Falls from heights remain the leading cause of fatalities in industrial construction, with OSHA reporting over 350 deaths annually from rooftop accidents alone. This sobering statistic underscores the critical importance of establishing comprehensive safety protocols around industrial roofing operations.

For facility managers and property owners, creating a safe workspace isn’t just about regulatory compliance—it’s about protecting lives and assets while ensuring operational continuity.

This manual examines essential components of industrial roofing safety, from fundamental OSHA regulations to advanced fall protection systems, providing actionable guidance for implementing and maintaining robust safety measures in industrial roofing environments.

SECTION 1: FUNDAMENTAL CONCEPTS

The safety of workers in and around industrial roofing systems is of utmost importance. A concerning statistic from the Occupational Safety and Health Administration (OSHA) reveals that falls are responsible for approximately 33% of fatalities in the construction sector. This alarming figure underscores the critical need for effective safety practices during roofing installations and maintenance. By grasping essential concepts like OSHA regulations, identifying fall hazards, and implementing basic safety protocols, the risks associated with roofing can be significantly minimized. This section aims to explore these vital areas, laying a strong groundwork for effective roof safety management.

OSHA Regulations Overview

OSHA regulations define the safety standards essential for industrial settings, including roofing operations. Adhering to these regulations is not merely a best practice; it’s a legal obligation. For example, when employees work at heights of six feet or more, employers are required to implement adequate fall protection systems in the construction industry.

In addition, OSHA requires regular safety training for workers, ensuring they are equipped to protect themselves effectively. Many organizations often overlook the significance of ongoing training, which can lead to a rise in accidents and penalties for non-compliance.

Employers must also carry out routine inspections and document all safety measures. These inspections are crucial for spotting potential hazards, thereby ensuring the roofing environment remains safe for every worker involved.

Neglecting OSHA regulations can result in severe financial penalties and heightened insurance costs. Staying informed about evolving regulations and best practices is essential for maintaining compliance and safeguarding employees.

Fall Hazard Identification

Recognizing fall hazards is vital for ensuring worker safety around industrial roofing. Common hazards include unprotected roof edges, skylights, and uneven surfaces, all of which require immediate attention to mitigate slips or falls.

Employers are advised to conduct comprehensive assessments of the roofing environment to pinpoint specific risks. This involves examining access points, work surfaces, and the availability of safety equipment.

It is also crucial to consider environmental conditions, such as wind or wet surfaces, which can worsen existing hazards and heighten the chances of accidents.

Moreover, effective communication about identified hazards is essential. Workers should receive training to recognize and report potential dangers, fostering a culture of safety within the organization.

Basic Safety Protocols

Implementing fundamental safety protocols can greatly reduce fall risks around industrial roofing. First and foremost, the use of proper personal protective equipment (PPE) is indispensable for all workers. This includes harnesses, helmets, and non-slip footwear.

Creating a safety plan tailored to the specific roofing project establishes clear guidelines. This plan should outline the steps to follow in case of an emergency, ensuring all workers understand their roles.

Hosting regular safety meetings reinforces safety protocols, reminds employees of potential hazards, and updates them on safety procedures. These meetings also provide a platform for workers to express concerns and suggest improvements.

Finally, ensuring that safety equipment like guardrails and safety nets is correctly installed and maintained can substantially decrease fall risks. Investing in robust safety measures not only protects workers but also enhances the company’s reputation and mitigates potential liabilities.

SECTION 2: SYSTEM COMPONENTS

Establishing a safe workspace around industrial roofing is essential for protecting workers and property. Falls are the leading cause of fatalities in the construction sector, according to the Occupational Safety and Health Administration (OSHA), making effective safety systems absolutely crucial. This section outlines the key components integral to any industrial roofing safety plan. A clear understanding of these systems can significantly reduce risks while fostering a culture of safety within the organization.

Guardrail Systems

Guardrail systems are a fundamental line of defense against falls from heights. Typically installed along roof edges, stairways, and elevated platforms, guardrails create a sturdy physical barrier that limits access to hazardous areas.

Ensuring proper installation is vital. The top rail should be positioned between 39 to 45 inches high and must withstand a force of 200 pounds to be effective. Regular inspections are critical to maintaining the structural integrity of guardrails and ensuring they comply with safety standards.

By using guardrail systems, facilities can greatly reduce the risk of falls, allowing workers to focus on their tasks without distraction. Additionally, incorporating adjustable or removable sections can provide flexibility for specific project requirements without compromising safety.

Implementing guardrails is not just about regulatory compliance; it reflects a serious commitment to worker safety and can enhance morale on the job site. This commitment is essential for attracting and retaining skilled workers while minimizing potential liability costs.

Personal Fall Arrest Systems

Personal Fall Arrest Systems (PFAS) are crucial for ensuring the safety of individual workers on roofing projects. These systems—which include harnesses, lanyards, and anchorage points—are designed to prevent workers from falling more than six feet or reaching a lower level.

For PFAS to function effectively, they must be properly fitted and used according to manufacturer guidelines. Training workers on how to wear and inspect their equipment enhances both safety and reliability. Additionally, regular maintenance is essential; worn or damaged components should be replaced immediately to ensure effectiveness.

Utilizing PFAS can significantly lower the chances of severe injuries from falls. Organizations investing in quality fall arrest systems and comprehensive training are taking proactive steps to create a safer work environment and protect their workforce.

Furthermore, PFAS can be combined with other safety measures like guardrails and safety nets. This layered approach provides multiple safety barriers, substantially diminishing overall fall risk while reinforcing a culture of safety within the team.

Warning Line and Safety Monitoring Systems

Warning line systems and safety monitoring play a pivotal role in alerting workers to potential fall hazards. Warning lines, typically set up at a safe distance from the roof’s edge, serve as a visible reminder of boundaries and encourage safe practices.

The ideal height for warning lines is around 39 inches, providing a prominent visual cue to deter workers from approaching dangerous edges. Regular training on recognizing and adhering to these indicators can improve their effectiveness significantly.

In conjunction with warning lines, safety monitoring systems utilize trained personnel to observe and communicate hazards in real time. This proactive approach enables immediate feedback and warnings, effectively reducing risks as they arise.

Combining warning line systems with safety monitors creates a robust safety solution that addresses risks in real-time. This integrated strategy not only enhances compliance with safety standards but also cultivates a safer working environment for all involved.

SECTION 3: IMPLEMENTATION METHODS

Creating a safe workspace around industrial roofing is critical. OSHA reports that falls account for 33% of fatalities in construction. Implementing effective safety protocols is not only a regulatory obligation but also a key factor in ensuring employee safety and protecting property owners from liability. This section provides guidance on conducting site assessments, selecting fall protection systems, and ensuring proper installation of safety equipment.

Site Assessment and Hazard Evaluation

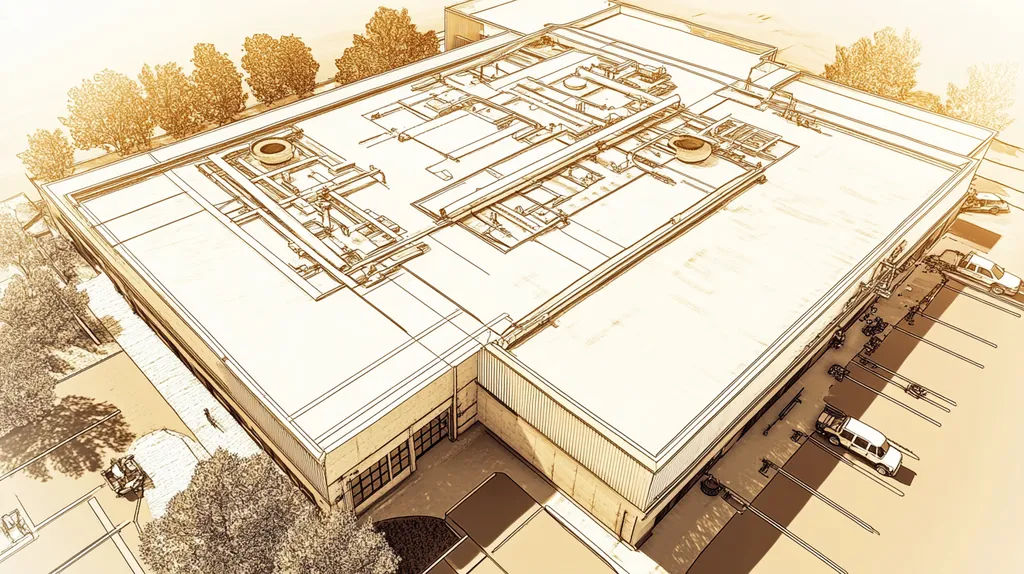

A comprehensive site assessment lays the foundation for a safe roofing workspace. Property owners must identify potential hazards such as roof slope, weather conditions, and access points. Each of these factors can significantly heighten the risk of accidents if left unchecked.

The evaluation should include an in-depth inspection of roofing materials and overall integrity. Older roofs may harbor hidden weaknesses that increase risks, making this step crucial. A meticulously documented hazard evaluation provides valuable insights for planning and executing roofing projects safely.

Engaging qualified safety professionals can enhance assessment accuracy. Their specialized expertise aids in identifying subtle risks that might escape an untrained eye, thus helping to avert accidents before they occur.

Finally, all findings should be thoroughly documented and shared with every team member involved. Effective communication fosters a collective understanding of safety measures and keeps everyone aware of potential hazards.

Selecting Appropriate Fall Protection Systems

Choosing the right fall protection systems is essential for ensuring worker safety on the roof. Numerous options exist, and each system should be assessed based on the specific site conditions uncovered during the initial evaluation.

Common options include guardrails, safety nets, and personal fall arrest systems (PFAS). Guardrails provide passive protection and are ideal for high-traffic areas, while PFAS offer flexibility for workers performing tasks beyond designated zones.

The type of equipment selected is only part of the equation; proper installation methods are equally important. Secure anchoring of PFAS to sturdy structural components is vital for their effectiveness. Training workers to understand the proper use and limitations of each system further enhances safety.

Regular inspections and maintenance of fall protection systems are crucial to ensure their effectiveness. Many organizations overlook this step, but failing to maintain equipment can result in catastrophic failures when they are most needed.

Proper Installation of Equipment

The correct installation of safety equipment is a keystone of workplace safety in industrial roofing. Essential equipment such as ladders, hoists, and safety railings must be set up precisely to ensure they provide the necessary protection.

Improper installation can lead to serious safety hazards. For instance, unsecured scaffolding may collapse under load, leading to injuries and extensive property damage. Following manufacturer guidelines during installation is essential for maintaining safety standards.

Training workers on installation techniques is equally important. They should be made aware of the specifications and limitations of each piece of equipment they handle to minimize risk. Regular training sessions can strengthen this knowledge base and promote a proactive safety culture.

Lastly, routine inspections of all installed equipment must be carried out to confirm they are functioning correctly. Regular checks not only keep compliance with safety regulations fresh but significantly lower the risk of accidents occurring on the job site.

SECTION 4: MAINTENANCE REQUIREMENTS

Regular maintenance of industrial roofing systems is not just important; it’s essential for safety and longevity. Without scheduled inspections, minor issues can escalate into severe problems like leaks and structural failures. In fact, research shows that a staggering 80% of roofing failures arise from inadequate upkeep. This section outlines crucial inspection procedures, the importance of equipment maintenance, and guidelines for post-event assessments to safeguard both workers and property.

Regular Inspection Procedures

Conducting regular inspections is vital for ensuring a safe workspace around industrial roofing. Property owners should aim to perform thorough evaluations at least twice a year. Focus should be placed on spotting issues such as loose materials, pooling water, and cracks that may worsen over time.

A comprehensive visual inspection of seams, flashing, and roof membranes is essential. Using a detailed inspection checklist can help ensure that no crucial area is overlooked, allowing property owners to address small problems before they develop into costly repairs.

Involving trained professionals in inspections can improve effectiveness significantly. They are equipped to detect potential hazards and can offer tailored recommendations for maintenance. Proper documentation of these inspections is also essential for compliance and for facilitating future evaluations.

Prioritizing regular inspections not only mitigates risks but also extends the lifespan of roofing systems, protecting the investment and the people who work there.

Equipment Maintenance and Repair

Maintaining roofing equipment is essential for ensuring a safe working environment. This involves regular inspections of safety gear, including harnesses and ladders, as well as roofing tools such as blowers and cutters. Consistent maintenance is key to preventing accidental injuries and ensuring equipment reliability.

Equipment should be scrutinized for signs of wear and tear. For example, frayed ropes on safety harnesses can jeopardize worker safety. Establishing a routine for the inspection and repair of equipment can dramatically reduce the chances of accidents occurring during roofing projects.

Replacing outdated or damaged equipment should be prioritized. Although high-quality tools may have a steep initial cost, they are a worthwhile investment in preventing accidents and improving project efficiency. Facilities managers must balance safety and functionality in their maintenance strategies.

Implementing a clear maintenance schedule for equipment ensures that all tools remain in optimal working order, fostering a safer work environment for the entire team.

Post-Event Inspection Guidelines

Post-event inspections are critical following severe weather events such as storms or heavy snowfall. These conditions can compromise roofing integrity, creating unsafe work conditions that must be assessed without delay.

After an event, it is crucial to check for visible signs of damage like missing shingles, punctures, or sagging sections. Inspections should be scheduled as soon as it is safe to do so, ensuring that no safety compromises occur.

Introducing a comprehensive post-event inspection protocol can help identify issues early, allowing for timely repairs. Documenting findings and tracking repairs ensures long-term roof health and compliance with safety standards.

It’s important to communicate with facility staff about ongoing safety measures until inspections are complete. Proactive evaluations after significant weather events not only maintain safety but can also prevent minor issues from escalating into major roofing failures.

SECTION 5: PERFORMANCE METRICS

Creating a safe workspace around industrial roofing is not just a regulatory requirement; it’s essential for protecting lives and ensuring business continuity. With falls responsible for 33.5% of construction-related fatalities according to OSHA, tracking performance metrics becomes critical. By closely monitoring compliance with OSHA standards, analyzing incident rates, and emphasizing worker training, organizations can identify safety gaps and enhance their operational protocols. This section will explore these key performance metrics to promote a safer roofing environment.

Compliance with OSHA Standards

Compliance with OSHA standards is vital for securing a safe working environment in industrial roofing operations. These regulations outline essential guidelines for areas such as fall protection, scaffolding safety, and ladder usage—all necessary in roofing activities. Facilities should conduct routine assessments to ensure they meet these standards and avoid costly fines that can arise from violations.

Facilities that adopt OSHA-compliant safety measures—like guardrails and safety nets—typically report fewer incidents on-site. Routine compliance tracking not only safeguards workers but also boosts the company’s image as a responsible employer. Regular assessments are crucial; failure to comply can jeopardize both worker safety and financial stability.

Property owners need to be well-informed about specific OSHA requirements relevant to their roofing projects. By implementing these regulations, they can foster a safety-first culture that significantly decreases the likelihood of workplace incidents. A proactive compliance approach builds trust and accountability among employees, enhancing overall safety.

Continuous training on OSHA standards is essential for keeping workers up to speed. Compliance is not a one-and-done checklist; it’s a continuous commitment to safety.

Incident Rate Analysis

Evaluating incident rates provides crucial insights into safety and operational efficiency. A high incident rate can indicate fundamental issues, including inadequate safety measures or insufficient training. By continuously monitoring these rates, facility managers can quickly identify problematic patterns and implement corrective measures.

For instance, if a specific roofing job consistently results in falls, it’s essential to analyze the contributing conditions. This focused, data-driven approach allows for timely interventions, such as improving safety protocols or providing additional safety equipment.

Comparing incident rates across various roofing projects helps assess a company’s safety performance effectively. Benchmarking against industry standards can reveal areas for improvement. Lower incident rates not only enhance worker safety but can also result in financial savings from reduced workers’ compensation claims.

Encouraging a culture of openness about reporting near-misses and incidents without fear of negative consequences is key. This transparency promotes collaborative safety efforts and helps refine safety metrics throughout the organization.

Worker Training and Proficiency

Training is critical for equipping employees with the knowledge of safety protocols for industrial roofing projects. Regularly scheduled training tailored to specific tasks can enhance skills and lower on-site risks. Organizations that prioritize ongoing training often see a notable decline in incident rates.

Training should cover not only the procedures but also the importance of reporting hazards. Workers must know how to effectively address identified safety risks and when to involve supervisors.

In addition, refresher courses can help maintain focus on safety protocols, especially in dynamic environments where new staff frequently join. A commitment to ongoing training fosters a proactive safety culture, making employees more vigilant and engaged.

By prioritizing worker training and proficiency, companies not only comply with safety regulations but also boost overall productivity. Well-trained employees are more capable of identifying potential risks, creating a safer work atmosphere for all involved.

SECTION 5: PERFORMANCE METRICS

Establishing a safe environment around industrial roofing is not just a regulatory necessity; it is a critical factor for the protection of workers and the viability of business operations. With OSHA reporting that falls are behind 33.5% of construction-related fatalities, understanding and monitoring performance metrics is essential. This section delves into compliance with OSHA standards, incident rate analysis, and the significance of effective worker training to identify safety gaps and improve overall safety protocols.

Compliance with OSHA Standards

Compliance with OSHA standards is essential for maintaining safety in industrial roofing. These regulations provide crucial guidelines for areas such as fall protection, scaffolding, and ladder safety—each of which is vital during roofing operations. Routine assessments of compliance help avoid significant fines that can come from any violations.

Facilities that adopt OSHA-compliant safety measures, such as guardrails and safety nets, experience fewer on-site incidents. It also enhances the company’s image as a dependable employer. Consistent evaluations are critical for safeguarding both workers and the financial health of the organization.

Property owners must familiarize themselves with the specific OSHA guidelines relevant to their roofing projects. By aligning with these standards, they foster a culture of safety that can drastically reduce workplace accidents. A proactive compliance approach builds trust and accountability among employees.

Moreover, regular training sessions on OSHA standards are crucial. Acknowledging that compliance is a continuous journey, not a one-time checklist, ensures that every worker remains knowledgeable about safety practices.

Incident Rate Analysis

Analyzing incident rates is key for understanding safety performance and operational efficiency. Elevated incident rates often indicate deeper issues, such as inadequate safety measures or insufficient training. Keeping track of these incidents enables facility managers to identify and address patterns quickly.

For instance, if one roofing project consistently reports falls, it’s crucial to evaluate the conditions contributing to those accidents. This data-driven method allows management to implement targeted interventions, such as improved safety protocols or more comprehensive safety equipment.

Understanding and comparing incident rates across different roofing projects provides valuable insights into safety performance. Facilities should benchmark against industry standards to identify areas for improvement. Reduced incident rates not only enhance workforce safety but can also result in savings on workers’ compensation claims.

Encouraging a culture that supports the reporting of near-misses and incidents without fear of retaliation is vital. This transparency fosters collaboration in enhancing safety metrics and reinforces the importance of safety throughout the organization.

Worker Training and Proficiency

Training employees is vital for ensuring they understand safety protocols in industrial roofing projects. Regularly scheduled training tailored to specific tasks improves skill levels and reduces onsite risks. Companies that prioritize ongoing training frequently observe a significant drop in incident rates.

Such training should not only cover safety procedures but also emphasize the critical importance of hazard reporting and proactive problem-solving. For example, workers who spot a safety issue must know how to address it effectively and when to escalate it to supervisors.

Additionally, refresher courses are essential for maintaining safety awareness, especially in dynamic environments where new personnel join frequently. This ongoing commitment to training promotes a proactive safety culture, helping workers remain alert and engaged.

By emphasizing worker training and proficiency, organizations achieve compliance with safety regulations while enhancing overall productivity. Well-trained employees are better equipped to identify risks, creating a safer work environment for everyone involved.

Moving Forward

With workplace falls causing over 350 deaths annually in industrial settings, the imperative for comprehensive roofing safety has never been clearer.

This manual demonstrates that creating a safe workspace requires an integrated approach spanning regulations, equipment, implementation, maintenance, and continuous monitoring.

Organizations that implement robust safety protocols see up to 70% fewer accidents while reducing insurance costs and improving operational efficiency.

The future of industrial roofing safety lies in proactive risk management, innovative protection systems, and data-driven performance tracking.

By following these established guidelines and maintaining vigilant oversight, facility managers can significantly reduce workplace accidents while fostering a culture of safety that protects both workers and assets.

FREQUENTLY ASKED QUESTIONS

Q. What are the OSHA regulations for commercial roof safety?

A. OSHA regulations outline essential safety standards for roofing operations, including fall protection requirements. Workers at heights of six feet or more must have adequate fall protection. Compliance is not only a best practice but a legal obligation, necessitating regular safety training and thorough inspections.

Q. How can guardrail systems protect workers on industrial roofs?

A. Guardrail systems provide a physical barrier against falls by being installed along roof edges and elevated surfaces. They must be properly designed and maintained to withstand specific force levels. When effectively used, guardrails greatly reduce fall risks, allowing workers to operate safely on site.

Q. What is involved in site assessments for industrial roofing?

A. A thorough site assessment identifies potential hazards, such as slope and access points. This process includes evaluating weather conditions and the integrity of roofing materials. Property owners should document findings and communicate them to the entire team to enhance safety awareness.

Q. How important are regular inspections for commercial roofs?

A. Regular inspections are crucial for safe industrial roofing. Conducting these evaluations at least biannually helps identify issues before they escalate, preserving roof integrity and worker safety. Including trained professionals can improve the assessment’s accuracy and effectiveness.

Q. What metrics help assess safety performance in industrial roofing?

A. Key metrics include compliance with OSHA standards, incident rates, and training effectiveness. Analyzing these factors helps identify safety gaps and improves safety protocols. Regular reviews of incident reports can lead to targeted interventions to enhance worker protection.

Q. Why is worker training critical for industrial roofing safety?

A. Regular training equips workers with essential knowledge about safety procedures and hazard identification. Ongoing training sessions significantly lower incident rates. When employees understand their roles in safety, they contribute to a proactive safety culture, which benefits everyone on site.

Q. How should post-event inspections be conducted for commercial roofs?

A. Post-event inspections should occur immediately after severe weather conditions. Look for signs of damage, such as missing shingles or sagging. Documenting issues and addressing them promptly ensures ongoing safety and compliance with regulations, preventing minor problems from escalating.