Commercial roofing failures cost U.S. businesses over $2 billion annually, with 80% of these incidents traced to inadequate monitoring and delayed maintenance responses.

As roofing systems become increasingly complex, traditional inspection methods are no longer sufficient to prevent costly damage and business disruptions.

Advanced monitoring technologies now offer facility managers powerful tools to detect problems early, from IoT sensors that provide real-time condition alerts to drone-based imaging systems that can spot developing issues before they escalate.

This comprehensive guide examines the critical factors in implementing an effective roof monitoring program, including performance metrics, financial considerations, compliance requirements, and operational best practices.

SECTION 1: PERFORMANCE FACTORS

Commercial roofing systems are under constant pressure from severe weather, aging materials, and the demand for cost-efficiency. Neglecting these roofs can lead to disastrous leaks and structural damage, costing businesses thousands of dollars annually. By adopting advanced monitoring technologies, facility managers can take a proactive stance in safeguarding their roofs. This section explores the key performance factors that significantly influence the longevity and stability of roofing systems, paving the way for actionable strategies.

Real-Time Monitoring with IoT Sensors

Internet of Things (IoT) sensors are transforming the way commercial roofs are monitored by providing real-time data on essential conditions. These smart sensors track factors such as temperature, humidity, and water levels, giving facility managers early alerts on potential issues. For instance, a rise in moisture levels could signal a developing leak, allowing for swift intervention.

With data accessible remotely, facility managers can make timely decisions that save both resources and money. Reports show that buildings utilizing IoT sensors saw a notable 30% reduction in maintenance expenses due to early problem detection. This proactive approach not only minimizes emergency repair situations but also extends the life of the roof.

Moreover, continuous monitoring enhances safety. By tracking conditions around the clock, the risks associated with roof collapses or dangerous leaks are significantly lowered. This advantage empowers facility managers to maintain a safe space while efficiently managing costs.

Key Action Items

Drone-Based Inspection Accuracy

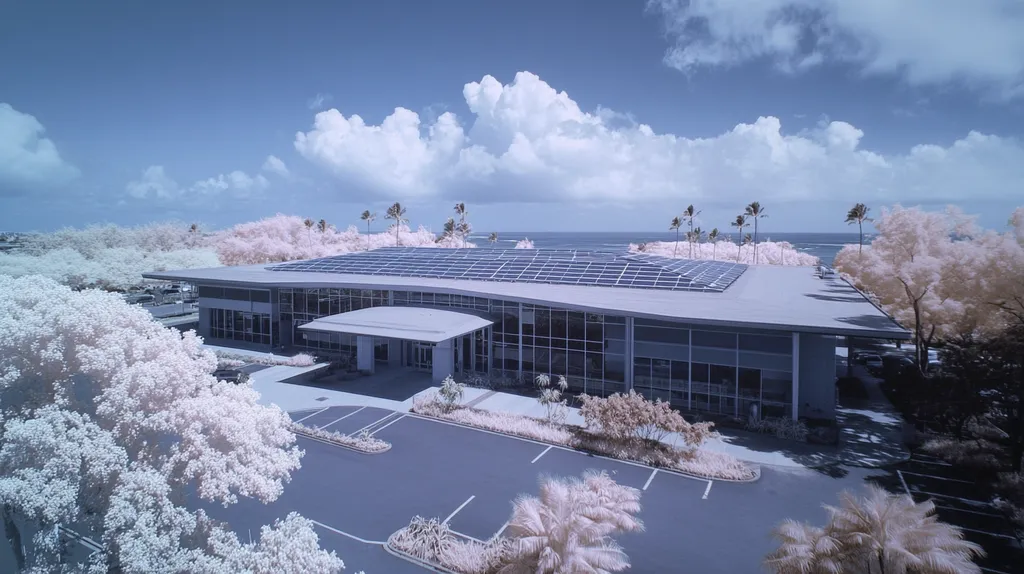

Traditional roof inspections can be labor-intensive and often overlook crucial problems. In contrast, drone inspections present a contemporary and efficient solution, capturing high-resolution images that reveal vulnerabilities. Drones can swiftly survey expansive roof areas while providing detailed visuals, enabling precise evaluations.

By leveraging drone technology, facility managers can conduct roof inspections without the need for ladders or scaffolding, significantly enhancing safety. This method not only cuts down on time needed for inspections but also allows for more frequent assessments, helping catch issues before they turn into significant repairs.

A prime example highlights a commercial property that implemented drone inspections and reduced emergency repair needs by 40%. Utilizing this technology enables better planning for maintenance and more accurate budgeting for future roofing needs.

Key Action Items

Thermal Imaging for Moisture Detection

Thermal imaging technology offers a crucial advantage in identifying moisture issues within roofing materials. By detecting temperature variations, thermal cameras can reveal hidden moisture buildup that may weaken the roofing structure. Identifying moisture early on is essential, as it can lead to more costly damage if left unaddressed.

Facility managers can incorporate thermal imaging during standard inspections to quickly identify areas needing attention. Addressing moisture issues proactively prevents mold growth and structural integrity problems, promoting a healthier environment and reducing long-term maintenance costs. Properties that have used thermal imaging report up to a remarkable 50% decrease in water damage claims.

Additionally, thermal imaging helps improve roof asset management by revealing insulation inefficiencies. Enhancing insulation not only fortifies the roofing system but also generates energy cost savings in heating and cooling. Regularly integrating this technology into maintenance routines maximizes both roof performance and energy efficiency.

Key Action Items

SECTION 2: FINANCIAL CONSIDERATIONS

Addressing commercial roof conditions isn’t just about upkeep; it’s also vital for financial health. Studies show that ignoring preventive measures can lead to hefty repair bills, averaging around $20,000 each time a problem arises. Having an effective monitoring system not only lowers long-term costs but also boosts asset value, making it essential for facility managers to prioritize advanced technologies in their financial planning. This section will delve into how predictive maintenance can save costs, how to budget for cutting-edge technologies, and the substantial return on investment from smart roofing systems.

Cost Savings Through Predictive Maintenance

Investing in predictive maintenance pays off handsomely. Conventional approaches often react to issues only after they arise, resulting in unexpected expenses due to leaks or structural failures. By utilizing monitoring technology, property owners can anticipate and address issues before they worsen, cutting repair costs by an impressive average of 30%.

Timely interventions become possible with continuous monitoring—whether it’s patching small leaks before they become gaping holes or fixing minor wear before it escalates. This proactive approach keeps business interruptions to a minimum, protecting revenue streams.

Moreover, predictive maintenance allows better allocation of resources. Facility managers can plan repairs for off-peak hours, lowering labor costs and ensuring operations stay steady. This investment not only extends the lifespan of the roof but also enhances overall financial management.

Key Action Items

Budgeting for Advanced Roofing Technologies

Thinking about budgeting for advanced roofing technologies? It’s crucial to view this as a strategic investment rather than just another expense. While initial costs might seem intimidating, the long-term advantages can significantly outshine those upfront costs. Facility managers should consider this a critical budget category to unlock maximum benefits.

Emerging technologies such as drone inspections and smart sensors provide valuable, real-time insights that can shape efficient maintenance tactics. Even though the initial investment can feel daunting, embracing these tools is essential for prolonging asset life and curtailing emergency repairs.

Additionally, several companies offer financing options or leasing arrangements for these advanced technologies, making them more financially viable. By incorporating these expenses into capital budgets, facility managers can manage costs more effectively, easing immediate financial pressures.

Key Action Items

ROI on Smart Roofing Investments

The financial benefits of implementing monitoring technology are substantial: smarter roofs lead to smarter savings. By minimizing roof failure risks, businesses can experience notable returns through decreased repair costs and enhanced energy efficiency. In fact, energy-efficient roofing systems can help save about 30% on energy bills each year.

Moreover, effective monitoring can increase the overall value of the property, making it more appealing to potential buyers or tenants. A well-maintained roof is a clear sign of responsible property management and sustainability, positively affecting leasing opportunities.

Facility managers can quantify ROI by analyzing data collected from these monitoring systems. This data-driven perspective highlights tangible advantages, justifying the initial financial outlay and encouraging ongoing investment in advanced technologies.

Key Action Items

SECTION 3: COMPLIANCE REQUIREMENTS

Compliance with building codes and regulations is essential for protecting commercial roofing investments. Failing to meet these standards can lead to hefty fines, soaring insurance premiums, and potential legal liabilities. Alarmingly, nearly 40% of commercial buildings do not meet local code requirements, putting property owners at risk. Facility managers must navigate the compliance landscape to ensure the durability and reliability of their roofing systems.

Meeting Building Code Standards

Building codes set fundamental standards for the design, construction, and upkeep of roofing systems. These codes are not just bureaucratic hurdles; they ensure safety and efficiency, protecting both assets and occupants. For example, energy codes may require reflective roofing materials that enhance energy efficiency and help lower utility bills.

Facility managers should stay informed about local regulations to avoid costly compliance issues. Regularly reviewing updates to the codes is crucial as they often change. By leveraging technology, facility managers can facilitate ongoing compliance monitoring, simplifying the process of meeting necessary standards.

In some areas, non-compliance can result in stop-work orders or mandated repairs, underscoring the need for proactive oversight and frequent inspections. Training staff and contractors in understanding building codes is crucial for navigating compliance challenges and minimizing risks, which is key to ensuring long-term roof performance and integrity.

Key Action Items

Regulatory Compliance for Roofing Systems

Regulatory compliance extends beyond local codes to include federal and state regulations that address environmental standards and material usage. For instance, the Environmental Protection Agency (EPA) restricts the use of toxic roofing materials, which affects material selection and application methods. Facility managers must ensure their roofing systems adhere to these health and safety regulations.

Neglecting regulatory requirements can result in financial penalties and damage to reputation. While compliant materials might have a higher upfront cost, their long-term benefits, including sustainability and safety, far outweigh initial expenditures. Facility managers should proactively monitor for updates in regulations to refine their maintenance strategies.

Adopting technological solutions that provide compliance updates can be invaluable, ensuring that facility managers stay ahead of regulatory changes. Regular staff training also helps maintain compliance and optimize resources effectively while lowering risks.

Key Action Items

Documentation for Inspection and Maintenance

Thorough documentation of inspections and maintenance is a crucial aspect of compliance. Keeping precise records serves as proof of adherence to regulations and can protect against future disputes. Well-maintained documentation is often necessary for processing insurance claims and can streamline recovery efforts in case of incidents.

Facility managers should organize documentation by type, including inspection reports, maintenance logs, and photographs of completed work. Utilizing digital platforms can enhance record-keeping, making access and updates more efficient. Regular audits of these documents can ensure they remain up-to-date and relevant.

Moreover, comprehensive documentation fosters better communication with roofing contractors. Detailed records allow for effective assessments of work quality and offer a historical perspective, benefiting compliance and overall roofing performance. Prioritizing documentation promotes a culture of accountability, leading to informed decisions that enhance operational efficiency and reduce long-term costs.

Key Action Items

SECTION 4: RISK MANAGEMENT

Roof failures can result in hefty financial burdens and significant disruptions for commercial properties. Industry estimates suggest that waiting too long to address roof issues can spike costs by as much as 30%. Effectively managing these risks is crucial for property owners and facility managers striving to protect their assets. This section will explore how to identify potential roof failures, utilize automated systems to mitigate hazards, and establish an emergency response plan.

Identifying Potential Roof Failures

Identifying potential roof failures before they escalate is vital for extending the lifespan of a commercial roof. Common issues such as water pooling, membrane punctures, and inadequate drainage systems can lead to leaks and structural damage if not detected early.

Monitoring technologies, like thermal imaging and moisture sensors, offer valuable insights into roof conditions. These tools can reveal hidden leaks and thermal problems, prompting timely interventions to prevent further damage. In addition, regular inspections paired with technology help enhance the understanding of potential vulnerabilities.

Understanding the impact of weather patterns is equally important. Stressors like heavy rainfall or snowfall can amplify existing vulnerabilities. By keeping an eye on weather forecasts, facility managers can proactively address risks before they worsen.

Key Action Items

Mitigating Hazards with Automated Systems

Automated roof monitoring systems are crucial for reducing the risks associated with maintenance. These systems, featuring smart sensors, provide real-time data about roof conditions to facility managers. For example, they can automatically alert managers of potential leaks before they develop into larger issues.

These systems also track environmental conditions such as temperature and humidity that directly affect roof integrity. By leveraging this data, facility managers can make informed decisions, thereby lowering the risk of catastrophic failures.

Moreover, automated monitoring leads to cost savings by optimizing maintenance schedules. Instead of relying solely on periodic inspections, managers can allocate resources efficiently based on immediate needs highlighted by automated alerts.

Key Action Items

Emergency Response Planning

An effective emergency response plan is vital for handling unexpected roof failures. Property owners should establish clear protocols that guide actions when issues arise, including designated communication channels for staff and emergency services.

Regular training drills are essential for ensuring facility teams are prepared for possible scenarios like severe leaks or structural collapses. Utilizing real roof condition data in these drills creates realistic, effective training environments.

Additionally, documenting past incidents and responses provides valuable insights for refining emergency protocol. Analyzing these events allows for continuous improvement, ensuring staff can rapidly address roof emergencies when necessary.

Key Action Items

SECTION 5: OPERATIONAL PROCEDURES

Implementing effective operational procedures is key to safeguarding commercial roofs. Delayed inspections or poorly executed maintenance can lead to major roof failures, costing property owners significantly in repairs. In fact, studies indicate that 30% of commercial roofing failures stem from inadequate maintenance. Facility managers can enhance roof longevity and mitigate risks by adopting structured operational procedures, such as scheduling inspections, utilizing maintenance checklists, and training staff on new technologies.

Scheduling Regular Roof Inspections

Regular roof inspections are vital for detecting potential issues before they escalate into costly repairs. Industry best practices recommend scheduling inspections at least bi-annually to ensure that wear and tear are managed promptly. Many facility managers underestimate the significance of routine evaluations, mistakenly believing their roofs will naturally endure the elements.

Leveraging advanced monitoring technologies makes inspections more efficient and less intrusive. Drones and thermal imaging systems can pinpoint leaks and insulation issues without needing extensive scaffolding or ladders, saving time and minimizing safety hazards for personnel.

Documenting the results of each inspection is equally important. A comprehensive log of findings enables tracking changes over time and informs future maintenance decisions. In this way, facility managers can shift from reactive responses to proactive management.

Key Action Items

Implementing Maintenance Checklists

Creating and utilizing maintenance checklists streamlines the roof upkeep process and ensures that no detail is overlooked. These checklists should cover crucial items, including debris removal, drainage assessments, and inspection of flashing and seams.

Standardized checklists promote consistency and efficiency in maintenance efforts. Each facility can customize their list based on specific roof types and environmental factors, such as prioritizing corrosion checks for coastal installations.

Digital checklists can further enhance procedures. Using cloud-based platforms allows managers to track task completion in real-time and share reports easily with relevant stakeholders. This accessibility keeps everyone informed and empowers data-driven decision-making.

Key Action Items

Training Personnel on New Technologies

The integration of technology can greatly improve roof monitoring and maintenance practices. However, without proper training, the potential benefits of these innovations may not be fully realized. Facility managers should prioritize equipping their teams with knowledge about new tools and systems.

Training sessions can cover essential skills, from using drones for inspections to leveraging software for documenting maintenance tasks. Empowering employees with this knowledge fosters confidence and nurtures a culture centered on proactive maintenance.

Staying updated on emerging technologies is also essential. The roofing landscape is rapidly evolving, with advancements like predictive analytics gaining traction. Facility managers must ensure their teams are well-informed and trained in these innovations to maintain a competitive advantage.

Key Action Items

SECTION 5: OPERATIONAL PROCEDURES

Establishing effective operational procedures is vital for the health and longevity of commercial roofs. Delays in inspections or maintenance can lead to significant damage, costing property owners thousands of dollars. Alarmingly, research indicates that poor maintenance practices account for 30% of commercial roof failures. By implementing structured procedures, facility managers can mitigate risks and extend the life of their roofs. This section outlines key steps including scheduling regular inspections, utilizing maintenance checklists, and training staff on the latest technologies.

Scheduling Regular Roof Inspections

Regular roof inspections are crucial for spotting potential issues before they become costly repairs. Bi-annual inspections are considered best practice in the industry, allowing for timely management of wear and tear. Many facility managers overlook the need for routine evaluations, believing their roofs will inherently withstand environmental challenges.

Advanced monitoring technologies enhance the effectiveness of inspections while reducing invasiveness. Drones and thermal imaging can identify leaks and insulation problems without requiring extensive scaffolding or ladders, saving time and reducing safety risks.

Documenting the outcome of each inspection is equally important. A thorough log allows managers to track changes over time and informs future maintenance strategies. This data-driven approach shifts maintenance from reactive to proactive management.

Seasonal considerations are vital as well. Preparing roofs for winter weather or assessing for damage in spring ensures they can withstand seasonal challenges effectively.

Key Action Items

Implementing Maintenance Checklists

Creating and using maintenance checklists simplifies the roof upkeep process and ensures no critical tasks are skipped. The checklist should cover items such as debris removal, drainage evaluations, and inspections of flashings and seams.

Standardized checklists promote consistency and efficiency within maintenance operations. Facilities can tailor their checklists to account for specific roof types and environmental challenges, like increased corrosion risk in coastal areas.

Digital checklists further enhance this process. Cloud-based solutions allow managers to track task completion in real-time and easily share reports with relevant teams, maintaining transparency.

Moreover, analyzing checklist data can help facility managers improve maintenance practices and measure the program’s effectiveness over time.

Key Action Items

Training Personnel on New Technologies

Integrating new technologies can significantly enhance roof monitoring and maintenance efforts. However, without proper training, these technological advancements may not be fully utilized. Facility managers should emphasize educating their teams on new tools and systems.

Training sessions can cover a variety of essential skills, including drone operation for inspections and using software for tracking maintenance tasks. Educating staff empowers them, instills confidence, and fosters a culture of proactive maintenance.

Keeping abreast of emerging technologies is also critical. As the roofing industry advances, facility managers must ensure their teams are trained in these innovations to stay competitive.

Regular training refreshers help maintain staff proficiency and adaptability as technologies evolve. Investing in ongoing education increases operational efficiency and maximizes the value derived from the roofing system.

Key Action Items

Looking Ahead

With commercial roofing failures costing businesses over $2 billion annually, implementing comprehensive monitoring solutions is no longer optional – it’s essential for survival.

Advanced technologies like IoT sensors, drones, and thermal imaging are revolutionizing how facility managers protect their roofing assets, with early adopters reporting up to 40% reduction in emergency repairs.

The integration of these monitoring tools, combined with structured maintenance programs and proper staff training, can extend roof life by 25-30% while significantly reducing operational costs.

As regulatory requirements become stricter and weather patterns more extreme, facilities that fail to embrace these technological advances risk costly failures, compliance violations, and competitive disadvantages.

The future of commercial roof management lies in proactive monitoring – the only question is whether organizations will adapt before experiencing catastrophic failures.

FREQUENTLY ASKED QUESTIONS

Q. What performance factors affect commercial roof condition?

A. Key performance factors include weather resilience, material aging, and maintenance practices. Regular monitoring helps you identify potential issues before they escalate, ensuring your roof remains in good condition and minimizes long-term costs.

Q. How can budgeting for a commercial roof be managed?

A. Treat budgeting for roofing technologies as an investment. Allocate resources for predictive maintenance tools and consider financing options. Proper budgeting can reduce long-term costs and enhance roof performance.

Q. What building code standards impact industrial roofs?

A. Building codes ensure safety and efficiency for industrial roofs. Familiarize yourself with local regulations to avoid penalties. Proactive monitoring will help maintain compliance and protect your investment.

Q. How can potential roof failures be identified?

A. Regular inspections and monitoring technologies like thermal imaging can spot vulnerabilities. Identifying signs such as water pooling or wear early helps extend the roof’s lifespan and prevent costly repairs.

Q. What are effective operational procedures for roof maintenance?

A. Establish structured procedures like regular inspections and employing maintenance checklists. Training staff on new technologies ensures proactive management and can help avoid costly failures from neglect.

Q. How to train staff on new roofing technologies?

A. Organize training sessions focusing on new tools and systems. Continuous education empowers your team and fosters a culture of proactive roof management, enhancing efficiency and technology adoption.

Q. What maintenance records should facility managers document?

A. Document inspection reports, maintenance logs, and photographs of completed work. Accurate records ensure compliance and help streamline insurance claims, playing a crucial role in effective roof management.