Every year, millions of dollars in commercial solar investments turn into maintenance nightmares because property owners treat their roofs as afterthoughts rather than critical system partners.

The brutal reality? Installing solar panels without coordinating roof maintenance creates hidden failure points that destroy energy savings faster than a summer hailstorm.

Smart facility managers who master this delicate balance enjoy decades of reliable energy production, while those who don’t face expensive repairs that make their accountants question career choices.

This guide reveals how to navigate the complex relationship between solar power and roof integrity, ensuring your energy investment enhances rather than compromises your building’s protection.

SECTION 1: THE BASICS EXPLAINED

Picture this: your commercial building is about to join the solar revolution, but there’s a plot twist nobody mentioned in the sales pitch. Those shiny panels promising decades of energy savings could turn into your roof’s worst nightmare if the marriage between solar and roofing goes wrong.

The reality? Installing solar arrays without considering roof maintenance is like buying a race car and forgetting about oil changes. This section demystifies what solar power really means for your roof, why this relationship makes or breaks your investment, and how these systems actually play together on your building.

What It Is (In Plain Language)

Commercial solar power transforms your roof into an electricity-generating powerhouse using photovoltaic panels that convert sunlight into usable energy. Think of each panel as a mini power plant that feeds electricity back to your building’s grid, slashing those monthly utility bills that make accountants weep.

But here’s where it gets interesting: commercial solar isn’t just “bigger residential solar.” We’re talking about massive arrays that can cover acres of rooftop space, turning your building into the neighborhood’s energy superhero. These installations often involve hundreds or thousands of panels working together like a well-choreographed solar symphony.

The mounting systems come in two primary flavors: ballasted racking that uses heavy weights to anchor systems without roof penetrations, and hybrid-ballasted systems which combine ballast and roof penetrations for wind load requirements. Your roof essentially becomes a foundation for this high-tech energy factory, which means every square foot needs to be ready for its starring role.

Installation involves far more than just plopping panels on your roof and calling it a day. The entire roofing system must integrate seamlessly with mounting hardware, electrical conduits, and monitoring equipment. It’s like orchestrating a complex dance between old-school roofing and cutting-edge technology.

Unlike a simple roof replacement, solar integration requires your roof to multitask: weather protection, structural support, and energy generation platform all rolled into one. This triple duty means every component must work in perfect harmony, or the whole system suffers. (source: Better Buildings Alliance)

Why It Matters (To Your Building)

Your building’s roof is about to become the hardest-working surface in your entire facility, and that workload demands respect. When solar panels and roofing systems work together properly, you get decades of reliable energy production plus a roof that actually lasts longer thanks to panel protection from UV rays and weather.

But when this partnership goes sideways, the consequences multiply faster than rabbits in springtime. Hidden moisture intrusion beneath arrays can turn small problems into catastrophic failures, while inadequate structural support can lead to costly deformation or even partial roof collapse under load.

The financial stakes are genuinely staggering: emergency roof repairs under solar arrays can cost three times more than standard maintenance because technicians must carefully work around expensive electrical equipment. Plus, any roof failure that damages solar components means you’re paying for both roofing and solar repairs simultaneously.

Smart integration planning protects your investment from day one and ensures maximum return on both your roofing and solar dollars. Buildings that nail this balance enjoy lower energy costs, extended roof life, and virtually zero weather-related surprises. Those that don’t often face premature replacement of both systems, wiping out years of projected savings.

The warranty implications alone should grab every property owner’s attention: improper solar installation can void existing roof warranties, while roof problems can invalidate solar equipment guarantees. Getting this relationship right means protecting multiple warranty coverages that represent hundreds of thousands in potential future value.

How It Works

Commercial solar mounting transforms your roof into a precision-engineered platform where every attachment point becomes a critical seal against weather infiltration. Mounting systems must penetrate or anchor to the roof surface while maintaining watertight integrity, which requires surgical precision and deep knowledge of roofing materials.

Different roofing types demand completely different installation approaches: membrane roofs need specialized sealants and flashing details, while metal roofs require specific fastener types and spacing. The mounting team essentially becomes roof surgeons, making calculated incisions that enhance rather than compromise your building’s weather protection.

Structural engineering calculations become absolutely essential because solar arrays create new load patterns your roof never experienced during original construction. Engineers analyze everything from panel weight to wind uplift forces, ensuring your roof structure can handle decades of additional stress without breaking a sweat.

Once installed, the maintenance game changes completely as panels create shadowed areas where problems can hide and flourish undetected. Regular inspection protocols must adapt to work around electrical equipment while ensuring both solar performance and roof integrity remain optimal throughout the system’s lifespan.

The real magic happens in the coordination between solar monitoring and roof maintenance teams. Modern installations often include sensors that can detect roof membrane issues before they become visible problems, creating an integrated approach where your solar investment actually helps protect your roof investment.

SECTION 2: PRACTICAL APPLICATIONS

Here’s where the rubber meets the roof – literally. Every day, facility managers across the country discover their “simple” solar installation has turned into a maintenance maze that would make a lab rat weep.

The stakes couldn’t be higher: one poorly planned solar project can transform your roof from a reliable building shield into a leaky, expensive headache that haunts you for decades. This section reveals where solar power shines brightest on commercial roofs, when timing makes or breaks your investment, and how these systems play with your building’s other critical components.

Common Uses & Examples

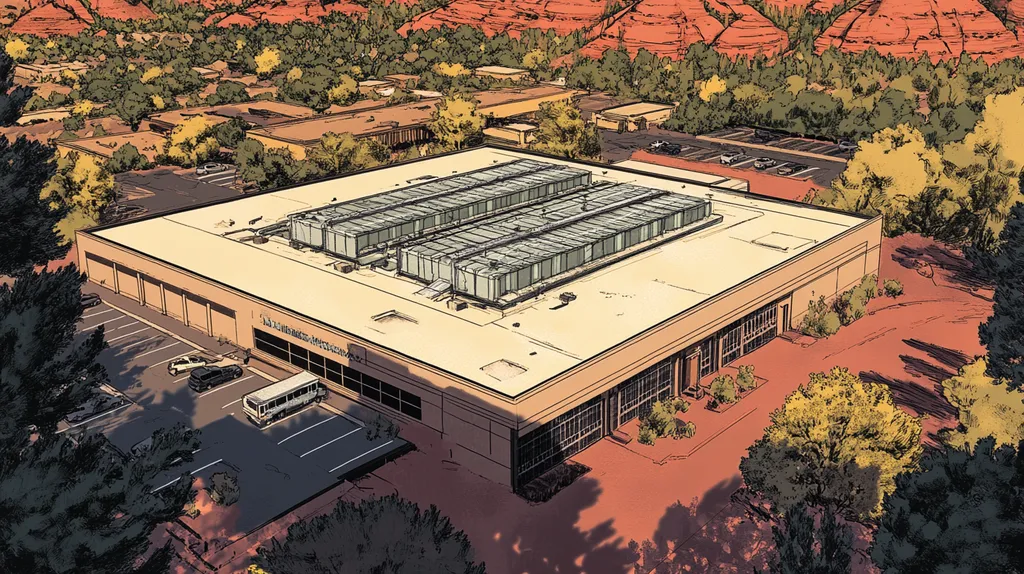

Massive warehouse rooftops have become the solar industry’s favorite playground, and for good reason – these sprawling flat surfaces can host solar farms that power entire distribution operations. Big box retailers routinely install arrays covering hundreds of thousands of square feet, turning their roofs into electricity factories that slash monthly utility bills by 70% or more.

Manufacturing facilities with energy-hungry operations find solar particularly attractive during peak production hours when electricity rates spike like a fever chart. These installations often feature rail mounting systems that allow panels to be tilted for optimal energy capture, making them perfect for flat commercial roofs where tilt angle dramatically affects efficiency.

The smartest facilities integrate solar planning with cool roof coatings and reflective membranes, creating a double-barreled approach to energy savings. Rail-less mounting offers lighter weight distribution and fewer roof penetrations, though it sacrifices the tilting capability that maximizes energy production on flat surfaces.

Multi-tenant office buildings frequently use solar as a competitive advantage, marketing lower operating costs to attract tenants while extending roof life through panel protection. The key lies in coordinating solar placement with existing rooftop equipment, ensuring maintenance crews can access both systems without playing roof-top hopscotch.

Healthcare facilities and schools represent growing solar markets where energy savings directly impact operational budgets. These installations require extra attention to mounting system integrity since any roof failure could disrupt critical services or educational activities. (source: Structural Fastening Systems)

When You Need It Most

The golden rule of solar timing reads like a fortune cookie: “Best solar installations happen during roof replacement projects.” When your roof is getting a complete makeover anyway, adding solar integration costs a fraction of retrofit pricing while eliminating the risk of mounting systems on aging membranes.

Properties facing skyrocketing energy costs or chasing sustainability certifications should prioritize solar integration before their roofs hit the five-year countdown to replacement. Waiting until your roof starts showing wear signs turns solar installation into an expensive gamble where mounting penetrations could accelerate existing problems.

Seasonal timing matters more than most people realize – dry seasons provide optimal installation windows where weather won’t sabotage critical sealing work. Rain during solar installation can turn mounting penetrations into express lanes for water infiltration, creating problems that won’t surface until the next heavy storm season.

Facilities experiencing frequent roof maintenance calls should pause and consider whether their aging roof can handle additional mounting loads and penetrations. Adding solar to a compromised roofing system often accelerates failure timelines, turning a manageable maintenance schedule into an emergency replacement scenario.

The sweet spot occurs when buildings have recently installed high-quality roofing systems with at least 15-20 years of expected service life remaining. This timing maximizes the overlap between roof and solar system lifespans, ensuring both investments pay dividends without premature replacement headaches.

Interactions With Other Systems

Rooftop HVAC units and solar panels engage in a delicate dance that requires careful choreography to avoid stepping on each other’s performance. Poor spacing between panels and mechanical equipment creates maintenance nightmares where technicians need circus skills to service both systems safely and efficiently.

Drainage systems become the unsung heroes of successful solar installations – panels and mounting hardware must work with, not against, water flow patterns that keep roofs dry and functional. Blocked drainage paths created by poorly planned solar layouts can turn minor storms into major flooding events that damage both roof and electrical systems.

Waterproofing integrity depends entirely on flashing expertise where solar mounts penetrate roof membranes, creating potential leak points that require surgical precision and ongoing vigilance. Every penetration represents a long-term commitment to maintenance and monitoring that extends far beyond the initial installation.

Roof insulation and coating systems can actually enhance solar performance when properly coordinated, but mismatched installation sequences can compromise both energy efficiency and weather protection. Adding insulation beneath panels changes roof elevation profiles, potentially disrupting drainage patterns that worked perfectly before solar installation.

The coordination between solar monitoring systems and roof maintenance protocols creates opportunities for predictive maintenance that can identify problems before they become expensive emergencies. Smart integration allows solar performance data to signal potential roof issues, turning your energy system into an early warning network for building protection.

SECTION 3: KEY TERMINOLOGY DECODED

Welcome to the wild west of roofing and solar terminology, where a single misunderstood word can turn your energy-saving dream into a wallet-draining nightmare. When contractors start throwing around terms like “ballasted systems,” “thermal bridging,” and “wind uplift coefficients,” facility managers often nod knowingly while secretly wondering if they’re being sold a solar system or a space shuttle.

The cost of confusion runs deeper than bruised egos at project meetings. Misinterpreting critical terminology leads to inappropriate system selections, inadequate structural preparations, and maintenance protocols that compromise both roof integrity and energy production.

This linguistic minefield separates successful solar installations from expensive disasters, making terminology mastery your secret weapon for protecting both your roof and your investment.

Essential Terms Explained

Photovoltaic (PV) panels serve as your roof’s new electricity-generating residents, but they’re picky houseguests that demand specific accommodation. These solar modules convert sunlight into usable power while adding permanent weight and creating new maintenance access challenges that transform routine roof care into a high-tech balancing act.

The roof membrane represents your building’s waterproof armor, and its material type dictates everything about solar compatibility. EPDM rubber membranes require different mounting approaches than TPO or PVC systems, while metal roofing demands entirely unique fastening strategies that respect thermal expansion and contraction cycles.

Ballasted mounting systems use strategic weight placement to anchor solar arrays without penetrating your roof membrane, minimizing leak risks while requiring substantial structural capacity. These systems essentially turn your roof into a high-tech chess board where every piece must be perfectly positioned to resist wind forces without crushing the underlying structure.

Penetrating mounts create direct mechanical connections through your roof membrane, offering superior wind resistance while demanding surgical precision in sealing and flashing details. Each penetration becomes a lifelong maintenance commitment that requires ongoing vigilance to prevent water infiltration disasters.

Understanding these fundamental terms transforms contractor conversations from confusing technical babble into productive planning sessions where you can ask intelligent questions and evaluate proposals with confidence.

Industry Jargon Translated

Dead load calculations determine whether your roof structure can handle the constant weight of solar equipment without turning into a structural pancake. Engineers analyze everything from panel weight to mounting hardware, ensuring your building’s bones can support decades of additional loading without compromising safety or performance.

Wind uplift forces represent Mother Nature’s attempt to turn your solar panels into expensive frisbees during storm events. These powerful upward pressures require mounting systems engineered to specific wind zone requirements, transforming your peaceful rooftop into a battlefield where proper anchoring means the difference between energy production and insurance claims.

Thermal bridging occurs when solar mounting hardware creates unwanted heat transfer pathways through your roof’s insulation system. Poor thermal design can increase heating and cooling costs while creating condensation problems that lead to moisture damage and reduced insulation effectiveness.

R-value measures your roof’s insulation effectiveness, and solar installations can either enhance or compromise these thermal performance characteristics. Smart integration maintains or improves insulation values, while poor planning creates thermal weak spots that increase energy consumption despite solar production gains.

Decoding this professional jargon enables clearer communication with contractors and deeper understanding of the engineering considerations that separate successful installations from expensive maintenance headaches.

Measurement & Units Simplified

System capacity measured in kilowatts (kW) or megawatts (MW) indicates your solar array’s maximum electricity generation potential under perfect conditions. Larger commercial roofs can accommodate higher-capacity systems, but structural limitations and electrical infrastructure often impose practical constraints that require careful engineering analysis.

Energy production tracking in kilowatt-hours (kWh) reveals the actual electricity your system generates over time, providing the real-world performance data needed for accurate return-on-investment calculations. This measurement becomes your scorecard for evaluating whether your solar investment delivers the promised financial benefits throughout its operational lifespan.

Roof slope measurements expressed in degrees or ratios directly impact both solar panel performance and water drainage effectiveness. Steeper slopes may optimize solar angles but create installation challenges, while flatter surfaces simplify mounting but require careful attention to drainage patterns around panel arrays.

Wind speed ratings and snow load capacities determine the engineering requirements for your specific geographic location and building characteristics. These measurements drive mounting system specifications that ensure your installation survives local weather extremes without damaging either solar equipment or roof systems.

Mastering these measurement units allows facility managers to accurately interpret contractor proposals, evaluate system performance claims, and make informed decisions that balance energy production goals with roof protection requirements. (source: SolarReviews)

SECTION 4: DECISION FACTORS

Picture this nightmare scenario: six months after your “revolutionary” solar installation, you’re staring at water stains spreading across your ceiling while contractors debate whether it’s a roofing problem or solar mounting failure. Meanwhile, your energy savings are evaporating faster than puddles in August.

The brutal truth? Most commercial property owners focus exclusively on solar panel specifications and energy projections while treating their roof as an afterthought. This backwards approach turns what should be a 25-year marriage between roof and solar into an expensive divorce that costs more than the original wedding.

Smart decision-making requires evaluating the complete picture: upfront costs that extend far beyond panel prices, performance trade-offs that affect both energy production and building protection, and durability factors that determine whether your investment pays dividends or demands constant repairs.

Cost Considerations

Here’s the plot twist nobody mentions in solar sales presentations: your roof condition determines whether installation costs stay reasonable or explode into budget-busting nightmares. Installing panels on an aging roof often requires complete membrane replacement first, potentially doubling your upfront investment before the first solar panel touches your building.

The mounting method choice dramatically impacts both installation and long-term costs, with ballasted racking offering lower installation expenses but requiring substantial structural capacity. Penetrating mounts cost more initially but provide superior wind resistance on roofs that can’t handle heavy ballast loads. The wrong choice here creates decades of expensive consequences.

Maintenance cost multiplication represents the hidden expense that catches most facility managers off-guard. Roof repairs under solar arrays require specialized labor and careful equipment handling, often tripling standard maintenance costs when problems inevitably arise.

Smart property owners evaluate total cost of ownership over the roof’s expected lifespan, factoring in both energy savings and increased maintenance complexity. The cheapest installation often becomes the most expensive mistake when emergency repairs start piling up faster than autumn leaves.

Regional incentives and utility programs can offset significant upfront costs, but these benefits disappear quickly when poor integration planning leads to premature system failures. The key lies in balancing incentive maximization with long-term reliability investments that protect both roof and solar performance.

Performance Trade-offs

Solar panels transform your roof into a complex ecosystem where energy production and weather protection must coexist without sabotaging each other’s performance. Panels provide excellent UV protection that can extend membrane life significantly, but they also create thermal dynamics that can accelerate roof degradation if ventilation design gets overlooked.

The mounting height sweet spot balances multiple competing factors: higher elevations improve airflow and reduce heat buildup while creating more wind resistance and installation complexity. Flush-mounted systems minimize wind loads but can trap heat that damages both roof membranes and solar panel efficiency over time.

Drainage patterns become critical performance factors as panels and mounting hardware create new water flow challenges that didn’t exist during original roof design. Poor drainage planning around solar arrays can turn minor rainstorms into major flooding events that damage both electrical and roofing systems simultaneously.

Regional climate considerations dramatically affect the performance equation, with hot climates benefiting from panel shading while cold regions face snow loading and ice dam challenges. Northern installations require different mounting strategies and drainage solutions compared to their sun-baked southern counterparts.

The smartest installations optimize both systems together rather than treating solar as an add-on afterthought. This integrated approach maximizes energy production while maintaining roof performance, creating win-win scenarios that deliver promised benefits for decades.

Lifespan & Durability Factors

The 25-year solar warranty becomes meaningless if your roof fails at year ten, turning your energy investment into an expensive lesson about system integration planning. Roof membrane selection directly impacts long-term success, with materials like TPO and PVC offering superior durability under the added stress and altered thermal conditions that solar arrays create.

Strategic panel placement prevents the concentrated loading patterns that can cause premature roof failure in high-stress areas. Spreading loads evenly across available roof space maintains structural integrity while providing optimal access pathways for maintenance crews who need to service both systems throughout their lifespans.

The choice between ballasted and penetrating mounts affects durability differently across roof types, with ballasted systems requiring minimal roof penetrations but demanding exceptional structural capacity. Penetrating systems create more potential leak points but offer superior wind resistance that protects both roof and solar equipment during severe weather events. (source: Better Buildings Alliance)

Maintenance coordination becomes the secret weapon for maximizing both roof and solar system lifespans through integrated inspection protocols and preventive care strategies. Buildings that treat these systems as partners rather than competitors enjoy extended service life from both investments.

The durability equation ultimately depends on initial integration quality and ongoing maintenance commitment. Cutting corners during installation or neglecting coordinated maintenance protocols transforms promising energy investments into expensive liability headaches that drain budgets for decades.

SECTION 5: COMMON CHALLENGES

Welcome to the Murphy’s Law playground of commercial roofing, where solar installations transform simple maintenance tasks into expensive treasure hunts for hidden problems. Picture this: your shiny new solar array is humming along beautifully while water quietly infiltrates through compromised mounting points, creating a slow-motion disaster that won’t surface until your next heavy storm season.

The harsh reality hits facility managers like a cold shower – what started as a straightforward energy efficiency project suddenly becomes a complex juggling act between roof integrity, solar performance, and escalating maintenance costs. These challenges multiply faster than weeds in springtime, turning manageable issues into budget-busting emergencies when early warning signs get ignored or misinterpreted.

Frequent Problems & Solutions

Roof membrane penetrations represent the number one villain in solar installation disasters, creating potential leak highways that compromise your building’s weather protection. Every mounting bracket that pierces your roof membrane becomes a long-term maintenance commitment requiring surgical precision in sealing and ongoing vigilance to prevent infiltration catastrophes.

The solution lies in choosing mounting strategies that match your roof’s capabilities and age: ballasted systems minimize penetrations while penetrating mounts offer superior wind resistance when properly executed. Working with contractors who understand both roofing and solar integration prevents the amateur-hour mistakes that turn minor installations into major headaches.

Blocked drainage pathways create the perfect storm for roof failure as solar arrays redirect water flow patterns that worked flawlessly for decades before panels arrived. Ponding water around panel bases accelerates membrane degradation while creating ice dam risks in northern climates that can damage both roofing and electrical components simultaneously.

Smart panel layout planning maintains natural drainage zones while incorporating adequate spacing for water flow during heavy rain events. This proactive approach prevents minor drainage issues from escalating into major flooding scenarios that threaten your entire building’s integrity.

Thermal cycling stress occurs when temperature fluctuations cause different expansion rates between solar mounting hardware and roof membranes, creating mechanical stress that can tear seals and compromise waterproofing. This invisible enemy works slowly but persistently, weakening critical connections until failure becomes inevitable.

High-quality flashing systems and flexible mounting details accommodate thermal movement without compromising weather sealing, turning potential stress points into durable long-term solutions. Investing in superior materials upfront prevents the exponentially higher costs of emergency repairs under energized solar equipment.

Warning Signs To Watch For

Interior water stains appearing near or under solar arrays serve as your building’s distress signals, indicating that mounting penetrations or flashing details have begun failing. These stains often appear during or after storm events, providing clear evidence that your roof’s weather protection has been compromised in specific locations.

Don’t ignore subtle signs like musty odors or minor discoloration – these early warnings give you precious time to address problems before they escalate into structural damage or mold remediation projects. Quick response to water intrusion signs prevents thousands in additional damage while protecting both roof and solar system investments.

Unusual ponding patterns around solar equipment indicate drainage disruption that threatens both roof longevity and electrical safety. Water that sits longer than 48 hours after rainfall creates breeding grounds for membrane degradation while increasing the risk of electrical component failure during subsequent weather events.

Energy production anomalies can actually signal roof-related problems when panels underperform due to moisture infiltration or mounting system movement. Smart monitoring systems that track both energy output and environmental conditions help identify roof issues before they become visible from inside your building.

Physical signs like loose mounting hardware, separated flashing details, or visible membrane damage around solar installations demand immediate professional attention. These problems rarely improve on their own and typically worsen rapidly once deterioration begins, making early intervention essential for cost-effective repairs.

Rail mounting systems offer superior flexibility for optimizing panel angles and accommodating thermal expansion on various roof types, while rail-less mounting provides lighter weight distribution suitable for structures not originally designed for solar loads. The mounting choice significantly impacts both installation complexity and long-term maintenance requirements that affect total cost of ownership.

Preventative Approaches

Integrated planning that coordinates roof replacement timing with solar installation creates the golden opportunity for seamless system integration. This strategic approach allows roofing professionals to prepare membrane details specifically for solar mounting while ensuring optimal coordination between weather protection and energy generation systems.

The cost savings from this coordination approach often exceed 30% compared to retrofit installations, while eliminating the risks associated with mounting systems on aging roof membranes. Smart property owners treat solar and roofing as partners rather than competitors, maximizing the performance and longevity of both investments.

Comprehensive maintenance protocols that address both roof and solar components simultaneously prevent the coordination nightmares that plague facilities using separate contractors for each system. Integrated inspection schedules catch developing problems while they’re still manageable, avoiding the emergency repair scenarios that destroy maintenance budgets.

These coordinated approaches also maintain warranty coverage for both systems by ensuring maintenance activities don’t inadvertently void protection from either roofing or solar equipment manufacturers. Professional documentation of coordinated maintenance creates the paper trail needed to protect valuable warranty investments.

Quality contractor selection focusing on dual expertise in both roofing and solar technologies eliminates the finger-pointing disasters that occur when separate specialty contractors blame each other for system failures. Experienced integrators understand the complex relationships between roof performance and solar mounting requirements.

Investing in contractors with proven track records in combined installations costs more initially but prevents the exponentially higher expenses of fixing integration mistakes after problems surface. (source: Structural Fastening Systems)

SECTION 6: NEXT STEPS & RESOURCES

Congratulations – you’ve survived the crash course in solar-roof integration without your brain melting into a puddle of technical jargon! But here’s where the rubber meets the rooftop: all this knowledge becomes worthless if you stumble at the finish line by choosing the wrong contractor or skipping critical planning steps.

The most expensive solar disasters happen to the smartest property owners who did their homework but forgot to ask the right questions when it mattered most. This final section arms you with the contractor-vetting ammunition that separates true professionals from smooth-talking installers who treat your roof like a practice dummy.

Questions To Ask Providers

Here’s your contractor interrogation playbook: start by demanding specific experience with your exact roof type, because the guy who’s a wizard with EPDM rubber might turn your TPO membrane into swiss cheese. Generic solar experience doesn’t cut it when your building’s weather protection hangs in the balance.

Ask for detailed pre-installation roof assessment protocols that go beyond casual visual inspections. Professional contractors should evaluate structural capacity, membrane condition, drainage patterns, and existing penetrations before proposing any mounting solutions.

Demand clarity on warranty coordination between roofing and solar systems – who becomes the bad guy when problems arise? The best contractors maintain relationships with roofing manufacturers and understand how to preserve existing warranties while adding solar equipment.

Drill down on their mounting method recommendations and why they’re proposing ballasted versus penetrating systems for your specific situation. Contractors should explain wind load calculations, structural requirements, and long-term maintenance implications in plain English you can actually understand.

Request references from recent projects involving similar roof types and building configurations, then actually call those references to ask about post-installation maintenance experiences. Horror stories surface quickly when you ask the right follow-up questions about hidden costs and ongoing headaches.

Industry Standards & Guidelines

The National Roofing Contractors Association (NRCA) publishes comprehensive guidelines specifically addressing rooftop solar installations that separate professional contractors from weekend warriors. These standards cover everything from structural analysis to waterproofing details that protect your investment for decades.

ANSI/SPRI ES-1 provides the engineering backbone for proper solar mounting systems, establishing testing protocols and performance requirements that ensure installations can survive real-world weather conditions. Contractors who reference these standards demonstrate serious commitment to long-term success rather than quick installation profits.

The Solar Energy Industries Association (SEIA) offers safety and installation best practices that protect both workers and building systems during solar projects. These guidelines help identify contractors who understand the complex dance between electrical work and roof integrity.

Local building codes often include specific requirements for solar installations that vary dramatically by geographic region and climate zone. Professional contractors should navigate these regulatory waters seamlessly while ensuring compliance that protects your permits and insurance coverage.

Hybrid-ballasted systems use a combination of ballast and roof penetrating anchors to fasten the system effectively while minimizing roof damage risks on flat commercial surfaces. Understanding these mounting options becomes crucial for protecting roof warranty and structural integrity throughout the system’s lifespan. (source: Better Buildings Solution Center)

Further Learning Simplified

The solar and roofing industries evolve faster than smartphone technology, making continuous learning your secret weapon for avoiding yesterday’s solutions on tomorrow’s problems. Industry webinars from NRCA and SEIA deliver bite-sized updates that keep you current without requiring engineering degrees to understand.

Trade publications like Roofing Contractor Magazine and Solar Power World translate complex technical advances into practical insights that facility managers can actually use. These resources often feature case studies that reveal both success stories and cautionary tales from real-world installations.

Roofing membrane manufacturers increasingly provide solar-specific guidance that explains how their products interact with different mounting systems. These manufacturer resources help you understand compatibility issues before they become expensive learning experiences on your building.

Local building and facility management associations create networking opportunities where you can learn from peers who’ve navigated similar solar integration challenges. These connections often prove more valuable than consultant reports when you need straight answers about contractor performance and long-term satisfaction.

The key lies in building knowledge gradually while focusing on practical applications rather than theoretical perfection. Smart facility managers become informed consumers who can evaluate proposals intelligently without becoming solar engineering experts themselves.

The Bottom Line

Every month, commercial property owners watch millions in solar investments crumble because they treated roof integration as an afterthought rather than mission-critical planning.

The harsh reality hits like a sledgehammer: solar panels without proper roof coordination don’t just underperform – they create maintenance nightmares that destroy decades of projected energy savings while compromising your building’s fundamental weather protection.

Smart facility managers who master this delicate balance enjoy reliable energy production for 25+ years, while those who gamble on shortcuts face emergency repairs that make accountants question their career choices.

The clock is ticking on energy incentives and aging roof systems alike. Properties that coordinate these investments now capture maximum benefits, while those who wait often face the brutal choice between expensive emergency repairs or starting over from scratch.

Your building’s future depends on getting this partnership right the first time.

FREQUENTLY ASKED QUESTIONS

Q. How does solar power impact my commercial roof’s maintenance needs?

A. Installing solar panels transforms your roof into an energy factory, but also adds maintenance complexity. Panels create shadowed spots where moisture can hide, and mounting systems may cause roof penetrations needing careful sealing. Without coordinated upkeep, small roof issues can escalate into costly repairs, turning your energy savings dream into a maintenance nightmare.

Q. What commercial roof types work best for solar installations?

A. Flat commercial roofs like warehouses and big-box retailers are solar favorites due to their vast, unobstructed surfaces. Membrane roofs require specialized mounting techniques, and metal roofs call for unique fasteners. Each roof type demands tailored solutions to ensure panels stay secure and weather-tight, so knowing your roof’s specifics is crucial before installation.

Q. What key terms should I know about commercial roof solar systems?

A. Understanding terms like “ballasted systems,” “thermal bridging,” and “wind uplift” empowers you to make smart decisions. For example, ballasted systems avoid roof penetrations but add weight, while thermal bridging can reduce your roof’s insulation efficiency. Knowing this lingo helps you communicate clearly with contractors and avoid costly mismatches.

Q. What factors affect commercial roof solar system cost and durability?

A. Costs depend not just on panels but your roof’s condition, mounting methods, and maintenance needs. Older roofs might require replacement before solar installation, inflating costs. Durability hinges on proper load distribution, weather sealing, and choosing between ballasted or penetrating mounts, with each choice impacting long-term performance and repair expenses.

Q. What common problems threaten a commercial roof with solar panels?

A. Leaks from mounting penetrations top the trouble list, often leading to hidden water damage. Blocked drainage caused by poorly arranged panels can cause ponding and ice dams. Thermal cycling stress also strains seals over time. Early warning signs include water stains, musty odors, or unusual ponding, signaling it’s time for professional inspection.

Q. What questions should I ask solar providers about commercial roof installations?

A. Start by confirming their experience with your specific roof type and detailed roof condition assessments. Ask how they preserve warranties for both roof and solar systems, and why they choose ballasted or penetrating mounts. Don’t forget to request references and dig into maintenance history—that’s where the true test of expertise shines.

Q. How can I ensure solar doesn’t void my commercial roof warranty?

A. Protecting your warranty starts with coordinating solar installation plans with your roofing manufacturer’s guidelines. Proper mounting methods, expert flashing, and scheduled inspections help maintain seal integrity. Make sure your contractor understands warranty requirements and documents all work carefully to avoid surprises that might invalidate coverage down the road.