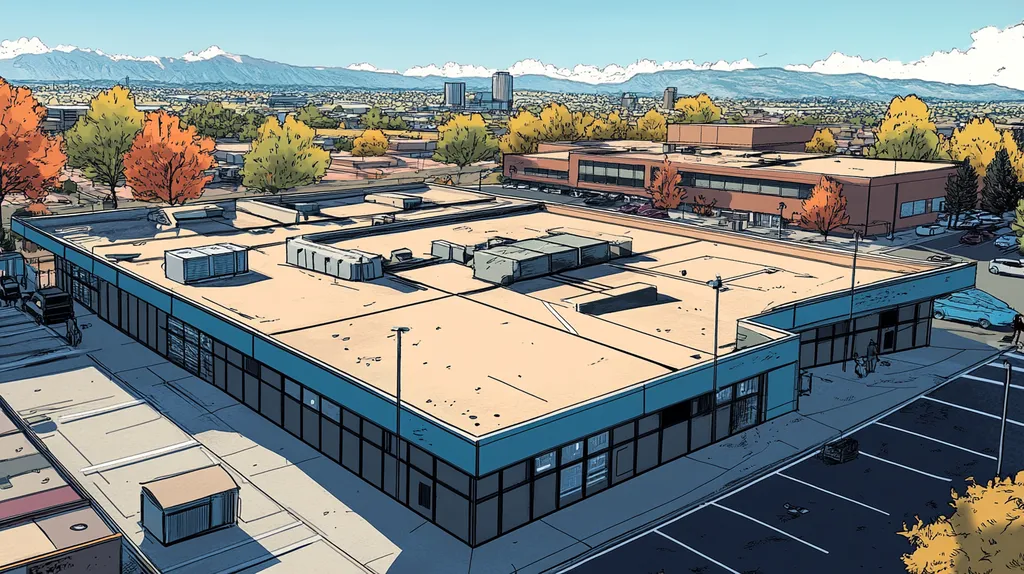

In industrial roofing, existing structures can reduce a new roof’s lifespan by up to 40% when their impact is overlooked during installation and maintenance. This oversight costs facility owners millions annually in premature replacements and emergency repairs.

Understanding how building components, from HVAC units to structural supports, affect roofing performance is crucial for protecting these significant investments.

This comprehensive analysis examines common misconceptions, practical implications, and evidence-based solutions that help property managers and owners make informed decisions about their industrial roofing systems.

SECTION 1: COMMON MISCONCEPTIONS

Recognizing the factors that impact the lifespan of an industrial roof is essential for property owners and facility managers. Misunderstandings in this area can lead to costly errors. Alarmingly, about 30% of roofing failures can be linked to disregarding how existing structures influence a new roof’s performance. By identifying and addressing these common misconceptions, decision-makers can protect their investments and enhance the value of their properties.

Ignoring Climate Impact on Roofing Materials

One major misconception is the tendency to overlook how local climate affects roofing materials. Different regions have unique weather patterns that can dramatically alter a roof’s longevity. For instance, in high-humidity areas, roofs are more prone to mold growth and material degradation.

If climate considerations are neglected during material selection, roofs may fail prematurely. A roof designed for arid conditions might struggle under heavy rains or extreme temperatures. This not only jeopardizes the roof’s integrity but can also create additional issues for the entire building.

It is crucial for property owners to seek advice from experts who understand how materials perform in specific climates. Investing in suitable materials tailored to environmental conditions will enhance durability and lower long-term costs. When this aspect is disregarded, it can significantly hamper the roof’s performance and lifespan, ultimately impacting the overall financial health of the property.

Incorporating a climate assessment into the roofing decision-making process is vital. This customized approach ensures the roofing system is resilient against local weather challenges, securing the investment for years to come.

Overlooking Installation Quality

The installation quality of a roofing system is another critical factor often underestimated. Even the top-tier materials will underperform if installed incorrectly. Research shows that improper installation is responsible for nearly 50% of roofing failures.

A variety of issues, such as poor sealing, incorrect layering, or inadequate fastening, can make roofs vulnerable to damage. For example, seams that aren’t tightly secured can allow water infiltration, leading to significant and costly repairs. This emphasizes the necessity of hiring certified professionals with expertise in proper installation practices.

Moreover, problems stemming from inferior installation can complicate future maintenance. Property owners could face unexpected expenditures due to issues linked to the initial installation quality. Therefore, rigorous installation standards are crucial in preventing these long-lasting complications.

Choosing professional installation is not merely optional; it’s essential. Prioritizing quality workmanship can significantly extend the life of an industrial roof and maintain the structural integrity of the building.

Believing All Roofs Are Created Equal

Another widespread misunderstanding is the belief that all roofing systems are interchangeable. In reality, different roofing materials cater to specific needs depending on the building type and application. For example, a single-ply membrane may be suitable for certain facilities, while built-up roofing systems may serve others more effectively.

This misconception that all roofs function alike can lead to poor decision-making. Property owners may choose roofing based solely on price, ignoring the unique requirements of their facility. Such decisions can result in insufficient protection and escalating repair costs over time.

Additionally, the expected lifespan of various roofing materials can differ significantly. While some systems require more frequent maintenance, others may provide longevity with minimal upkeep. Understanding these variations enables property owners to make informed selections that align with their operational objectives.

Ultimately, a tailored approach to roof selection is crucial. Recognizing that roofs are not all created equal empowers property owners to invest wisely, ensuring optimal performance and longevity for their industrial roofing systems.

SECTION 2: PRACTICAL IMPLICATIONS

In industrial roofing, understanding practical implications is vital for ensuring the durability and efficiency of a new system. Issues such as poor drainage, insufficient maintenance, and incorrect material selection can dramatically shorten a roof’s lifespan. For example, a roof with ineffective drainage can lead to significant failures, culminating in costly repairs and operational downtime. It is essential for property owners and facility managers to grasp these factors to safeguard their investments and maintain the integrity of their buildings.

Effects of Poor Drainage Systems

Poor drainage is one of the most pressing challenges for industrial roofs. When water pools on the roof surface, it not only adds excessive weight but also increases the risk of structural failure. This can lead to a short-lived roof and potential safety hazards for workers below.

Moreover, standing water can expedite the breakdown of roofing materials, causing leaks and further damage over time. For instance, single-ply membranes are especially susceptible to punctures when exposed to stagnant water, forcing facilities to undergo frequent and costly repairs.

Additionally, ineffective drainage systems can encourage mold and mildew growth, which not only compromises structural integrity but also jeopardizes the health of the building’s occupants. Regular drainage inspections and prompt corrective actions are crucial in maintaining optimal roof performance.

In short, implementing a well-designed drainage system is not just a recommendation but a requirement for prolonging the life and functionality of industrial roofs.

Consequences of Inadequate Maintenance

Neglecting routine maintenance can have severe repercussions for industrial roofing systems. Regular inspections and timely repairs can identify minor issues before they escalate into major problems. However, failing to maintain the roof often leads to costly and avoidable failures.

For example, not having gutters cleared of debris can result in overflow and water pooling on the roof. This not only degrades materials but increases the risk of leaks. The longer such issues remain unaddressed, the more expensive repairs become.

Furthermore, small defects like loose flashing or brittle seams can quickly evolve into significant repair needs. These situations often require considerable downtime, adversely affecting facility operations.

Thus, a proactive maintenance schedule is critical for ensuring the longevity of industrial roofs. Property owners should emphasize regular evaluations to protect their investments and sustain operational efficiency.

Impact of Incorrect Material Selection

The importance of selecting appropriate roofing materials cannot be overemphasized. Choosing the wrong materials can lead to premature failures and costly replacements. For instance, lightweight materials used in high-wind areas may suffer from blow-offs, resulting in increased maintenance over time.

Moreover, different materials are equipped to handle specific weather conditions and roof designs, making it essential to choose wisely for durability. Roofing systems not suited to local climates often falter under extreme temperatures, leading to expensive repairs.

The financial repercussions of poor material selection are significant. An early roof failure due to improper choices can result in unexpected costs and operational disruptions, negatively impacting productivity.

In conclusion, making informed material selections is a pivotal decision that greatly affects the lifespan and performance of an industrial roof. Expert guidance can help facility managers ensure their roofs withstand the test of time.

SECTION 3: COST OF MISINFORMATION

The financial consequences of misinformation in industrial roofing can be significant and detrimental. Property owners often make expensive choices influenced by inaccurate evaluations of existing structures. Research indicates that as many as 70% of roof replacements are conducted prematurely, leading to inflated costs. Recognizing these challenges equips stakeholders to make informed decisions, ultimately lessening unnecessary expenses while extending roof longevity.

Financial Burden of Premature Replacement

One of the most pressing consequences of misinformation is the heavy financial burden from premature roof replacements. When facility managers misinterpret a roof’s life expectancy based on incorrect data, they may undertake costly renovations instead of conducting thorough evaluations. This often results in avoidable expenses that strain financial resources.

For instance, a facility that replaces its roof five years earlier than necessary could face costs exceeding $100,000. Additionally, these premature decisions can limit funds available for other essential facility improvements or repairs. Tactically aligning roofing timelines with accurate assessments can preserve budgetary flexibility.

The massive costs associated with removing and disposing of an outdated roof can further compound initial expenditures. By delaying action until proper evaluations are performed, property owners can avert unforeseen financial burdens and prolong overall roof lifespan.

In summary, avoiding unnecessary replacements can create substantial savings. Investing in accurate assessments allows for informed decision-making, ultimately benefiting the bottom line.

Costs Associated with Leak Repairs

The expenses tied to leaks, often stemming from misinformation regarding existing structures, can quickly escalate. These leaks typically result from overlooked issues during the initial assessments, leading to expensive emergency repairs. Neglecting structural weaknesses can exacerbate damage, ultimately compromising the roofing system as a whole.

Statistics reveal that the average costs for leak repairs can soar to over $10,000, depending on the severity and extent of the damage. The financial impact intensifies when materials and equipment are damaged due to ongoing water exposure, complicating the repair process further.

Additionally, significant leak repairs can interfere with normal business operations, causing productivity and revenue losses. These indirect costs can outstrip the immediate repair expenses, creating an even larger, long-term financial strain.

To lessen leak risks, property owners must prioritize accurate evaluations of their roofs. A persistent focus on structural integrity can ultimately lead to significant savings in repair costs over time.

Losses Due to Structural Damage

Inaccurate assumptions about existing structures often lead to severe structural damage, representing another significant financial concern. For instance, miscalculating the weight-bearing capacity can result in the collapse of a roof section, causing substantial repair costs and safety hazards for occupants.

Repairing structural damage frequently requires comprehensive evaluations, which can lead to increased facility downtime. On average, businesses may experience losses of up to $25,000 per day due to operational disruptions stemming from structural repairs.

Moreover, construction delays often result in higher expenses for temporary facilities, diverting funds that could support valuable improvements. By staying well-informed about the conditions of existing structures, property owners can avert costly damages while ensuring operational continuity.

Being cognizant of these potential risks empowers property owners and managers to make proactive decisions, thereby supporting the longevity and safety of their roofing systems.

SECTION 4: REALITY CHECK

Property owners must face a crucial reality: existing structures significantly impact the lifespan of a new industrial roof. Research indicates that inadequate planning can shorten a roof’s lifespan by as much as 30%. Factors such as structural integrity, environmental influences, and installation techniques all play vital roles. Gaining a clear understanding of these issues is essential for making informed decisions that protect investments. This section explores key factors affecting roof longevity and highlights effective strategies for improvement.

Understanding Roofing Material Lifespans

The longevity of roofing materials varies widely depending on their type. For example, traditional asphalt shingles typically last between 15 to 30 years, while metal roofs can last 40 years or more. However, numerous factors can alter these lifespan estimates. Insufficient drainage caused by nearby structures can accelerate water-related damage, significantly reducing material longevity.

Additionally, interactions between incompatible materials can lead to stress points. A junction between an older roof and a new installation may be particularly vulnerable to premature failure. Thus, understanding the nuances of material selection in the context of existing structures is essential.

Moreover, installation quality and design choices can dramatically influence a roof’s lifespan. Property owners may not realize how vital proper insulation and ventilation are to prolonging the longevity of a roofing system. Making informed selections in these areas can safeguard investments for years to come.

Ultimately, the expertise of architects and contractors is crucial. They should consider the chosen materials and the conditions of existing structures to create a roofing system designed for maximum durability. This informed approach creates a strong foundation for more resilient roofing solutions.

The Role of Regular Inspections

Conducting regular inspections is key to extending the lifespan of industrial roofs. Routine evaluations help identify potential problems before they develop into costly repairs. Studies indicate that facilities with regular roof inspections experience lifespans that are three times longer than those without such diligence.

During inspections, professionals can detect signs of wear and damage related to existing structural issues, such as tree branches causing punctures. Proactive measures taken now can significantly mitigate future repair costs.

Additionally, inspections allow facility managers to assess material performance under actual conditions. Factors like moisture buildup and weather-related wear can inform a tailored maintenance plan, ultimately protecting the property and prolonging roof life.

Property managers should schedule these inspections at least twice a year. Even in adverse weather, checking for structural issues can prevent further complications. Investing in regular inspections leads to significant savings and longer-lasting roofing systems.

Climate-Specific Roofing Considerations

Climate plays a pivotal role in determining the lifespan of industrial roofs. Different roofing materials react differently to regional weather conditions, including temperature changes, rainfall patterns, snow loads, and UV exposure. For instance, a roof built for a hot, arid climate will not perform effectively in a colder, snowy environment.

Awareness of the local climate influences choices regarding materials, insulation techniques, and drainage designs. In regions prone to heavy rainfall, low-slope roofs may be unsuitable due to the risks of water pooling and subsequent leaks. Conversely, roofs in dryer areas need to withstand high UV exposure without deteriorating.

Adapting roofing practices to local climate trends enhances longevity. For example, using reflective materials can reduce cooling costs in hot climates, while sturdy aluminum roofs may protect better against hail damage in storm-prone regions. Tailoring roofing solutions based on climatic conditions ensures optimal performance and durability.

Ultimately, the interplay between climate and existing structures is crucial for roof longevity. Property owners who consider these factors are more likely to make informed, cost-effective decisions that enhance the longevity of their roofing investments.

SECTION 5: EVIDENCE-BASED ALTERNATIVES

In the current industrial roofing landscape, reliance on outdated materials and practices jeopardizes the lifespan and durability of new roofs. Alarmingly, over 36% of commercial roofs see premature failure, making it imperative for property owners and facility managers to take proactive measures. By exploring innovative solutions, they can enhance durability and significantly reduce long-term costs. This section highlights several evidence-based alternatives that should be top of mind for informed decision-making.

Benefits of Metal Roofing Systems

Metal roofing systems emerge as an excellent choice for industrial applications, known for their remarkable durability and longevity. With lifespans ranging from 40 to 70 years, metal roofs withstand severe weather conditions, cutting down on the frequency of replacements.

Additionally, these roofs boast high reflectivity, leading to lower energy costs as they minimize heat absorption. A cooler indoor environment is particularly beneficial for energy-intensive facilities. Their resilient design also effectively resists issues like rust, mold, and pest infestations.

Furthermore, many metal roofing systems are recyclable, aligning with sustainability goals while delivering a strong return on investment. By choosing metal roofs, businesses can not only protect their assets but also enhance property value and reduce maintenance disruptions.

Advantages of Intelligent Rooftop Monitoring

Implementing intelligent rooftop monitoring systems provides significant advantages in maintaining roof integrity. Utilizing advanced sensors, these systems monitor real-time data on moisture levels, temperature shifts, and structural stresses.

Early identification of potential issues, such as leaks or structural weaknesses, allows facility managers to initiate repairs before they escalate into costly problems. Research indicates that proactive monitoring can increase roof lifespan by up to 25%.

Moreover, this technology helps structure maintenance schedules by predicting when specific tasks should be addressed based on actual rooftop conditions. Consequently, this data-driven approach promotes more efficient resource allocation and minimizes unanticipated costs.

Integrating smart monitoring systems not only safeguards the roofing investment but also enhances safety and operational efficiency across facilities.

Importance of Sustainable Roofing Materials

Embracing sustainable roofing materials is becoming essential in the industrial sector, particularly as environmental regulations and concerns increase. Selecting materials that meet sustainability standards is critical in reducing a company’s ecological footprint.

Many sustainable roofing options, such as rubber and green roofs, offer superior insulation, lower energy bills, and improved air quality. For instance, green roofs effectively absorb rainwater, mitigating runoff and enhancing drainage, which is vital in urban environments.

Additionally, these materials often come with certifications that enhance a building’s appeal to eco-conscious tenants or customers, thereby increasing property value. Furthermore, many sustainable roofing solutions prove durable and require less maintenance, providing long-term cost benefits.

Investing in sustainable roofing not only bolsters a company’s market position but also supports a healthier environment, making it an increasingly important consideration in today’s business world.

SECTION 6: TEST AND VERIFY

In the world of industrial roofing, routine testing and verification are essential to ensure the long-term durability of a roof. Alarmingly, over 40% of roofing failures can be traced back to insufficient maintenance and lack of inspections. By prioritizing regular assessments, property owners can prevent costly repairs and extend the lifespan of their roofs. This section will explore crucial practices such as conducting routine inspections, utilizing advanced leak detection technologies, and ensuring compliance with industry standards.

Conducting Routine Roof Inspections

Conducting routine roof inspections is pivotal for spotting potential issues before they evolve into costly problems. Regular evaluations enable facility managers to identify signs of wear, debris buildup, and any structural damage that could shorten the roof’s lifespan. It is advisable to schedule inspections at least twice a year, ensuring a thorough assessment of both the roof and its underlying structures.

Inspection focus should include seals, flashing, and drainage systems, all of which face the most wear and tear. Properly assessing these components can uncover vulnerabilities that might compromise the roof’s integrity over time.

Engaging certified roofing professionals can greatly enhance the accuracy and reliability of inspections. Their expertise ensures that assessments are precise and lead to actionable recommendations, ultimately improving the roof’s longevity. This proactive stance not only prevents failures but also facilitates budgeting for needed maintenance.

Investing time and resources into routine inspections proves beneficial in the long run. Facilities that prioritize them frequently encounter fewer emergency repairs, avoiding the financial strain and operational disruptions that such situations entail.

Using Advanced Leak Detection Technologies

Advanced leak detection technologies are transforming how industrial facilities maintain roof integrity. Traditional inspection methods often rely on visual checks, which may miss hidden leaks. Innovations like infrared thermography and electronic leak detection systems provide critical insights that standard practices simply cannot offer.

Infrared thermography identifies temperature variations in roof materials, revealing moisture that could endanger the building’s structure. Early leak detection prevents water damage and mold growth, significantly prolonging the roof’s lifespan. Facilities utilizing these technologies often experience enhanced reliability and fewer operational interruptions.

Electronic leak detection adds another layer of assurance. By applying a low-voltage electric charge across the roof surface, this method can precisely locate leaks before they result in extensive damage. Such tools save facility managers time and significantly reduce repair costs.

Incorporating advanced technologies into maintenance schedules creates a proactive risk management strategy. Although the initial investment may be substantial, the long-term savings in repair costs and the peace of mind gained are well worth it.

Ensuring Compliance with Industry Standards

Ensuring compliance with industry standards is essential for optimizing the performance and longevity of industrial roofing systems. Organizations like the American Society for Testing and Materials (ASTM) set guidelines that help ensure roofing materials and techniques meet quality benchmarks. Adhering to these standards helps prevent roof-related issues that could arise from inadequate installations.

Regularly reviewing compliance practices ensures that facilities are aligned with best practices and emerging technologies. It’s crucial for facilities managers to verify that both contractors and materials meet the latest regulatory requirements. Non-compliance can result in costly litigation and insurance complications.

Beyond legal necessities, meeting industry standards builds trust among stakeholders. A roof that follows established benchmarks signals reliability and safety, which are paramount for property owners and tenants alike. The long-term benefits of compliance far outweigh any short-term challenges.

By embedding compliance into the roofing process, facilities managers can enhance roof performance and extend its lifespan. This dedication not only protects the financial investment but also contributes to the overall sustainability of the building.

Moving Forward

The data is clear: existing structures can reduce industrial roof lifespans by up to 40% when their impact is overlooked, costing facility owners millions in premature replacements annually.

Through evidence-based assessment of structural influences, proper material selection, and regular monitoring, facilities can extend roof lifespans by 15-20 years while reducing maintenance costs by up to 30%.

The stakes are significant: over $2.5 billion is lost annually due to industrial roof failures stemming from structural oversight.

By implementing comprehensive inspection protocols, utilizing advanced monitoring technologies, and selecting climate-appropriate materials, facility managers can protect their roofing investments and ensure optimal performance for decades to come.

The future of industrial roofing depends on this strategic integration of existing structures into both planning and maintenance processes.

FREQUENTLY ASKED QUESTIONS

Q. What misconceptions exist about commercial roofs affecting lifespan?

A. One major misconception is overlooking local climate effects on roofing materials. Each region has unique weather patterns that significantly impact a roof’s durability. If incorrect materials are chosen based on these misconceptions, roofs may fail prematurely, leading to unexpected costs and repairs.

Q. How do poor drainage systems affect industrial roofs?

A. Poor drainage systems pose serious risks by allowing water to pool, which adds weight and encourages structural failure. Standing water not only accelerates material breakdown but also increases the likelihood of leaks and mold growth, complicating maintenance and repairs over time.

Q. What are the financial impacts of misinformation on industrial roofing?

A. Misinformation can lead to expensive premature roof replacements, often exceeding $100,000 due to misjudged lifespan. Additionally, unexpected leaks and necessary repairs can compound costs and disrupt facility operations, indicating the necessity for accurate evaluations.

Q. How does climate impact the lifespan of a new industrial roof?

A. Climate greatly affects the performance and longevity of roofing materials. Different materials respond uniquely to regional conditions like rainfall and temperature extremes. Understanding these environmental influences helps in selecting suitable roofing systems that can endure specific weather challenges.

Q. What modern alternatives can enhance industrial roof durability?

A. Metal roofing systems are a top alternative, offering great durability and lifespans of 40 to 70 years. Additionally, adopting intelligent rooftop monitoring technologies can detect issues early, significantly increasing a roof’s lifespan and facilitating scheduled maintenance as needed.

Q. How often should inspections be conducted on industrial roofs?

A. Inspections should ideally be conducted at least twice a year to identify potential issues early. Regular evaluations help catch problems related to wear and tear, enabling timely repairs and ultimately extending the roof’s lifespan by mitigating small issues before they escalate.

Q. What roles do sustainable materials play in industrial roofing?

A. Sustainable roofing materials, such as green roofs and rubber systems, improve energy efficiency and indoor air quality. They also reduce a company’s ecological footprint. By investing in these options, businesses can ensure durability while appealing to eco-conscious tenants, enhancing overall property value.