Every year, commercial properties lose millions of dollars to pest-related roof damage that could have been prevented through proper resistance measures. Industry data shows that 40% of premature roof failures stem from inadequate pest protection.

For property managers, separating fact from fiction regarding pest resistance has become crucial as infestations grow more aggressive and treatment costs spiral upward.

This analysis examines common misconceptions, practical implications, and evidence-based solutions for protecting commercial roofing assets from destructive pest activity.

SECTION 1: COMMON MISCONCEPTIONS

Commercial roofing faces constant threats from pests, yet many property managers operate under dangerous misconceptions about pest resistance. These misunderstandings can lead to premature roof failure, unexpected repair costs, and business disruptions. A commercial roofing system begins experiencing wear and tear from installation day, making proper pest management crucial for maintaining structural integrity and preventing costly damage.

Myth: Roofing Materials Are Pest-Proof

Modern commercial roofing materials provide significant pest resistance, but no system is completely impenetrable. Even advanced materials like TPO and PVC membranes can be compromised by determined pests seeking entry points.

The misconception of total pest immunity often leads property managers to overlook early warning signs. Small entry points around HVAC units, vents, and flashing become major vulnerabilities when left unchecked.

While some materials offer enhanced resistance to specific pests, this protection diminishes over time. Environmental factors, UV exposure, and regular wear can create weak points that pests exploit.

Understanding these limitations helps property managers implement more realistic and effective pest management strategies.

Misunderstanding Pest Behavior on Roof Surfaces

A commercial roofing system endures multiple challenges from the moment of installation, including debris accumulation, weather exposure, and pest activity. Over its lifetime, these factors combine to create ideal conditions for pest infestations. (source: Hershey Exteriors)

Property managers often fail to recognize how pests systematically test and exploit roofing vulnerabilities. What appears as random damage often follows predictable patterns based on pest behavior and seasonal changes.

Different pests target specific roofing components. Birds damage protective coatings, rodents chew through membranes, and insects establish colonies in insulation layers.

Understanding these behavior patterns enables more targeted and effective prevention strategies.

False Belief: Pest Resistance Means No Maintenance Needed

The most dangerous misconception is that pest-resistant materials eliminate the need for regular maintenance. This belief leads to delayed inspections and overlooked warning signs.

Even the most advanced pest-resistant systems require periodic inspection and maintenance. Accumulated debris, standing water, and weathering create conditions that attract pests and compromise resistance features.

Successful pest management requires an integrated approach combining material selection, regular maintenance, and proactive monitoring. Relying solely on material properties inevitably leads to system failures.

Property managers must recognize that pest resistance is an ongoing process rather than a one-time solution. Regular maintenance preserves both pest-resistant properties and overall roof integrity.

SECTION 2: PRACTICAL IMPLICATIONS

When pests compromise commercial roofing systems, the consequences ripple throughout the entire building envelope. A single roof rat colony can cause over $200,000 in damage through destroyed insulation, compromised waterproofing, and secondary water damage. Beyond the immediate structural threats, pest infestations create cascading effects that impact building operations, tenant satisfaction, and property values.

Impact of Pest Activity on Roof Integrity

Pest damage to commercial roofs typically begins subtly but escalates rapidly. Rodents create entry points as small as a quarter-inch, which quickly expand into major breaches that compromise waterproofing systems.

Birds pose a distinct threat through both mechanical damage and chemical deterioration. Their droppings contain acids that break down protective coatings, while nesting materials block drainage systems and create dangerous ponding conditions.

Insect infestations particularly target roof substrate materials. Carpenter ants and termites hollow out wooden components, while other species burrow into insulation layers, creating thermal efficiency losses.

The compounding nature of pest damage means small breaches quickly evolve into system-wide failures. What starts as minor surface damage can progress to complete roof system compromise within months.

How Pest Infestation Affects Building Operations

The operational impacts of roof pest infestations extend far beyond structural concerns. Energy costs spike as damaged insulation and compromised air barriers reduce HVAC efficiency.

Pest activity creates liability risks through potential health code violations and workplace safety issues. The presence of droppings, nesting materials, and pest-related debris can trigger regulatory compliance problems.

Building occupants often report reduced productivity and increased sick days when pest infestations occur. These issues directly impact tenant satisfaction and lease renewal rates.

The New York City Board of Education demonstrated that comprehensive integrated pest management programs significantly reduce both pesticide usage and associated costs while improving building performance. (source: Institute of Integrated Pest Management)

Challenges in Pest Control for Commercial Roofs

Commercial roof pest control requires specialized approaches that balance effectiveness with material compatibility. Standard pest control methods often prove inadequate or potentially damaging to roofing components.

Access limitations and safety requirements complicate treatment programs. Many pest control professionals lack the specific training needed to work safely on commercial roofing systems while delivering effective treatments.

Weather conditions and exposure severely impact treatment longevity. Wind, rain, and UV radiation can quickly degrade traditional pest control products, requiring more frequent applications.

Seasonal pest behavior patterns demand dynamic management strategies. Different species become active at various times throughout the year, requiring continuous monitoring and adaptive response protocols.

The complexity of modern roofing systems means pest control measures must protect multiple layers and components simultaneously. This demands carefully coordinated approaches that preserve both pest resistance and roof integrity.

SECTION 3: COST OF MISINFORMATION

The financial impact of pest-related roofing damage reaches far beyond simple repair costs. Industry data shows that commercial properties face an average of $12,000 to $25,000 in unplanned expenses annually due to pest-related roof issues. For large facilities, these costs can escalate into six-figure territory when accounting for structural damage, energy losses, and business interruption.

Financial Risks from Ignoring Pest Vulnerabilities

When pest issues go unaddressed, seemingly minor problems rapidly evolve into major structural concerns. Initial entry points as small as a quarter-inch can expand to compromise entire roofing sections within months.

The deterioration often accelerates during seasonal changes, as pests seeking shelter can double or triple their damage output. This creates a compounding effect where each generation of pests expands existing damage.

Insurance claims for pest-related damage frequently face partial or complete denial due to classification as “preventable damage.” This leaves property owners fully exposed to repair costs that could have been avoided through proper prevention.

Expense of Reactive Pest Damage Repairs

Emergency repairs typically cost 3-5 times more than planned maintenance interventions. This premium reflects both the urgent nature of the work and the extensive scope of damage that develops before detection.

The Institute of Pest Management reports that implementing proper Integrated Pest Management (IPM) strategies, while requiring initial investment, significantly reduces long-term repair expenses and pesticide costs. (source: Institute of Integrated Pest Management)

Beyond direct repair costs, businesses face substantial losses from operational disruptions. A single day of closure for emergency repairs can cost retailers thousands in lost revenue, while manufacturing facilities may lose tens of thousands per hour.

Hidden Costs of Ineffective Pest Prevention Strategies

Inadequate pest prevention creates a cascade of unexpected expenses throughout building systems. Compromised insulation increases energy costs by 20-30%, while damaged vapor barriers lead to moisture accumulation and accelerated deterioration.

Poor pest management strategies often result in repeated treatment applications that damage roofing materials. These treatments can void warranties and create additional repair needs, multiplying the original prevention costs.

The environmental impact of ineffective pest control carries its own price tag. Regulatory fines for improper pesticide use or environmental contamination can reach $10,000 per incident, while remediation costs multiply that figure.

Property values suffer when pest issues become apparent, often reducing market value by 10-15%. This depreciation compounds other losses and can impact financing terms for future improvements.

SECTION 4: REALITY CHECK

Despite significant advances in commercial roofing technology, pest-related damage continues to plague facilities nationwide. Industry data shows that nearly 40% of premature roof failures stem from inadequate pest resistance measures and compromised materials. Understanding the true capabilities and limitations of roofing systems, along with implementing proper design and inspection protocols, can mean the difference between a roof that lasts decades and one that fails prematurely.

Actual Pest Resistance Characteristics of Roofing Materials

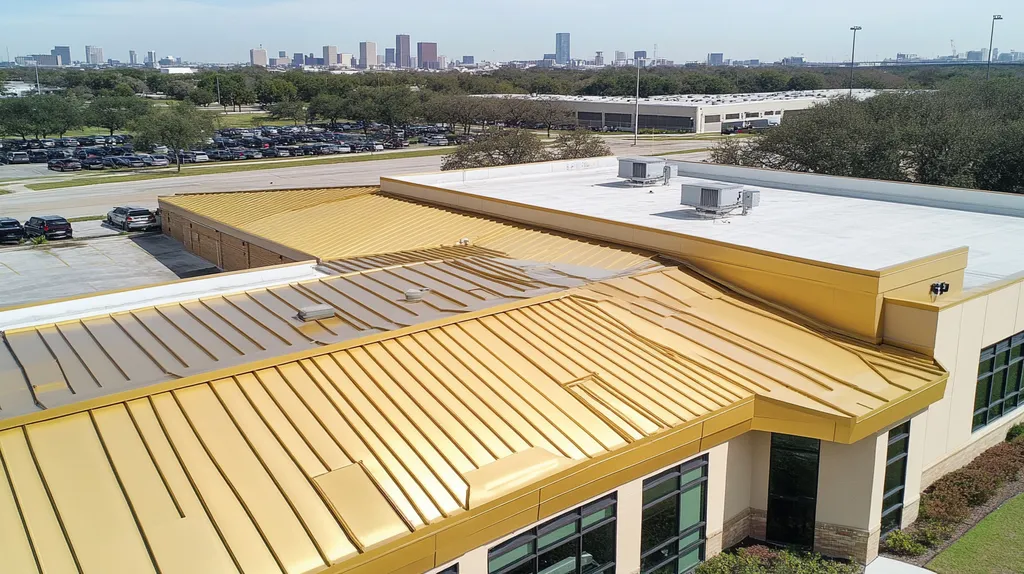

Modern commercial roofing materials offer varying degrees of pest resistance, with significant differences in long-term performance. Metal roofing systems with interlocking panels provide superior protection against pest intrusion while delivering exceptional durability and energy efficiency. (source: Cambieroofing.com)

Single-ply membranes like TPO and PVC offer strong initial pest resistance but require careful attention to seams and penetrations. These vulnerable points often become entry targets for determined pests seeking access to underlying insulation layers.

Built-up roofing systems present unique challenges, as multiple layers can provide nesting opportunities if not properly sealed. The gravel surface, while protective against UV damage, may harbor insects and provide cover for larger pests.

Material selection must account for both immediate pest resistance and long-term durability under sustained pest pressure. Even the most resistant materials require proper installation and maintenance to maintain their protective properties.

Role of Roof Design in Pest Deterrence

Effective pest resistance begins with thoughtful roof design that eliminates common vulnerability points. Proper slope and drainage patterns prevent standing water accumulation that attracts insects and provides drinking sources for larger pests.

Strategic placement of mechanical equipment and penetrations reduces potential entry points. Clustering these elements allows for more effective monitoring and simplified maintenance access.

Parapet walls and edge details require careful design consideration to prevent pest harborage. Incorporating deterrent features like angled surfaces and smooth finishes makes these areas less attractive to birds and rodents.

Ventilation systems must balance air flow requirements with pest exclusion. Properly sized and screened openings maintain necessary airflow while preventing pest entry.

Importance of Regular Roof Inspections for Pest Control

Professional roof inspections serve as the frontline defense against pest infiltration. Monthly visual assessments can identify early warning signs like material displacement, unusual debris accumulation, or pest activity markers.

Seasonal inspections should focus on potential entry points that develop through thermal cycling and weathering. Areas around flashings, penetrations, and equipment curbs require particular attention as these commonly develop gaps over time.

Documentation of inspection findings creates valuable trending data for predicting and preventing pest issues. This information helps facility managers allocate resources more effectively and justify preventive maintenance budgets.

Inspection programs must adapt to changing pest pressures throughout the year. Different species become active during various seasons, requiring adjustments to inspection focus and frequency.

SECTION 5: EVIDENCE-BASED ALTERNATIVES

Modern commercial roofing faces unprecedented pest challenges that threaten both structural integrity and operational continuity. With pest-related damages costing facilities an average of $15,000-30,000 annually, property managers need proven solutions beyond traditional approaches. Evidence-based alternatives in material selection, integrated management, and maintenance protocols can dramatically reduce these risks while extending roof lifespans.

Selecting Roofing Materials with Proven Pest Resistance

Material selection serves as the foundation of effective pest resistance. Advanced polymer-based membranes like reinforced TPO and PVC provide superior resistance to pest penetration through their non-organic composition and seamless installation methods.

Multi-layer systems combining different materials create redundant barriers against pest intrusion. This approach pairs tough outer membranes with specialized underlayments that resist nesting and burrowing.

Protective coatings and treatments enhance inherent material resistance. UV-stable elastomeric coatings not only waterproof but also discourage pest activity by maintaining surface temperatures outside optimal ranges for common pests.

Edge materials and flashing components require equally careful consideration. Heavy-gauge metal components with interlocking joints eliminate common entry points while providing decades of reliable performance.

Integrated Pest Management Approaches for Roofs

Comprehensive pest management requires coordinated strategies that address both immediate concerns and long-term prevention. IPM programs emphasize prevention through pest exclusion and environmental management rather than reactive chemical treatments.

Strategic monitoring protocols help identify pest activity before significant damage occurs. Regular inspections focus on high-risk areas like mechanical penetrations, drainage points, and material transitions.

Non-chemical control methods provide the first line of defense. Physical barriers, deterrent systems, and habitat modification effectively discourage pest activity without risking material damage.

The IPM Institute reports that properly implemented programs can reduce pest control costs by up to 30% while minimizing chemical usage and improving prevention outcomes. (source: Institute of Integrated Pest Management)

Maintenance Practices that Reduce Pest Attraction

Proactive maintenance dramatically reduces pest attraction factors. Regular cleaning removes organic debris, eliminates food sources, and prevents pest habitat formation before infestations establish.

Drainage system maintenance prevents water accumulation that attracts insects and provides drinking sources for larger pests. Clear gutters, functioning drains, and proper slope maintenance ensure rapid water removal.

Structural repairs must address both obvious and subtle damage. Even minor gaps or separations in roofing components can provide pest entry points that expand rapidly under continued exploitation.

Vegetation management around roof perimeters creates buffer zones that discourage pest access. Regular trimming and removal of overhanging branches eliminates natural bridges that pests use to access roofing systems.

Documentation of maintenance activities enables trend analysis and early problem identification. Tracking inspection results, repair history, and pest activity patterns supports more effective prevention strategies.

SECTION 6: TEST AND VERIFY

Comprehensive testing and verification systems are essential safeguards against devastating pest damage in commercial roofing. Industry data shows that undetected pest infestations cost U.S. businesses over $500 million annually in premature roof replacements and structural repairs. Early detection through systematic monitoring reduces repair costs by up to 65% while extending roof lifespans by preventing cascading damage from pest activity.

Methods for Assessing Roof Pest Infestation

Professional assessment protocols combine multiple detection methods to create comprehensive pest activity profiles. Surface mapping using specialized UV markers reveals pest travel patterns and entry points that remain invisible during standard inspections.

Acoustic monitoring systems detect pest movement within roof assemblies before visible damage occurs. These tools are particularly effective for identifying rodent activity in concealed spaces and tracking colony expansion patterns.

Chemical marker analysis of debris and residue provides precise identification of pest species and infestation levels. This information enables targeted treatment protocols that protect roofing materials while effectively addressing specific pest threats.

Pressure testing around penetrations and transitions reveals compromised seals and potential entry points. This method identifies vulnerabilities before pests exploit them, enabling preventive repairs that maintain system integrity.

Monitoring Tools and Technologies for Pest Detection

Advanced monitoring systems combine environmental sensors with automated alert protocols to provide 24/7 pest surveillance. Motion detection arrays integrated with thermal imaging identify pest activity patterns while distinguishing between species based on size and movement characteristics.

Smart monitoring platforms aggregate data from multiple sensor types to generate comprehensive activity reports. These systems track pest pressure changes over time and correlate them with environmental conditions and seasonal patterns.

Remote monitoring capabilities enable real-time observation of roof conditions without physical access. High-resolution imaging combined with AI analysis identifies subtle changes that indicate emerging pest problems.

Wireless sensor networks throughout the roof assembly track temperature, moisture, and vibration changes that signal pest activity. This data helps facility managers target inspections and maintenance to high-risk areas.

Verification Protocols to Confirm Pest Resistance Effectiveness

The Institute of Pest Management demonstrates that combining detection tools like monitoring boards with regular professional audits significantly reduces chemical treatments while improving prevention outcomes. Multiple verification methods ensure comprehensive protection against pest intrusion. (source: Institute of Integrated Pest Management)

Performance testing of pest-resistant materials must occur under actual service conditions. Laboratory ratings often fail to predict real-world effectiveness, making field verification essential for system evaluation.

Documentation protocols track both successful and failed pest resistance measures. This data enables continuous improvement of prevention strategies while identifying emerging vulnerability patterns.

Regular calibration of monitoring equipment ensures accurate detection capabilities. False readings from improperly maintained sensors can mask developing pest problems until significant damage occurs.

Integration of verification data with maintenance scheduling optimizes resource allocation. This coordination ensures that identified issues receive prompt attention before escalating into major problems.

The Bottom Line

With pest-related roof damage costing U.S. businesses over $2 billion annually, the need for evidence-based pest resistance has never been more critical.

The industry’s shift toward integrated pest management, advanced monitoring technologies, and specialized material selection demonstrates the evolution beyond outdated approaches that left buildings vulnerable.

Property managers who implement comprehensive pest resistance strategies see up to 65% reduction in repair costs while extending roof lifespans by 5-10 years.

Success requires moving past common misconceptions and embracing proven solutions that combine material science, systematic monitoring, and preventive maintenance.

The future of commercial roofing depends on this fundamental shift from reactive repairs to proactive pest resistance management.

FREQUENTLY ASKED QUESTIONS

Q. Are commercial roof materials completely pest-proof?

A. No roofing materials are entirely pest-proof. While modern options offer good resistance, pests can still find vulnerabilities. It’s essential to conduct regular inspections and maintenance to protect your roof effectively.

Q. How does pest activity affect commercial roof integrity?

A. Pest activity can severely damage a roof’s structural integrity. Rodents can create entry points, while birds and insects may cause significant wear. Early detection and management are critical to prevent worsening damage.

Q. What are the financial risks of ignoring pest issues on commercial roofs?

A. Ignoring pest issues can lead to significant repair costs, inflation in energy expenses, and even insurance claims denial. Proactive management is essential to safeguarding your investment and controlling costs over time.

Q. Why is regular roof inspection important for industrial roofs?

A. Regular inspections help identify vulnerabilities early, preventing pest infestations and roof failures. Consistent monitoring is vital for maintaining roof integrity and ensuring long-term performance, particularly in industrial settings.

Q. What maintenance practices help reduce pest attraction on commercial roofs?

A. Regular cleaning, proper drainage maintenance, and vegetation management are crucial practices. Keeping the roof free of debris and ensuring efficient water runoff significantly decreases the chances of pest infestations.

Q. What advanced technologies help detect pests on commercial roofs?

A. Technologies like acoustic monitoring, UV markers, and smart monitoring systems help identify pest activities. These tools provide valuable insights into potential infestations before visible damage occurs, enhancing control strategies.

Q. How do integrated pest management (IPM) approaches benefit commercial roofs?

A. IPM focuses on prevention through exclusion and environmental management. This proactive strategy minimizes chemical use and significantly reduces overall pest control costs while improving roof longevity.