Every year, industrial facilities waste millions on preventable roof repairs, with 80% of commercial roof failures traced directly to inadequate maintenance practices. Despite advanced materials and installation methods, myths about roof care continue causing costly mistakes.

From ignoring seasonal inspections to believing in ‘maintenance-free’ systems, these misconceptions lead to premature aging and unexpected failures. The consequences ripple through entire operations, affecting everything from energy efficiency to employee safety.

This guide separates roofing fact from fiction, offering evidence-based solutions for facility managers committed to protecting their valuable assets.

SECTION 1: COMMON MISCONCEPTIONS

Many property owners and facility managers operate under dangerous misconceptions about industrial roof maintenance. Shockingly, studies reveal that 40% of roofing failures stem from inadequate upkeep. Critical mistakes, such as skipping seasonal inspections or subscribing to the ‘set and forget’ mentality, can lead to expensive repairs or even premature roof replacements. This section aims to dismantle these myths and underscore the necessity of proactive maintenance practices.

Ignoring Seasonal Inspections

A prevalent misconception is that seasonal inspections aren’t needed, particularly in temperate climates. However, these check-ups are vital for catching problems before they escalate. For instance, a minor crack could allow moisture to seep in, setting the stage for mold growth and costly structural damage.

Research reveals that roofs subjected to regular inspections can last up to 30% longer than those that aren’t. Neglecting these crucial evaluations can transform minor wear and tear into expensive emergencies. Overlooking seasonal check-ups can cost property owners hundreds—if not thousands—of dollars in repairs.

Seasonal inspections also help pinpoint debris accumulation, which can trap moisture and degrade roofing materials. By sticking to an inspection schedule, facility managers can proactively tackle these issues and preserve the roof’s integrity.

In summary, making seasonal inspections a fixture of maintenance routines isn’t just smart; it’s essential for prolonging the roof’s health and securing long-term savings.

Believing in ‘Set and Forget’ Roofs

Another common myth is that once a roof is installed, minimal attention is needed thereafter. This ‘set and forget’ mindset poses serious risks. Every roof, no matter its materials or design, demands ongoing care to endure the challenges posed by weather and time.

For example, regularly cleaning gutters and drainage systems is crucial for preventing water pooling, which can lead to leaks and structural damage. Property managers may assume that an intact appearance means everything is fine, but underlying problems can develop without warning.

Environmental changes, like new plant growth or nearby construction, can also affect a roof’s performance. Such factors can hasten wear and tear, requiring prompt action to avert costly repairs.

Ultimately, treating a roof as a ‘set and forget’ investment compromises its longevity and can result in unexpected expenses and operational disruptions.

Overlooking Equipment Impact

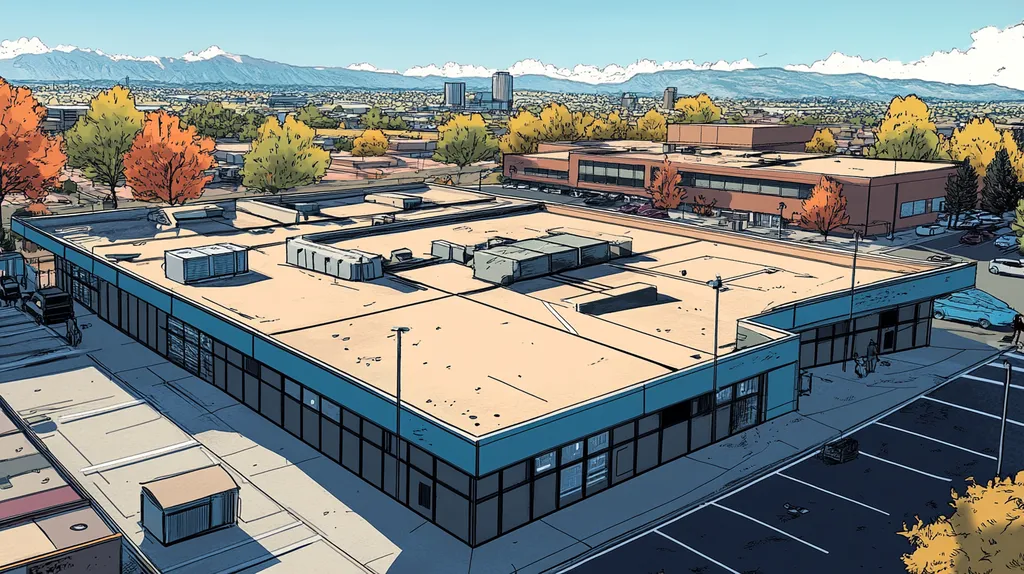

Many facility managers underestimate the impact rooftop equipment has on the roofing system. This includes HVAC units, vents, and other installations that can degrade roofing materials over time. Inadequately maintained equipment can result in leaks and other damage.

For instance, poorly serviced HVAC units may release condensate that harms the roof underneath. Additionally, equipment ill-suited for the roof’s surface can hasten wear and undermine structural integrity. Regular assessments should encompass both the roof and the condition of any rooftop equipment.

Ensuring proper weight distribution and clear drainage pathways around equipment is crucial for damage prevention. Ignoring equipment issues could lead to severe complications, like compromised waterproofing or mold growth.

Incorporating equipment impact assessments into a comprehensive maintenance plan is vital for upholding the roof’s longevity and escaping unnecessary repair costs.

SECTION 2: PRACTICAL IMPLICATIONS

Neglecting the maintenance of industrial roofs can lead to serious, often costly repercussions. Failing to address seemingly minor issues, like small leaks or cracks, can spiral into major problems that threaten the entire structure. In fact, studies suggest that a staggering 70% of roof failures are linked to insufficient maintenance. Recognizing these implications is crucial for property owners and facility managers dedicated to safeguarding their investments.

Consequences of Deferred Maintenance

When routine maintenance is ignored, roofs deteriorate faster than expected. Small problems can quickly evolve into significant damage, resulting in hefty repair bills or the need for a complete roof replacement. For example, a minor leak, left unchecked, can compromise insulation and structural components, escalating the repair cost substantially.

Moreover, putting off maintenance can shorten the lifespan of roofing materials significantly. Industrial roofs are typically engineered to endure for decades, but neglect can slash that longevity. In fact, routine upkeep has been shown to extend a roof’s life by a remarkable 50%.

Additionally, operational costs can skyrocket due to the inefficiencies caused by a deteriorating roof. Facility managers may face increased energy bills as failing insulation forces HVAC systems to work harder to maintain comfortable conditions.

Ultimately, the choice to defer maintenance rarely translates into savings. On the contrary, investing in proactive care ensures smoother operations and substantial long-term savings for property owners.

Impact on HVAC and Ventilation

The state of an industrial roof has a profound impact on HVAC system performance. A well-maintained roof keeps leaks and moisture intrusion at bay, protecting insulation and ductwork from damage. Conversely, when roofs are neglected, HVAC systems are forced into overdrive, resulting in increased energy use and accelerated wear.

For instance, a compromised roof can allow heat to escape, making heating systems work harder during chilly months. This not only drives up utility bills but can also shorten the lifespan of expensive HVAC units.

Additionally, a poorly maintained roofing system can let pollutants and contaminants infiltrate a building. This can create health hazards and negatively affect indoor air quality, endangering employee well-being and productivity.

By committing to regular roof maintenance, businesses can enhance HVAC efficiency, reduce energy costs, and create a more comfortable indoor environment for everyone.

Effects on Employee Comfort and Safety

Prioritizing employee comfort and safety is essential for any industrial facility. A neglected roof can lead to hazardous situations, such as leaks that create slippery floors or mold growth that poses serious health risks to workers.

Furthermore, roofs often support critical equipment, including ventilation systems and exhaust fans. If maintenance is deferred, the functionality of this equipment may be compromised, leading to dangerous fume accumulation and poor air circulation.

For example, if drainage systems aren’t kept clear, water can pool and cause structural damage, jeopardizing the safety of employees below. Regular roof maintenance is vital to prevent accidents and maintain a safe working environment.

By proactively caring for the roof, facilities can foster a better work atmosphere. A strong focus on safety reinforces a company’s commitment to its workforce, resulting in enhanced morale and productivity.

SECTION 3: COST OF MISINFORMATION

The risks associated with overlooking proper roof maintenance are dire for industrial property owners. A staggering study reveals that a whopping 80% of roofing failures can be traced back to a lack of regular upkeep. When misconceptions about maintenance are allowed to take root, the financial fallout can be severe. Underestimating the necessity of routine inspections means property owners may unintentionally prepare for costly repairs and a significant drop in property value.

Financial Burden of Neglect

The financial consequences of neglecting roofing maintenance can accumulate alarmingly. While property owners might think they’re saving money by skipping inspections, this short-sighted strategy often results in skyrocketing costs later. A neglected roof can develop leaks, allowing water to wreak havoc on the building’s interior and structure.

When water seeps into compromised roofing, it triggers a cascade of issues. The cost to remedy water damage can easily dwarf what regular maintenance would have cost. Businesses might find themselves spending thousands on fixing structural damage, remediating mold, and dealing with lost operational time.

Emergency repairs come with their own price tag, typically much higher than scheduled maintenance. These unexpected expenses can stretch budgets thin and lead to unplanned financial burdens, negating any previous savings tied to maintenance neglect. The more urgent these issues become, the greater the bill climbs.

In essence, the choice to bypass regular inspections can lead to a compounding financial headache, making it vital for property owners to embrace proactive maintenance as a standard practice.

Increased Repair and Replacement Costs

Misunderstandings about roofing longevity can drive repair and replacement costs through the roof—literally. Many property owners mistakenly assume that a roof can soldier on without maintenance for years. This misguided belief can postpone vital repairs that, if attended to in time, could significantly extend the roof’s lifespan.

A simple issue, like a worn-out sealant, could go unnoticed during sporadic inspections, giving water just the opening it needs to infiltrate. What began as a trivial repair can snowball into a full-blown roof replacement, a costly endeavor that can range from tens to hundreds of thousands of dollars.

Moreover, neglecting a roof can lead to structural instabilities in the building itself. This deterioration can render a facility unsafe, possibly incurring additional expenses due to code violations and enforcement actions. Increased repair costs can severely slice into profit margins, detracting from potential investments in more strategic areas of the business.

Loss of Property Value

Misguided beliefs regarding roofing maintenance can have a profound negative impact on property value. A well-maintained roof is a cornerstone of any industrial building’s marketability. When maintenance is ignored, the overall perception of the facility’s quality suffers.

Potential buyers often scrutinize the condition of roofs when weighing investment decisions. A roof that exhibits signs of neglect can raise alarm bells, prompting prospective buyers to reconsider their offers. This cautious approach can translate into lower purchase prices or, in some cases, derail deal negotiations altogether.

Furthermore, properties in poor roofing condition can become financial liabilities, demanding significant investments before they can be offloaded. As the months of deferred maintenance stack up, the value of the property dips further. The resultant loss isn’t just an individual concern; it can ripple through the local real estate market.

In the end, consistent investment in regular maintenance is essential for preserving both the functionality and the value of a property, ensuring it remains an attractive option for future buyers.

SECTION 4: REALITY CHECK

For industrial property owners, the stakes of rooftop maintenance couldn’t be higher. A staggering 90% of roof leaks are traced back to poor maintenance and neglecting inspections. Regular upkeep isn’t merely a recommendation; it is essential for preventing costly repairs and extending a roof’s lifespan. This section delves into the critical need for regular inspections, the invaluable role of professional roofing contractors, and the importance of maintaining detailed maintenance records.

Importance of Regular Inspections

Regular roof inspections are the frontline defense against potential issues lurking up high. Ignoring these essential check-ups can escalate minor concerns into major challenges, including leaks, structural damage, and even safety hazards. Studies show that thorough inspections can uncover up to 80% of problems before they spiral out of control, saving property owners substantial amounts in repair costs.

Beyond catching issues, these inspections assess the condition and performance of roof materials over time. A skilled inspector can identify areas needing urgent attention and prioritize repairs, ensuring a proactive maintenance strategy that extends the life of the roof while meeting industry standards and regulations.

Facility managers often underestimate how environmental factors like severe weather and debris accumulation affect roof integrity. Regular inspections play a crucial role in evaluating how external influences, such as heavy snowfall, may lead to water pooling—an issue that can severely damage roofing materials if not promptly addressed.

Finally, consistent inspections yield documentation that becomes invaluable for warranty claims or real estate transactions. Having a detailed inspection record can bolster a property’s value and provide protection against disputes, ensuring that owners are prepared for any eventuality.

Role of Professional Roofing Contractors

Engaging qualified roofing contractors is pivotal for maintaining roof health and effectiveness. These professionals bring not only technical expertise but also access to cutting-edge materials and technologies. A seasoned contractor can navigate the intricacies of the roofing system, ensuring maintenance tasks are executed correctly and safely.

Moreover, these experts stay informed about the latest industry trends and regulatory requirements, which helps ensure compliance and promotes the longevity of the roofing system. An experienced contractor can also suggest enhancements or upgrades, aligning with evolving standards to optimize roof performance.

Additionally, professional contractors can customize a maintenance program that specifically addresses the unique needs of each building. This all-encompassing strategy may include regular inspections, cleaning, repair, and restoration services, fostering a culture of proactive care instead of reactive fixes.

Lastly, many contractors offer warranties on their services, providing added peace of mind for property owners. With such warranties in place, owners can feel secure knowing that any arising issues will be managed without unexpected expenses.

Need for Detailed Maintenance Records

Maintaining detailed records is essential for effective roof management. Comprehensive documentation simplifies processes and mitigates liability. These records should include inspection reports, service histories, and photographs that capture the roof’s condition over time, creating a clear picture of its maintenance journey.

Additionally, robust maintenance records become powerful allies during insurance negotiations or property transactions. A thorough documentation history reflects diligence on the part of the owner, often favorably influencing insurers and potential buyers alike.

Such records also make it easy to track which maintenance tasks have been completed, ensuring that no critical services fall through the cracks. This organized approach helps maintain compliance with warranty obligations and prevents losing coverage due to missed maintenance schedules.

Establishing a meticulous logging system can reveal trends in repair frequency and costs, enabling property managers to budget more efficiently for future maintenance needs. Ultimately, these insights contribute to informed long-term roofing strategies that prioritize durability and cost-effectiveness.

SECTION 5: EVIDENCE-BASED ALTERNATIVES

Neglecting routine maintenance for industrial roofs can lead to soaring repair costs and unexpected failures. Research shows that regular upkeep can extend a roof’s lifespan by an impressive 50%. It’s crucial for property owners to grasp the importance of implementing structured maintenance practices, strategically budgeting, and curtailing unnecessary foot traffic to protect their investments. This section explores these essential strategies for ensuring roof longevity.

Implementing Preventive Maintenance

Preventive maintenance is non-negotiable for anyone serious about their roofing strategy. Regular inspections can catch small concerns before they become hefty problems. For example, simply checking for debris buildup can prevent damaging water pooling that often leads to leaks.

Industry experts recommend conducting roof inspections twice a year, ideally in spring and fall. This timing allows for quick identification of any wear and damage caused by changing seasons. Creating a checklist for maintenance tasks can further streamline the process and help ensure no detail is missed.

Documenting these maintenance activities can yield valuable insights over time. This data helps facility managers track roof performance and influences future decisions regarding repairs and replacements. Informed decision-making based on hard evidence leads to better resource allocation and can result in significant cost savings.

While investing in preventive maintenance might seem costly initially, it typically pays off over time. A well-maintained roof is far less likely to suffer unexpected expenses due to serious damage, ultimately fortifying the facility’s financial health.

Budgeting for Routine Maintenance

Smart budgeting is key to keeping an industrial roof in top shape. Owners should earmark a specific percentage of the property’s value annually for ongoing roof upkeep. Studies suggest that allocating 1-3% of a building’s value can help guard against larger costs in the future.

Regularly reviewing the maintenance budget ensures it adapts to the evolving needs of the roof. Key considerations include the local climate, the roof’s age, and the type of materials used. For instance, a flat roof in a heavy rainfall area may require more frequent attention than one in a dry region.

It’s also essential to prioritize routine maintenance projects within the budget. Immediate concerns, such as leaks or debris damage, should take precedence over cosmetic upgrades. This focus safeguards the assets and keeps operations running smoothly.

A proactive budgeting approach cultivates a maintenance-first culture within the organization. This mindset promotes better communication between property managers and maintenance teams, ensuring everyone understands the importance of timely roof care.

Minimizing Foot Traffic on Roofs

Foot traffic can be a significant factor in wearing down roofing materials prematurely. Excessive foot traffic can lead to surface degradation, threatening the roof’s overall integrity. Reducing access not only protects the roof but also enhances safety for all personnel.

Implementing designated walkways or access points can effectively manage roof traffic. Adding protective materials, like walk pads, can minimize wear in high-traffic zones. These minor investments can lead to big savings by avoiding costly repairs related to roof damage.

Educating staff about the effects of foot traffic is equally important. Raising awareness fosters a culture that respects the roof and its maintenance requirements. Regular training sessions can reinforce these principles and ensure everyone grasps the significance of limiting unnecessary roof access.

Additionally, scheduling maintenance tasks during off-peak hours can ease congestion on the roof. This approach allows for essential work to be completed without impacting ongoing operations or jeopardizing the roof’s integrity.

SECTION 6: TEST AND VERIFY

In the fast-paced world of industrial roofing, the stakes are high. Failing to conduct routine maintenance can lead to thousands of dollars in repairs and even premature roof failure. A study by the Roofing Industry Alliance for Progress reveals that diligent preventative care can extend the lifespan of a roof by up to 50%. That’s why systematic testing and verification are not just smart—they’re essential for protecting investments and ensuring compliance with industry standards.

Conducting Semi-Annual Inspections

Regular semi-annual inspections are the secret weapon against roof deterioration. These inspections should zero in on high-risk areas such as seams, penetrations, and flashings—spotting trouble before it turns into a crisis. Trained professionals can unearth weaknesses that might go unnoticed to the untrained eye.

Visual checks paired with moisture scanning can reveal hidden leaks that threaten the roof membrane. For example, unnoticed water intrusion can shorten a roof’s lifespan drastically. Tackling these issues head-on prevents them from escalating into major repairs down the line.

Documenting findings from these inspections creates a clear record of the roof’s condition over time. This valuable information not only aids in future maintenance decisions but also helps when budgeting for repairs, making the roof management process more strategic.

In essence, routine inspections serve as a safety net, enabling facility managers to implement preventive measures before minor issues evolve into significant obstacles.

Evaluating Roof Performance Post-Weather Events

Severe weather poses a significant threat to industrial roofs. After storms, heavy snowfall, or high winds, assessing roof performance becomes a top priority. Facility managers should conduct these evaluations promptly to catch any damage early.

For instance, strong winds may dislocate membrane sections, while heavy snow can strain the structure. Inspecting the roof immediately after these events allows for quick repairs, preserving the roofing system’s integrity.

Leveraging technology, such as drones, can greatly enhance post-weather evaluations. Drones provide detailed aerial views, allowing for thorough assessments without risking safety during hazardous conditions.

Ultimately, understanding how weather affects roof performance informs future design choices, increasing resilience and longevity for roofing systems.

Verifying Adherence to Industry Standards

Adhering to industry standards is not just about regulatory compliance; it’s the foundation for roofing durability. Facility managers must ensure their roofs meet guidelines established by organizations like the American Society for Testing and Materials (ASTM).

Verification involves assessing materials, installation methods, and ongoing maintenance practices. Using certified materials helps roofs withstand environmental stresses and ensures a prolonged lifespan.

Additionally, implementing maintenance that aligns with industry standards mitigates potential liability issues. Regular audits serve as proof of compliance, which is valuable for insurance claims and warranty protections.

Ultimately, validating adherence to these standards not only safeguards investments but also boosts the overall performance and safety of industrial roofing systems.

The Bottom Line

With 80% of industrial roof failures traced to poor maintenance, facility managers can’t afford to perpetuate myths about roofing care.

Regular inspections, professional maintenance, and detailed record-keeping aren’t optional extras—they’re essential investments that can extend a roof’s lifespan by up to 50%.

The evidence is clear: proactive maintenance costs just 1-3% of a building’s value annually, while reactive repairs can spiral into hundreds of thousands in emergency fixes and operational disruptions.

By implementing systematic inspections, establishing clear maintenance protocols, and staying current with industry standards, facility managers can protect their assets and avoid joining the ranks of preventable roofing failures.

The choice is simple: invest in maintenance now or pay exponentially more later.

FREQUENTLY ASKED QUESTIONS

Q. What misconceptions exist about commercial roof maintenance?

A. Many believe seasonal inspections are unnecessary, which can lead to severe problems. Ignoring these check-ups often transforms minor issues into costly emergencies. Regular evaluations are crucial to prevent mold, leaks, and extensive repairs, ensuring your roof remains strong and reliable.

Q. How can neglecting industrial roof maintenance affect me?

A. Ignoring regular maintenance can lead to leaks and dangerous structural issues. Over time, minor problems can escalate into major damage, resulting in costly repairs or even a complete roof replacement. Proactive care ensures long-term savings and protects your investment.

Q. What financial burdens arise from neglecting my industrial roof?

A. Neglect can lead to hidden leaks and increased repair costs. A simple oversight can snowball into substantial expenses due to water damage, mold remediation, and operational disruptions. Committing to regular inspections saves from unforeseen financial strains later on.

Q. Why are regular inspections essential for industrial roofs?

A. Regular inspections catch potential issues before they evolve into costly repairs. They assess roof material conditions and minimize the risk of leaks and structural damage. Staying ahead of problems can extend a roof’s lifespan while ensuring compliance with safety standards.

Q. How can I optimize my budget for commercial roof maintenance?

A. Set aside 1-3% of your property’s value annually for maintenance tasks. Regularly reviewing this budget based on your roof’s needs and local climate can prevent costly repairs. Prioritize urgent issues, ensuring ongoing roof care aligns with your financial planning.

Q. What role do professional contractors play in roof maintenance?

A. Qualified contractors bring expertise and knowledge of the latest materials. They ensure that maintenance tasks follow best practices and industry standards. Hiring professionals helps maximize roof longevity while reassuring owners with potential warranties and compliance with regulations.

Q. How does weather affect the maintenance of my industrial roof?

A. Severe weather can cause significant damage to industrial roofs. Regular evaluations after storms or heavy snowfall are crucial to spot issues early. Utilizing technology like drones for inspections can ensure safety and accuracy while assessing the roof’s condition post-weather events.