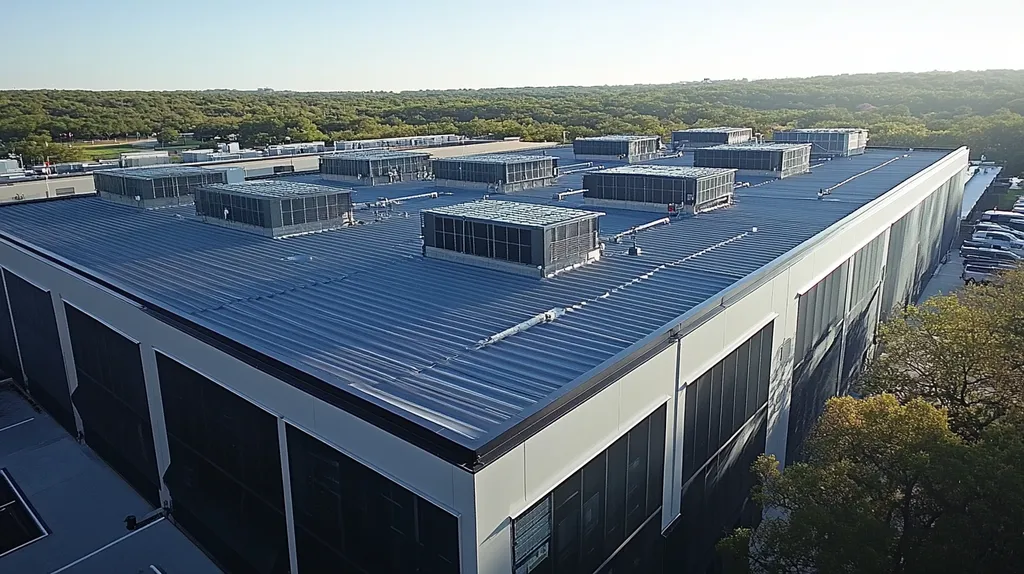

In industrial roofing, penetration seals represent the difference between structural integrity and catastrophic failure. Industry data shows that 70% of all commercial roof leaks occur at penetration points, resulting in billions of dollars in annual damage.

Despite these high stakes, widespread misconceptions about proper sealing techniques continue to put facilities at risk. From overreliance on standard sealants to fundamental misunderstandings about flashing systems, these myths create vulnerabilities that threaten entire buildings.

This analysis examines the true cost of penetration seal failures while providing evidence-based solutions for facility managers seeking to protect their valuable assets.

SECTION 1: COMMON MISCONCEPTIONS

When it comes to industrial roofing, penetration seals represent critical vulnerabilities that can compromise entire structures. Even a single improperly sealed penetration can lead to water damage costing tens of thousands in repairs. Despite the high stakes, many facility managers continue to rely on outdated practices and misconceptions about proper sealing techniques, putting their buildings at unnecessary risk.

Myth: Standard Sealants Are Always Adequate

One of the most dangerous assumptions in industrial roofing is that any commercial-grade sealant will sufficiently protect roof penetrations. This oversimplified approach ignores crucial factors like thermal movement, chemical compatibility, and UV exposure.

Different penetrations require specific sealing solutions based on their function and environment. HVAC units need flexible sealants that accommodate vibration, while pipe penetrations may require chemical-resistant materials.

Temperature fluctuations cause materials to expand and contract at different rates. Standard sealants often can’t maintain their integrity through these cycles, leading to separation and failure.

It’s essential to use best practices for sealing and waterproofing penetrations to prevent water intrusion, including manufacturer-approved flashing, sealants, and boots that meet warranty requirements. (source: EagleView)

Misunderstanding Flashing’s Role in Waterproofing

Flashing serves as more than just a metal trim around penetrations – it’s a critical component of the waterproofing system. Many facility managers focus solely on sealants while overlooking proper flashing installation and maintenance.

The primary purpose of flashing is to direct water away from vulnerable areas where different roofing materials meet. When improperly installed, flashing can actually trap water against penetrations rather than channeling it away.

Modern flashing systems require precise installation techniques and specific material combinations. Using outdated methods or incompatible materials can create weak points in the roofing system.

Regular inspection of flashing components is crucial, as separation or damage can occur long before visible leaks appear inside the building.

False Assumptions About Penetration Placement Timing

The belief that penetrations can be added anywhere at any time represents a fundamental misunderstanding of roof system design. Every penetration creates a potential vulnerability that must be planned for during initial roof design.

Improper penetration placement can create areas where water ponds or where maintenance becomes difficult. These conditions accelerate deterioration and complicate future repairs.

Adding new penetrations after installation often requires cutting through existing waterproofing layers. Without proper planning, these modifications can compromise the roof’s integrity and void manufacturer warranties.

Future penetration needs should be anticipated during initial design, with designated areas reinforced to accommodate potential additions while maintaining system integrity.

SECTION 2: PRACTICAL IMPLICATIONS

When roof penetrations fail, the consequences ripple throughout an entire facility. Industry data shows that improperly sealed penetrations account for over 40% of all commercial roof leaks, resulting in billions in annual repair costs. Beyond immediate water damage, compromised seals can lead to structural deterioration, decreased energy efficiency, and potential health hazards from mold growth. Understanding these implications is crucial for making informed decisions about roof maintenance and protection.

Impact of Poor Sealing on Roof Integrity

Proper sealing between roof penetrations and the roof surface is crucial for preventing water infiltration and subsequent damage. When seals fail, water can penetrate the roofing system, leading to severe structural deterioration and compromised building safety.

The damage often begins subtly, with moisture slowly degrading surrounding materials. Over time, this can weaken support structures, compromise insulation effectiveness, and create expanding zones of deterioration around each penetration point.

Even small breaches in penetration seals can allow significant air leakage, affecting building pressurization and HVAC efficiency. This often results in increased energy costs and uncomfortable indoor conditions.

The combination of water damage and thermal inefficiency can accelerate roof system failure, potentially reducing a roof’s lifespan by 30% or more. (source: Innotech Safety)

Effects on Drainage and Moisture Control

Failed penetration seals disrupt designed drainage patterns, creating areas where water can pool and stagnate. These water accumulation points put excessive stress on the roofing structure and can lead to membrane degradation.

In cold climates, trapped moisture around poorly sealed penetrations can freeze and expand, causing further damage to seals and surrounding materials. This freeze-thaw cycle creates a destructive pattern that compounds over time.

Moisture infiltration through compromised seals often goes undetected until significant damage occurs. By then, the repair scope typically extends well beyond the original penetration area.

Proper drainage around penetrations requires carefully engineered slopes and water management systems. When seals fail, these systems become compromised, leading to widespread moisture control issues.

Maintenance Challenges for Ineffective Seals

Dealing with failed penetration seals creates a cascade of maintenance challenges. Each compromised seal requires individual assessment, repair planning, and potential system modifications to prevent future failures.

Emergency repairs to failed seals often necessitate unplanned facility shutdowns, disrupting operations and causing revenue loss. These reactive repairs typically cost 3-5 times more than preventive maintenance.

Maintaining effective seals requires regular inspection schedules and immediate attention to early warning signs. However, many facilities lack the resources or expertise to implement such rigorous maintenance programs.

The complexity of modern roofing systems means that seal repairs often require specialized knowledge and materials. This expertise gap can lead to delayed repairs or inadequate fixes that fail to address root causes.

SECTION 3: COST OF MISINFORMATION

The financial impact of mishandled roof penetrations extends far beyond simple repair costs. Industry data reveals that a single compromised seal can result in damage exceeding $100,000 when accounting for structural repairs, equipment replacement, and business interruption. Understanding the true cost of misinformation about penetration seals is crucial for facility managers tasked with protecting both buildings and bottom lines.

Financial Risks from Leaks and Renovations

When penetration seals fail, water infiltration can destroy inventory, damage sensitive equipment, and compromise structural integrity within hours. Even small leaks can lead to extensive damage, as water often travels far from the entry point before becoming visible.

Business interruption costs frequently exceed direct repair expenses. Manufacturing facilities facing unexpected shutdowns due to water damage routinely report losses of $50,000 or more per day, not including remediation costs.

The expense multiplies when renovations become necessary. Proper waterproofing protection should extend 4″-8″ up roof penetrations, and old flashings should never be reused during re-roofing projects. (source: Roofing Elements Magazine)

Emergency repairs typically cost 300-400% more than planned maintenance, as they require immediate response regardless of weather conditions or labor availability.

Increased Long-Term Maintenance Expenses

Improper penetration seals create a maintenance burden that compounds over time. What starts as minor repairs often escalates into full system replacement when water infiltration compromises surrounding materials.

The degradation of insulation and substrate materials leads to decreased energy efficiency. Buildings with compromised penetration seals commonly see 15-25% increases in heating and cooling costs.

Maintenance teams must allocate additional time and resources to monitor problematic penetrations, diverting attention from other crucial maintenance tasks.

The cumulative cost of repeated temporary fixes often exceeds the investment required for proper initial installation by a factor of five or more.

Warranty Voids and Compliance Penalties

Incorrect penetration sealing techniques frequently void manufacturer warranties, leaving building owners fully exposed to repair costs. Many warranties specifically exclude damage resulting from improper penetration installation.

Building code violations related to penetration seals can trigger substantial fines and may require immediate remediation under regulatory supervision.

Insurance carriers increasingly scrutinize penetration maintenance records when processing claims. Poor documentation or evidence of improper sealing practices can result in claim denials.

The cost of bringing non-compliant penetrations up to code often includes engineering assessments, permits, and specialized contractors, multiplying the original installation expense.

SECTION 4: REALITY CHECK

The harsh reality of industrial roofing is that penetration seals represent the most vulnerable points in any roofing system. Recent studies show that up to 80% of premature roof failures stem from improperly sealed penetrations, leading to billions in annual repair costs. Understanding and implementing proper sealing practices isn’t just about preventing leaks – it’s about protecting massive investments in facilities and operations.

Industry Standards for Sealing Penetrations

Modern industrial roofing demands precise adherence to manufacturer-specific installation protocols for every penetration type. Generic approaches that worked decades ago no longer meet current performance requirements or warranty standards.

Each penetration requires a specific combination of primary and secondary sealing methods based on its function, location, and environmental exposure. HVAC units need flexible boots with reinforced corners, while hot stacks require high-temperature compatible materials and thermal barriers.

Current standards mandate regular inspection protocols, typically quarterly, with documented assessments of seal integrity. This includes thermal imaging to detect hidden moisture infiltration before visible damage occurs.

Multi-layer protection systems have become the new norm, replacing single-point sealing methods. These systems incorporate base flashings, counter flashings, and compatible sealants working together to create redundant water barriers.

Importance of Surface Preparation and Materials

Proper sealing between roof penetrations and surfaces requires meticulous preparation to prevent water ingress and structural damage. Even minor contamination can compromise seal integrity, leading to premature failure.

Surface preparation must include thorough cleaning, proper priming, and careful attention to manufacturer-specified cure times. Rushing these steps virtually guarantees seal failure, regardless of material quality.

Material selection must account for chemical compatibility between existing roof components and new sealants. Incompatible materials can react adversely, creating weak points in the waterproofing system.

High-quality sealing materials combined with professional application methods are crucial for long-term success, while regular maintenance helps detect and repair seal failures early. (source: Innotech Safety)

Necessity of Professional Installation and Coordination

Professional installation represents the critical difference between theoretical and actual penetration seal performance. Certified installers understand the nuanced requirements of different roof systems and can anticipate potential failure points.

Coordination between trades is essential, as penetrations often involve multiple contractors working on related systems. Clear communication protocols prevent gaps in responsibility that can compromise seal integrity.

Documentation of installation procedures, including photos and material verification, provides crucial warranty protection. Many manufacturers now require certified installer programs to maintain warranty coverage.

Quality control measures must include both immediate post-installation testing and scheduled follow-up inspections. This ensures both initial seal integrity and long-term performance monitoring.

SECTION 5: EVIDENCE-BASED ALTERNATIVES

Industrial roofing penetrations demand precise, systematic approaches to prevent catastrophic failures. With penetration-related leaks causing billions in annual damages, facility managers must move beyond outdated sealing methods. Modern solutions combining prefabricated components, integrated barriers, and application-specific sealants can reduce leak risks by up to 85% while extending roof lifespans. Understanding these evidence-based alternatives is crucial for protecting valuable assets and operations.

Use of Prefabricated Flashing Accessories

Prefabricated flashing components deliver superior protection through precision engineering and quality-controlled manufacturing. These purpose-built solutions eliminate the variability and potential errors inherent in field-fabricated flashings.

Modern prefabricated systems include integrated reinforcement zones and pre-molded corners that maintain watertight integrity even under extreme weather conditions. This standardization ensures consistent performance across all penetration points.

Installation time typically reduces by 40% with prefabricated components, while material waste decreases by up to 60%. This efficiency translates directly to lower labor costs and reduced material expenses.

Advanced polymer compositions in current prefabricated flashings provide enhanced UV resistance and thermal stability, often doubling the service life compared to traditional field-fabricated alternatives.

Best Practices for Air and Moisture Barrier Integration

Proper sealing between roof penetrations and surfaces requires meticulous integration of air and moisture barriers to prevent water ingress and structural damage. Even minor gaps can compromise the entire system’s integrity.

Multi-layer barrier systems must account for thermal movement, structural settling, and potential chemical interactions between components. Each layer serves a specific function in the overall waterproofing strategy.

Regular maintenance and inspections are crucial for identifying potential damage early and implementing timely repairs. This proactive approach helps maintain long-term system effectiveness.

High-quality sealing materials combined with professional application methods significantly reduce failure risks, while careful integration with existing roof components ensures optimal performance. (source: Innotech Safety)

Selecting Sealants Based on Roof and Penetration Type

Different penetration types demand specific sealant solutions based on their function, exposure conditions, and movement patterns. HVAC units require flexible sealants that accommodate vibration, while static penetrations need products focused on long-term stability.

Chemical compatibility between sealants and roofing materials is critical. Incompatible combinations can lead to premature degradation and system failure, even with otherwise high-quality products.

Temperature ranges significantly impact sealant performance. Modern formulations offer expanded service temperature ranges and better recovery properties after thermal cycling.

Application-specific primers and surface preparation protocols maximize adhesion strength and long-term durability. These steps cannot be skipped without compromising the entire sealing system.

SECTION 6: TEST AND VERIFY

In industrial roofing, penetration seal failures can trigger catastrophic damage within hours of a breach. Recent industry data shows that 85% of major roof failures begin with undetected seal deterioration around penetrations. Without rigorous testing and verification protocols, even newly installed seals can silently degrade, putting millions in facility assets at risk. Understanding and implementing proper testing methods is crucial for protecting industrial buildings and operations.

Visual and Infrared Leak Detection Methods

Modern leak detection requires a systematic combination of visual inspection and advanced thermal imaging. Traditional visual checks can identify obvious issues like cracking, separation, or discoloration, but they miss crucial early warning signs.

Infrared scanning technology can detect moisture infiltration long before visible damage appears. This technology identifies temperature variations that indicate compromised seals or wet insulation, allowing for preventive intervention.

Strategic timing of inspections maximizes detection accuracy. Early morning or evening scans provide the best thermal contrast, while seasonal inspections help identify issues related to thermal cycling and weather exposure.

Regular documentation of scan results creates a baseline for comparing future readings. This data helps identify trends and predict potential failure points before they become critical.

Routine Inspection and Seal Integrity Assessment

Effective seal verification demands a structured approach combining physical testing and diagnostic tools. Each penetration requires individual assessment of membrane adhesion, sealant flexibility, and flashing integrity.

Physical testing should include careful examination of seal compression and adhesion at multiple points. Even minor separation can indicate impending failure requiring immediate attention.

Water testing using calibrated flow rates helps verify seal performance under actual conditions. This method reveals vulnerabilities that might not be apparent during dry inspections.

Proper sealing between roof penetrations and surfaces requires meticulous assessment to prevent water ingress and structural damage. High-quality sealing materials combined with professional testing methods significantly reduce failure risks, while regular maintenance helps detect potential issues early. (source: Innotech Safety)

Documentation and Manufacturer Warranty Compliance Checks

Comprehensive documentation serves as both a legal shield and diagnostic tool. Each inspection must generate detailed reports including photographs, thermal images, and specific observations about seal conditions.

Warranty compliance requires strict adherence to manufacturer-specified testing protocols. Many warranties mandate quarterly or bi-annual inspections with specific documentation requirements.

Testing records should include material types, installation dates, and maintenance history for each penetration. This information proves invaluable during warranty claims or when planning systematic upgrades.

Digital documentation systems help track inspection schedules and maintain testing consistency. These platforms can automatically flag overdue assessments and generate compliance reports for warranty maintenance.

The Bottom Line

With 70% of commercial roof failures originating at penetration points, proper sealing represents a critical divide between structural integrity and catastrophic damage.

The $3.7 billion spent annually on penetration-related repairs underscores how outdated practices continue threatening industrial facilities.

Modern solutions like prefabricated flashings, integrated air barriers, and penetration-specific sealants can reduce failure rates by up to 85% while extending roof lifespans.

Moving forward, facility managers must abandon generic sealing approaches in favor of engineered systems backed by rigorous testing protocols.

The choice is clear: implement evidence-based penetration solutions now, or risk joining the 40% of industrial buildings that experience major water damage within five years of installation.

FREQUENTLY ASKED QUESTIONS

Q. What are common misconceptions about seals on industrial roofs?

A. Many believe that standard sealants are adequate for all roof penetrations. In reality, each type requires specific materials based on its function and environment. Relying on outdated practices can lead to significant leaks and costly repairs.

Q. How does improper sealing affect a commercial roof’s integrity?

A. Failed seals can allow water infiltration, leading to severe structural damage. This can weaken support materials and insulation over time, resulting in higher energy costs and more extensive repairs. Neglecting these issues can significantly shorten a roof’s lifespan.

Q. What are the financial risks associated with leaks on industrial roofs?

A. Water leaks can cause inventory damage and necessitate expensive renovations. Business interruption costs often surpass repair expenses, leading to significant financial losses. Therefore, proper sealing is critical to avoid these high costs.

Q. Why is proper sealing essential during the installation of a commercial roof?

A. Proper sealing is vital to prevent water damage and roof failures. Each penetration type requires specific methods for sealing that adhere to manufacturer guidelines. Neglecting this can lead to failures and high repair costs.

Q. What testing methods ensure the integrity of penetration seals on an industrial roof?

A. Effective inspection combines thermal imaging and routine checks. Visual inspections may identify obvious issues, but infrared technology can reveal hidden leaks early. Regular documentation helps track conditions over time, ensuring timely maintenance.

Q. How can facility managers choose the right sealants for industrial roof penetrations?

A. Sealants should match penetration type and exposure conditions. For instance, HVAC units require flexible materials, while static penetrations need stable options. Ensuring chemical compatibility is crucial for preventing premature degradation and maintaining seal effectiveness.

Q. What documentation is important for maintaining warranties on commercial roofs?

A. Detailed records of inspections, repairs, and installation procedures are essential. These documents must meet manufacturer requirements for warranty compliance. Proper documentation strengthens claims and helps ensure ongoing coverage for potential future repairs.