Welcome to today’s Battle Royale featuring two roofing heavyweights: “Variable Refrigerant Flow (VRF) Systems” in the east corner versus “Rooftop Packaged Units” in the west!

Tonight’s showdown pits these contenders against each other across six punishing rounds designed to test every aspect of their performance for HVAC Role in Commercial Roof Lighting Setup.

At stake? Millions in potential costs, decades of building protection, and the critical performance demands of modern commercial and industrial facilities.

Our professional judging panel will evaluate each round on technical merit, real-world performance, and value delivery. After all six rounds, we’ll declare our ultimate champion.

Ladies and gentlemen, facility managers and building owners… it’s time to rumble!

ROUND 1: INITIAL COSTS & INSTALLATION

When it comes to commercial HVAC decisions, the stakes couldn’t be higher. With lighting systems consuming up to 50% of total annual electrical energy in U.S. office buildings, choosing between VRF systems and RTUs has massive implications for both initial setup and long-term operations.

The U.S. Department of Energy emphasizes that proper integration of HVAC and lighting systems is crucial for maintaining consistent illumination while minimizing energy loads. (source: U.S. Department of Energy)

Material Expenses

VRF systems represent the Tesla of HVAC – sleek, sophisticated, and priced accordingly. Their advanced zoning capabilities and precise control systems push initial costs significantly higher than traditional options.

RTUs, meanwhile, are the reliable pickup trucks of the HVAC world. Their standardized designs and mass production keep material costs predictable and generally lower.

While VRF systems promise future savings through efficiency, their premium components and specialized parts make the initial investment substantially higher. For budget-conscious projects, this price difference can be a deal-breaker.

ADVANTAGE: RTUs

Installation Complexity

Installing a VRF system is like conducting an orchestra – everything must work in perfect harmony. The intricate network of refrigerant lines, multiple indoor units, and complex controls requires specialized expertise and careful coordination.

RTUs, by comparison, are more like plug-and-play devices. Their all-in-one design means fewer components to coordinate and simpler connections to existing ductwork.

The learning curve for VRF installation means fewer qualified contractors and higher labor costs. RTUs benefit from decades of standardization and a larger pool of experienced installers.

ADVANTAGE: RTUs

Project Timeline

VRF installations often stretch timelines like warm taffy. The precision required for proper installation means more planning, more testing, and more coordination between trades.

RTU installations follow a well-worn path: crane it up, bolt it down, hook it up. This simplicity translates to faster project completion and quicker return to normal operations.

When time equals money, RTUs’ straightforward installation process gives them a clear edge. Their predictable timelines help keep projects on schedule and businesses running.

ADVANTAGE: RTUs

ROUND 1 WINNER: RTUs

ROUND 2: DURABILITY & LIFESPAN

When your HVAC system fails during peak business hours, theoretical debates about efficiency suddenly become painfully real. As commercial buildings evolve into increasingly complex environments, the durability gap between VRF systems and RTUs can mean the difference between smooth operations and costly disruptions. With replacement costs potentially reaching six figures, choosing between these systems demands careful consideration of their long-term resilience.

Material Durability

VRF systems shine in the durability department, with their distributed architecture spreading wear and tear across multiple components. Their modular design means that even if one component fails, the entire system doesn’t come crashing down like a house of cards.

These systems employ high-grade copper piping and corrosion-resistant materials that laugh in the face of harsh weather. Think of them as the Navy SEALs of HVAC – built to perform under pressure and engineered to last.

RTUs, while sturdy, concentrate all their components in one exposed location. This makes them more vulnerable to environmental stress and creates single points of failure that can bring down entire zones of operation.

ADVANTAGE: VRF Systems

Maintenance Requirements

VRF systems come equipped with sophisticated self-diagnostic capabilities that catch small issues before they become expensive problems. Their modular nature also means repairs can often be handled without shutting down the entire system.

The distributed design of VRF systems allows for selective maintenance, much like having multiple generators instead of one massive power plant. When service is needed, it’s typically less disruptive and more targeted.

RTUs demand more frequent attention, with their all-in-one design requiring regular comprehensive checkups. While these units are straightforward to service, their maintenance needs tend to be more intensive and disruptive.

ADVANTAGE: VRF Systems

Performance Longevity

VRF systems typically maintain their efficiency longer, with performance degradation occurring more gradually over time. Their ability to operate at partial capacity reduces wear and tear, extending useful life beyond traditional systems.

These systems excel at load management, automatically adjusting output to match demand. This intelligent operation prevents the kind of stress that ages equipment prematurely.

RTUs, while reliable workhorses, tend to show their age faster. Their simpler on/off cycling creates more mechanical stress, leading to earlier efficiency drops and potentially shorter operational lifespans.

ADVANTAGE: VRF Systems

ROUND 2 WINNER: VRF Systems

ROUND 3: PERFORMANCE FACTORS

When HVAC systems underperform, the consequences ripple through every corner of commercial operations. With lighting systems generating substantial heat loads, choosing between VRF and RTU systems can make or break your energy budget. Modern facilities face unprecedented demands – from 24/7 operations to precise environmental controls for sensitive equipment.

Today’s commercial buildings generate more heat from lighting and equipment than ever before. The wrong HVAC choice doesn’t just waste energy – it can turn your roof into an expensive liability that compromises operations and crushes your bottom line.

Energy Efficiency

VRF systems operate like precision instruments, adjusting refrigerant flow in real-time to match actual demand. Their variable-speed compressors can throttle down to 10% capacity during low-demand periods, dramatically reducing energy waste.

These systems excel at heat recovery, capturing excess heat from one zone to warm another. This intelligent load sharing can cut energy consumption by up to 40% compared to traditional systems.

RTUs, meanwhile, are like light switches – either fully on or fully off. While modern units include two-stage compressors, they can’t match the granular control of VRF systems. Their all-or-nothing operation creates efficiency valleys between cycles.

ADVANTAGE: VRF Systems

Operational Flexibility

VRF systems shine in buildings with diverse heating and cooling needs. Their zoning capabilities allow simultaneous heating and cooling across different areas, perfect for buildings with varying solar exposure or equipment loads.

The modular nature of VRF means you can expand capacity without replacing the entire system. This flexibility proves invaluable as building needs evolve or tenant requirements change.

RTUs offer simpler zoning through dampers and VAV boxes, but lack the precision of VRF systems. Their centralized design makes it challenging to accommodate different comfort preferences or varying heat loads across floors.

ADVANTAGE: VRF Systems

Peak Load Management

VRF systems handle peak loads like expert traffic controllers, redistributing capacity where it’s needed most. Their ability to shift refrigerant flow means no zone gets shortchanged during high-demand periods.

The sophisticated controls in VRF systems can anticipate demand spikes and adjust gradually, preventing the energy surges that plague traditional systems. This predictive capability helps avoid demand charges and extends equipment life.

RTUs respond to peak loads with brute force, ramping up to full capacity regardless of actual needs. This sledgehammer approach leads to higher energy costs and more wear and tear on components.

ADVANTAGE: VRF Systems

ROUND 3 WINNER: VRF Systems

ROUND 4: MAINTENANCE REQUIREMENTS

In the high-stakes world of commercial HVAC, maintenance isn’t just a line item – it’s the difference between smooth operations and catastrophic failure. With modern lighting systems pushing heat loads to new extremes, proper HVAC maintenance becomes critical for protecting million-dollar investments and preventing business disruptions.

Today’s sophisticated building systems demand more than just changing filters and hoping for the best. When maintenance shortcuts lead to system failures, the cascade of problems can bring operations grinding to a halt.

Maintenance Complexity

VRF systems are the Swiss watches of HVAC – precise, sophisticated, and demanding specialized expertise. Their intricate networks of refrigerant lines, electronic controls, and multiple indoor units require technicians with advanced training and diagnostic tools.

Finding qualified VRF technicians can be challenging, especially in smaller markets. When problems arise, the wait for specialized service can stretch from days into weeks.

RTUs benefit from decades of standardization and widespread familiarity among service providers. Their consolidated design means fewer components to maintain and easier access for repairs.

ADVANTAGE: RTUs

Frequency of Service

VRF systems demand rigorous preventive maintenance schedules to maintain peak performance. Their sophisticated components need regular inspection and adjustment, typically requiring service visits every quarter.

The distributed nature of VRF systems means more inspection points and longer service times. Missing maintenance intervals can lead to cascading efficiency losses and premature component failure.

RTUs thrive on simpler, less frequent maintenance routines. Their robust design and centralized layout allow for efficient twice-yearly service visits that cover all critical components.

ADVANTAGE: RTUs

Long-Term Cost Implications

VRF maintenance costs can snowball over time as components age and specialized replacement parts become necessary. The complexity of these systems means repairs often require multiple service visits and extensive diagnostic time.

The high-tech nature of VRF systems also means more potential points of failure. When problems occur, they tend to be more expensive to diagnose and repair.

RTUs offer more predictable maintenance costs and readily available replacement parts. Their straightforward design means repairs are typically completed in a single visit with standard components.

ADVANTAGE: RTUs

ROUND 4 WINNER: RTUs

ROUND 5: SUSTAINABILITY CREDENTIALS

In today’s climate-conscious market, HVAC sustainability isn’t just about green bragging rights – it’s about survival. With commercial buildings under increasing pressure to meet ambitious environmental targets, choosing between VRF systems and RTUs can make or break sustainability goals. Modern lighting systems generate substantial heat loads that must be managed efficiently to avoid turning your environmental aspirations into empty promises.

Carbon Footprint

VRF systems excel at minimizing carbon emissions through precision control and heat recovery capabilities. Their variable-speed operation means they consume only the energy needed, reducing unnecessary carbon output during partial load conditions.

These systems can recover waste heat from cooling operations to provide heating elsewhere, effectively getting two uses from the same energy input. This dual-purpose efficiency significantly reduces the overall carbon footprint compared to traditional systems.

RTUs operate more like sledgehammers than scalpels, running at full capacity even when partial cooling would suffice. Their all-or-nothing approach wastes energy and generates unnecessary emissions through inefficient cycling.

ADVANTAGE: VRF Systems

Refrigerant Management

VRF systems utilize advanced refrigerant technologies that maximize heat transfer while minimizing environmental impact. Their sealed systems reduce the risk of leaks and require less refrigerant volume per ton of cooling capacity.

However, VRF installations require extensive refrigerant piping throughout the building. This distributed network increases the potential points of failure and makes leak detection more challenging.

RTUs concentrate their refrigerant charge in one location, simplifying monitoring and maintenance. Their compact design means fewer connection points and lower risk of refrigerant leaks into the environment.

ADVANTAGE: RTUs

Resource Efficiency

VRF systems demonstrate superior resource efficiency through their modular design and adaptive operation. Their ability to transfer heat between zones reduces the total energy input needed for building comfort.

The longevity of VRF components means fewer replacement parts ending up in landfills. Their gradual performance degradation allows for planned maintenance rather than emergency replacements.

RTUs consume more resources through their shorter service life and more frequent component replacements. Their simpler design may use fewer materials initially but requires more frequent total system replacements.

ADVANTAGE: VRF Systems

ROUND 5 WINNER: VRF Systems

ROUND 6: SPECIALIZED APPLICATIONS

When HVAC and lighting systems clash, energy bills soar and comfort plummets. With lighting generating up to 37% of internal heat loads in commercial buildings, choosing between VRF systems and RTUs can make or break your operational budget.

The stakes are particularly high for facilities with specialized lighting requirements, where the wrong HVAC choice can create a cascade of temperature control issues that compromise both equipment and occupant comfort.

Heat Load Management

HVAC systems must effectively handle heat loads generated by space lighting to maintain optimal indoor conditions. VRF systems excel at this challenge through their precise zoning capabilities and variable-speed operation. (source: Consulting-Specifying Engineer)

These systems can instantly adjust cooling capacity room by room, responding to changing lighting conditions and occupancy patterns throughout the day. Their sophisticated controls allow for seamless integration with lighting automation systems.

RTUs struggle with varying heat loads, operating at full capacity regardless of actual cooling needs. Their one-size-fits-all approach often results in temperature swings and energy waste.

ADVANTAGE: VRF Systems

Space Utilization

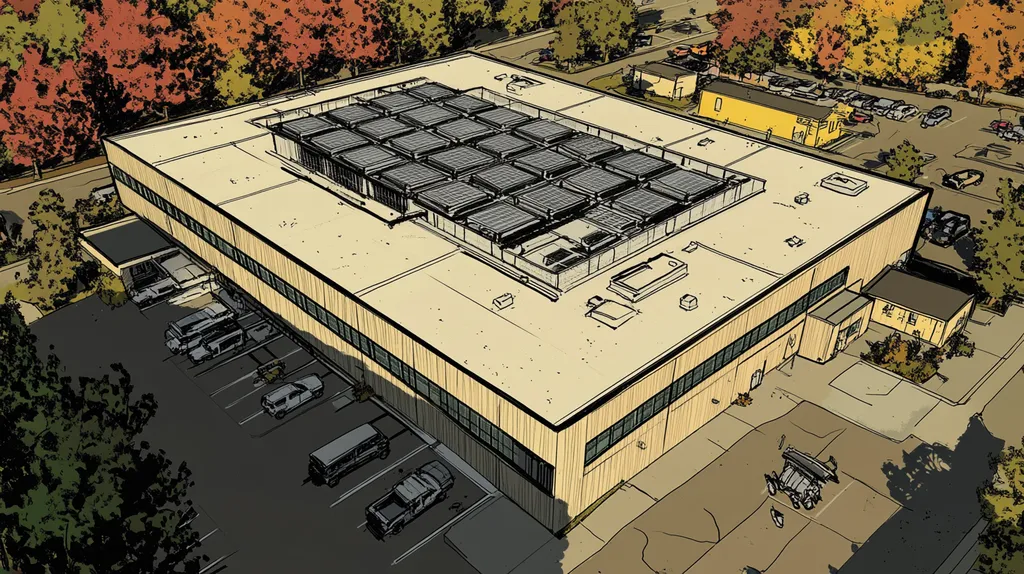

VRF systems minimize rooftop footprint by distributing components throughout the building. This design approach leaves more space for skylights, solar panels, and other roof-mounted lighting solutions.

Their compact outdoor units and flexible refrigerant piping allow for creative installation solutions that preserve valuable roof real estate. This flexibility proves invaluable for buildings with complex lighting layouts.

RTUs consume significant roof space, limiting options for natural lighting solutions and creating potential shading issues for solar installations. Their bulky footprint can complicate roof maintenance and restrict future lighting upgrades.

ADVANTAGE: VRF Systems

Integration Capabilities

VRF systems feature advanced controls that seamlessly integrate with building automation systems. This allows for coordinated operation between HVAC and lighting systems, optimizing energy usage across both platforms.

Their sophisticated sensors and controls can adjust cooling based on daylight levels and occupancy patterns. This smart integration helps maintain consistent comfort while minimizing energy waste.

RTUs offer basic integration options but lack the granular control needed for advanced lighting coordination. Their limited automation capabilities can result in missed opportunities for energy savings.

ADVANTAGE: VRF Systems

ROUND 6 WINNER: VRF Systems

AND THE WINNER IS…

After six grueling rounds of technical warfare, the judges’ scorecards are in! With a decisive 4-2 victory, Variable Refrigerant Flow (VRF) Systems have claimed the HVAC championship belt!

VRF dominated with superior performance in durability, energy efficiency, sustainability, and specialized applications. Its precision control, heat recovery capabilities, and integration flexibility proved unbeatable in modern commercial environments.

But don’t count Rooftop Packaged Units out of the fight! RTUs showed their muscle in initial costs and maintenance simplicity. For smaller buildings with straightforward cooling needs and budget constraints, RTUs remain a formidable contender.

Ladies and gentlemen, we must emphasize: Every building brings its own unique challenges to the ring. Local climate conditions, existing infrastructure, and specific operational requirements can dramatically impact system performance. Individual results may vary based on building size, usage patterns, and regional factors.

Before making your final HVAC selection, consult with qualified professionals who can evaluate your specific situation. They’ll help ensure your chosen champion is truly the right fighter for your corner.

Remember, folks – in the high-stakes arena of commercial HVAC, the real victory comes not from blindly following the champion, but from choosing the system that best answers your building’s unique call to battle!

FREQUENTLY ASKED QUESTIONS

Q. What are initial costs for commercial roof HVAC systems?

A. Initial costs for VRF systems are significantly higher than RTUs, which are cheaper and simpler to install. Budget-conscious property owners should consider whether that premium pays off in the long run.

Q. How do durability and lifespan compare for industrial roof systems?

A. VRF systems generally outlast RTUs because of their distributed design that mitigates single points of failure. Meanwhile, RTUs, while robust, can fail in harsh conditions due to concentrated components.

Q. What performance factors matter for commercial roof HVAC systems?

A. Energy efficiency and peak load management are crucial. VRF systems excel here with modulating compressors, while RTUs often operate at full throttle, wasting energy.

Q. What are maintenance requirements for commercial roof HVAC systems?

A. VRF systems require specialized technicians and frequent service, which can complicate maintenance schedules. In contrast, RTUs are easier to maintain, needing only biannual checkups.

Q. Which HVAC system is better for sustainability in commercial roofs?

A. VRF systems outperform RTUs in sustainability due to energy-efficient operations and heat recovery features. RTUs waste energy and generate higher emissions by running at full capacity all the time.

Q. How do VRF and RTUs handle specialized applications on industrial roofs?

A. VRF systems are superior for specialized applications as they can dynamically adjust to varying heat loads, unlike RTUs, which struggle with fluctuating conditions and often waste energy.

Q. What should I consider when upgrading HVAC on my commercial roof?

A. Consider installation complexity, energy efficiency, and long-term maintenance costs. Choose a system that meets your building’s unique needs while ensuring it integrates smoothly with existing equipment.