Commercial roof failures due to moisture intrusion cost property owners over $3.3 billion annually, yet industry practices remain stuck in the technological dark ages.

While sleek marketing materials tout “innovative” solutions, most moisture detection still relies on outdated visual inspections that miss critical damage until it’s too late.

This analysis examines how current commercial roof maintenance approaches consistently fail to leverage moisture mapping capabilities, leading to preventable structural damage, unnecessary repair costs, and potential safety hazards.

SECTION 1: CURRENT PRACTICES

Ignoring moisture problems in commercial roofing isn’t just a minor oversight; it can lead to catastrophic failures. Research reveals that nearly 50% of all roofing failures occur because of water intrusion. Despite this, many property owners and facility managers cling to outdated maintenance practices, exposing both their finances and the safety of occupants to significant risk. This section dives into the current landscape of roof maintenance, pinpointing where drastic improvements are overdue.

Reactive vs Proactive Maintenance

Many commercial property managers lean on a reactive maintenance strategy, fixing issues only when they become glaringly obvious. This knee-jerk approach often leads to expensive emergency repairs, especially after water damage wreaks havoc on the structure. Studies show that proactive maintenance can extend a roof’s lifespan by up to 20%, yet a staggering 70% of property owners tackle maintenance only after the damage is done.

In contrast, proactive maintenance includes regular inspections and timely repairs, nipping major issues in the bud. However, a mere 30% of property owners make these practices routine, putting their assets and occupants at risk. Waiting for leaks to appear often escalates damage, with moisture jeopardizing insulation and fostering mold growth, compounding health hazards.

The message is clear: property owners must shift their mindset. Ongoing assessments should take precedence over last-minute repairs, fortifying their roofing systems against the unexpected.

Limited Use of Advanced Tools

Despite significant technological advancements, many property managers still cling to outdated inspection methods. Basic visual evaluations simply can’t compete with the precision of modern tools. Innovations like infrared thermography and moisture meters can detect moisture that’s just itching to wreak havoc beneath the surface.

An alarming 70% of leaks go unnoticed due to a lack of advanced inspection technologies. This oversight can cost property owners a pretty penny in unforeseen repairs. By integrating modern detection methods, businesses can identify moisture intrusion early, slashing repair costs significantly. However, awareness and training remain hurdles to widespread adoption.

Investing in cutting-edge technology is no longer a luxury; it’s a necessity for effective roof management. Embracing advanced tools bolsters maintenance strategies and safeguards valuable investments.

Inconsistent Inspection Protocols

Inconsistent inspection protocols represent a major flaw in commercial roofing. Facilities often follow erratic schedules for roof inspections, leading to missed windows for preventive maintenance. Seasonal inspections are a smart move, yet many properties skip them entirely.

Buildings that undergo regular inspections see far fewer issues than those that don’t. An inconsistent approach not only drives up costs but also compromises the safety of tenants and employees. When inspections lack standardization, critical moisture problems can slip under the radar.

The personnel conducting these inspections may not have adequate training or follow uniform procedures, complicating matters further. This inconsistency raises alarms about the accuracy of roof condition reports, ultimately heightening risks.

Having a consistent inspection protocol that includes thorough checklists and proper training can dramatically enhance the effectiveness of roof maintenance. Regular, dependable inspections are vital to keeping a high-performance roofing system in check.

SECTION 2: SYSTEMIC ISSUES

Commercial roofing plays a crucial role in safeguarding property investments, yet many maintenance practices fall woefully short in addressing hidden moisture risks. A jaw-dropping statistic from the National Roofing Contractors Association reveals that over 50% of flat roofs are plagued with moisture issues that could be mitigated through proper mapping. The failure to implement effective moisture detection translates into significant systemic problems, including inaccurate damage assessments and communication breakdowns among key stakeholders. Tackling these issues head-on is essential for extending roof lifespan and improving overall durability.

Lack of Standardization in Moisture Detection

The commercial roofing sector is plagued by a chaotic mishmash of moisture detection methods, leading to wildly varying effectiveness in moisture mapping. Without a unified approach, many roofing contractors continue to rely on outdated techniques, allowing moisture to lurk undetected and unaddressed. This inconsistency can spell disaster for property owners, as unnoticed leaks often escalate into major structural dilemmas.

To make matters worse, different technologies yield disparate results, leaving facility managers scratching their heads. One technician might use infrared thermography, while another resorts to nuclear density gauges—both having merits and drawbacks. With such disarray, decision-making often occurs without complete or reliable data.

This absence of standardized procedures complicates contract negotiations as well. Property owners find it challenging to evaluate contractors’ qualifications when each adopts a unique detection method. Such confusion can result in poor choices, further exposing roofs to moisture threats.

A push for uniform standards in moisture detection would unite all players in the industry, enhancing diagnostic accuracy and streamlining repair recommendations. This more cohesive framework could greatly benefit everyone involved—property owners, contractors, and tenants alike.

Inaccurate Damage Assessments

Inaccurate damage assessments present dire consequences for property owners. A lot of roofing professionals lack the training to properly interpret moisture mapping data, which can lead to them either overestimating or underestimating the repairs needed. This inconsistency can translate into wasted money, or worse, delays in addressing urgent maintenance needs.

For example, a roof might look perfectly fine from the outside, yet hidden moisture could be wreaking havoc beneath the surface. Such miscalculations can result in catastrophic failures—think roof collapses or health risks from mold exposure. Financial repercussions can be staggering; repairs can cost thousands, and legal liabilities could loom large.

Inaccurate assessments also muddy the waters during insurance claims. If a property owner tries to file a claim for moisture-related damage, insurance companies may be hesitant to provide coverage without solid initial assessments. This leaves property owners in a financial bind, facing unexpected costs.

To navigate these pitfalls, it’s vital to employ skilled professionals who excel in moisture detection and damage assessments. Proper training ensures that evaluations are accurate, leading to timely and effective repairs that ultimately protect the investment.

Communication Gaps Between Stakeholders

Communication breakdowns among contractors, property owners, and facility managers can worsen existing roofing challenges. These stakeholders often speak different languages, each with their own priorities, which can lead to misunderstandings around moisture mapping and repair requirements. What a contractor deems a minor issue may be viewed as urgent by the facility manager—talk about a recipe for chaos.

Reliable information about moisture conditions frequently doesn’t flow easily between teams. Property owners might not get timely reports, or facility managers may misread data, resulting in neglected maintenance. These lapses allow small issues to balloon into expensive repairs.

Effective communication is also essential for scheduling inspections and maintenance. When isolated departments fail to coordinate, maintenance tasks risk being sidelined until they reach crisis mode. This reactive mentality jacks up repair costs and disrupts business operations.

To bolster roof health, promoting open and collaborative communication is key. Stakeholders should organize regular updates and discussions to review moisture mapping findings, establish maintenance priorities, and lay out repair timelines. This teamwork will ensure everyone stays informed and aligned, ultimately enhancing the roof’s longevity and performance.

SECTION 3: MISSED OPPORTUNITIES

In the realm of commercial roofing, ignoring moisture mapping is akin to walking a tightrope without a safety net; the stakes are high. Many property owners and facility managers continue to overlook the substantial benefits of moisture mapping, even as maintenance costs soar. Studies reveal that improper moisture management can yield repair bills as much as ten times higher than investing in preventative solutions. This section will explore the untapped potential of moisture mapping, the neglect of substantial long-term savings, and how the needs of clients and adjusters are often sidelined.

Untapped Potential of Moisture Mapping

The possibilities that moisture mapping offers for commercial roofing maintenance remain vastly underexplored. Many organizations rely on outdated inspection techniques that miss critical moisture issues before they snowball into major headaches. By harnessing advanced tools like infrared technology, property managers can identify moisture lurking beneath the surface, facilitating proactive maintenance instead of reactive fixes.

Take, for example, a facility manager who discovers unexpected moisture infiltration that eludes conventional visual checks. This knowledge enables targeted repairs, saving both time and money compared to broad, inefficient approaches. Transitioning to moisture mapping can transform maintenance strategies, creating a healthier roof and ultimately prolonging its life.

Moreover, moisture mapping generates crucial data that can enhance decision-making. Evaluating moisture levels allows property managers to prioritize maintenance efforts effectively. A data-driven methodology not only optimizes efficiency but also significantly bolsters overall facility management.

Investing in moisture mapping may seem like a shift from the norm, but it’s a strategic move toward long-lasting durability. It’s high time property owners woke up to this potential and leveraged it for better asset management.

Neglect of Long-Term Cost Savings

Despite clear benefits, numerous businesses fail to grasp how moisture mapping can lead to meaningful long-term savings. Conventional roofing strategies often prioritize reaction over prevention, resulting in repairs only after visible issues arise. This delay can shoot repair costs up by as much as 300%, leading to unnecessary spending and crisis situations.

Implementing moisture mapping allows for early and less invasive repairs, averting extensive damage and asset loss. For instance, catching a small leak in its infancy can spare property managers the hefty bill of a complete roof replacement while minimizing disruption to tenants’ daily lives.

Proactive maintenance strategies informed by moisture mapping empower businesses to use their resources more wisely. By honing in on problem areas flagged by accurate moisture readings, funds that would typically go toward significant repairs could instead enhance the overall building infrastructure.

Cost savings aren’t just a bonus; they’re vital for budget sustainability. By investing in moisture mapping, property owners can decrease the overall lifetime expenses linked to roofing maintenance and repairs. Prioritizing preventive action is both a wise financial strategy and a necessity for sustainable operations.

Overlooking Client and Adjuster Needs

Neglecting moisture mapping often results in overlooking crucial client and insurance adjuster needs. With properties facing erratic climate conditions and intensified weather challenges, clients now demand thorough and reliable roofing assessments that moisture mapping can deliver.

For insurance adjusters, detailed moisture mapping information provides the necessary data to support claims and justify repair or replacement actions. Relying on traditional inspection techniques may not meet their accuracy demands, resulting in disputes or prolonged claim processes. Implementing a moisture mapping protocol equips property owners with solid evidence that streamlines assessments and builds trust.

Furthermore, clients benefit from a clearer picture of their roofs’ health. The transparency provided by moisture mapping fosters informed decision-making, offering peace of mind. Having clear data on vulnerabilities strengthens long-term relationships with clients, helping to build loyalty.

Overlooking the expectations of clients and adjusters undermines the effectiveness of roofing management. Meeting these needs through moisture mapping implementation not only enhances roof assessments but also promotes smoother operations and more favorable outcomes for all parties involved.

SECTION 4: ROOT CAUSES

Understanding the root causes of poor moisture management in commercial roofing is imperative for property owners and facility managers. Over 60% of roofing failures stem from moisture-related issues, causing not just asset loss but also safety risks. A trifecta of outdated practices, insufficient training, and budget constraints creates a perfect storm, compromising the integrity of commercial roofs. This section delves into these crucial issues and their influence on maintenance strategies.

Insufficient Training and Expertise

A lack of specialized training in the roofing sector significantly contributes to moisture management failures. Many technicians aren’t equipped with the skills required to accurately identify and address moisture penetration, which leads to incorrect assessments and maintenance practices.

Shockingly, only 35% of roofing contractors possess formal training in moisture mapping. This lack of expertise results in missed warning signs of water intrusion, leaving property owners blissfully unaware of looming issues. Investing in ongoing education is critical for competent roof management.

Furthermore, poorly trained technicians can’t leverage modern technology effectively. Misinterpreted moisture readings can lead to catastrophic decisions, exacerbating the problem rather than solving it. Employers must prioritize educational programs to strengthen their teams and enhance moisture management.

Inadequate training doesn’t just impair individuals; it ripples through entire organizations, exposing critical vulnerabilities. A workforce skilled in moisture detection can foster a proactive approach, safeguarding commercial roofs and extending their lifespan.

Outdated Technology and Methods

Many facilities cling to outdated technologies that fail to deliver accurate moisture readings. Traditional methods, like simple infrared thermography, often miss subtle nuances of moisture infiltration. Consequently, critical issues can remain undetected until extensive damage occurs.

As time passes, existing equipment deteriorates. Older moisture mapping devices come with limitations that hinder precise data collection. This lack of accuracy can lead to shocking repair costs and prolonged downtime as facilities grapple with roofing failures.

Embracing modern moisture detection technologies, such as non-destructive testing methods, can significantly enhance accuracy. Property owners must assess their current systems and invest in contemporary solutions that empower effective maintenance practices.

Ignoring the latest innovations can leave facilities vulnerable to unforeseen risks. By adopting advanced technologies, property owners can establish better moisture management, leading to stronger, more resilient roofing systems.

Budget Constraints and Prioritization

Budget limitations can drastically shape maintenance decisions related to commercial roofs. Often, facility managers prioritize short-term revenue-generating projects over essential maintenance tasks. This oversight frequently results in neglecting routine moisture mapping and inspections, setting the stage for long-term issues.

Alarmingly, over 50% of facility budgets are consumed by emergency repairs stemming from avoidable neglect. This knee-jerk, reactive approach is detrimental; moisture-related problems could have been easily addressed with planned maintenance. Allocating funds for preventive measures is crucial to avert costly repairs down the line.

Leadership must champion the importance of preventive maintenance funding, ensuring resources are available for routine evaluations. Overlooking the necessity of regular assessments jeopardizes roofs, risking premature failure—a situation that could have widespread financial repercussions.

Ultimately, challenging the current budget prioritization mindset is essential. When property owners recognize the value of sustained maintenance investments, they enhance both the longevity and performance of their commercial roofing systems.

DATA DRIVEN EVIDENCE

Moisture can be a stealthy saboteur in commercial roofing, causing extensive damage that translates into steep repair bills. In fact, research indicates that nearly 30% of flat roofs are plagued with significant moisture issues, often lurking unseen. Property owners who lack accurate data are essentially driving blind, risking uninformed decisions that could worsen existing problems. This section explores how to quantify moisture damage, effectively track the drying process, and highlights compelling case studies that demonstrate the tangible benefits of moisture mapping.

Quantifying Moisture Damage Accurately

Relying solely on visual inspections is like playing a game of hide-and-seek with damage—you’re bound to miss the hidden moisture lurking just beneath the surface. To truly quantify this damage, advanced technologies are essential. Tools such as infrared thermography and dielectric scanners allow property owners to obtain reliable data, pinpointing those damp spots that would otherwise go unnoticed.

Research shows that identifying moisture presence not only helps with immediate repairs but also lays the groundwork for long-term maintenance strategies. For example, discovering moisture beneath a roof’s membrane before it spirals into structural damage can save property owners thousands in repair costs.

Furthermore, accurate quantification enables facility managers to allocate resources judiciously. With precise information in hand, they can prioritize repairs effectively, avoiding unnecessary budget drains. This proactive mindset minimizes disruption while extending the lifespan of the roofing system.

Ultimately, understanding the extent of moisture damage is the game-changer that shifts property owners from a reactive to a proactive approach, making maintenance decisions clearer and more effective.

Tracking Drying Progress Effectively

Monitoring the drying process is essential to making sure that moisture remediation efforts are not only efficient but also successful. Moisture mapping does the heavy lifting by pinpointing where water intrusion has occurred while keeping track of changes over time to confirm the effectiveness of drying methods. This ongoing vigilance is vital for preventing recurring issues that could threaten the roof’s integrity.

Advanced moisture tracking technologies, such as capacitance and resistance meters, give facility managers the tools to establish a baseline and monitor fluctuations. Real-time data transforms guesswork into informed decisions regarding whether to continue with further remediation or maintenance actions.

Additionally, consistent documentation creates a crucial historical record. This enables property owners to recognize patterns of moisture incursions, informing strategic planning for renovations or new roofing projects.

In the end, a systematic approach to tracking drying progress empowers investment decisions, assuring property owners that their roofing systems are on the road to a complete recovery.

Case Studies on Successful Moisture Mapping

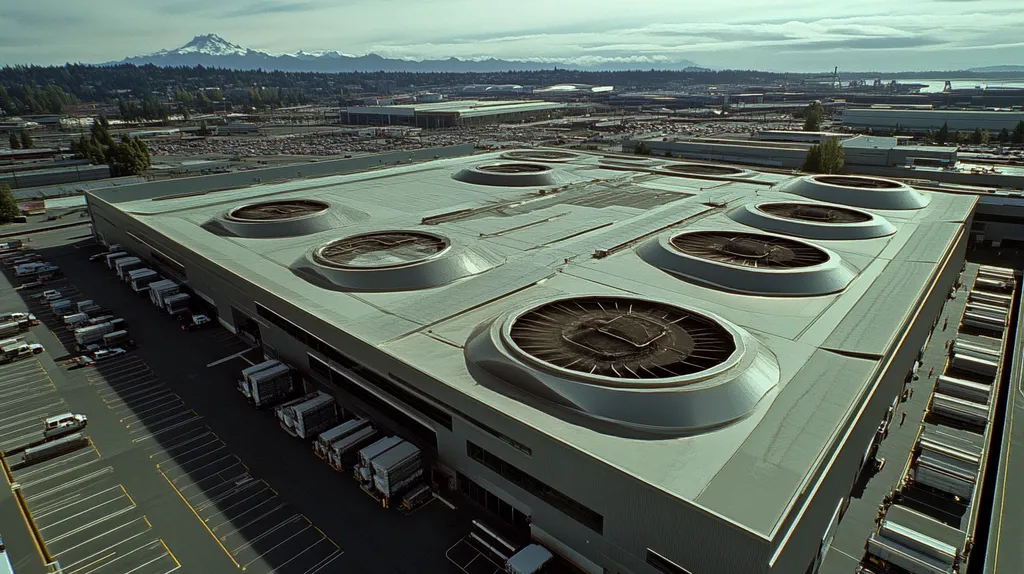

A number of industry case studies showcase the impressive benefits of moisture mapping in commercial roofing. For example, one case involved a manufacturing facility that uncovered hidden moisture beneath its roof membrane, a situation that could have led to extensive rot and structural failure.

Thanks to state-of-the-art moisture mapping technology, the facility’s management was able to address the issue before it turned into a full-blown crisis. This proactive intervention not only cut potential repair costs but also minimized disruption to operations.

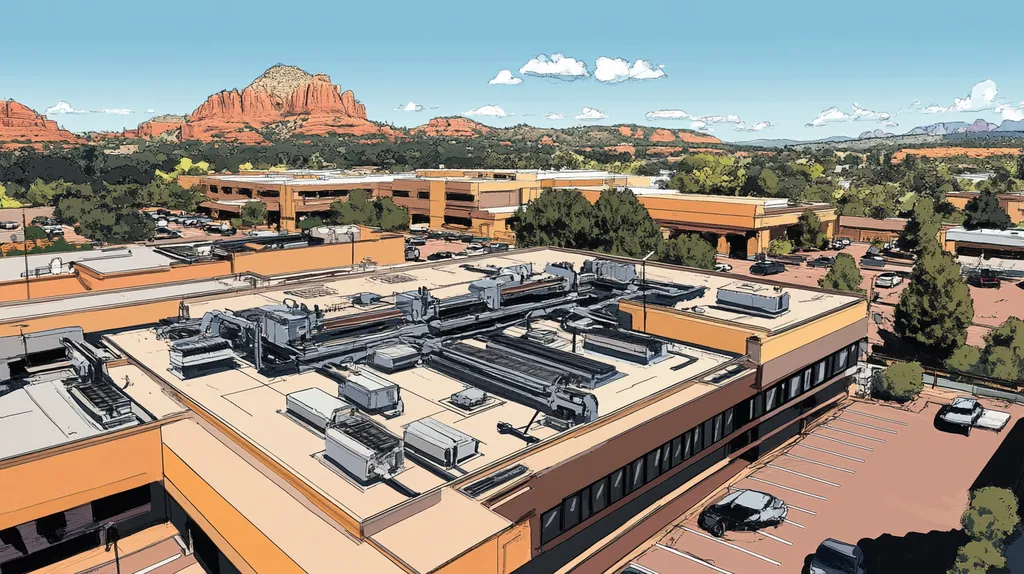

In another case, a retail center plagued by recurring leaks turned its fortunes around through data-driven moisture mapping. The management was able to identify and target critical areas of concern, resulting in focused repairs that dramatically improved the roof’s performance and enhanced the overall shopping experience for customers.

These examples illustrate how successful moisture mapping empowers better decision-making and translates to significant cost savings. By embracing this technology, commercial properties can ensure operational efficiency while safeguarding their long-term value.

SECTION 6: ALTERNATIVE SOLUTIONS

As commercial roofs deteriorate at an alarmingly rapid pace, proactive moisture management isn’t just a good idea—it’s essential. Studies indicate that nearly 30% of roofs encounter moisture-related issues that can lead to staggering repair costs. Ignoring innovative strategies not only jeopardizes structural integrity but can also wreak havoc on maintenance budgets. This section explores alternative solutions that elevate commercial roof longevity and reliability, highlighting the crucial role of moisture mapping.

Implementing Comprehensive Moisture Mapping

Comprehensive moisture mapping offers a clear snapshot of a roof’s health by unearthing hidden moisture pockets. This sophisticated approach employs advanced sensors and technologies to generate moisture profiles that reveal vulnerable areas. Traditional inspection practices often miss these crucial moisture accumulations, setting the stage for severe future consequences.

Integrating moisture mapping into routine maintenance allows property owners to catch issues early. This proactive mindset enables timely interventions, preventing expensive damage and extending the roof’s life. Neglecting these strategies can lead to unexpected structural failures and escalating long-term costs.

Moreover, weaving moisture mapping into annual inspections boosts the reliability of maintenance schedules. This data-driven strategy helps facility managers prioritize attention on roof sections that demand urgent care. An informed approach translates to improved safety and operational continuity, ultimately safeguarding valuable investments.

Utilizing Advanced Detection Tools

Advanced detection tools are key players in unveiling moisture infiltration issues in commercial roofs. Technologies like infrared thermography and electronic moisture meters enable non-invasive assessments, revealing problem areas that would remain hidden otherwise. These high-tech tools deliver immediate, accurate data vital for making well-informed decisions.

For instance, infrared thermography can detect temperature variations that signal moisture problems. This capability allows facility managers to identify leaks before they escalate into significant headaches. By embracing these modern technologies, the industry’s reliance on outdated inspection practices becomes a thing of the past.

Additionally, electronic moisture meters quantify moisture levels and their implications. This actionable data empowers maintenance teams to respond swiftly and effectively. Integrating these advanced tools isn’t merely a possibility; it’s a necessary leap for proficient roof management.

Integrating Moisture Data into Maintenance Plans

Integrating moisture data into maintenance plans radically changes how commercial roofing systems are managed. By utilizing moisture readings for every inspection, property managers can craft maintenance schedules grounded in real data, not mere assumptions. This analytical approach nurtures a proactive maintenance culture.

Establishing a moisture data repository fosters long-term planning and budget forecasting. It enables facility managers to allocate resources judiciously while minimizing the risk of unexpected water-related costs. Historical data also lends itself to trend analysis, which is critical for forecasting future roof performance.

Ultimately, basing maintenance strategies on moisture data leads to smarter decisions and healthier roofs. This comprehensive approach enhances the lifespan of roofing systems, protects investments, and ensures operational efficiency.

The Bottom Line

With moisture-related roof failures costing billions annually, the commercial roofing industry can no longer ignore the transformative potential of moisture mapping technology.

Traditional inspection methods miss up to 70% of moisture issues that ultimately lead to catastrophic damage, yet only 30% of properties utilize advanced detection tools.

The data is clear: properties implementing comprehensive moisture mapping reduce repair costs by up to 300% while extending roof lifespans by 20% or more.

Continuing to rely on outdated visual inspections and reactive maintenance isn’t just shortsighted—it’s financially reckless.

The technology exists to revolutionize commercial roof maintenance through data-driven moisture mapping. The only question is whether property owners will embrace it before their next major leak.

FREQUENTLY ASKED QUESTIONS

Q. Why are current commercial roof maintenance practices ineffective?

A. Many property managers rely on outdated methods and reactive maintenance strategies. This approach increases the risk of costly repairs since issues are addressed only after they become serious. Proactive maintenance and regular inspections can significantly reduce expenses and extend roof lifespan.

Q. How does moisture mapping help my industrial roof?

A. Moisture mapping identifies hidden leaks, enabling timely repairs that prevent severe, costly damage. This proactive approach ensures effective resource allocation, preventing unforeseen expenses that could arise from neglected issues. With data-driven insights, you can maintain a healthier roof.

Q. What are the risks of not implementing moisture mapping?

A. Neglecting moisture mapping can lead to undetected leaks and extensive structural damage, compromising safety. By avoiding this critical assessment, property owners risk major repair costs and potential liabilities. It’s essentially playing with fire, and that never ends well.

Q. Can outdated training affect my commercial roof’s maintenance?

A. Absolutely! Insufficient training in moisture detection and roofing technologies leads to poor assessments and decision-making. When technicians lack the necessary skills, critical moisture problems often go unnoticed, ultimately jeopardizing the integrity of your commercial roof.

Q. How does budget prioritization impact roof maintenance?

A. Budget constraints often lead to prioritizing short-term projects over essential maintenance tasks. This oversight can result in costly repairs due to neglect; therefore, allocating funds for routine inspections and preventive maintenance is critical for long-term roof health.

Q. What technologies are recommended for effective moisture detection?

A. Embracing cutting-edge technologies like infrared thermography and moisture meters is essential for accurate assessments. Non-invasive detection methods provide crucial insights into moisture issues, allowing for timely interventions that prevent extensive and costly damage.

Q. How can I future-proof my commercial roof investment?

A. Implementing a regular moisture mapping strategy, utilizing advanced detection tools, and investing in proper training for maintenance staff are key steps. A proactive approach helps mitigate risks, extending roof lifespan and ensuring your investment remains secure against moisture-related issues.