Welcome to today’s Battle Royale featuring two roofing heavyweights: “Infrared Thermography” in the east corner versus “Drone Inspections” in the west!

Tonight’s showdown pits these contenders against each other across six punishing rounds designed to test every aspect of their performance for Industrial Roof Damage Detection.

At stake? Millions in potential costs, decades of building protection, and the critical performance demands of modern commercial and industrial facilities.

Our professional judging panel will evaluate each round on technical merit, real-world performance, and value delivery. After all six rounds, we’ll declare our ultimate champion.

Ladies and gentlemen, facility managers and building owners… it’s time to rumble!

ROUND 1: INITIAL COSTS & INSTALLATION

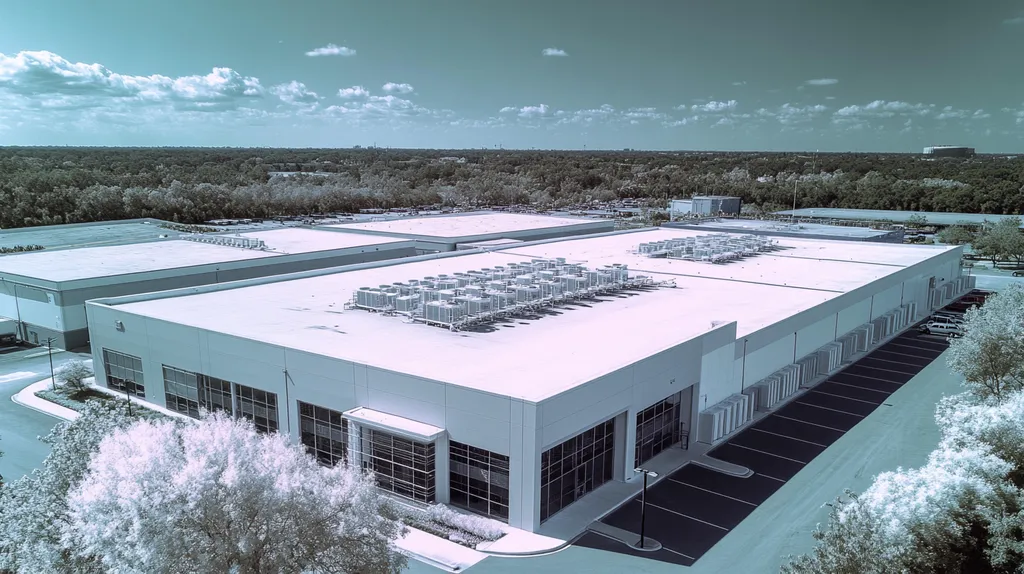

When industrial roofs fail, the consequences can be catastrophic – from inventory damage to complete production shutdowns. Modern detection technologies offer unprecedented accuracy in identifying potential failures before they occur, but implementing these systems requires careful consideration of costs and logistics. Property owners must weigh immediate expenses against long-term value while ensuring minimal disruption to operations.

Material Expenses

The initial investment in roof inspection technology represents a significant portion of implementation costs. Professional-grade infrared cameras typically range from $8,000 to $15,000, with additional costs for specialized software and calibration equipment.

Commercial drone systems equipped for roof inspections start at $12,000 and can exceed $40,000 for advanced models with thermal and multispectral capabilities. These systems also require ongoing maintenance, battery replacements, and potential repairs.

While both technologies demand substantial upfront investment, infrared systems generally cost less to acquire and maintain. For most facilities, the lower entry point makes infrared more accessible. Therefore, the “ADVANTAGE” goes to Infrared Thermography.

Installation Complexity

Setting up an infrared inspection program requires extensive preparation of the roof surface and careful timing to achieve optimal thermal conditions. Technicians need specialized training to properly operate equipment and interpret thermal images.

Drone inspection systems require less physical roof preparation but face more regulatory hurdles. Operators must obtain FAA certification and necessary permits, though actual setup time is minimal once approvals are secured.

Despite regulatory requirements, drone systems offer faster deployment and fewer physical access challenges. The “ADVANTAGE” goes to Drone Inspections.

Project Timeline

Infrared inspections typically require specific environmental conditions and often must be conducted at night or early morning. This timing requirement can extend project duration by days or weeks waiting for optimal conditions.

Drone inspections can be conducted during normal business hours and complete surveys more quickly. Most facilities can be fully mapped in a single day, with results available within 24-48 hours.

The flexibility and speed of drone operations significantly reduce project timelines. The clear “ADVANTAGE” belongs to Drone Inspections.

ROUND 1 WINNER: Drone Inspections

ROUND 2: DURABILITY & LIFESPAN

Industrial roof inspections demand reliable, long-lasting detection systems that can consistently identify potential failures before they become catastrophic. The durability and operational lifespan of these technologies directly impact maintenance budgets and inspection effectiveness. Understanding how these systems perform over time is crucial for facility managers making strategic investment decisions.

Equipment Longevity

Professional-grade infrared cameras demonstrate remarkable durability when properly maintained, with most units remaining effective for 8-10 years. Regular calibration and proper storage significantly extend their operational life, though sensor sensitivity may gradually decrease over time.

Commercial inspection drones typically last 3-5 years under regular use, with components like motors and batteries requiring more frequent replacement. Environmental factors and operational intensity can significantly impact their lifespan.

The proven track record and longer service life of infrared equipment gives it the clear “ADVANTAGE” in this category.

Maintenance Requirements

Infrared systems require annual calibration and periodic software updates to maintain accuracy. These maintenance tasks are relatively straightforward and can often be performed without extended equipment downtime.

Drone systems demand more frequent maintenance checks, including motor testing, propeller replacement, and battery conditioning. They also require ongoing software updates and occasional repairs due to their complex mechanical nature.

With lower maintenance demands and simpler upkeep requirements, the “ADVANTAGE” goes to Infrared Thermography.

Technology Evolution

Infrared technology has reached a mature state, with improvements focusing on software analysis rather than hardware capabilities. This stability means current systems will remain relevant longer, though they may miss out on revolutionary advances.

Drone technology continues to evolve rapidly, with new capabilities emerging regularly. Automated damage detection powered by AI and deep learning algorithms now enables drones to analyze roof imagery with unprecedented accuracy, reducing human error while ensuring comprehensive evaluation. (source: Loveland Innovations)

The rapid pace of innovation and expanding capabilities gives Drone Inspections the clear “ADVANTAGE” in this category.

ROUND 2 WINNER: Infrared Thermography

ROUND 3: PERFORMANCE FACTORS

Industrial roof damage detection has evolved dramatically in recent years, driven by advances in sensing technology and data analysis. Undetected roof issues can escalate repair costs by up to 40% within the first year alone, making early detection critical. The performance capabilities of modern inspection methods directly impact a facility’s ability to prevent catastrophic failures and maintain operational continuity.

Accuracy of Detection

Infrared Thermography excels at identifying subsurface issues, particularly moisture infiltration and insulation degradation. The technology can detect temperature variations as small as 0.1°C, revealing problems invisible to the naked eye.

This precision is particularly crucial for facilities with complex roofing systems. The construction of solar arrays and green roof installations significantly increases the risk of moisture-induced structural damage, making accurate detection essential. (source: Nordic Industrial Services)

Drone inspections provide high-resolution visual data but struggle to identify subsurface issues. While excellent for documenting surface damage and general wear patterns, drones cannot detect internal moisture migration or thermal bridging without specialized sensors.

For detection accuracy, Infrared Thermography claims the clear ADVANTAGE.

Coverage Efficiency

Infrared surveys require methodical scanning patterns and careful attention to environmental conditions. While thorough, this process can be time-consuming for large facilities, especially when multiple passes are needed to ensure complete coverage.

Drone systems excel at rapid coverage of extensive roof areas, capturing comprehensive data in a single flight. Their automated flight patterns ensure consistent documentation without gaps or oversights.

Modern drones can survey a 100,000-square-foot roof in under an hour, compared to 4-6 hours for traditional infrared scanning. The ADVANTAGE goes to Drone Inspections.

Data Analysis Capabilities

Infrared data interpretation requires significant expertise but provides immediate insights during the inspection. Technicians can identify and document issues in real-time, enabling faster decision-making for urgent repairs.

Drone systems generate massive amounts of visual data that require post-processing and analysis. While this allows for detailed documentation, the delay between inspection and results can impact response times for critical issues.

The ability to identify and address problems immediately gives Infrared Thermography the ADVANTAGE in this category.

ROUND 3 WINNER: Infrared Thermography

ROUND 4: MAINTENANCE REQUIREMENTS

Maintaining industrial roof inspection systems represents a critical factor in protecting facility investments. Studies show that inadequate maintenance protocols can reduce detection accuracy by up to 40% within the first year of implementation. As these technologies become more sophisticated, understanding their ongoing requirements becomes essential for maximizing return on investment and preventing costly oversights.

Equipment Upkeep

Infrared thermography systems require regular calibration and sensitivity testing to maintain detection accuracy. Professional-grade thermal cameras need annual recertification by qualified technicians to ensure precise temperature readings and reliable moisture detection. (source: Roof Expert)

Drone systems demand more frequent but simpler maintenance tasks. Monthly checks of propulsion systems, cameras, and control electronics help prevent operational failures, while battery replacement occurs every 200-300 flight cycles.

The straightforward nature of drone maintenance compared to precision calibration requirements gives Drone Inspections the ADVANTAGE.

Operator Training

Maintaining proficiency with infrared systems requires extensive ongoing training. Technicians must stay current with thermal imaging interpretation techniques and understand how different roofing materials affect readings.

Drone operators need initial certification and periodic updates on regulations and safety protocols. The standardized nature of drone operation makes skill maintenance more straightforward than interpreting complex thermal data.

With lower training demands and more standardized procedures, the ADVANTAGE goes to Drone Inspections.

System Updates

Infrared inspection systems typically require minimal software updates, focusing mainly on analysis tools and reporting features. These updates rarely impact core functionality and can usually be performed without disrupting inspection schedules.

Drone systems demand regular firmware updates to maintain safety features and comply with evolving regulations. These updates can temporarily ground inspection operations and may require recertification of flight protocols.

The stability and simplicity of infrared system updates gives Infrared Thermography the ADVANTAGE.

ROUND 4 WINNER: Drone Inspections

ROUND 5: SUSTAINABILITY CREDENTIALS

Environmental impact and sustainability have become critical factors in industrial roofing decisions. Modern damage detection methods must balance effectiveness with ecological responsibility. Studies show that inefficient roof inspection practices can increase energy waste by up to 30% and lead to premature material disposal, making the choice of technology crucial for meeting environmental goals.

Energy Efficiency Impact

Infrared thermography systems consume minimal power during operation, requiring only the camera unit and basic processing equipment. Their ability to precisely identify thermal leaks enables targeted repairs that significantly improve building energy efficiency.

The technology’s precision in detecting insulation gaps and moisture infiltration allows facilities to maintain optimal thermal performance. This capability often leads to energy savings of 15-25% through improved roof system efficiency.

Drone systems require frequent battery charging and power-hungry processing for their extensive data collection. While their operation is relatively efficient, the cumulative energy consumption exceeds that of infrared systems.

The superior energy profile and efficiency benefits give Infrared Thermography the clear “ADVANTAGE” in this category.

Material Conservation

Infrared inspections enable precise identification of damaged areas, minimizing unnecessary removal of sound roofing materials. This targeted approach significantly reduces waste and extends the lifespan of existing roof systems.

Drone inspections excel at early detection of surface deterioration, preventing extensive damage that would require large-scale material replacement. Their comprehensive coverage ensures no developing issues go unnoticed.

Both technologies demonstrate strong capabilities in minimizing material waste through accurate problem identification, resulting in a “TIE” for this category.

Environmental Impact

Infrared systems have minimal environmental impact beyond their energy consumption. The equipment is durable, with components lasting many years before requiring replacement.

Drone systems involve more complex environmental considerations, including battery disposal and replacement of mechanical components. However, their ability to conduct rapid, non-invasive inspections reduces the need for physical access equipment and associated environmental impacts.

The simpler lifecycle and reduced waste generation gives Infrared Thermography the “ADVANTAGE” in this category.

ROUND 5 WINNER: Infrared Thermography

ROUND 6: SPECIALIZED APPLICATIONS

Industrial roof damage detection demands precise, specialized solutions for diverse facility needs. Studies show that improper inspection method selection leads to missed defects in 40% of cases, resulting in premature roof failure. Understanding the unique capabilities of modern detection technologies enables facility managers to deploy the right tool for specific challenges.

Targeted Inspections

Infrared thermography excels at pinpointing specific problem areas, particularly subsurface issues that visual inspection cannot detect. The technology uses infrared cameras to detect temperature variations in the roof, revealing hidden moisture infiltration and insulation failures that could compromise structural integrity. (source: Roof Expert)

Drone inspections provide comprehensive surface mapping but may miss subtle thermal anomalies. While high-resolution cameras capture excellent detail, they cannot penetrate beyond the roof’s surface without specialized sensors.

For precision in identifying specific problem areas, particularly those involving moisture or thermal issues, the ADVANTAGE goes to Infrared Thermography.

Access to Difficult Areas

Traditional infrared scanning requires relatively close proximity to the roof surface, making some areas challenging or dangerous to inspect. Complex roof geometries and restricted access points can limit coverage and effectiveness.

Drone systems excel at reaching difficult or dangerous areas safely. Their ability to maneuver over obstacles and inspect hard-to-reach sections while maintaining stable imaging makes them ideal for complex roof structures.

The superior accessibility and safety advantages in challenging locations gives Drone Inspections the clear ADVANTAGE.

Real-Time Analysis

Infrared systems provide immediate feedback during inspections, allowing technicians to investigate anomalies as they’re discovered. This real-time capability enables faster decision-making for urgent repairs.

Drone inspections typically require post-flight data processing before detailed analysis can begin. While the actual inspection is quick, the delay between data collection and analysis can impact response times.

The ability to identify and assess problems immediately gives Infrared Thermography the ADVANTAGE in this category.

ROUND 6 WINNER: INFRARED THERMOGRAPHY

AND THE WINNER IS…

After six grueling rounds of technical evaluation, we have our verdict… With a score of 4 rounds to 2, INFRARED THERMOGRAPHY claims the championship belt!

This heavyweight champion dominated the competition with superior accuracy in damage detection, proven long-term durability, and impressive sustainability credentials. Its real-time analysis capabilities and precision in identifying subsurface issues proved decisive in securing victory.

But don’t count Drone Inspections out! This innovative challenger showed impressive strength in rounds focused on installation speed, maintenance simplicity, and access to difficult areas. For facilities with complex geometries or restricted access points, drone technology remains a formidable contender.

IMPORTANT NOTICE: While this analysis reflects general industry performance, every facility faces unique challenges. Local climate conditions, building design, and specific operational requirements can significantly impact inspection technology effectiveness. Property owners and managers should consult qualified roofing professionals to evaluate their specific needs and circumstances before making final decisions.

Ladies and gentlemen, in the high-stakes arena of industrial roof protection, there’s no substitute for matching the right technology to your facility’s specific requirements. Choose your champion wisely – because when it comes to protecting your assets, everyone’s fighting for a knockout victory!

FREQUENTLY ASKED QUESTIONS

Q. What are the costs of commercial roof inspection technologies?

A. The initial investment for infrared cameras ranges from $8,000 to $15,000, whereas drone systems start at $12,000. Infrared systems generally have lower ongoing costs compared to drones, making them more accessible for most facilities. Property owners need to consider these expenses against the long-term value.

Q. How long do infrared systems last for industrial roofs?

A. Infrared cameras can remain effective for 8-10 years with proper maintenance. In contrast, commercial drones typically last about 3-5 years, necessitating more frequent replacements. The longer lifespan of infrared equipment highlights its reliability for sustained use.

Q. Which roof inspection method offers better detection accuracy?

A. Infrared Thermography provides superior accuracy by identifying subsurface issues like moisture infiltration. This technology detects temperature changes as small as 0.1°C, surpassing the capabilities of drone inspections, which mainly document surface conditions without revealing underlying problems.

Q. How often do I need to maintain industrial roof inspection equipment?

A. Infrared thermography systems need annual calibration and periodic testing to ensure accuracy. Drone systems require monthly checks and battery replacements every 200-300 cycles. While both need regular maintenance, the infrared system’s requirements are more extensive.

Q. What is the sustainability impact of roof inspection technologies?

A. Infrared thermography has minimal environmental impact and contributes to energy efficiency improvements by detecting leaks. Drones consume more energy and present disposal challenges due to battery replacement. Therefore, infrared technology generally shows greater sustainability benefits in roof inspections.

Q. Which inspection method is better for accessing difficult areas on commercial roofs?

A. Drones excel in accessing challenging areas due to their ability to maneuver safely. They can conduct inspections over obstacles and in hard-to-reach sections, making them more effective for complex roof geometries than traditional infrared methods.

Q. Are drone inspections quick in providing results for commercial roofs?

A. Yes, drone inspections can complete surveys of large roofs in under an hour. Results are typically available within 24-48 hours, allowing for rapid response to any detected issues. This swift timeline helps facility managers make timely decisions regarding roof maintenance.