Commercial roofs fail 6-8 years earlier than their designed lifespan due to preventable maintenance oversights, costing U.S. businesses over $3.7 billion annually in premature replacements.

Understanding core principles of roof system optimization can extend service life by decades while dramatically reducing repair costs and business disruptions.

This comprehensive guide examines the critical components, implementation methods, and maintenance strategies that industry leaders use to maximize commercial roof performance and protect their building investments.

SECTION 1: FUNDAMENTAL CONCEPTS

Every commercial roof represents a critical investment that directly impacts building integrity and operational costs. Research shows that premature roof failures cost U.S. businesses billions annually in repairs, yet many of these failures are preventable through proper understanding and maintenance. When property owners grasp fundamental roofing concepts, they can make informed decisions that significantly extend their roof’s lifespan and protect their investment.

Basic Roofing Terminology

Clear communication between property owners and roofing professionals starts with understanding essential terminology. Key structural elements include the deck, which provides the foundational support, and the membrane that serves as the primary waterproofing barrier.

Flashings protect vulnerable areas where the roof meets walls, pipes, or other structures. These components require particular attention during inspections as they are common sources of leaks.

Understanding drainage terminology is crucial for maintaining roof health. Terms like scuppers, internal drains, and positive slope directly impact how water moves off the roof surface.

Knowledge of insulation terms such as R-value and thermal barriers helps owners make informed decisions about energy efficiency and condensation control.

Roofing Materials Overview

Modern commercial roofing materials offer diverse solutions for different building needs. Single-ply membranes like TPO and EPDM provide excellent flexibility and UV resistance, while modified bitumen systems offer superior durability in harsh conditions.

Built-up roofing (BUR) systems combine multiple layers of bitumen and reinforcing fabrics. This time-tested approach creates a robust barrier against severe weather conditions and foot traffic.

Metal roofing systems deliver exceptional longevity and wind resistance. Their higher initial cost is often offset by reduced maintenance needs and extended service life.

Each material choice impacts not only durability but also energy efficiency and maintenance requirements. Selecting appropriate materials and adhering to design standards during specification are fundamental for durable commercial roofs. (source: Insurance Institute for Business & Home Safety)

Design and Specification Process

Proper roof design begins with a thorough analysis of building requirements, local climate conditions, and code compliance. This initial assessment determines crucial factors like slope requirements and load-bearing capacity.

The specification process translates design requirements into detailed material and installation guidelines. This includes identifying appropriate insulation levels, membrane thickness, and attachment methods.

Wind uplift calculations and drainage capacity requirements must be precisely detailed. These specifications ensure the roof system can withstand expected environmental stresses.

Quality control measures should be built into the specification process. This includes requirements for material testing, installation inspection points, and warranty compliance verification.

SECTION 2: SYSTEM COMPONENTS

A commercial roof’s performance depends entirely on how well its core components work together as an integrated system. Studies show that 90% of roof failures stem from problems with basic components rather than severe weather events. Understanding these critical elements – from the underlying structure to the protective outer layers – enables property owners to make decisions that can double or triple their roof’s functional lifespan.

Roof Decking and Substrate

The roof deck forms the literal foundation of every commercial roofing system, bearing the weight of all other components while providing structural integrity. A compromised deck can lead to catastrophic failure, making it the most crucial yet often overlooked element.

Steel, concrete, and wood decking each offer distinct advantages for different building types. Steel provides excellent strength-to-weight ratios, while concrete offers superior fire resistance and durability in coastal environments.

The substrate layer between deck and membrane requires careful consideration during both installation and maintenance. Poor substrate selection or installation commonly leads to membrane failure and costly repairs.

Regular deck inspections should focus on detecting early signs of deterioration like rust, rot, or deflection. Catching these issues early prevents exponentially more expensive structural repairs later.

Membrane Options and Materials

The roofing membrane serves as the primary water barrier and must withstand constant exposure to UV rays, temperature extremes, and physical stress. Selecting the wrong membrane type for specific building conditions virtually guarantees premature failure.

TPO membranes excel in hot climates due to their reflective properties and heat resistance. EPDM provides superior durability in cold regions where freeze-thaw cycles stress roofing materials.

PVC membranes offer excellent chemical resistance for industrial facilities, while modified bitumen systems provide exceptional durability under heavy foot traffic. Each option requires specific maintenance protocols to achieve maximum lifespan.

Membrane thickness significantly impacts longevity – thicker isn’t always better. The optimal thickness depends on factors like roof slope, exposure conditions, and anticipated traffic patterns.

Flashing and Edging Systems

Flashing and edge details represent the most vulnerable points in any roofing system. Statistics show that over 80% of leaks occur at these transition areas rather than in the main roof field.

Different flashing types serve specific purposes: base flashings protect vertical transitions, counter flashings shield upper terminations, and edge metals provide clean water runoff while securing membrane edges.

Proper installation of these components requires precise attention to detail and material compatibility. Even minor installation errors can create major leak paths that compromise the entire system.

Routine maintenance of flashing systems and edge details directly impacts overall roof performance. Roof maintenance programs focused on comprehensive inspection of these components consistently extend service life and prevent costly failures. (source: Carlisle SynTec Systems)

SECTION 3: IMPLEMENTATION METHODS

Implementation methods can make or break a commercial roof’s longevity, with industry data showing that installation errors account for over 47% of premature failures. Every step of the installation process – from initial membrane placement to final seam sealing – creates either a potential point of failure or a lasting defense against the elements. Understanding and executing proper implementation methods can extend a roof’s functional lifespan by decades while protecting the substantial investment commercial roofs represent.

Roof Installation Techniques

Proper sequencing stands as the cornerstone of successful roof installation. Starting with a clean, dry substrate ensures optimal adhesion and prevents trapped moisture that could compromise the entire system.

Temperature and environmental conditions significantly impact installation quality. Membrane materials must be installed within specific temperature ranges to achieve proper expansion and contraction properties.

Seam construction requires meticulous attention to detail. Overlap specifications, weld temperatures, and pressure applications must be precisely controlled to create watertight bonds that maintain integrity over decades.

Equipment calibration and maintenance directly affect installation quality. Regular testing of welding equipment and careful monitoring of application temperatures ensure consistent results across large roof areas.

Adhesion and Bonding Methods

Selection of appropriate adhesion methods depends on multiple factors including substrate type, membrane material, and local climate conditions. Mechanical fastening provides excellent wind uplift resistance but creates potential water entry points that must be properly sealed.

Full adhesion techniques offer superior performance in high-wind zones but require strict temperature and humidity control during application. Partial adhesion systems can accommodate building movement while maintaining waterproof integrity.

Proper adhesive application rates significantly impact long-term performance. Under-application leads to membrane separation, while over-application wastes materials and can create surface irregularities.

Quality control measures during bonding processes must include adhesion testing at regular intervals. Pull tests verify proper attachment strength and identify potential weak points before they become problems.

Safety Measures and Regulations

Safety protocols must be integrated into every phase of roof installation. Technical design and installation standards improve not only worker safety but also overall roofing system resilience and longevity.

Fall protection systems require careful planning and implementation. Permanent anchor points should be incorporated during installation to facilitate future maintenance while meeting OSHA requirements.

Equipment placement and material staging areas need strategic planning to prevent overloading roof sections. Clear pathways must be maintained for emergency access and efficient material movement.

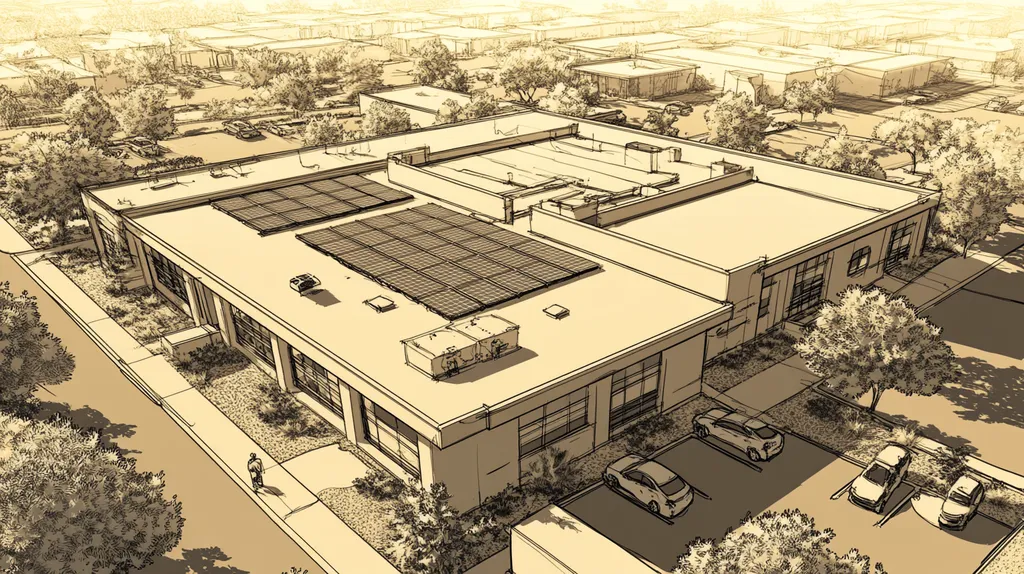

Integration of new technologies such as photovoltaic panels demands specialized safety considerations and installation methods to ensure long-term performance while protecting worker safety. (source: Insurance Institute for Business & Home Safety)

SECTION 4: MAINTENANCE REQUIREMENTS

Studies reveal that up to 80% of commercial roofs fail prematurely due to inadequate maintenance, costing businesses millions in avoidable repairs. A well-maintained roof can last 20-30 years, while neglected systems often require replacement in less than 10 years. Understanding and implementing proper maintenance protocols represents the single most impactful way to protect this critical building asset and maximize return on investment.

Preventative Maintenance Scheduling

Every commercial roof requires a customized maintenance schedule based on its age, material type, and exposure conditions. Seasonal changes dramatically impact roofing systems, making spring and fall the critical periods for comprehensive inspections.

Digital maintenance tracking systems help facility managers coordinate inspection schedules, document findings, and plan necessary repairs. These platforms ensure no maintenance tasks slip through the cracks while building a detailed history of roof performance.

Emergency response protocols must be integrated into maintenance schedules. Having pre-approved contractors and materials ready allows rapid response to storm damage or unexpected leaks.

Budget planning should allocate resources for both routine maintenance and potential repairs. Properties that underfund maintenance programs typically spend 3-4 times more on emergency repairs.

Regular Inspection Protocols

Effective inspections require systematic evaluation of all roof components, from membrane condition to drainage systems. Special attention must focus on high-risk areas like penetrations, seams, and flashings where most leaks originate.

Roof access points need careful monitoring to prevent damage from maintenance traffic. Designated walkways protect the membrane while providing safe paths for mechanical equipment servicing.

Documentation through photographs and detailed reports creates accountability and tracks deterioration patterns over time. This evidence proves invaluable for warranty claims and repair planning.

Thermal imaging and moisture detection equipment can identify hidden problems before visible damage occurs. Early detection through these tools prevents minor issues from escalating into major repairs.

Repair Best Practices

Proper repairs begin with correct diagnosis of underlying issues rather than just treating visible symptoms. Water testing often reveals that apparent leak locations don’t match actual entry points.

Material compatibility is critical when making repairs. Using the wrong sealants or patches can create new problems while attempting to fix existing ones.

Regular cleaning and debris removal protect membrane surfaces from chemical damage and prevent drain blockages. TPO and PVC roofing systems require special attention to remove grease accumulation and industrial contaminants.

Maintenance crews must use appropriate protection when servicing rooftop equipment. Designated walkways and careful tool handling prevent accidental membrane punctures that compromise roof integrity. (source: Insurance Institute for Business & Home Safety)

SECTION 5: PERFORMANCE METRICS

Reliable performance metrics are the foundation of effective commercial roof management. Studies show that buildings lacking systematic measurement protocols experience 65% more roof failures and 40% higher energy costs. While most property owners track basic maintenance costs, few implement comprehensive metrics that could prevent premature failures and optimize their roofing investment’s full potential.

Measuring Roof Durability

Durability measurement begins with establishing clear baseline conditions through detailed membrane thickness readings, seam strength tests, and drainage flow rates. These metrics create benchmarks for tracking deterioration patterns over time.

Advanced monitoring tools like electronic leak detection and infrared moisture mapping provide precise data about membrane integrity. This technology can identify potential failures months before visible damage occurs.

Wind uplift resistance testing should occur annually, particularly in areas prone to severe weather. These assessments verify that attachment systems maintain their original design strength.

Documentation of surface degradation rates through standardized photography and measurement protocols enables accurate lifespan predictions. This data drives informed decisions about timing of preventive maintenance versus full replacement.

Energy Efficiency Assessments

Thermal efficiency tracking requires continuous monitoring of heat flow through the roof assembly. Specialized sensors measure temperature differentials that indicate insulation performance and identify areas of excessive heat loss.

Solar reflectance index (SRI) measurements track how well roof surfaces maintain their heat-reflecting properties. Regular testing ensures cool roof systems continue delivering promised energy savings.

Air barrier integrity testing identifies pathways where conditioned air escapes through the roof assembly. Addressing these leakage points can reduce HVAC loads by up to 30%.

Energy consumption data from building management systems should be correlated with roof performance metrics. This analysis reveals the direct impact of roofing conditions on operational costs.

Cost-Benefit Analysis Tools

Modern cost tracking platforms integrate maintenance records, energy data, and repair histories into comprehensive financial models. These tools calculate true lifecycle costs by factoring in both direct and indirect expenses.

Predictive analytics help forecast future repair needs based on current performance trends. This capability enables more accurate budget planning and optimal timing of major investments.

Return on investment calculations must consider multiple factors including energy savings, extended service life, and reduced repair frequency. Regular maintenance and targeted upgrades can extend roof lifespan well beyond 30 years when guided by proper metrics.

Systematic performance tracking creates accountability and validates maintenance investments. Property owners who implement comprehensive metrics consistently achieve better outcomes while optimizing their roofing expenditures. (source: Carlisle SynTec Systems)

SECTION 6: OPTIMIZATION STRATEGIES

Strategic roof optimization directly impacts both building performance and operational costs. Industry data shows that buildings implementing comprehensive optimization strategies achieve 40% longer roof lifespans and 25% lower maintenance costs compared to reactive approaches. Yet many property owners struggle to integrate the core elements of successful optimization: seasonal planning, technological solutions, and strategic budgeting. Understanding and implementing these strategies can transform a vulnerable building component into a durable, high-performing asset.

Seasonal Maintenance Planning

Effective seasonal maintenance requires a structured approach that anticipates and prevents weather-related damage. Each season presents unique challenges that must be addressed through targeted inspection and maintenance protocols.

Spring maintenance focuses on repairing winter damage and preparing for increased UV exposure. This includes thorough cleaning of drainage systems and inspection of seams that may have been stressed by freeze-thaw cycles.

Summer protocols emphasize UV protection and monitoring expansion/contraction patterns. Regular surface temperature readings help identify areas where additional protective coatings may be needed.

Fall maintenance prioritizes drainage system preparation and membrane integrity verification before winter. Special attention must focus on flashing conditions and roof penetrations where water infiltration commonly occurs.

Technological Integrations for Efficiency

Modern roofing technology provides unprecedented visibility into system performance. IoT sensors monitor temperature, moisture levels, and structural movement in real-time, enabling early detection of potential problems.

Drone-based inspection systems equipped with thermal imaging capabilities can rapidly survey large roof areas. This technology identifies hidden moisture intrusion and insulation failures before they cause visible damage.

Building automation systems integrate roofing data with HVAC operations to optimize energy efficiency. Smart controls adjust ventilation based on roof conditions, reducing thermal stress on the membrane.

Digital maintenance management platforms streamline inspection scheduling and documentation. These systems ensure consistent protocol execution while building comprehensive performance histories.

Budgeting and Cost Management

Strategic roof management requires balancing immediate maintenance needs with long-term capital planning. Learn 5 proven strategies to extend your commercial roof’s life 10+ years by maximizing ROI through strategic maintenance that adds years of service life while avoiding catastrophic downtime. (source: CLS Roofing)

Life-cycle cost analysis helps determine optimal timing for repairs versus replacement. This approach considers energy savings, maintenance reduction, and potential tax benefits when evaluating roofing investments.

Reserve funds should allocate 15-20% of anticipated replacement costs annually. This ensures resources are available for both planned maintenance and unexpected repairs without disrupting operating budgets.

Performance metrics tracking helps justify maintenance investments by documenting cost savings. Regular analysis of repair histories, energy data, and maintenance expenses validates optimization strategies while identifying areas for improvement.

The Bottom Line

With commercial roof replacements costing $8-15 per square foot and rising annually, protecting these essential assets has never been more critical for business sustainability.

Through proper implementation of the strategies outlined in this guide – from systematic maintenance protocols to data-driven performance metrics – property owners can extend their roof’s functional lifespan by 15-20 years beyond standard expectations.

The key lies in shifting from reactive to proactive management through scheduled inspections, preventative maintenance, and strategic budgeting.

Organizations that embrace these proven optimization methods consistently achieve 40% lower lifecycle costs while preventing the catastrophic business disruptions that plague 65% of commercial properties with inadequate roof management programs.

FREQUENTLY ASKED QUESTIONS

Q. What fundamental concepts should I know about my commercial roof?

A. Understanding your commercial roof involves key concepts like the roof deck, membrane, and drainage systems. Each component plays a critical role in maintaining structural integrity and preventing leaks. Familiarizing yourself with basic terminology empowers you to make informed decisions about maintenance and repairs.

Q. How do the core components of my industrial roof work together?

A. The performance of your industrial roof is reliant on the interaction of core components like decking, membranes, and flashings. A failure in any of these elements can lead to significant issues, including leaks and premature deterioration. Regular maintenance ensures these components function harmoniously to extend the roof’s lifespan.

Q. What implementation methods can enhance my commercial roof’s longevity?

A. Proper installation techniques, including precise seam construction and environmental adjustments, critically impact your roof’s lifespan. Mistakes during installation can lead to severe defects and short-lived systems. Adhering to best practices during each phase will significantly enhance your roof’s durability and resistance to future issues.

Q. How critical is maintenance for my commercial roof?

A. Maintenance is essential for prolonging your commercial roof’s life and preventing costly repairs. Regular inspections and a proactive maintenance schedule can identify minor issues before they escalate, ensuring your roof lasts significantly longer. Neglect can lead to premature failures and increased long-term costs.

Q. What performance metrics should I track for my commercial roof?

A. Key performance metrics include measuring membrane thickness, seam integrity, and drainage efficiency. Monitoring these elements provides insights into your roof’s condition and helps forecast maintenance needs. Implement systematic tracking to prevent failures and optimize energy efficiency, ultimately extending your roof’s lifespan.

Q. How can I optimize my commercial roof’s performance?

A. Strategic planning, seasonal maintenance, and modern technology integrations are key to optimizing your roof. Implementing regular inspections, real-time monitoring, and efficient budgeting can improve durability and minimize unexpected repairs. This proactive approach enhances your building’s performance while reducing overall operational costs.

Q. When should I consider a roof replacement for my commercial roof?

A. Consider a roof replacement if extensive leaks, significant membrane wear, or structural integrity issues arise. A lifespan of over 20 years with frequent costly repairs may also signal it’s time for replacement. Consulting professionals can provide guidance tailored to your building’s specific needs and conditions.