As commercial solar installations surge by 30% annually, building owners face a critical challenge: supporting heavy panel arrays without compromising roof structural integrity. Recent industry data shows improper installations cause over $250 million in roof damage each year.

From load distribution and attachment methods to drainage patterns and maintenance access, every aspect of a solar installation impacts long-term roof performance. Understanding these structural considerations helps prevent catastrophic failures that can exceed $100,000 in repair costs.

This comprehensive guide examines essential factors for evaluating roof structural capacity, implementing proper support systems, and maintaining safe, efficient solar arrays.

SECTION 1: THE BASICS EXPLAINED

Every year, thousands of commercial building owners consider solar panel installations to reduce energy costs and meet sustainability goals. However, these installations can add 3-6 pounds per square foot of dead load to existing roof structures. Without proper evaluation and planning, this additional weight can compromise roof integrity, leading to structural failures that cost businesses millions in repairs and lost operations.

What It Is (In Plain Language)

Structural integrity describes your roof’s ability to safely support both its own weight and additional loads like solar panels, HVAC equipment, and environmental forces. Think of it as your roof’s strength rating – the maximum weight it can handle before risking damage or collapse.

This capacity depends on multiple factors: the building’s frame construction, roofing materials, support beams, and existing mechanical equipment. Each component must work together to distribute weight evenly across the structure.

For solar installations, structural integrity focuses specifically on the roof’s ability to handle both the static weight of panels and dynamic forces like wind uplift and snow accumulation. Understanding these limitations helps prevent overloading that could compromise the entire roofing system.

Why It Matters (To Your Building)

A compromised roof structure threatens not just the solar investment but the entire building’s operations. Water infiltration from stressed attachment points can damage inventory, equipment, and interior finishes.

Insurance carriers may deny claims related to structural failures if proper engineering assessments weren’t conducted before solar installation. This leaves building owners fully exposed to repair costs that can exceed six figures.

Building codes and safety regulations require specific load capacities for commercial roofs. Failing to maintain these standards through improper solar installation can result in code violations, fines, and mandatory building closures until repairs are completed.

How It Works

The solar installer should conduct a roof assessment to evaluate the roof’s structural integrity and design a PV system to meet snow and/or wind loads. (source: Better Buildings Solution Center)

This evaluation starts with determining the “dead load” – the existing weight of the roof structure, materials, and equipment. Then engineers calculate the “live load” capacity – the additional weight the roof can safely support from temporary forces like maintenance crews, snow, or rain.

Solar racking systems must be engineered to distribute panel weight across structural support points. Attachment methods vary based on roof type, with some requiring reinforcement of existing purlins or joists.

Regular inspections after installation ensure mounting systems remain secure and waterproof. These checks help identify potential issues before they develop into major structural problems.

SECTION 2: PRACTICAL APPLICATIONS

Commercial rooftop solar installations have grown by 30% annually over the past five years, driven by rising energy costs and sustainability mandates. However, successful implementation requires careful attention to structural requirements. Understanding how these systems interact with existing roof structures can mean the difference between a profitable energy investment and a costly structural failure.

Common Uses & Examples

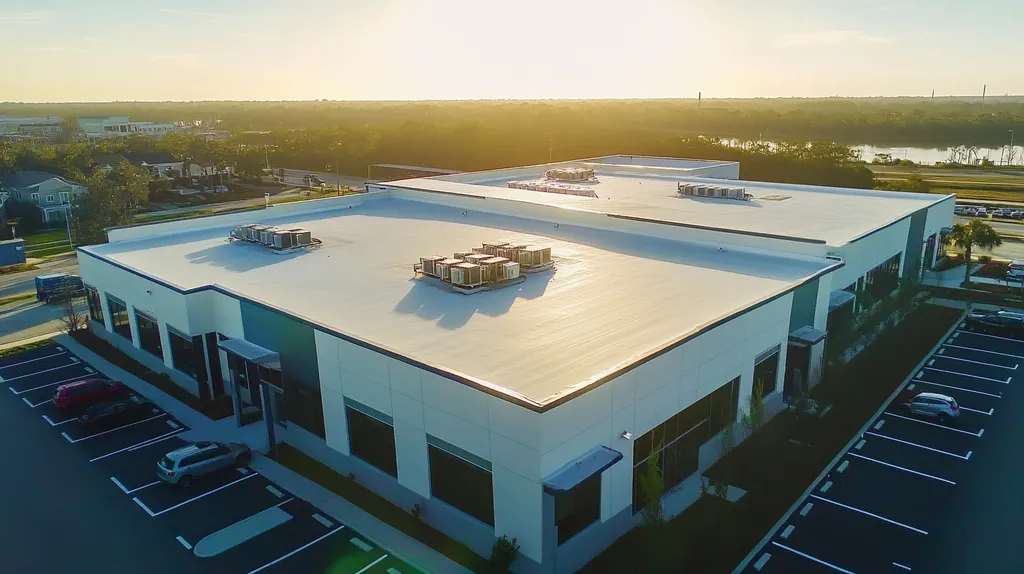

Large commercial facilities like warehouses, manufacturing plants, and retail centers represent the most common applications for rooftop solar arrays. These buildings typically offer extensive flat or low-slope roof areas ideal for panel placement.

Distribution centers have emerged as leading adopters, with installations often covering 75-80% of available roof space. These projects demonstrate how proper structural integration can support massive arrays while maintaining roof integrity.

Healthcare facilities and educational institutions frequently combine solar installations with other sustainable roofing solutions. This integrated approach maximizes both energy generation and structural durability.

Data centers present unique opportunities, using solar arrays to offset their substantial power consumption while maintaining critical facility operations. These installations require especially rigorous structural assessment due to the mission-critical nature of the facilities.

When You Need It Most

Major renovations and roof replacements provide optimal timing for structural evaluation and solar integration. These projects allow for comprehensive assessment and necessary reinforcement before panel installation.

Aging buildings approaching their 20-year mark require particular attention to structural capacity. Many structures built before current energy codes may need significant reinforcement to support modern solar arrays.

Regions with heavy snow loads or high wind exposure demand enhanced structural analysis. The combined weight of environmental forces and solar equipment can exceed original design limits without proper engineering.

Property acquisitions or facility expansions necessitate thorough structural assessment before adding solar capacity. Understanding existing load limits helps prevent costly retrofits or restrictions on future solar deployment.

Interactions With Other Systems

The solar installer should conduct a roof assessment to evaluate the roof’s structural integrity and design a PV system to meet snow and/or wind loads. (source: Better Buildings Solution Center)

Drainage systems require special consideration when installing solar arrays. Panel placement must maintain proper water flow while preventing concentrated drainage that could stress structural components.

HVAC equipment and other rooftop mechanical systems impact solar layout and structural loading. Maintaining adequate clearance ensures both system performance and structural integrity.

Lightning protection and electrical conduit runs must be integrated without compromising waterproofing or structural elements. This requires careful coordination between roofing, electrical, and structural contractors.

Regular maintenance access paths need structural reinforcement to handle increased foot traffic. These designated walkways protect both maintenance personnel and roof integrity.

SECTION 3: KEY TERMINOLOGY DECODED

Understanding structural terminology can mean the difference between a successful solar installation and catastrophic roof failure. Each year, commercial buildings suffer millions in damage from improperly assessed roof loads. A single misunderstood term or miscalculated measurement can compromise an entire roofing system, threatening both the solar investment and building operations.

Essential Terms Explained

A roof assessment must evaluate structural integrity, load-bearing capacity, reserve capacity, and overall suitability before any solar installation proceeds. Mounting solar panels on unstable roofs with undersized framing creates immediate safety hazards that can lead to devastating failures. (source: Lockatong Engineering)

Dead load refers to the permanent weight of the roof structure itself, including decking, insulation, and existing equipment. This baseline measurement determines how much additional capacity remains for solar panels.

Live load encompasses temporary or variable weights like snow, maintenance crews, and solar arrays. Understanding the relationship between dead and live loads helps predict how a roof will perform under combined stresses.

Point loads occur where concentrated weight bears down on specific areas, often at solar panel mounting locations. Proper distribution of these loads prevents localized structural damage.

Industry Jargon Translated

Purlins and joists form the underlying support structure, determining where solar mounting points can safely attach. Their spacing and capacity directly impact panel layout options.

Ballasted systems use weighted components to secure panels without penetrating the roof membrane. This approach requires careful analysis of total roof loading.

Attachment points describe where solar racking connects to structural members. These connections must maintain waterproofing while transferring loads properly to the building frame.

Wind uplift refers to negative pressure that tries to lift panels off the roof. Understanding uplift forces ensures proper anchor selection and placement.

Measurement & Units Simplified

Pounds per square foot (PSF) measures how much weight each section of roof can support. Most commercial roofs handle 20-30 PSF, while solar installations typically add 3-6 PSF.

Span refers to distances between support points, typically measured in feet. Longer spans generally mean less available load capacity for solar equipment.

Reserve capacity indicates additional weight a roof can safely support beyond existing loads. This crucial measurement determines feasibility of solar installations.

Point load ratings specify maximum weight allowed at individual attachment locations. These limits prevent structural damage from concentrated forces.

SECTION 4: DECISION FACTORS

Installing solar panels transforms a commercial roof from a basic weather barrier into a complex energy-generating system. This evolution demands careful evaluation of structural requirements, costs, and long-term performance implications. Without proper assessment, businesses risk structural failures that can exceed $100,000 in damage while compromising both their solar investment and building operations. Understanding key decision factors helps facility managers navigate these challenges while maximizing their renewable energy investment.

Cost Considerations

Initial structural evaluations typically range from $5,000 to $15,000 but prevent hundreds of thousands in potential damage. This assessment identifies necessary reinforcements and modifications before installation begins.

Roof strengthening costs vary widely based on building age and condition. Older structures may require extensive structural upgrades, while newer buildings often need minimal reinforcement.

Insurance premiums often increase with solar installations due to additional risk factors. However, many carriers offer discounts for properties that complete thorough structural assessments and regular inspections.

Maintenance costs increase due to specialized equipment requirements and additional inspection points. Building these ongoing expenses into operational budgets prevents deferred maintenance that could compromise structural integrity.

Performance Trade-offs

Proper design and engineering of solar panel structures must account for wind loads, snow loads, and seismic forces while complying with International Building Code requirements. These factors significantly influence system layout and attachment methods. (source: Exactus Energy)

Panel positioning affects both energy generation and structural loading. Optimal solar angles may concentrate weight in ways that stress building components.

Roof access becomes more challenging with solar installations. Maintaining clear paths for inspections and repairs requires sacrificing potential panel space.

Water drainage patterns change as panels redirect rainfall. Modified drainage solutions often require additional structural support to prevent ponding.

Lifespan & Durability Factors

Solar panels typically last 25-30 years, while commercial roofs average 15-20 years. This mismatched lifespan requires careful planning for future roof replacement.

Mounting systems must maintain watertight integrity throughout thermal cycling and building movement. Premium attachment solutions cost more initially but prevent structural deterioration.

Environmental exposure varies by region, affecting both structural requirements and system longevity. Coastal areas face increased corrosion risk, while snow regions require enhanced load capacity.

Regular structural inspections become critical after solar installation. Small issues can quickly escalate when hidden beneath panels, making early detection essential for preserving building integrity.

SECTION 5: COMMON CHALLENGES

Commercial building owners face mounting pressure to adopt solar technology while protecting their structural investments. Recent industry data shows that improper solar installations lead to over $250 million in roof damage annually. Without proper assessment and ongoing maintenance, these renewable energy solutions can compromise roof integrity, creating hazards that threaten both property and operations.

Frequent Problems & Solutions

Proper design and engineering of solar panel structures must account for wind loads, snow loads, and seismic forces while complying with International Building Code requirements. These factors significantly influence both mounting methods and structural reinforcement needs. (source: Exactus Energy)

Point load concentration remains a critical issue, with mounting brackets creating stress points that can compromise roofing materials. Installing additional support blocking or reinforcing existing structural members helps distribute these loads effectively.

Water infiltration around mounting penetrations causes significant damage when flashing details fail. Using certified installation teams and premium waterproofing materials prevents costly moisture-related structural deterioration.

Poor panel layout often blocks drainage paths, creating ponding that stresses roof structures. Careful array design must maintain proper water flow while avoiding concentrated drainage patterns.

Warning Signs To Watch For

Visible deck deflection between support members indicates potential structural overload. Even minor sagging can accelerate once panels are installed, leading to catastrophic failure.

Membrane wrinkles or bubbles around mounting points suggest movement or stress that compromises waterproofing. These early warning signs require immediate investigation to prevent water damage.

Rust stains or corrosion on fasteners and support hardware point to potential structural compromise. Regular inspection of these components helps identify deterioration before failure occurs.

Ceiling stains or drips often appear long after roof damage begins. Establishing routine infrared scanning programs detects moisture infiltration before interior damage occurs.

Preventative Approaches

Comprehensive structural evaluation must precede any solar installation. This assessment should analyze both current conditions and future load requirements across the entire roof area.

Creating detailed maintenance protocols ensures regular inspection of critical components. These programs should track mounting point integrity, drainage patterns, and structural performance.

Installing monitoring systems helps detect unusual movement or stress. Real-time data allows facility teams to address potential issues before they become critical failures.

Maintaining accurate documentation of structural modifications supports future maintenance decisions. This history proves invaluable when planning repairs or system upgrades.

SECTION 6: NEXT STEPS & RESOURCES

Commercial rooftop solar installations are projected to double by 2025, yet 40% of building owners lack proper structural evaluation protocols. This knowledge gap leads to over $300 million in annual roof damage from improperly assessed solar installations. Understanding key assessment criteria, following established guidelines, and accessing credible resources can prevent catastrophic structural failures while maximizing renewable energy investments.

Questions To Ask Providers

Request detailed documentation of previous commercial solar installations, including structural modifications and long-term performance data. This history demonstrates the provider’s experience with similar projects and anticipated challenges.

Verify the provider’s methodology for calculating total roof loading, including both static panel weight and dynamic forces from wind and snow. These calculations should account for existing mechanical equipment and future maintenance needs.

Discuss specific attachment methods proposed for your roof type and how they maintain waterproof integrity. Different roofing materials require varied mounting solutions to prevent moisture infiltration and structural damage.

Ask about monitoring systems that track structural performance after installation. Real-time data helps identify potential issues before they compromise roof integrity.

Industry Standards & Guidelines

Proper design and engineering of solar panel structures must account for wind loads, snow loads, and seismic forces while complying with International Building Code requirements. These factors significantly influence system layout and attachment methods. (source: Exactus Energy)

Review local building codes that specify minimum structural requirements for solar installations. Many jurisdictions have adopted enhanced standards that exceed basic safety margins.

Follow manufacturer guidelines for specific mounting systems and weight distribution. These specifications ensure warranty coverage while protecting structural integrity.

Implement inspection protocols aligned with industry best practices. Regular evaluation prevents minor issues from escalating into major structural failures.

Further Learning Simplified

Access technical bulletins from roofing manufacturers that detail proper integration of solar mounting systems. These resources provide specific guidance for maintaining warranty coverage.

Participate in professional development courses focused on structural assessment methods. Understanding evaluation techniques helps facilities teams identify potential issues early.

Review case studies of successful commercial solar installations that demonstrate proper structural integration. Learning from others’ experiences prevents common installation mistakes.

Connect with local engineering firms specializing in roof structural analysis. Their expertise ensures comprehensive evaluation of existing conditions and reinforcement needs.

The Bottom Line

With solar installations growing 30% annually, proper structural assessment has never been more critical for commercial properties. Industry data shows structural failures from improper installations now exceed $300 million in annual damages.

Success requires understanding load calculations, maintaining drainage patterns, and implementing rigorous inspection protocols. Even minor oversights in structural evaluation can cascade into catastrophic failures exceeding $100,000 in repairs.

Building owners must partner with qualified engineers and installers who understand both solar technology and structural requirements. Regular monitoring and maintenance become essential safeguards against potential failures.

The future of commercial solar depends on this careful balance between renewable energy adoption and structural integrity. Those who master this integration will maximize their investment while avoiding costly structural compromises.

FREQUENTLY ASKED QUESTIONS

Q. What is structural integrity in a commercial roof?

A. Structural integrity refers to a roof’s ability to support its weight and additional loads without sustaining damage. It ensures that the roof can safely hold solar panels, along with other equipment, without risking collapse or structural failure. Understanding this capacity is vital for maintaining a safe and efficient commercial building.

Q. How do I know if my commercial roof is suitable for solar panels?

A. Determining your roof’s suitability involves a thorough structural assessment by a qualified professional. This evaluation checks the roof’s load-bearing capacity and existing conditions to ensure it can support solar panels effectively without compromising safety. Proper evaluation helps avoid costly repairs and enhances operational efficiency.

Q. What common challenges do commercial roofs face with solar installations?

A. Common challenges include improper load distribution, water infiltration from mounting penetrations, and drainage issues. Additionally, improper installation can lead to point load stresses that compromise the roof’s structural integrity. Addressing these challenges through careful planning and professional installation is essential for optimal performance.

Q. What is the cost of a structural assessment for solar panels on my industrial roof?

A. A structural assessment typically ranges from $5,000 to $15,000, varying based on building condition. This upfront investment can prevent significant repair costs down the line by identifying necessary reinforcements before solar installation. Prioritizing safety and compliance can save money over the long term.

Q. How can I maintain my commercial roof after installing solar panels?

A. Regular inspections, ideally semi-annually, are crucial to maintain the roof’s integrity post-installation. Inspect mounting points, drainage systems, and potential water infiltration areas to identify issues early. Establish maintenance protocols and keep a record of inspections to ensure the roof remains safe and functional.

Q. What is a common lifespan for solar panels on commercial roofs?

A. Solar panels generally have a lifespan of 25-30 years, while commercial roofs may last 15-20 years. This discrepancy necessitates careful planning for roof replacement and potential panel reinstallation. Awareness of these timelines ensures better long-term energy investment and roof management.

Q. Why is proper installation of solar panels crucial for commercial roofs?

A. Proper installation is essential to avoid structural failure and protect the roof’s integrity. Incorrectly installed panels can create heavy point loads and lead to water infiltration, resulting in extensive damage and costly repairs. Ensuring correct installation safeguards your investment and maximizes energy savings.