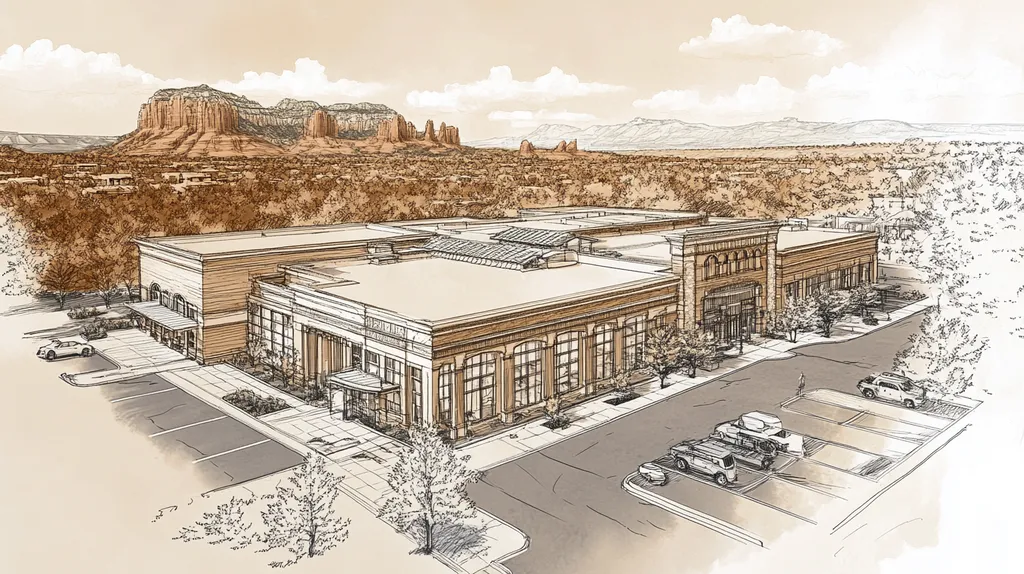

Retail complexes and shopping centers represent coating superstar territory, where expansive flat roofs face relentless winter punishment. These buildings typically feature multiple roof penetrations—HVAC units, skylights, and drainage systems—that create perfect entry points for water infiltration during freeze-thaw cycles.

Manufacturing facilities and distribution centers leverage coatings as thermal shock absorbers, protecting massive roof areas from the constant expansion and contraction that turns reliable roofs into cracked disasters. The coating acts like a flexible bandage that moves with the building, preventing stress fractures that multiply faster than rabbits in springtime.

Office buildings and medical facilities often deploy reflective coatings as energy-saving champions that bounce winter sunlight away during those deceptively warm February afternoons. This prevents the thermal roller-coaster effect that stresses roof materials beyond their breaking point.

ArmorPoxy’s commercial roof coatings are crafted with elasticity and tensile strength, allowing them to expand and contract with the building structure under varying temperatures without cracking or peeling (source: ArmorPoxy). Hospital complexes and schools particularly benefit from these eco-friendly formulations that maintain air quality while delivering bulletproof protection.

When You Need It Most

September through October represents the golden window for coating applications—temperatures stay stable enough for proper curing while giving facilities a protective head start before winter’s first sneak attack. Missing this window turns coating projects into risky gambles with weather forecasts.

Emergency mid-winter coating becomes necessary when existing protection fails spectacularly, leaving facility managers scrambling for temporary solutions. Specialized winter-grade coatings can provide stopgap protection during brief warm spells, but they’re like emergency surgery—effective when needed, but not the preferred game plan.

Buildings showing stress signals—ponding water, visible cracks, or membrane deterioration—need immediate attention before winter amplifies small problems into facility-shuttering disasters. Waiting until spring means gambling with thousands of dollars in potential damage and operational disruption.

Facilities in harsh winter climates should prioritize coating renewals every 3-5 years, treating them like insurance policies that pay dividends when Mother Nature throws her worst tantrums. Proactive timing prevents reactive panic when winter storms expose unprotected vulnerabilities.

Interactions With Other Systems

Roof coatings don’t work solo—they’re team players that must coordinate with existing membranes, insulation systems, and drainage networks like synchronized swimmers performing a complex routine. Compatibility testing prevents coating chemistry disasters that turn protective layers into destructive nightmares.

EPDM and TPO membrane roofs require specific coating formulations that bond properly without causing chemical reactions that weaken the underlying system. Getting this wrong creates a protection failure that’s worse than having no coating at all.

Insulation beneath the roof deck directly impacts coating cure times and performance, acting like a thermal regulator that affects how quickly coatings reach full protective strength. Insufficient insulation can create condensation problems that undermine coating adhesion from below.

Drainage systems must maintain proper water flow patterns after coating application, since even slight changes in roof surface texture can redirect water into problem areas. Coordinating coating thickness with existing slopes prevents the ponding water situations that turn protective coatings into breeding grounds for roof deterioration.

HVAC equipment interactions require careful planning around maintenance access and heat exhaust patterns that can accelerate coating degradation in concentrated areas. Smart application accounts for these hot spots before they become coating failure zones.

SECTION 3: KEY TERMINOLOGY DECODED

Picture a facility manager frantically calling contractors at 2 AM because their “waterproof” coating turned into a disaster during the season’s first freeze. The culprit? A simple misunderstanding of coating terminology that transformed winter protection into winter chaos.

When coating conversations sound like a foreign language, expensive mistakes multiply faster than ice crystals on an unprotected roof. Every technical term carries weight—understanding them means the difference between bulletproof winter protection and costly emergency repairs when temperatures plummet.

Essential Terms Explained

“Elastomeric” isn’t just fancy coating talk—it’s your roof’s survival superpower during winter’s temperature roller coaster. These rubber-like coatings stretch and bounce back like a yoga instructor, moving seamlessly with your roof as it expands and contracts through daily freeze-thaw cycles.

“Dry Film Thickness” (DFT) determines whether your coating performs like armor or tissue paper when winter storms attack. Think of it as the coating’s muscle—too thin and it can’t handle the punishment, too thick and it might crack under pressure like an over-inflated balloon.

“Adhesion” describes how stubbornly your coating clings to the roof surface, like a determined barnacle that refuses to let go. Poor adhesion during winter freeze-thaw cycles creates the dreaded peeling and blistering that turns protective coatings into water-trapping disasters.

“VOC levels” matter more than many realize—these volatile organic compounds affect everything from environmental compliance to worker safety during application. Lower VOC coatings keep both regulators and building occupants happy while delivering the winter protection your facility demands.

Industry Jargon Translated

“Substrate” is contractor-speak for whatever surface receives the coating—whether it’s metal, concrete, or that modified bitumen roof that’s seen better decades. Understanding substrate compatibility prevents chemistry disasters that weaken protection when you need it most.

“Permeability” walks the tightrope between blocking liquid water and allowing vapor escape, like a bouncer who keeps troublemakers out while letting fresh air flow freely. Get this balance wrong, and trapped moisture creates bigger problems than the original roof issues.

Temperature fluctuation and the freeze-thaw-freeze effect are major causes of commercial roof damage in winter, as melting snow seeps into cracks, then refreezes causing expansion and damage, increasing the chances of leaks and mold (source: Inland Coatings). “Thermal shock” describes this brutal cycle that transforms minor vulnerabilities into facility-threatening disasters without proper coating protection.

“Cure time” versus “dry time” creates confusion that leads to premature foot traffic and coating damage. Dry means touchable, cured means bulletproof—understanding the difference prevents well-meaning maintenance crews from accidentally sabotaging fresh protection.

Measurement & Units Simplified

Coating thickness gets measured in “mils”—not miles, but thousandths of an inch that pack serious protective punch. Most winter-worthy coatings need 20-60 mils DFT, where going too thin means inadequate protection and going too thick risks cracking like dried mud.

“Coverage rates” tell you how far each gallon stretches across your roof, typically expressed in square feet per gallon. Winter applications often require adjusted coverage calculations since cold weather affects how coatings flow and level out during application.

“Pot life” describes how long mixed coatings stay workable before they start setting up in the bucket like concrete. Cold weather extends pot life while hot weather shortens it, making timing critical for successful winter coating projects.

Understanding “service life” expectations helps budget for future recoating cycles, typically ranging from 10-20 years depending on coating type and weather exposure. Smart facility managers treat these numbers as planning tools rather than guarantees, scheduling inspections before protection expires.

SECTION 4: DECISION FACTORS

Picture a facility manager staring at three coating proposals, each promising winter protection—one dirt cheap, one premium-priced, and one somewhere in between. By February, only one building in the district stays leak-free while the others become emergency repair disasters.

Winter coating decisions separate the strategic thinkers from the penny-wise, pound-foolish crowd faster than ice forms on unprotected roofs. Smart facility managers know that choosing coatings based on upfront price alone turns winter protection into expensive gambles with their building’s future.

Cost Considerations

Winter coating projects come loaded with hidden costs that blindside unprepared budgets like surprise snowstorms. Surface preparation becomes more expensive when crews battle freezing temperatures, and specialized equipment for cold-weather applications can double labor expenses overnight.

Heated enclosures and winter-grade additives transform simple coating jobs into complex operations that require careful financial planning. These upfront investments seem painful until compared to the astronomical costs of emergency repairs when cheap coatings fail during the season’s worst storms.

Smart facility managers calculate total cost of ownership rather than just material prices, factoring in extended cure times, weather delays, and potential operational disruptions. A coating that costs 30% more upfront but lasts twice as long delivers superior value over its lifetime.

Energy savings from reflective coatings offset initial investments faster than many realize, especially on large commercial roofs where thermal efficiency directly impacts heating costs. Buildings with properly coated roofs report energy savings that pay for the coating investment within 3-5 years.

Performance Trade-offs

Winter coating performance walks a tightrope between cure speed and long-term flexibility—rush the process and sacrifice durability, wait too long and risk weather interference. Fast-curing formulations might seem attractive but often lack the elasticity needed for brutal freeze-thaw cycles.

Elastomeric coatings deliver superior thermal movement accommodation but require perfect weather windows for proper curing. Single-component systems offer application simplicity while two-component formulations provide enhanced chemical resistance and adhesion strength.

Water permeability becomes critical during winter months when trapped moisture turns protective coatings into roof-destroying ice makers. Coatings with excellent waterproofing properties might sacrifice breathability, potentially creating condensation problems in improperly ventilated systems.

Castagra’s Ecodur Roof Coatings provide exceptional durability and flexibility, expanding and contracting with the roof to prevent cracks and leaks caused by thermal movement while extending roof lifespan and reducing maintenance costs (source: Castagra). These performance characteristics become make-or-break factors when winter temperatures fluctuate wildly from day to night.

Lifespan & Durability Factors

Winter-applied coatings face an immediate trial by fire—or rather, trial by ice—that reveals their true durability within months rather than years. Coatings that survive their first brutal winter season typically deliver decades of reliable protection, while inferior products fail spectacularly during their inaugural freeze-thaw challenge.

UV resistance becomes surprisingly important during winter months when snow reflection intensifies solar exposure on roof surfaces. High-altitude facilities and buildings in snow-heavy regions experience accelerated coating degradation without proper UV protection formulations.

Maintenance accessibility affects long-term durability since winter-damaged coatings require prompt attention to prevent small problems from becoming catastrophic failures. Coatings that enable easy spot repairs and touch-ups maintain their protective integrity longer than systems requiring complete reapplication.

Substrate compatibility determines whether coatings develop the molecular-level bond necessary for surviving thermal shock and mechanical stress. Proper surface preparation and primer selection create the foundation for durability that weathers decades of seasonal punishment without surrendering protection.

SECTION 5: COMMON CHALLENGES

Picture walking into your facility on a frigid Monday morning to discover water dripping from the ceiling—right where last month’s “expert” coating application promised bulletproof winter protection. That sinking feeling multiplies across commercial districts nationwide as improperly applied winter coatings transform from protective shields into expensive disasters.

Winter coating challenges don’t announce themselves with fanfare—they lurk quietly until the first major storm exposes every shortcut, mistake, and overlooked detail. Understanding these coating killers and their sneaky warning signs arms facility managers with the knowledge needed to prevent winter protection from becoming winter catastrophe.

Frequent Problems & Solutions

Temperature ambushes rank as the number one coating assassin, striking when surface temperatures drop below manufacturer specifications faster than afternoon shadows. Cold substrates reject coating adhesion like oil repels water, creating the dreaded peeling and blistering that turns protection into a liability within weeks of application.

Moisture infiltration plays the role of coating saboteur, hiding in tiny surface pores and emerging during freeze-thaw cycles to create bubbling disasters. Even microscopic amounts of trapped water can transform during cold snaps, expanding with enough force to rip coatings apart from the inside out.

Smart contractors combat these enemies with substrate heating systems that warm roof surfaces to optimal bonding temperatures before application begins. Moisture detection equipment reveals hidden dampness that the naked eye misses, preventing costly application over compromised surfaces.

Winter-specific coating formulations offer built-in cold-weather resilience, curing properly even when temperatures hover near the danger zone. These specialized products cost more upfront but deliver protection that survives conditions that destroy standard coatings.

Professional heating enclosures create controlled micro-environments that extend application seasons safely into colder months. These temporary structures maintain ideal conditions long enough for proper curing, turning impossible weather windows into workable opportunities.

Warning Signs To Watch For

Coating edges that curl like autumn leaves signal adhesion failure that spreads faster than gossip in a small town. These lifting edges create water entry points that multiply during every freeze-thaw cycle, turning small problems into roof-wide disasters.

Color changes and chalky surfaces reveal UV degradation and chemical breakdown that accelerate in winter’s harsh conditions. What starts as subtle discoloration evolves into coating failure that leaves underlying roof materials defenseless against the elements.

Ponding water that refuses to drain properly indicates coating thickness variations or surface preparation failures that create low spots. These water collection zones become ice-formation headquarters that stress coatings beyond their breaking point.

Roof coatings act as an impenetrable shield, forming a seamless and waterproof barrier over your existing roof, reducing the risk of leaks and ensuring your building remains dry and comfortable (source: Rodd Roofing). When this seamless barrier shows cracks or separation lines, immediate attention prevents small vulnerabilities from becoming catastrophic failures.

White crystal formations around coating edges indicate moisture intrusion and salt deposits that signal deeper infiltration problems. These seemingly innocent deposits mark the beginning of coating system breakdown that accelerates without prompt intervention.

Preventative Approaches

Pre-application roof detective work prevents more coating failures than all the premium materials and expert techniques combined. Thorough substrate analysis reveals hidden moisture, structural issues, and compatibility problems before they sabotage expensive coating investments.

Weather window planning transforms coating projects from gambling adventures into strategic successes. Smart facility managers schedule applications during stable weather periods while maintaining backup plans for unexpected temperature drops or moisture intrusion.

Contractor vetting separates winter coating specialists from fair-weather applicators who lack the knowledge and equipment for cold-weather success. Experienced winter coating crews bring specialized tools, techniques, and materials that general contractors often lack.

Post-application monitoring programs catch developing problems while they remain fixable rather than catastrophic. Regular inspections during winter’s worst weather reveal performance issues early enough for preventive maintenance rather than emergency replacement.

Maintenance scheduling that includes snow and ice management protects coating investments from mechanical damage and excessive loading. Proactive facility care extends coating life while preventing the accumulation damage that destroys protection systems over time.

SECTION 6: NEXT STEPS & RESOURCES

Picture a facility manager confidently navigating winter coating decisions while their peers scramble through emergency repairs and budget overruns. The difference? They armed themselves with the right questions, trusted resources, and industry knowledge before winter’s first punch landed.

Smart facility managers don’t wing it when winter protection hangs in the balance—they systematically gather intelligence, verify credentials, and tap into proven resources that separate coating success stories from disaster tales. The next steps you take now determine whether your roof laughs at winter storms or becomes their next victim.

Questions To Ask Providers

Start with the temperature torture test: “What’s your minimum application temperature, and how do you verify surface conditions before coating?” Contractors who hem and haw or give vague answers reveal their inexperience with winter’s tricky conditions faster than thermometers drop at sunset.

Demand specific examples: “Show me three similar facilities you’ve coated during winter months in the past two years.” Photos, references, and detailed project timelines separate genuine winter coating specialists from fair-weather contractors trying to expand their seasonal reach.

Press for protection details: “What happens if your coating fails during the first winter, and how do you handle warranty claims during emergency weather?” This question exposes whether you’re dealing with a stand-behind-their-work professional or a disappear-when-problems-arise amateur.

Challenge their technical knowledge: “How do you handle substrate preparation when temperatures fluctuate, and what backup equipment do you bring for unexpected weather changes?” Real winter coating experts come loaded with contingency plans and specialized gear that keeps projects on track when Mother Nature throws curveballs.

Industry Standards & Guidelines

The Roof Coatings Manufacturers Association (RCMA) serves as your coating bible, providing winter application guidelines that separate professional-grade work from expensive experiments. Their technical bulletins decode the mystery of minimum temperatures, humidity limits, and cure time requirements that make or break winter coating success.

ASTM standards provide the testing backbone that proves coating performance under brutal conditions, giving you ammunition to challenge contractors who recommend shortcuts or substandard materials. These specifications aren’t suggestions—they’re survival requirements for winter coating success.

National Roofing Contractors Association (NRCA) guidelines bridge the gap between manufacturer recommendations and real-world application challenges. Their best practices documentation helps you evaluate contractor proposals and spot potential problems before they become costly disasters.

By incorporating Ecodur Roof Coatings into your roofing maintenance plan, you can extend the lifespan of your roof, reduce maintenance costs, and enhance the overall weather resistance of your commercial building (source: Castagra). These industry-backed standards ensure you’re investing in proven protection rather than rolling the dice with experimental approaches.

Further Learning Simplified

Free webinars from coating manufacturers unlock insider knowledge without the sales pressure, covering everything from chemistry basics to troubleshooting common winter application challenges. These educational goldmines often reveal industry secrets that separate amateur applications from professional-grade results.

Trade publication archives contain real-world case studies that show both spectacular successes and costly failures, providing the kind of practical wisdom that prevents you from repeating other facility managers’ expensive mistakes. These stories offer invaluable lessons learned through trial and error—without the error part.

Regional contractor associations maintain member directories with specialty certifications and performance track records that help identify qualified winter coating specialists in your area. These professional networks provide peer recommendations that carry more weight than online reviews or sales pitches.

Manufacturer technical support hotlines offer direct access to coating chemistry experts who can answer specific questions about your facility’s unique challenges. These conversations often reveal application tricks and compatibility insights that generic literature doesn’t cover, giving you insider knowledge for better decision-making.

The Bottom Line

While facility managers across the country face another winter season, those who treat roof coating as an afterthought will join the ranks of emergency repair statistics flooding contractor hotlines every February.

Winter doesn’t negotiate—it exposes every coating shortcut, reveals every corner cut, and punishes every decision made without proper planning.

The facilities that sail through brutal freeze-thaw cycles without missing a beat share one common thread: they approached winter coating as a strategic investment rather than a maintenance expense.

From understanding elastomeric properties to selecting qualified contractors who bring heated enclosures and specialized equipment, every decision compounds into either bulletproof protection or catastrophic vulnerability.

The choice facing facility managers is stark—invest in proper winter coating protection now, or explain to upper management why emergency repairs are draining budgets when competitors stay operational and profitable.

Winter’s first major storm doesn’t wait for perfect timing or convenient budgets.

FREQUENTLY ASKED QUESTIONS

Q. What is a commercial roof coating and why is it crucial for winter protection?

A. Think of a roof coating as a liquid armor that cures into a flexible, seamless shield for your roof. This protective film blocks water infiltration and fights freeze-thaw damage that can turn tiny cracks into costly leaks during winter. It’s a low-disruption way to toughen up roofs, keeping your facility dry and operations smooth through stormy weather.

Q. How should industrial roof coatings be applied for the best winter results?

A. Timing and strategy are everything: aim to apply coatings in stable, cooler months before winter’s full arrival to ensure proper curing. Coatings must be matched to roof materials and account for penetrations like HVAC units to avoid weak spots. Skipping planning risks costly failures that can shutter building sections during critical cold snaps.

Q. What commercial roof coating terms should facility managers know this winter?

A. Key terms include “elastomeric” for flexible coatings that stretch with temperature changes, “dry film thickness” which is the protective layer’s muscle, and “adhesion”—how tightly the coating sticks to your roof surface. Knowing these prevents costly misunderstandings that turn your winter shield into a leak magnet.

Q. What factors influence choosing the right commercial roof coating for winter?

A. Don’t just shop by price—consider durability, cure time, UV resistance, and compatibility with your roof’s surface. Premium coatings often cost more upfront but save money by avoiding repairs and energy wastage. Performance in freeze-thaw cycles and ability to resist cracking are the real deal makers for winter resilience.

Q. What are common winter challenges with commercial roof coatings and how to prevent them?

A. The harshest enemies are cold temperatures that reduce adhesion, trapped moisture causing bubbling, and ice formation stressing the coating. Prevention includes thorough surface prep, moisture detection, warm substrate applications, and using winter-grade coatings. Regular inspections catch early damage before leaks bring disaster.

Q. What questions should I ask contractors about commercial roof coatings for winter?

A. Ask about their minimum application temperatures, winter project references, warranty policies, and substrate prep methods. Experts will have clear, confident answers and plans for weather challenges. Avoid contractors who dodge these questions—they can cost you big when winter strikes.

Q. How can reflective commercial roof coatings improve winter energy efficiency?

A. Reflective coatings bounce winter sunlight away, reducing thermal expansion and contraction that stress roofs. This minimizes heat loss and stabilizes indoor temperatures, lowering energy costs for heating. Plus, it prevents the freeze-thaw damage cycle, keeping your roof tougher for longer.