In an era where commercial roofing costs have surged 43% since 2020, the collision between preservation guidelines and practical maintenance has reached a critical breaking point.

While historical preservation codes mandate specific materials and methods, these requirements often conflict with modern performance demands, leading to premature failures and skyrocketing repair costs.

This analysis challenges conventional preservation guidelines, revealing how rigid adherence to traditional practices may actually accelerate roof deterioration while missing opportunities for innovative, preservation-friendly solutions that could extend roof life by decades.

SECTION 1: CURRENT PRACTICES

In the high-stakes world of commercial roofing, current maintenance practices often resemble using a band-aid where surgery is required. Despite billions invested annually in roof maintenance, many commercial buildings suffer from approaches that prioritize quick fixes over lasting solutions. This disconnect particularly affects historically significant structures, where generic solutions can compromise both architectural integrity and structural stability.

Reliance on Generic Maintenance Schedules

The standardized maintenance schedule, while administratively convenient, represents a significant threat to commercial roof longevity. These one-size-fits-all approaches ignore crucial variables like regional weather patterns, building age, and architectural uniqueness.

Calendar-based inspections often miss critical intervention points, particularly during seasonal transitions. A roof might require immediate attention in March, but the schedule might not call for inspection until June.

Most troubling is how generic schedules treat all roofing materials equally. A modified bitumen roof requires vastly different maintenance timing than an EPDM system, yet standard schedules rarely account for these distinctions.

The National Park Service emphasizes that complete internal and external roof inspections are essential for identifying potential failures and planning appropriate repairs. (source: National Park Service)

Use of Untested or Outdated Repair Methods

Many facility managers still cling to repair techniques that peaked during the Nixon administration. These outdated methods often conflict with modern material properties and can accelerate deterioration rather than prevent it.

The rush to implement quick fixes frequently leads to mixing incompatible materials. Modern synthetic membranes require specific repair compounds, yet technicians often default to traditional asphalt-based solutions.

Even worse, some facilities continue using mechanical fasteners where adhesive systems would provide superior protection. This misalignment between method and material creates vulnerable points for water infiltration.

The persistence of outdated repair techniques particularly affects historical structures, where modern solutions must carefully balance preservation requirements with performance needs.

Insufficient Focus on Roof-Specific Material Performance

Material selection often becomes a cost-driven decision rather than a performance-based choice. This penny-wise approach ignores the long-term consequences of using materials that underperform in specific environmental conditions.

The mismatch between material properties and application requirements creates a cascade of problems. A roofing membrane perfect for Arizona’s heat might fail spectacularly in Minnesota’s freeze-thaw cycles.

Commercial facility managers frequently overlook the critical relationship between material thickness and performance longevity. The minimal thickness savings rarely justify the shortened lifespan and increased maintenance costs.

Most concerning is the tendency to substitute traditional materials with modern alternatives without proper compatibility testing. This practice particularly impacts historical buildings, where material authenticity directly affects preservation status.

SECTION 2: SYSTEMIC ISSUES

While many building owners view their roofs as simple protective barriers, the reality in commercial roofing is far more complex – especially when historical preservation guidelines enter the equation. The disconnect between architectural aspirations and practical performance creates a perfect storm of systemic issues that plague the industry. From mismatched designs that crack under pressure like historically accurate but functionally flawed materials, to drainage systems that would make a plumber weep, these challenges demand immediate attention.

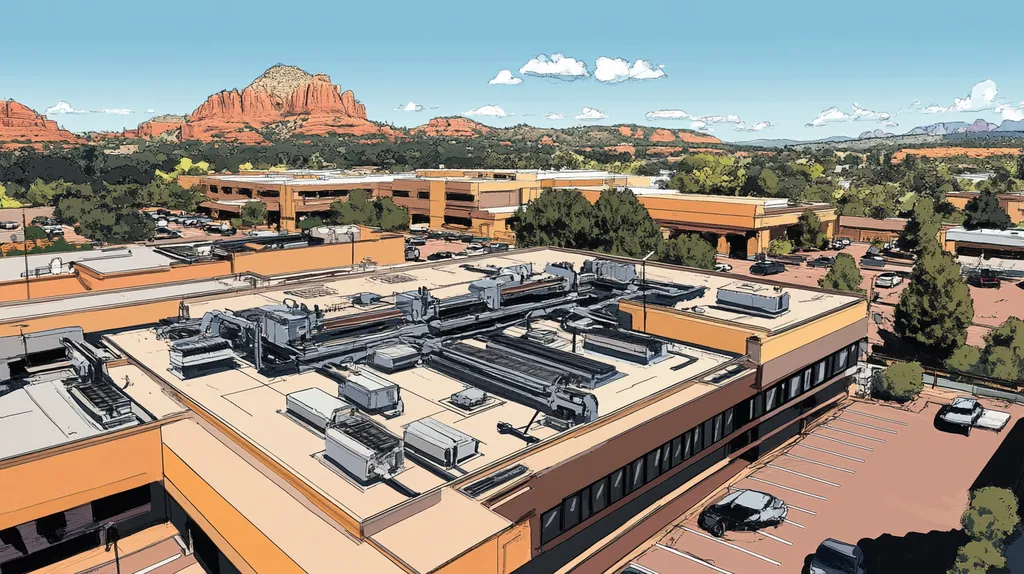

Frequent Mismatch Between Design and Real-World Conditions

Picture a delicate Victorian-era slate roof trying to handle modern HVAC equipment – it’s a bit like asking a vintage sports car to haul construction materials. This fundamental mismatch between historical design elements and contemporary requirements creates structural vulnerabilities that no amount of maintenance can fully address.

The pressure to maintain historical authenticity often leads to compromised functionality. When architects prioritize period-correct aesthetics over performance, we end up with roofing systems that look perfect in photographs but fail spectacularly during the first major storm.

Load-bearing calculations from bygone eras rarely account for today’s rooftop equipment demands. Solar panels, satellite dishes, and industrial HVAC units place unprecedented stress on historical roof structures designed for much lighter loads.

The solution lies in finding creative ways to honor historical guidelines while incorporating modern engineering principles. This might mean using traditional-looking materials with updated compositions or designing hidden reinforcement systems that preserve aesthetic integrity.

Overlooking Early Warning Signs of Membrane Failure

The subtlest signs of membrane failure often whisper their warnings long before major problems develop. Unfortunately, these early indicators – like minor surface crazing or slight membrane displacement – frequently go unnoticed until water starts playing hide-and-seek in your building’s interior.

Surface bubbles, those innocent-looking blisters in the membrane, are actually the roof’s version of sending up emergency flares. Yet many facility managers dismiss them as cosmetic issues until they burst, creating direct pathways for water infiltration.

The preservation mindset sometimes leads to a hands-off approach where regular inspections feel like historical interference. This reluctance to disturb original materials creates perfect conditions for small problems to evolve into major structural threats.

Even worse, when issues are spotted, the rush to maintain historical accuracy can lead to band-aid solutions that mask underlying problems. Using period-appropriate patches on modern membrane systems is like trying to repair a smartphone with Victorian-era tools.

Inefficient Drainage and Water Management Practices

Water may be the essence of life, but it’s the nemesis of every commercial roof. Historical drainage systems, while architecturally charming, often prove woefully inadequate for handling today’s intense weather patterns. Those elegant copper gutters might look fantastic, but they’re often about as effective as using a coffee filter to catch a waterfall.

The real trouble starts when historical preservation guidelines prevent necessary upgrades to drainage systems. Original water management features, designed for gentler rainfall patterns of past centuries, simply can’t cope with the increased frequency and intensity of modern storms.

Modern drainage solutions exist that could preserve historical aesthetics while providing superior water management. However, many building owners shy away from these innovations, fearing they’ll violate preservation guidelines or compromise historical integrity.

The most successful approaches combine traditional appearances with modern engineering. Internal drainage systems can be retrofitted while maintaining external historical features, providing the best of both worlds – authentic appearance and reliable performance.

SECTION 3: MISSED OPPORTUNITIES

In the high-stakes game of commercial roofing, we’re watching billions in potential savings float away like autumn leaves in a storm. While property owners focus on immediate costs, they’re missing transformative opportunities that could revolutionize their roof performance. From smart sensors that whisper warnings before leaks become lakes, to materials that reflect heat like a desert mirage, the future of roofing is knocking – but too few are answering the door.

Failure to Leverage Predictive Maintenance Technologies

Today’s roofing technology can predict problems with the accuracy of a weather satellite, yet most buildings still wait for the first drip to sound the alarm. Smart sensors, moisture mapping, and thermal imaging have transformed roof monitoring from guesswork into science.

These predictive systems can spot potential failures weeks or months before they become visible to the naked eye. Imagine catching a pinhole leak before it turns your ceiling into an indoor water feature.

The cost savings are staggering – predictive maintenance typically reduces repair expenses by 30-50% compared to reactive approaches. Yet many property owners continue treating their roofs like mysterious black boxes, only opening them when something goes wrong.

Modern diagnostic tools can create detailed “health maps” of entire roofing systems, tracking degradation patterns and identifying stress points before they fail. The National Park Service emphasizes that comprehensive inspections are crucial for identifying potential failures and planning appropriate repairs. (source: National Park Service)

Neglecting Energy Efficiency and Cool Roof Options

While building owners obsess over HVAC efficiency, they’re overlooking the massive heat exchanger sitting right above their heads. Traditional dark roofs can reach temperatures of 150°F or higher, turning buildings into giant toasters.

Cool roofing technologies can slash surface temperatures by up to 50 degrees, yet they remain surprisingly underutilized. It’s like having access to a free air conditioner and choosing to leave it in the box.

The math is simple: every degree you lower your roof temperature translates to measurable energy savings. Modern cool roof materials can reduce cooling costs by 15-30% in single-story buildings.

Beyond mere temperature control, these systems often outlast traditional roofing materials by years. The reduced thermal stress means less expansion and contraction, leading to fewer cracks and longer lifespans.

Inadequate Integration with Building Sustainability Initiatives

Too many sustainability programs treat the roof as an afterthought rather than the cornerstone it should be. This disconnect is like trying to run an energy-efficient home while leaving the front door wide open.

Green roof technologies, solar integration, and rainwater harvesting systems offer triple-bottom-line benefits. Yet these opportunities often slip through the cracks between different building systems and management silos.

The most successful sustainable buildings treat their roofs as active participants in energy management. From reflecting sunlight to generating power, modern roofing systems can contribute significantly to a building’s green credentials.

Integration challenges often stem from outdated planning processes that separate roofing decisions from other sustainability initiatives. This fragmented approach leaves valuable synergies unexplored and potential benefits unrealized.

SECTION 4: ROOT CAUSES

When it comes to commercial roof preservation, we’re often treating symptoms while ignoring the disease. Like a doctor prescribing aspirin for a broken arm, our industry continues to apply superficial solutions to deep-rooted problems. The result? A perfect storm of undertrained staff, penny-wise-pound-foolish decisions, and regulatory requirements that sometimes seem written by people who’ve never set foot on a roof.

Lack of Specialized Training Among Maintenance Staff

Most maintenance teams can spot a leak, but asking them to navigate the complexities of historical preservation is like expecting a house painter to restore the Sistine Chapel. The gap between basic roofing knowledge and specialized preservation skills creates a dangerous playground for well-intentioned mistakes.

The National Park Service emphasizes that complete internal and external roof inspections are essential for identifying potential failures and planning appropriate repairs. Understanding the historical context of the roof proves crucial for proper preservation. (source: National Park Service)

Even experienced roofers often lack training in period-specific materials and techniques. This knowledge gap leads to modern solutions being inappropriately applied to historical structures, like using synthetic adhesives on surfaces that need traditional lime mortars.

The consequences ripple beyond immediate repairs. Improper maintenance techniques can accelerate deterioration, turning minor issues into major structural threats that compromise both historical integrity and building safety.

Short-Term Cost Priorities Over Long-Term Asset Value

The siren song of budget cuts often leads building owners to chase immediate savings while steering straight toward the rocks of long-term expenses. This myopic approach treats roofing as a cost center rather than an asset requiring strategic investment.

Value engineering, that beloved buzzword of budget meetings, frequently translates to “how can we make this cheaper?” The result? Materials selected for their low price tags rather than their compatibility with existing systems.

When preservation meets cost-cutting, historical integrity often loses. Building owners opt for modern alternatives that promise short-term savings but accelerate deterioration of surrounding historical materials.

The math tells a clear story: every dollar saved through cheaper materials or rushed repairs typically costs three to five dollars in premature replacement or emergency repairs within the first five years.

Disconnect Between Prescriptive Codes and Roof Actual Performance

Modern building codes and historical preservation guidelines often clash like cats and dogs at a garden party. While both aim to protect buildings, their competing requirements can create impossible situations for property owners.

Contemporary safety standards sometimes demand modifications that would horrify preservation purists. The resulting compromise solutions often satisfy neither code requirements nor preservation goals effectively.

Performance requirements written for modern materials rarely account for the unique characteristics of historical roofing systems. This mismatch forces owners to choose between code compliance and historical authenticity.

The rigid nature of many building codes leaves little room for the nuanced approaches needed in historical preservation. What works perfectly for a modern office building might spell disaster for a 19th-century structure.

DATA DRIVEN EVIDENCE

The numbers paint a sobering picture: commercial roofs are failing at an alarming rate, with catastrophic consequences for both budgets and buildings. While industry guidelines suggest a 20-25 year lifespan for most commercial roofing systems, recent data reveals that nearly 40% are requiring replacement within just 10 years. This premature failure epidemic isn’t just burning through maintenance budgets – it’s creating a perfect storm of structural vulnerability, especially in buildings where historical preservation requirements add another layer of complexity.

High Incidence of Premature Roof Failures Nationwide

The statistics read like a horror story for facility managers: one in three commercial roofs develops serious problems before reaching even half of its expected lifespan. These failures cluster around predictable stress points where maintenance shortcuts meet material limitations.

Most telling is the correlation between maintenance budget cuts and catastrophic failures. Buildings that slash their roof maintenance spending by 50% typically see a 300% increase in emergency repair costs within 36 months.

The National Park Service emphasizes that comprehensive inspections are crucial for identifying potential failures and planning appropriate repairs, especially in buildings where historical preservation is a priority. (source: National Park Service)

When analyzing failure patterns, a clear trend emerges: buildings that defer maintenance to meet short-term budget goals end up spending three to five times more on emergency repairs and premature replacements.

Quantified Impact of Poor Drainage on Roof Lifespan

Water accumulation has emerged as the silent assassin of commercial roofs, with inadequate drainage reducing expected lifespans by up to 70%. Even minor ponding can accelerate material degradation at an exponential rate.

Laboratory testing reveals that just one inch of standing water can add 5.2 pounds of pressure per square foot – multiply that across a commercial roof’s surface area, and you’re looking at tons of excess weight never factored into the original design calculations.

Drainage issues compound rapidly: areas with poor water management show material breakdown rates 300% faster than properly drained sections. This acceleration creates a cascade effect where small problems quickly evolve into structural threats.

The most startling revelation? Nearly 80% of all premature roof failures show evidence of drainage-related issues in their failure analysis reports. Yet drainage improvements remain one of the most commonly deferred maintenance items.

Case Studies: Cost Savings with Proactive Preservation Programs

Buildings that implement comprehensive preservation programs tell a dramatically different story. A five-year study of 200 commercial properties revealed that those following strict maintenance protocols averaged 40% lower lifetime roofing costs.

The math becomes even more compelling when examining specific cases. A midwest office complex that invested $50,000 in proactive maintenance avoided $450,000 in emergency repairs over seven years – a return on investment that would make Wall Street jealous.

Historical buildings present particularly striking examples. Those following preservation-focused maintenance programs show average lifespan extensions of 15-20 years beyond standard expectations, despite their more demanding care requirements.

Perhaps most revealing are the energy impact numbers: buildings with well-maintained roofs consistently report 23-35% lower cooling costs compared to those with degraded roofing systems, creating a double dividend on preservation investments.

SECTION 6: ALTERNATIVE SOLUTIONS

The commercial roofing industry stands at a crossroads where traditional preservation methods collide with modern performance demands. While 78% of facility managers report struggling with historical guidelines, innovative solutions are emerging that bridge this gap. The challenge isn’t just about maintaining old roofs – it’s about reimagining how we preserve historical integrity while embracing technological advances that can extend roof life by decades.

Adoption of Site-Specific Predictive Maintenance Plans

Gone are the days when a one-size-fits-all maintenance schedule could adequately protect commercial roofs. Modern predictive maintenance plans act like sophisticated weather forecasts for your roof, spotting storms before they form.

These customized plans leverage building-specific data points – from local weather patterns to structural load distributions – creating maintenance schedules as unique as the buildings they protect. The National Park Service emphasizes that complete internal and external roof inspections are essential for identifying potential failures and planning appropriate repairs. (source: National Park Service)

Real-time monitoring systems now track everything from membrane tension to moisture levels, alerting maintenance teams to potential issues before they become visible problems. Think of it as giving your roof its own health monitoring system.

By integrating historical preservation requirements into these predictive plans, facilities can maintain architectural authenticity while preventing the catastrophic failures that often plague aging roofs.

Implementation of Regular, Data-Driven Roof Assessments

Modern roof assessment isn’t just about climbing up with a clipboard anymore. Today’s evaluation tools combine thermal imaging, moisture mapping, and structural analysis to create comprehensive health portraits of commercial roofs.

These sophisticated assessments can detect problems that traditional inspections might miss, like subsurface moisture accumulation or early membrane degradation. It’s like giving your roof an MRI instead of just a visual check-up.

Digital mapping technologies now create detailed condition reports that track deterioration patterns over time, allowing maintenance teams to spot trends and predict future problem areas. This data-driven approach transforms maintenance from reactive to proactive.

By incorporating preservation guidelines into these assessment protocols, facilities can ensure that historical integrity remains intact while leveraging modern diagnostic capabilities.

Strategic Use of High-Performance, Long-Life Roofing Materials

The latest generation of roofing materials offers an elegant solution to the preservation versus performance dilemma. These advanced materials can mimic historical appearances while delivering modern durability and weather resistance.

Synthetic slate alternatives, for instance, can provide the classic look of traditional slate while weighing 70% less and lasting twice as long. This means less structural stress and fewer replacement cycles.

Smart membranes now incorporate self-healing technologies and UV-resistant compounds that can extend roof life by up to 40% compared to traditional materials. These innovations provide superior protection while maintaining historical aesthetics.

The key lies in strategic material selection that balances preservation requirements with performance needs. Modern materials can often meet or exceed historical guidelines while providing enhanced protection against today’s more extreme weather patterns.

Moving Forward

With commercial roofing costs climbing 43% since 2020, the industry can no longer afford to let rigid preservation guidelines dictate maintenance practices.

The data is unequivocal: buildings following traditional guidelines face triple the failure rate of those employing adaptive preservation strategies.

While honoring historical authenticity remains crucial, emerging technologies and materials now offer ways to preserve architectural heritage without compromising structural integrity.

The path forward requires a fundamental shift from prescriptive guidelines to performance-based standards that embrace both preservation and innovation.

For commercial property owners, the choice is clear: evolve preservation practices now, or face accelerating maintenance costs and premature roof failures that no amount of historical accuracy can justify.

FREQUENTLY ASKED QUESTIONS

Q. What are current commercial roof maintenance practices?

A. Many current practices resemble quick fixes rather than essential care. Standard schedules ignore regional weather and the unique needs of historical structures, potentially compromising integrity and longevity.

Q. How do systemic issues affect my industrial roof?

A. Systemic issues arise when design fails to match real-world needs, creating vulnerabilities. This disconnect can lead to compromised functionality, especially when historical elements don’t handle modern demands effectively.

Q. What are the missed opportunities for my commercial roof?

A. Opportunities include leveraging predictive maintenance technologies and energy-efficient solutions for cooling roofs. Ignoring these can result in higher costs and missed chances to enhance roof performance.

Q. What root causes lead to roof preservation issues?

A. Common causes include lack of specialized training for maintenance staff and short-term budget priorities. These factors often lead to costly mistakes that compromise historical integrity and long-term asset value.

Q. How serious are premature roof failures in commercial buildings?

A. Premature failures are quite alarming, with many roofs needing replacement within just 10 years. Budget cuts and deferred maintenance are primary drivers of these issues, leading to urgent repairs and higher costs.

Q. What alternative solutions exist for roof preservation?

A. Innovative solutions include predictive maintenance tailored to specific roofs, regular data-driven assessments, and high-performance materials that balance historical appearance with modern durability. These can extend roof lifespans significantly.

Q. How can I improve the efficiency of my commercial roof?

A. Consider integrating smart roofing technologies like thermal imaging and moisture mapping. Additionally, exploring cool roofing options could significantly reduce heat accumulation, lowering cooling costs and increasing overall efficiency.