Ineffective access coordination during industrial roof installations leads to 40% longer project timelines and creates unnecessary safety risks that threaten both workers and facility operations. With commercial roofing projects becoming increasingly complex, the stakes for proper access management have never been higher.

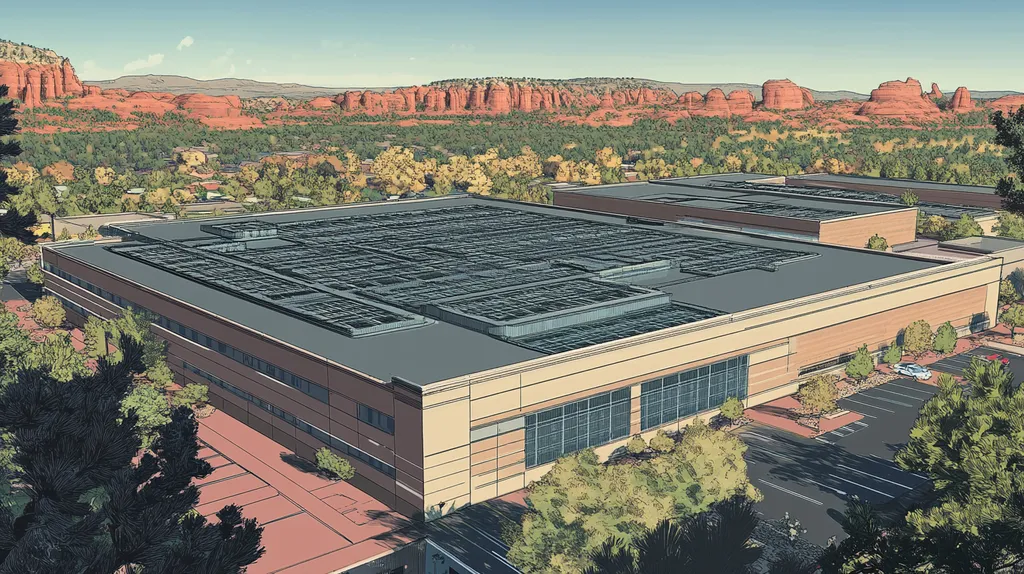

Modern industrial roofing demands sophisticated access systems that balance worker safety with installation efficiency. From elevated walkways to digital monitoring platforms, today’s access solutions require careful coordination across multiple components and stakeholders.

This comprehensive guide explores the essential elements of access coordination, providing facility managers with actionable strategies to optimize safety, efficiency, and long-term performance during industrial roof installations.

SECTION 1: FUNDAMENTAL CONCEPTS

Industrial roofing installations demand meticulous access planning to ensure worker safety and project efficiency. Recent industry data shows that improper access management contributes to 40% of installation delays and safety incidents. While many facility managers focus primarily on material selection and cost, access coordination often determines whether a project succeeds or fails.

Defining Roof Access Needs

Every industrial roofing project requires a detailed access assessment that accounts for building height, roof configuration, and surrounding obstacles. This evaluation determines equipment requirements, staging areas, and material transport routes.

Project scope significantly influences access requirements. Large-scale installations may need multiple access points and heavy equipment, while smaller projects might utilize simpler solutions like aerial lifts.

Site conditions play a crucial role in access planning. Factory operations, adjacent buildings, and utility lines can restrict equipment placement and material staging areas.

Time constraints also shape access requirements. Night work or weekend installations may require specialized lighting and additional safety measures to maintain proper access control.

Understanding Roof Hazards

The International Mechanical Code specifies that portable ladders are only permitted for vertical roof access up to 16 feet, with permanent ladders or approved means required beyond that height. These ladders must extend 30 inches above the parapet for safe transition. (source: ICC Building Safety Journal)

Weather conditions create dynamic hazards during installation. Wind can affect material handling, while rain or snow accumulation increases slip risks and impacts access equipment stability.

Edge protection becomes critical when working near roof perimeters. Proper guardrails and warning lines must be installed before work begins to prevent falls.

Moving materials across the roof surface presents unique challenges. Designated pathways and load distribution systems help prevent damage to existing roof components while ensuring worker safety.

Regulatory Compliance Overview

OSHA requirements mandate specific safety measures for different types of roof access. These include proper tie-off points, guardrail systems, and warning line arrangements based on roof height and configuration.

Local building codes often impose additional access requirements. These may include restrictions on equipment placement, working hours, and noise levels that affect access planning.

Insurance carriers typically require documented access plans before coverage activation. These plans must detail fall protection systems, emergency procedures, and access control measures.

Environmental regulations can impact access strategies, particularly in sensitive areas. Proper containment systems and material handling procedures must be integrated into the access plan to maintain compliance.

SECTION 2: SYSTEM COMPONENTS

Modern industrial roofing installations require sophisticated access systems to protect worker safety and maintain productivity. Research shows that proper access components can reduce installation time by up to 30% while significantly decreasing safety incidents. Understanding and implementing the right combination of walkways, stairs, and guardrails creates a foundation for successful roof installation while ensuring regulatory compliance.

Elevated Walkway Systems

Elevated walkway systems form the backbone of safe roof access during installation projects. These pathways create designated routes for workers and materials, preventing damage to newly installed sections while maintaining clear traffic patterns.

Load capacity represents a critical consideration when selecting walkway materials. Premium systems typically support 500-750 pounds per linear foot, accommodating both workers and equipment loads safely.

Weather resistance plays an equally important role in walkway selection. Non-slip surfaces, proper drainage channels, and corrosion-resistant materials ensure these systems remain functional throughout the installation process.

Strategic placement of walkways can dramatically improve workflow efficiency. Connecting material staging areas, work zones, and access points creates an integrated system that reduces worker fatigue and accelerates installation timelines.

Stair Access Towers Design

Stair access towers serve as primary entry points for workers and materials during roof installation. Their design must balance safety requirements with practical considerations for material transport and emergency evacuation.

Tower placement significantly impacts installation efficiency. Positioning towers near material staging areas and primary work zones minimizes travel distance while maintaining clear sight lines for safety monitoring.

Weather protection becomes essential for maintaining safe access throughout the project. Covered landings, proper drainage, and wind barriers help ensure continuous accessibility regardless of conditions.

Integration with existing building systems requires careful planning. Mechanical systems, wall penetrations, and structural supports must be coordinated to avoid conflicts while maintaining required clearances.

Guardrail Installation Standards

Proper guardrail systems provide essential fall protection during roof installation work. These systems must be installed before other work begins, creating a safe perimeter for all rooftop activities.

OSHA standards require guardrail heights between 39 and 45 inches above the walking surface, with rails capable of withstanding 200 pounds of outward force. Additionally, any elevation change of 19 inches or more requires appropriate access measures. (source: AAA Roofing & Waterproofing)

Installation sequence impacts both safety and efficiency. Starting with perimeter protection allows other components to be installed systematically while maintaining continuous fall protection.

Material selection affects long-term performance and maintenance requirements. Galvanized steel offers durability and strength, while aluminum systems provide lighter weight alternatives without compromising safety standards.

SECTION 3: IMPLEMENTATION METHODS

Implementation of proper access methods during industrial roof installation directly impacts both worker safety and project efficiency. Studies show that well-planned access systems can reduce installation time by up to 35% while significantly lowering incident rates. However, coordinating these systems requires careful attention to three critical areas: route planning, equipment platform security, and comprehensive fall protection.

Planning Roof Access Routes

Strategic route planning forms the foundation of efficient roof installation. These pathways must accommodate both worker movement and material transport while maintaining clear lines of sight for safety monitoring.

Load distribution represents a crucial consideration when establishing routes. High-traffic areas require additional reinforcement to prevent damage to newly installed roofing components and existing structures.

For all commercial building managers, providing safe and reliable rooftop access requires keeping equipment at least six feet from roof edges and establishing elevated walkways with railings near perimeter zones. (source: PHP Systems/Design)

Weather protection must be integrated into route planning. Proper drainage, non-slip surfaces, and wind barriers help maintain safe access during adverse conditions.

Securing Equipment Platforms

Equipment platforms serve as critical staging areas throughout the installation process. These zones must be properly secured and maintained to prevent shifting or collapse under dynamic loads.

Platform placement significantly impacts workflow efficiency. Positioning these areas near primary work zones and material storage locations minimizes transport distance while maintaining safe working conditions.

Regular inspection protocols ensure platform stability throughout the project. Daily checks should focus on connection points, support structures, and surface conditions that could compromise safety.

Integration with existing building systems requires careful coordination. Mechanical equipment, utility lines, and structural elements must be protected while maintaining necessary platform access.

Ensuring Fall Protection

Comprehensive fall protection systems create a safe working environment for all rooftop activities. These systems must be installed and tested before any installation work begins.

Protection zones should be clearly marked and maintained throughout the project. Warning lines, safety nets, and guardrail systems work together to prevent accidents while allowing efficient material movement.

Emergency response procedures must be integrated into fall protection planning. Quick access routes for first responders and clear evacuation paths help minimize risk during critical situations.

Environmental monitoring becomes essential for maintaining protection systems. Weather conditions can impact equipment stability and worker safety, requiring regular adjustments to maintain protection levels.

SECTION 4: MAINTENANCE REQUIREMENTS

Maintaining proper access systems during industrial roof installation directly impacts both worker safety and project success. Industry data shows that 65% of rooftop accidents occur due to inadequate maintenance of access equipment and safety systems. While many facilities focus on the initial installation, ongoing maintenance of access points and safety equipment proves equally critical for protecting workers and preserving roof integrity.

Regular Inspection Schedules

Scaffolding, work platforms, and mobile elevating work platforms require systematic inspection to ensure continued safety. These temporary access solutions demand particular attention to structural integrity and stability throughout the installation process.

Fixed crawl boards and roof ladders used for permanent access must incorporate non-slip surfaces and appropriate cleating. Regular checks of these components help prevent accidents while maintaining consistent access to work areas. (source: WorkSafe New Zealand)

Weather exposure can compromise access system integrity over time. Scheduling inspections after severe weather events helps identify potential weaknesses before they create hazardous conditions.

Documentation of inspections provides essential tracking of system conditions. This information guides maintenance scheduling while creating accountability for safety compliance.

Maintenance Log Keeping

Detailed maintenance logs serve as critical tools for tracking access system conditions. These records should document inspection dates, findings, and corrective actions taken to address identified issues.

Digital logging systems streamline documentation while enabling quick reference during safety audits. Modern platforms can generate automated maintenance alerts based on usage patterns and environmental conditions.

Photo documentation strengthens maintenance records by providing visual evidence of system conditions. These images help track deterioration patterns and validate repair needs.

Regular review of maintenance logs helps identify recurring issues that may indicate systemic problems. This analysis guides proactive improvements to access systems and maintenance protocols.

Cleaning and Repair Techniques

Access systems require regular cleaning to maintain proper function and prevent deterioration. Removing debris, dirt, and corrosive materials helps preserve structural integrity while ensuring safe operation.

Proper cleaning techniques vary by component type and material composition. Using appropriate cleaning agents and methods prevents damage while extending system lifespan.

Immediate repair of identified issues prevents escalation of access problems. Quick response to maintenance needs helps maintain continuous safe access throughout installation projects.

Replacement of worn components must follow manufacturer specifications to maintain system integrity. Using approved parts and qualified technicians ensures repairs meet safety standards while preserving warranty coverage.

Regular application of protective coatings helps prevent corrosion and wear on access components. This preventive measure reduces long-term maintenance costs while extending service life.

SECTION 5: PERFORMANCE METRICS

Performance metrics in industrial roofing installations directly impact both safety outcomes and project success rates. Recent data shows that properly tracked metrics can reduce installation accidents by up to 40% while improving completion times by 25%. However, many facilities overlook crucial measurements that could prevent costly delays and dangerous safety incidents. Understanding and implementing comprehensive performance tracking creates a foundation for successful installations.

Safety Incident Tracking

Systematic tracking of safety incidents provides essential data for preventing accidents and improving installation procedures. This monitoring should encompass near-misses, minor incidents, and potential hazards to build a complete safety profile.

Digital tracking systems enable real-time reporting and immediate response to safety concerns. These platforms can generate automated alerts when incident patterns emerge, allowing for rapid intervention before serious accidents occur.

Quarterly inspections of stairs, treads, fasteners, and handrails, combined with annual checks of roof hatches for corrosion and weather sealing, form the backbone of preventive safety measures. This systematic approach helps identify potential failures before they create hazardous conditions. (source: Lapeyre Stair)

Training programs should incorporate lessons learned from incident tracking data. This feedback loop helps workers understand common hazards while developing safer installation practices.

Access System Efficiency

Measuring access system efficiency reveals opportunities for improving installation speed and worker productivity. Key metrics include setup time, material transport rates, and worker movement patterns throughout the project.

Time studies of different access configurations help optimize placement and selection of equipment. These assessments can reduce wasted movement while improving material flow to work areas.

Weather impact tracking helps teams anticipate and plan for conditions that affect access efficiency. This data enables better scheduling and resource allocation during challenging weather periods.

Regular efficiency audits identify bottlenecks and workflow obstacles. Addressing these issues promptly maintains productivity levels while reducing worker fatigue.

Cost-Benefit Analysis

Comprehensive cost analysis must consider both immediate expenses and long-term value of access systems. Initial investment often correlates directly with installation efficiency and safety outcomes.

Equipment utilization rates provide crucial data for optimizing access system investments. Tracking these metrics helps justify expenditures while identifying opportunities for cost reduction.

Labor cost analysis reveals the relationship between access system quality and installation efficiency. Premium systems often reduce overall labor hours despite higher upfront costs.

Safety incident costs, including insurance impacts and productivity losses, must factor into benefit calculations. This holistic approach provides accurate return-on-investment figures for access system decisions.

Regular review of cost-benefit metrics enables continuous improvement in access planning. These assessments help refine future installation strategies while maximizing current system effectiveness.

SECTION 6: OPTIMIZATION STRATEGIES

Industrial roofing installations face increasing complexity as facilities expand and modernize. Recent data shows that over 60% of major roof installation delays stem from inadequate access optimization, while proper strategies can reduce project timelines by up to 35%. By focusing on worker training, access system design, and technology integration, facilities can dramatically improve both safety outcomes and installation efficiency.

Enhancing Worker Safety Training

Modern industrial roofing demands comprehensive safety training that evolves with changing technology and installation methods. Virtual reality simulations now allow workers to practice access procedures in risk-free environments, building muscle memory before stepping onto actual roofs.

Regular certification updates ensure workers maintain proficiency with current safety standards and equipment. Monthly safety audits help identify knowledge gaps while reinforcing best practices for access procedures.

Cross-training programs enable workers to understand multiple aspects of access systems, creating more versatile teams. This broader knowledge base improves problem-solving capabilities while reducing dependency on specialized personnel.

Documentation of training completion and competency assessments creates accountability while protecting both workers and facilities. These records prove invaluable during safety audits and incident investigations.

Improving Access System Design

Successful access system design requires careful coordination between structural engineers and facility managers to ensure safe, efficient roof installations. Quarterly inspections of stairs, treads, fasteners, and handrails, combined with annual checks of roof hatches, maintain system integrity throughout the project lifecycle. (source: Lapeyre Stair)

Modular access systems offer flexibility for different roof configurations while maintaining consistent safety standards. These adaptable solutions accommodate changing work zones without compromising protection.

Strategic placement of access points reduces worker fatigue while improving material flow. Careful analysis of traffic patterns helps optimize system layout for maximum efficiency.

Weather protection features integrated into access design ensure consistent availability regardless of conditions. Proper drainage, wind barriers, and non-slip surfaces maintain safe access during adverse weather.

Technology Integration for Efficiency

Digital monitoring systems provide real-time tracking of access point usage and conditions. These platforms alert managers to potential issues before they impact safety or productivity.

Automated material handling systems reduce physical strain while improving transport efficiency. Conveyor systems and mechanical lifts coordinate seamlessly with access points to maintain steady workflow.

Mobile applications enable quick reporting of access system issues and maintenance needs. This immediate communication helps prevent delays while ensuring prompt repairs.

Data analytics help identify patterns in access system usage and performance. This information guides optimization efforts while supporting evidence-based improvements to installation procedures.

Looking Ahead

With industrial roofing incidents costing the industry over $1.2 billion annually, proper access coordination represents a critical safety and financial imperative that facilities cannot afford to ignore.

Modern access systems, combining advanced monitoring technology with strategic design principles, can reduce installation timelines by up to 35% while dramatically improving safety outcomes.

The integration of digital tracking platforms, modular access components, and comprehensive training programs creates a foundation for successful industrial roof installations that protect both workers and facility investments.

Facilities that implement robust access coordination strategies position themselves to navigate increasingly complex roofing projects while maintaining regulatory compliance and operational efficiency.

The future of industrial roofing depends on systematic access planning that elevates safety standards while driving installation productivity to new levels.

FREQUENTLY ASKED QUESTIONS

Q. What are the access needs for commercial roof installations?

A. Each project requires a detailed access assessment focusing on building height, roof configuration, and surrounding obstacles. This evaluation helps determine the necessary equipment, staging areas, and safe transport routes for materials and workers, all essential for a smooth installation process.

Q. How important are guardrails for industrial roof safety?

A. Proper guardrail systems provide essential fall protection during installations. According to safety standards, guardrails must be in place before any work begins and should adjust for varying heights, ensuring a safe working environment and reducing the risk of accidents.

Q. Why is route planning crucial for industrial roof access?

A. Effective route planning creates safe pathways for worker movement and material transport. These pathways must consider load distribution and incorporate strategies for maintaining clear sight lines for safety monitoring during the installation process, minimizing risk and enhancing efficiency.

Q. How can maintenance logs improve roof access systems?

A. Detailed maintenance logs track inspection dates, findings, and corrective actions, helping to ensure ongoing safety. These records identify recurring issues and guide proactive improvements, ultimately enhancing the reliability and effectiveness of access systems during installations.

Q. What metrics are important for evaluating industrial roof installations?

A. Important metrics include tracking safety incidents, measuring access system efficiency, and conducting cost-benefit analyses. These measurements help identify trends, improve installation processes, and measure the return on investments related to access systems.

Q. How does worker training impact access safety?

A. Comprehensive safety training, including simulations, enhances workers’ confidence and skills with access procedures. Regular updates and cross-training ensure that all personnel are equipped to handle evolving safety challenges, ultimately leading to improved incident rates and project outcomes.

Q. What innovation can optimize industrial roof access systems?

A. Integrating digital monitoring systems can greatly enhance access system effectiveness. These platforms provide real-time tracking of usage and conditions, allowing for timely maintenance and quick identification of potential safety issues, thus improving both safety and installation efficiency.