The longevity of modified bitumen roofing systems has become a critical concern for industrial property owners, with recent studies indicating a 40% failure rate within the first decade of installation.

These premature failures result in billions of dollars in repair costs annually, challenging long-held assumptions about traditional installation and maintenance practices.

As material science advances and building requirements evolve, the limitations of conventional modified bitumen applications have become increasingly apparent through documented performance data and systematic analysis.

This examination explores the systemic issues underlying current practices, identifies missed opportunities for enhancement, and presents evidence-based solutions for improving industrial roof durability.

SECTION 1: CURRENT PRACTICES

As industrial roofing systems contend with the relentless pressures of severe weather and daily operations, property owners face significant long-term consequences from their roofing choices. Modified bitumen systems, once celebrated for their strength, are now under scrutiny for their durability over time. Alarmingly, statistics show that nearly 40% of flat roofs start to show problems within their first ten years. Consequently, grasping the nuances of current installation and maintenance practices is vital for enhancing roof longevity.

Standard Installation Methods

The typical installation methods for modified bitumen roofs include torch-applied and cold-adhered techniques. Historically, these approaches have proven effective, yet they are often implemented without sufficient training or strict quality control measures. Such inconsistencies can result in weak seams and ineffective waterproofing, increasing the risk of premature roof failure.

Inadequate substrate preparation is another common pitfall that contributes to early roof deterioration. Without proper cleaning or priming, the bitumen may fail to adhere effectively, leaving the roof vulnerable to damage. This oversight during installation can significantly diminish the roof’s overall lifespan.

Numerous case studies reveal that roofs installed using these standard methods frequently encounter substantial wear far earlier than initially expected. Property owners often find themselves facing expensive repairs or replacements much sooner than they had planned.

To enhance the longevity of modified bitumen roofs, it is essential to embrace best practices that emphasize comprehensive training and strict adherence to installation protocols. Implementing robust installation practices can greatly bolster overall durability.

Maintenance and Inspection Protocols

Regular maintenance and inspection play crucial roles in extending the lifespan of modified bitumen roofs; however, these areas are often neglected by property owners. Many inspections are carried out only after issues surface, which is too late for effective intervention.

Research indicates that roofs with proactive maintenance plans can last as much as 20% longer than those without regular evaluations. Scheduled inspections allow for the early detection of minor issues, such as blisters or cracks, preventing them from developing into more significant, costly repairs.

Common maintenance oversights include neglecting to remove debris and failing to address damage promptly. These lapses can trap water on the roof, leading to water infiltration and ongoing degradation of roofing materials.

A robust maintenance strategy involves regular inspections and quick repairs to maximize the lifespan of modified bitumen roofs. By staying proactive, property owners can better safeguard their investments against future problems.

Common Material Selection Criteria

The choice of materials for modified bitumen roofing has a profound impact on the overall effectiveness of the system. While property owners often focus on upfront costs, neglecting long-term durability can result in inferior roofing solutions.

Key selection criteria include membrane thickness, UV resistance, and flexibility. A lack of attention to these aspects can yield a roofing system that deteriorates quickly under environmental stress. For example, thinner membranes may be more affordable but are also more susceptible to punctures and tears.

Studies demonstrate that higher-quality, thicker membranes provide better resistance to wear and tear, ultimately enhancing longevity. Opting for materials based on short-term savings rather than long-term performance can lead to significant expenses down the line.

Implementing a strategic approach to material selection that weighs cost against long-term benefits is essential. Investing in superior materials can dramatically lower the likelihood of repairs and extend the durability of modified bitumen roofs, proving crucial for long-term success.

SECTION 2: SYSTEMIC ISSUES

The longevity of modified bitumen roofing systems is jeopardized by persistent systemic issues that detrimentally affect performance and longevity. Failures in installation practices expose roofs to vulnerabilities, resulting in expensive damage. For instance, reports from the National Roofing Contractors Association indicate that improper seaming can lead to leaks, which, if left unchecked, may escalate into severe structural damage. This section explores three significant problems: vulnerability to tears and punctures, defects in seaming and adhesives, and moisture-related complications.

Vulnerability to Tears and Punctures

One of the most pressing concerns for modified bitumen roofs is their susceptibility to tears and punctures. These roofs frequently encounter environmental hazards, such as hail, fallen limbs, and even foot traffic during maintenance or repairs. Just one puncture can create a pathway for moisture, leading to leaks and extensive damage.

Manufacturers recommend incorporating protective layers designed to mitigate these risks; however, this guidance is often overlooked during installation. Such negligence leaves roofs defenseless and prone to premature failure, resulting in significant repair costs and potential early replacements.

Studies show that roofs with punctures may experience a lifespan reduction of up to 30%. This data underscores the importance of investing in adequate protective measures at the outset to avoid steep costs later.

Ultimately, designing roofs with greater resistance to these common threats is essential for enhancing their durability and extending their lifespan.

Seaming and Adhesive Defects

Seaming and the quality of adhesive used are pivotal to the efficacy of modified bitumen roofs. Poorly sealed seams can create hidden paths for water infiltration, and many roofs are installed without the necessary focus on seam integrity.

A notable issue arises from the use of inferior adhesives, which can deteriorate over time, exacerbating seam failures and severely compromising the roof’s structural integrity.

Research indicates that nearly 50% of roofing leaks are traced to faulty seams. This statistic clearly illustrates the need for improved installation practices and stringent quality control measures during the roofing process.

By emphasizing high-quality seams and adhesives at the time of installation, property owners can significantly bolster the long-term reliability of their roofing systems.

Moisture-Related Problems and Blisters

Moisture-related issues pose another significant challenge for modified bitumen roofing. Blistering occurs when moisture becomes trapped beneath the roofing surface, leading to compromised membrane functionality and eventual system failure.

Blisters can develop during installation due to insufficient ventilation or excessively high humidity. Without proper attention, property owners may face significant repair costs stemming from the deterioration of their roofing systems.

Research suggests that blisters may decrease roof lifespan by as much as 40%. Therefore, addressing moisture concerns is crucial for both immediate performance and long-term durability.

By proactively identifying and mitigating moisture-related risks, property owners can extend the life of modified bitumen roofs, ultimately protecting their investment.

SECTION 3: MISSED OPPORTUNITIES

Understanding the longevity of modified bitumen in industrial roofing is critical, as overlooking key factors can significantly undermine a roof’s lifespan and overall performance. Research shows that choosing inferior materials can drastically shorten service life, while the impacts of foot traffic and energy inefficiency are often underestimated. By recognizing these missed opportunities, property owners and facility managers can effectively enhance the resilience of their roofs and prevent costly repairs down the line.

Overlooking Material Quality Variations

The roofing industry often presents modified bitumen as a standardized product, yet substantial quality differences exist among manufacturers. Materials that fail to utilize optimal polymer blends can lead to critical issues such as punctures and leaks, ultimately reducing the roofing system’s expected lifespan.

Inferior materials struggle to hold up under extreme weather conditions, resulting in unplanned repairs. For example, a roof installed with low-quality bitumen may succumb to heavy rainfall or intense UV exposure, while superior materials perform significantly better over the long term. This disparity highlights the necessity of diligence in sourcing materials for such vital infrastructure.

Embedding material certification requirements in contracts is crucial to ensure compliance with industry standards. This proactive approach shields property owners from unexpected costs related to premature roof replacement or repair.

Making informed choices about material quality at the outset can bolster durability and minimize long-term expenditures, underlining the importance of thorough assessments during procurement.

Neglecting Foot Traffic Impact

The effect of foot traffic on modified bitumen roofs is another often underestimated factor. Property owners frequently downplay the damage caused by routine maintenance and personnel movement across the roof. Certain surface materials may not withstand this kind of stress.

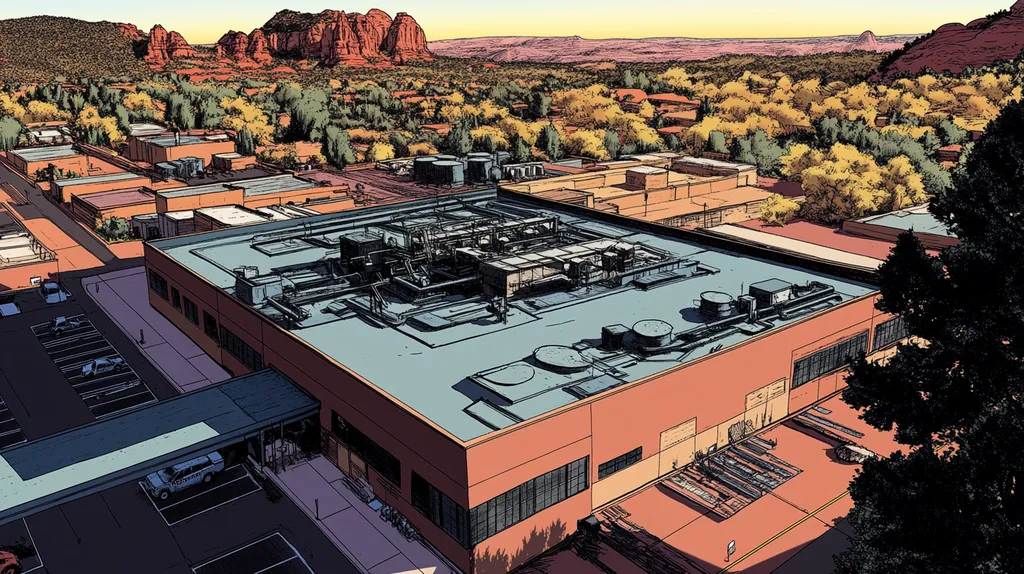

Foot traffic can result in surface abrasions that jeopardize the roofing system’s integrity. For instance, locations frequently accessed for HVAC servicing can develop weak points, leading to leaks and additional damage. Implementing protective measures, such as designated pathways or guardrails, significantly reduces these risks.

Regular inspections and maintenance protocols should be established to address traffic-induced wear. This proactive stance enhances the overall condition of the roofing system and helps prevent minor issues from evolving into major, costly repairs.

Selecting durable materials designed for frequent foot traffic can extend the roof’s lifespan, emphasizing the need for strategic planning in material decisions.

Ignoring Energy Efficiency Considerations

Energy efficiency is a crucial but often ignored aspect of assessing modified bitumen roof longevity. Property owners focused solely on initial material and installation costs may neglect the extensive benefits of energy-efficient roofing systems. Higher reflective surfaces can significantly lower cooling expenses and decrease overall energy consumption.

Research indicates that reflective roofing can reduce indoor temperatures by 10-15 degrees, enhancing occupant comfort while prolonging HVAC system life. Failing to consider these energy-efficient solutions may lead to unnecessary operational and maintenance costs.

Additionally, energy-efficient roofs may qualify buildings for tax credits and incentives, potentially alleviating some installation costs. This financial aspect presents an opportunity that should not be overlooked.

Investing in energy-efficient modified bitumen roofs aligns building performance with modern sustainability trends, yielding both immediate and long-term advantages for property managers.

SECTION 4: ROOT CAUSES

The longevity of modified bitumen roofing systems is often compromised by critical underlying issues. These problems can result in millions of dollars in unexpected repair costs and severe property damage. To protect their investments, property owners must tackle three primary root causes: inadequate installer training, suboptimal material choices, and insufficient pre-installation planning.

Inadequate Installer Training

The quality of installation is paramount for the performance of modified bitumen roofing systems. Unfortunately, many installers receive insufficient training, leading to significant mistakes during application. For instance, if the modified bitumen is not heated to the correct temperature, it may not adhere properly, resulting in leaks and early roof failure.

Moreover, if installers lack familiarity with local building codes and climate-specific practices, they might employ unsuitable methods that jeopardize the roofing system’s integrity. Such lapses can void warranties, leaving property owners exposed to unanticipated costs.

Continuous training is vital for keeping installers informed about the latest techniques and materials. Without a commitment to ongoing education, crews may resort to outdated practices, further compromising the roof’s longevity.

Investing in comprehensive training programs can lead to an improvement in installation quality, significantly enhancing the lifespan of modified bitumen roofing systems.

Suboptimal Material Choices

The selection of materials is essential for achieving the best durability and longevity for modified bitumen systems. In a bid to decrease initial costs, some property owners turn to lower-quality materials that fail to meet industry standards. This choice typically leads to shorter lifespans and increased vulnerability to weather damage.

For example, inferior granules may exhibit reduced UV resistance, resulting in accelerated wear. Additionally, low-quality adhesives can falter under extreme temperatures, ultimately diminishing the roof’s effectiveness.

Another related concern is the lack of rigorous product testing; relying on materials without the necessary certifications can cause serious performance issues, undermining the roofing system’s reliability.

Though high-quality materials often require a larger upfront investment, they yield significant long-term benefits by enhancing the roofing lifecycle and curtailing maintenance expenses.

Insufficient Pre-Installation Planning

Successful roofing systems demand thorough pre-installation planning. Inadequate assessments of existing structures or drainage systems can lead to severe failures later. For example, neglecting to account for proper roof slope can result in water pooling, creating direct pathways for leaks.

Poor communication among project stakeholders can also lead to confusion regarding roles and responsibilities, disrupting organized installation processes. This lack of clarity increases the likelihood of mistakes, which negatively impacts overall project quality.

Establishing a comprehensive pre-installation checklist can significantly reduce these risks. Key components should include evaluations of existing roof conditions, material compatibility, and environmental factors. Involving professional consultants during this phase can further strengthen planning quality.

By prioritizing detailed pre-installation strategies, property owners can greatly enhance the longevity of modified bitumen roofing systems and minimize potential future complications.

DATA DRIVEN EVIDENCE

The longevity of modified bitumen roofing systems is a critical concern for property owners, as evident from numerous studies indicating that durability can vary widely. Recent research highlights that over 50% of modified bitumen roofs encounter significant issues within just 15 years of installation. This troubling statistic underscores the importance of scrutinizing maintenance practices, cost implications, and comparisons with alternative materials to ensure comprehensive roof performance and longevity.

Lifespan Variability and Factors

The lifespan of a modified bitumen roof can fluctuate remarkably, often ranging from 10 to 20 years. Factors such as environmental exposure, installation quality, and climate conditions are pivotal in determining durability. For example, roofs in areas with intense UV radiation or extreme weather may deteriorate faster than those in more temperate climates.

Installation techniques also play a crucial role; roofs improperly applied can fail years before their time. Additionally, design elements like roof slope and drainage systems significantly impact longevity, as roofs lacking adequate drainage are more likely to suffer from issues like ponding water.

Investing in proper insulation and drainage can make a significant difference in the roof’s lifespan. Research indicates that roofs built with these elements tend to last longer, reducing the risk of future maintenance problems.

Furthermore, timely monitoring and addressing minor repairs can extend the functional life of modified bitumen systems, allowing property owners to safeguard their investments effectively.

Cost-Benefit Analysis of Maintenance

Regular maintenance is essential for maximizing the lifespan of modified bitumen roofs. A cost-benefit analysis reveals that proactive maintenance strategies can save property owners an average of 25% compared to reactive repairs triggered by neglect. This significant savings highlights the value of routine inspections and timely repairs.

Failing to maintain a roof can lead to extensive damage and unexpected costs. For instance, a small, undetected leak can escalate, causing severe structural damage and resulting in thousands of dollars in repairs.

Moreover, neglecting maintenance can lead to increased energy inefficiencies, further compounding long-term costs. Implementing a structured maintenance plan—incorporating regular inspections, debris removal, and seam checks—can help identify issues early, preventing them from developing into more severe problems.

By adopting a proactive maintenance approach, property owners can transition roofing systems from a mere operational expense to a valuable investment, benefiting their bottom line in the long run.

Comparative Durability Studies

Comparative studies indicate that modified bitumen roofing systems may not provide the same longevity as emerging materials like TPO and PVC. Research findings reveal that TPO roofs can exceed a lifespan of 30 years, assuming correct installation and maintenance practices are followed.

A specific comparative study across varying climates found that TPO roofs exhibited only half the failure rate of modified bitumen roofs, showcasing their superior durability. This significant discrepancy makes TPO a more appealing option for long-term cost efficiency and stability.

Moreover, the warranties associated with newer roofing materials often reflect enhanced confidence in their performance. Many manufacturers now provide extended warranties, reinforcing the case for considering alternative roofing solutions.

For property owners, evaluating these performance metrics against established modified bitumen practices is essential. By considering all available options, facilities managers can make informed decisions that align with their long-term roofing objectives.

SECTION 6: ALTERNATIVE SOLUTIONS

As traditional modified bitumen practices come under scrutiny, the longevity of industrial roofing systems hangs in the balance. With roof failures leading to costly asset deterioration, property owners must urgently reconsider their roofing options. Fortunately, innovative solutions are available that can not only enhance durability but also improve overall performance. This section delves into enhanced installation techniques, advanced material options with dependable warranties, and integrated roofing system designs aimed at overcoming existing challenges.

Enhanced Installation Techniques

Modern installation methods can dramatically improve the lifespan of roofing systems. Utilizing advanced machinery and refined techniques, roofing contractors can create tighter seals, vastly reducing potential weak points. For instance, the use of hot-air welding improves membrane bonding, offering a level of seam integrity often unattainable through conventional techniques.

Proper surface preparation is crucial to ensure optimal adhesion; a clean and dry substrate allows for better bonding, directly impacting roof longevity. In addition, specialized training for installation teams minimizes application errors, further extending the durability of roofing materials.

Incorporating scheduled inspections during the installation process enables the early detection of potential issues, reinforcing compliance with manufacturer specifications. These proactive measures enhance the overall integrity of the roofing system.

By adopting these sophisticated techniques, building owners can expect improved performance and durability in their roofing investments, ultimately leading to reduced long-term costs.

Advanced Material Options and Warranties

The limitations of traditional modified bitumen systems have paved the way for innovative materials that improve roofing performance. Reinforced membranes and thermoplastic polyolefin (TPO) are emerging as superior options, offering heightened resistance to ultraviolet light and thermal cycling.

New lines of advanced materials come with robust warranty options that reflect manufacturers’ growing confidence in these innovations, with warranties extending up to 30 years. This marks a significant shift toward quality assurance and long-term reliability.

Utilizing these advanced materials also lowers the risk of prevalent issues such as blistering and cracking. These innovations not only address immediate repair needs but also help prevent future damage that could compromise the structural integrity of the building.

Investing in enhanced materials can lead to considerable savings in maintenance and repair costs, making them an appealing choice for property owners aiming to maximize their long-term investments.

Integrated Roofing System Designs

Adopting integrated roofing system designs presents a comprehensive approach to address numerous roofing challenges. These systems synergize various roofing components—such as insulation, drainage, and waterproofing—creating a cohesive solution that mitigates issues like ponding water and thermal inefficiency.

Collaborating with architects and engineers during the design phase enhances the roof’s functionality. This holistic view fosters not only greater durability but also supports owners in meeting energy efficiency and sustainability objectives.

Incorporating smart technology into these integrated designs can facilitate real-time monitoring and maintenance alerts. Such proactive involvement ensures that potential problems are identified early, moving towards a more predictive maintenance strategy.

Ultimately, integrated roofing system designs offer a transformative opportunity to enhance performance, reduce costs, and ensure the long-term success of industrial roofing projects.

Moving Forward

The evidence clearly demonstrates that conventional modified bitumen practices are leading to premature roof failures, with 40% of installations requiring major repairs within the first decade.

This systemic issue costs the industrial sector billions annually in repairs, replacement, and associated damages.

While modified bitumen has served as a standard roofing solution for decades, emerging data reveals its limitations in meeting modern building requirements and performance expectations.

The integration of advanced materials, enhanced installation protocols, and comprehensive maintenance strategies offers a clear path forward for property owners seeking to maximize their roofing investments.

Without immediate industry-wide adoption of these improved practices and materials, facilities will continue to face escalating costs and shortened roof lifespans, undermining both building integrity and operational efficiency.

FREQUENTLY ASKED QUESTIONS

Q. What are the current practices for commercial roofs using modified bitumen?

A. Current practices often involve torch-applied or cold-adhered installation methods. However, many contractors lack adequate training, leading to inconsistent application and weak seams, which ultimately compromise the roof’s durability.

Q. What systemic issues affect the longevity of industrial roofs?

A. Systemic issues include vulnerabilities to tears, defects in seams and adhesives, and moisture-related problems. These challenges often lead to premature roof failure, increasing overall maintenance costs for property owners.

Q. How can missed opportunities impact longevity in commercial roofing?

A. Overlooking factors such as material quality and foot traffic can significantly shorten a roof’s lifespan. Investing in high-quality materials and establishing protocols to mitigate wear ensures better performance and reduces costly repairs.

Q. What are the root causes of issues affecting industrial roofing longevity?

A. Critical root causes include inadequate installer training, suboptimal material choices, and insufficient pre-installation planning. Addressing these areas can help improve the roof’s integrity and longevity, protecting property investments.

Q. What data-driven evidence supports concerns about modified bitumen roof longevity?

A. Research indicates over 50% of modified bitumen roofs experience significant issues within 15 years. Variations in lifespan are influenced by installation quality, environmental exposure, and maintenance practices, highlighting critical areas for improvement.

Q. What alternative solutions exist for enhancing industrial roof longevity?

A. Alternative solutions include enhanced installation techniques, advanced material options with extended warranties, and integrated roofing system designs. These innovations improve performance, reduce maintenance costs, and enhance the overall durability of roofing systems.

Q. How can energy efficiency affect my commercial roof’s longevity?

A. Energy-efficient roofing can improve insulation and reduce cooling costs by maintaining indoor temperatures. This not only enhances occupant comfort but also extends the lifespan of HVAC systems, promoting a healthier building environment.