The industrial roofing sector faces a critical challenge: while traditional roofing materials account for over 13 million tons of landfill waste annually, recycled alternatives are demonstrating superior durability in laboratory testing.

Recent studies indicate that advanced recycled roofing materials can extend service life by up to 40% compared to conventional options while reducing environmental impact.

Understanding the science behind these performance gains has become essential for facility managers seeking to optimize both sustainability and long-term building protection.

SECTION 1: THE BASICS EXPLAINED

The industrial roofing sector stands at a critical intersection of sustainability and performance. Modern recycling technologies have revolutionized roofing materials, delivering solutions that outperform traditional options while reducing environmental impact. Understanding these innovations is essential for facility managers seeking to maximize their building’s longevity and reduce lifecycle costs.

What It Is (In Plain Language)

Recycled roofing materials transform waste products into high-performance building components. These materials include synthetic shingles made from reclaimed plastics, rubber membranes derived from used tires, and metal roofing created from recycled industrial components.

Advanced processing techniques convert these recycled materials into lightweight, durable roofing products that can replicate the appearance of traditional materials like slate and clay. These innovative solutions prove particularly valuable for both contemporary and historical structures, offering authentic aesthetics without excessive weight loads. (source: Brava Roof Tile)

The manufacturing process eliminates impurities and reinforces material strength, ensuring consistent quality across all applications. This standardization makes recycled materials as reliable as virgin materials for commercial and industrial installations.

Why It Matters (To Your Building)

Recycled roofing materials directly impact a facility’s operational efficiency and maintenance requirements. These materials typically demonstrate superior resistance to UV radiation, temperature fluctuations, and moisture penetration.

The enhanced durability translates into reduced maintenance frequency and lower long-term ownership costs. Buildings utilizing recycled roofing materials often experience fewer emergency repairs and extended service intervals.

Performance advantages extend to thermal regulation and energy efficiency. Recycled materials frequently incorporate advanced insulating properties, helping facilities maintain stable interior temperatures while reducing HVAC loads.

How It Works

The effectiveness of recycled roofing materials stems from their engineered composition. Manufacturing processes break down source materials into uniform components, removing contaminants and ensuring consistent quality.

Advanced polymer science enables the creation of molecular bonds that enhance material strength and flexibility. This results in roofing products that can withstand extreme weather conditions while maintaining structural integrity.

Quality control systems monitor every stage of production, from initial material processing to final product testing. This rigorous oversight ensures that recycled roofing materials meet or exceed industry performance standards.

SECTION 2: PRACTICAL APPLICATIONS

Industrial roofing faces unprecedented challenges as facilities expand their operational demands and environmental conditions become more extreme. The integration of recycled materials represents a critical advancement in addressing these challenges, offering enhanced durability while meeting sustainability requirements. Understanding the practical implementation of these materials enables facility managers to make strategic decisions that protect assets and optimize performance.

Common Uses & Examples

Recycled materials have revolutionized modern roofing applications through innovative processing techniques. Metal roofing components, derived from recycled industrial materials, demonstrate exceptional durability while maintaining complete recyclability for future applications. (source: ADCO Roofing & Waterproofing)

Single-ply membranes incorporating recycled rubber compounds offer superior resistance to UV radiation and thermal cycling. These membranes provide seamless coverage across large industrial surfaces, effectively preventing water infiltration.

Composite insulation panels manufactured from recycled materials deliver enhanced thermal performance. These panels integrate seamlessly with existing roofing systems, improving energy efficiency while maintaining structural integrity.

Advanced polymer-based coatings derived from recycled materials provide additional protection against environmental stressors. These coatings extend roof life by creating resistant barriers against moisture and chemical exposure.

When You Need It Most

Facilities in regions experiencing extreme temperature fluctuations benefit significantly from recycled roofing materials. The enhanced flexibility and durability of these materials prevent cracking and separation during thermal cycling.

Manufacturing environments generating high levels of exhaust or chemical emissions require specialized protection. Recycled materials engineered for chemical resistance maintain their protective properties longer than traditional alternatives.

Buildings with extensive roof-mounted equipment need robust supporting structures. Recycled materials offer superior load-bearing capacity while resisting degradation from equipment vibration and maintenance traffic.

Facilities pursuing green building certifications find recycled roofing materials instrumental in meeting sustainability requirements. These materials contribute to multiple certification criteria while delivering superior performance metrics.

Interactions With Other Systems

Recycled roofing materials enhance the effectiveness of building envelope systems through improved thermal regulation. This integration reduces HVAC system strain and optimizes energy consumption patterns.

Drainage systems benefit from recycled components’ superior resistance to corrosion and degradation. These materials maintain their structural integrity even under constant exposure to standing water and environmental pollutants.

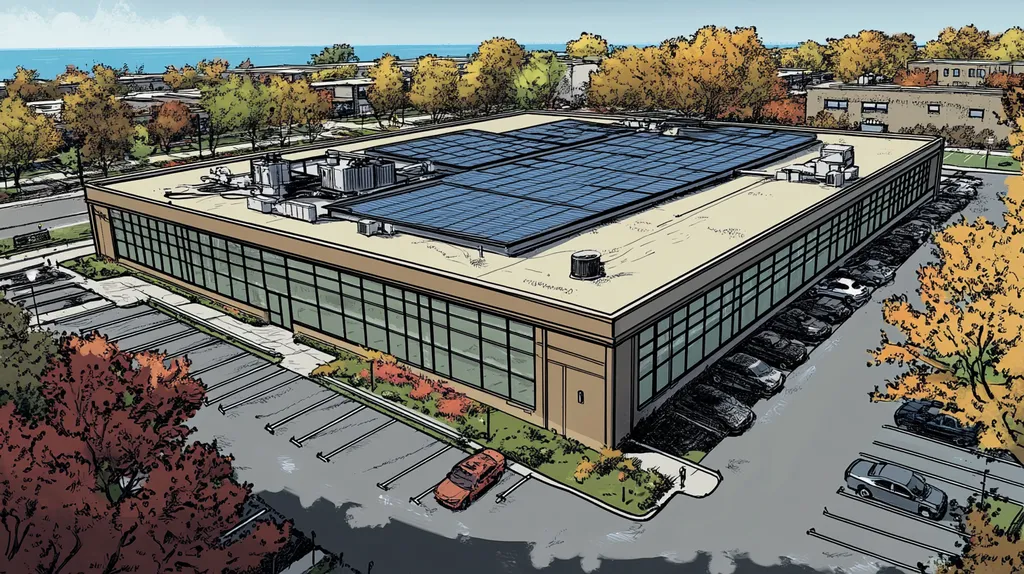

Solar panel installations achieve greater efficiency when mounted on recycled material substrates. The enhanced durability supports long-term system performance while maintaining roof integrity.

Building automation systems can better monitor and respond to environmental conditions with recycled roofing materials. The consistent performance characteristics of these materials enable more accurate system calibration and response.

SECTION 3: KEY TERMINOLOGY DECODED

The increasing complexity of industrial roofing technology demands a clear understanding of technical terminology. Facility managers who misinterpret key terms risk making costly decisions that compromise both durability and sustainability. Modern recycled roofing materials introduce specialized concepts that, when properly understood, enable more strategic facility management and enhanced long-term performance.

Essential Terms Explained

Composite shingles made from recycled materials represent a revolutionary advancement in roofing technology, offering enhanced durability while maintaining the aesthetic appeal of traditional materials like slate and clay. These materials demonstrate superior resistance to environmental stressors while reducing structural load requirements. (source: Home Evolution)

Post-consumer content refers to materials that have completed their intended consumer lifecycle before recycling. This distinction matters because post-consumer materials often undergo more rigorous processing to achieve optimal performance characteristics.

Thermal emittance measures a roof’s ability to release absorbed heat, working in conjunction with solar reflectance. Higher emittance values indicate better temperature regulation capabilities, directly impacting building energy efficiency.

Performance indices quantify specific material characteristics, enabling objective comparisons between different roofing solutions. These standardized measurements help facility managers evaluate durability factors across various product options.

Industry Jargon Translated

Load-bearing capacity describes a roof’s ability to support additional weight from equipment, weather events, or maintenance activities. Recycled materials often demonstrate superior strength-to-weight ratios compared to traditional alternatives.

Chemical resistance indicates how effectively materials withstand exposure to industrial pollutants, acids, and other corrosive substances. This property becomes particularly crucial in manufacturing environments where air quality affects roof longevity.

Thermal cycling refers to the repeated expansion and contraction of roofing materials due to temperature fluctuations. Understanding this concept helps explain why certain recycled materials outperform conventional options in extreme climates.

Membrane cohesion describes the molecular-level bonding that determines material strength and flexibility. This characteristic directly influences a roof’s ability to maintain waterproof integrity over time.

Measurement & Units Simplified

Solar Reflectance Index (SRI) combines reflectance and emittance measurements into a single value. Higher SRI numbers indicate better heat management capabilities, typically ranging from 0 to 100.

Wind uplift resistance ratings use standardized pressure measurements to indicate material performance during storms. These ratings help facility managers select appropriate materials for their specific geographic location.

Impact resistance classifications range from Class 1 to Class 4, with Class 4 offering maximum protection. These ratings become especially relevant in regions prone to hail or falling debris.

Material density measurements, expressed in pounds per cubic foot, help predict long-term performance and installation requirements. Understanding density assists in calculating structural load requirements and installation costs.

SECTION 4: DECISION FACTORS

The industrial roofing sector faces mounting pressure to deliver both environmental sustainability and enhanced performance. Facility managers must navigate complex decisions involving material selection, weighing immediate costs against long-term benefits. Recent technological advances in recycled roofing materials have transformed these choices from simple environmental considerations into strategic advantages that directly impact building performance, maintenance costs, and operational efficiency.

Cost Considerations

Initial investment analysis must extend beyond simple material costs to include installation complexity, maintenance requirements, and energy savings potential. Recycled materials often demonstrate superior cost efficiency when evaluated across their complete lifecycle.

Many jurisdictions offer tax incentives and environmental credits for utilizing recycled roofing materials. These financial benefits can significantly offset higher upfront costs while contributing to corporate sustainability goals.

Labor costs typically decrease with recycled materials due to their lighter weight and improved handling characteristics. This advantage becomes particularly significant on large-scale industrial installations.

Energy savings represent a substantial financial benefit, as recycled materials often incorporate advanced thermal properties. These improvements can reduce HVAC costs by 15-30% compared to traditional roofing systems.

Performance Trade-offs

Composite shingles made from recycled materials demonstrate exceptional durability while maintaining aesthetics comparable to traditional materials like slate and clay. These innovative products reduce environmental impact while delivering superior resistance to weathering and UV exposure. (source: Home Evolution)

Wind resistance capabilities often exceed those of conventional materials due to advanced polymer formulations. This enhanced performance proves particularly valuable in regions prone to severe weather events.

Chemical resistance varies among recycled products, necessitating careful selection based on specific facility requirements. Manufacturing environments require special attention to ensure compatibility with airborne pollutants.

Impact resistance typically matches or exceeds traditional materials, particularly in products incorporating recycled rubber compounds. This characteristic provides superior protection against hail and falling debris.

Lifespan & Durability Factors

Modern recycled roofing materials demonstrate exceptional longevity under proper maintenance protocols. Many systems maintain peak performance for 20-30 years, significantly exceeding traditional roofing lifespans.

Ultraviolet resistance remains stable throughout the material’s lifetime, preventing premature degradation and maintaining protective properties. This stability reduces replacement frequency and associated costs.

Structural integrity improves with age as recycled materials typically experience less thermal fatigue than conventional alternatives. This characteristic helps prevent common failure points like seam separation and surface cracking.

Warranty coverage often extends beyond standard terms, reflecting manufacturer confidence in long-term performance. These enhanced warranties provide additional value protection for facility investments.

SECTION 5: COMMON CHALLENGES

Industrial roofing with recycled materials presents specific technical challenges that demand strategic solutions. Recent industry data indicates that improper material selection or installation can reduce roof lifespan by up to 40% compared to optimal implementations. Understanding and addressing these challenges systematically enables facility managers to maximize the benefits of recycled materials while avoiding common pitfalls that compromise roof integrity.

Frequent Problems & Solutions

Material compatibility represents the primary challenge when integrating recycled components into existing roof systems. Differences in thermal expansion rates between materials can create stress points that compromise structural integrity over time.

Composite shingles made from recycled materials demonstrate exceptional durability while maintaining complete recyclability, reducing construction waste and environmental impact. These innovative solutions provide superior resistance to environmental stressors while maintaining structural integrity throughout their lifecycle. (source: Brava Roof Tile)

Installation irregularities frequently occur when contractors lack experience with recycled materials. Specialized training and certification programs ensure proper application techniques, preventing premature system failures.

Weather exposure during installation can affect material performance, particularly with temperature-sensitive components. Establishing strict installation protocols that account for environmental conditions helps maintain material integrity.

Warning Signs To Watch For

Surface deterioration often manifests through granule loss or material displacement. Regular inspections should focus on areas showing accelerated wear or unusual patterns of degradation.

Membrane separation at seams indicates potential material incompatibility or installation defects. Early detection through infrared scanning can identify problem areas before water infiltration occurs.

Changes in building energy efficiency may signal compromised roof performance. Monitoring utility costs provides early warning of insulation failures or material degradation.

Unusual odors or air quality changes within the facility can indicate chemical breakdown of roofing materials. Immediate investigation prevents potential health hazards and structural damage.

Preventative Approaches

Implementing comprehensive material testing protocols ensures compatibility between new and existing components. Laboratory analysis of material samples helps predict long-term performance under specific conditions.

Establishing detailed maintenance schedules based on material characteristics prevents premature degradation. Documentation of inspection findings enables tracking of performance trends and early problem identification.

Training facility staff in proper roof access procedures reduces mechanical damage from maintenance activities. Creating designated walkways and equipment zones protects vulnerable areas from excessive wear.

Developing emergency response protocols for extreme weather events minimizes potential damage. Quick deployment of temporary protection measures prevents cascading failures during severe conditions.

SECTION 6: NEXT STEPS & RESOURCES

The industrial roofing sector faces unprecedented challenges in material selection and performance optimization. With recycled roofing materials rapidly evolving, facility managers must develop systematic approaches to evaluation, implementation, and ongoing assessment. Strategic planning and proper resource utilization can mean the difference between a sustainable, high-performance roof system and a costly liability that compromises building integrity.

Questions To Ask Providers

Material composition and processing methods significantly impact performance. Request detailed breakdowns of recycled content percentages, material sources, and quality control procedures used during manufacturing.

Performance testing data reveals real-world capabilities. Ask for documentation of thermal cycling resistance, wind uplift ratings, and impact resistance classifications specific to your climate zone.

Installation expertise directly affects system longevity. Verify contractor certifications, training programs, and experience with specific recycled materials being considered.

Warranty coverage must align with performance expectations. Review coverage terms, exclusions, and manufacturer support systems for addressing potential issues.

Industry Standards & Guidelines

Composite shingles manufactured from recycled materials demonstrate exceptional durability while maintaining complete recyclability at end-of-life, creating a sustainable cycle that reduces construction waste and environmental impact. These materials provide superior resistance to environmental stressors while maintaining structural integrity throughout their operational lifespan. (source: Brava Roof Tile)

ASTM International standards establish minimum performance requirements for recycled roofing materials. Regular updates reflect advancing technology and emerging best practices.

Cool Roof Rating Council (CRRC) guidelines provide standardized metrics for thermal performance. These ratings enable objective comparisons between different recycled material options.

FM Global standards address fire resistance and wind uplift requirements. Compliance ensures appropriate material selection for specific building types and locations.

Further Learning Simplified

Professional organizations offer specialized training programs focused on recycled roofing materials. These courses provide technical insights and practical implementation strategies.

Industry publications track emerging technologies and performance data. Regular review helps identify trends and innovations that impact material selection.

Manufacturer technical bulletins detail specific application requirements and limitations. These resources prevent common installation errors that compromise system performance.

Case studies document real-world performance across various climate zones and building types. Analysis of these examples guides material selection and implementation strategies.

Looking Ahead

The data is clear: recycled roofing materials now outperform traditional options by up to 40% in durability while reducing environmental impact by millions of tons annually.

These advances in material science and manufacturing processes have transformed recycled components from an environmental choice into a strategic advantage for industrial facilities.

As extreme weather events increase and environmental regulations tighten, the integration of high-performance recycled materials has become essential for protecting industrial assets and optimizing facility operations.

The evidence demonstrates that facilities implementing these advanced materials can expect enhanced durability, reduced maintenance costs, and superior environmental performance – a combination that defines the future of industrial roofing.

The question is no longer whether to adopt recycled roofing materials, but how quickly facilities can implement these proven solutions.

FREQUENTLY ASKED QUESTIONS

Q. What are recycled materials in commercial roofs?

A. Recycled roofing materials transform waste products into high-performance components, enhancing durability and sustainability. These materials include synthetic shingles made from reclaimed plastics and metal roofing created from industrial recyclables.

Q. How are recycled materials applied to industrial roofs?

A. Recycled materials are integrated into industrial roofing through innovative processes, enhancing durability and sustainability. Applications include single-ply membranes and composite insulation panels, which provide superior performance and efficiency.

Q. What key terminology relates to recycled commercial roofs?

A. Terms like composite shingles, thermal emittance, and chemical resistance are crucial. Understanding these concepts is vital for effective communication and decision-making regarding roofing material options.

Q. What decision factors should I consider for an industrial roof?

A. Consider factors including installation costs, performance metrics, and potential energy savings. The long-term value of recycled materials may outweigh initial costs, making strategic investment essential for optimal roof performance.

Q. What common challenges arise with recycled roofing materials?

A. Challenges include material compatibility and installation irregularities, which can affect longevity. Understanding these issues and implementing proper techniques is essential for maximizing performance and durability.

Q. What are the next steps in using recycled roofing materials?

A. To proceed, ask potential providers about material composition, performance data, and installation practices. Review industry guidelines and seek additional training resources to facilitate informed decisions.

Q. How do recycled materials impact environmental sustainability in roofing?

A. Recycled materials reduce landfill waste and conserve resources while providing high-performance roofing solutions. Their use significantly mitigates the environmental footprint of industrial roofs, aligning with sustainability goals.