In an era where a single roof replacement can exceed $250,000, commercial property owners face a critical dilemma. Traditional damage prevention strategies are failing spectacularly, with 80% of commercial roofs requiring replacement before reaching their expected lifespan.

From inadequate drainage designs to neglected maintenance programs, the industry’s established approaches increasingly fall short against modern challenges like extreme weather events and aging infrastructure.

This analysis challenges conventional wisdom about roof damage prevention, revealing systemic flaws in current practices while presenting data-driven alternatives that could revolutionize commercial roof protection.

SECTION 1: CURRENT PRACTICES

As roof repair costs skyrocket into the tens of thousands, commercial property owners face high stakes. Neglecting preventative measures can result in devastating water damage, structural failures, and serious disruptions to business operations. Current industry norms—routine inspections, debris clearance, and reactive repairs—form the foundation of roof maintenance, but they may fall short in an era of extreme weather and aging infrastructure.

Regular Inspection Schedules

For many commercial properties, established inspection schedules are the first line of defense against roof damage. Typically conducted twice a year or after severe weather, these inspections can spot visible issues but often miss smaller, developing problems that can escalate into pricey repairs.

Inconsistencies in inspection timing—often dependent on staff availability—can lead to reports lacking in-depth analysis or actionable insights. When inspections are treated as mere checkboxes, potential red flags can slip through the cracks, leaving roofs vulnerable to unanticipated failures.

Additionally, conducting inspections during peak business hours can disrupt daily operations, delaying crucial repairs and putting roofing systems at risk. With climate change ushering in unpredictable weather patterns, a reactive inspection routine can further expose properties to damage. Adopting flexible and robust inspection protocols is essential for proactive roof management.

Debris Clearance Protocols

Clear debris is often hailed as critical for maintaining a roof’s integrity. Property managers are typically advised to keep surfaces clean since accumulated debris can cause water pooling, leading to accelerated wear. Yet merely clearing away visible debris neglects deeper issues.

Most debris clearance strategies focus on periodic cleanouts, which can overlook less obvious threats. Small twigs and fallen leaves, for example, can trap moisture and create slow leaks, often going undetected until significant damage occurs. Without consistent, thorough inspections alongside effective debris management, minor problems can escalate into major concerns.

Moreover, relying solely on scheduled clean-ups can backfire, especially after storms when roofs may require immediate attention. Waiting for pre-planned clearances can exacerbate damage and lead to potentially hazardous situations. Employing real-time monitoring technology and investing in staff training could revolutionize debris management, ensuring roofs stay protected while offering peace of mind.

Reactive Repair Strategies

Reactive repair strategies frequently form the first line of defense when roofing problems arise. Many property managers procrastinate until damage occurs before calling contractors for repairs, leading to excessive costs as even minor leaks can wreak havoc on roofing materials and internal structures.

This approach echoes the age-old adage, “fix it when it breaks,” a mentality that may seem cost-effective but often ignores the root causes of issues. This shortsightedness can result in a cycle of repeated repairs and escalating costs over time.

Additionally, waiting for visible damage can severely disrupt business operations. Internal leaks may lead to damage to inventory or create safety hazards, both of which can impact profitability. To break free from this cycle, facility managers must shift towards an integrated maintenance strategy that prioritizes proactive repairs and ongoing assessments.

Investing in preventive measures today can save substantial expenses in the future, improving the overall resilience of facilities and safeguarding their operations.

SECTION 2: SYSTEMIC ISSUES

Commercial roofs face a range of systemic flaws that can jeopardize their durability and safety. Inadequate drainage systems, neglect of high-risk areas, and limited access to roofs create a perfect storm for damage that could otherwise be prevented. These issues often lead to costly repairs and increased liability for property owners. Tackling these systemic flaws is crucial for ensuring the long-term performance of roofing systems.

Inadequate Drainage Designs

Poorly designed drainage systems are a leading culprit in roof failures. When rainwater can’t flow off a roof effectively, it pools and places excessive stress on roofing materials. This might seem like a minor inconvenience, but over time, it can result in leaks and major structural problems that require extensive repairs.

Research indicates that nearly 40% of commercial roof failures are linked to inadequate drainage. Roofs designed without proper slopes or drainage points can trap water, accelerating wear and tear. Regular maintenance and thorough engineering reviews are essential to ensure these systems function as intended.

Investing in updated drainage designs can ultimately save property owners a significant amount of money. Implementing superior drainage solutions not only mitigates risks but also extends a roof’s lifespan. Consequently, architects and contractors should prioritize addressing drainage needs from the very beginning of the design process to sidestep future complications.

To bolster drainage efficiency, property managers should conduct routine inspections to identify and clear any blockages or clogs. A proactive maintenance strategy is vital for catching issues before they escalate, safeguarding the building’s investment.

Neglect of High-Risk Areas

High-risk areas on commercial roofs—like penetrations, flashing, and seams—need extra attention to prevent hazards. These spots are often the weak links in a roofing system, and when neglected, they become breeding grounds for leaks and water infiltration.

For instance, poorly sealed roof penetrations can allow moisture to seep in, causing rotting and damage to internal structures. Typically, these issues go unnoticed until significant damage has occurred, resulting in expensive repairs.

Property managers should make it a priority to inspect high-risk areas regularly. By scheduling specific check-ups for these critical points, they can catch potential problems early. Timely repairs in these areas can help maintain the integrity of the entire roof, ultimately reducing the likelihood of costly emergency fixes.

Understanding the vulnerabilities associated with high-risk areas empowers property owners to take informed actions. This knowledge paves the way for proactive initiatives that ensure long-term roof functionality.

Limited Access Control

Limited access to commercial roofs can seriously impede maintenance efforts, increasing the risk of damage. Insufficient access points discourage routine inspections and repairs, leading to neglected issues that can snowball into costly disasters.

Many commercial roofs lack adequate access points, making it challenging for inspectors to monitor conditions on a regular basis. This lack of accessibility often results in necessary maintenance tasks falling by the wayside, compromising the entire roofing system.

To tackle this problem, property owners should enhance roof access. Installing additional access hatches and safe walkways streamlines maintenance and promotes regular inspections. The easier it is to access the roof, the more likely maintenance staff will perform critical assessments.

Moreover, it’s essential to equip maintenance personnel with proper training on safe access practices. Ensuring that those inspecting the roof are well-prepared can lead to early detection of potential problems, saving resources and protecting the entire structure in the long run.

SECTION 3: MISSED OPPORTUNITIES

The risks associated with commercial roof maintenance couldn’t be clearer. With a staggering 80% of roof failures attributed to inadequate maintenance, the potential for costly repairs and operational chaos looms large. Property owners and facility managers frequently overlook vital opportunities for damage prevention. In this section, we will delve into critical areas where preventative measures tend to be neglected, ultimately leading to steep consequences.

Overlooking Roof Accessories

Many property owners underestimate the critical role of roof accessories such as drains, vents, and flashing. Neglecting these components can set the stage for issues like ponding water and leaks. Regular inspections of these accessories are not just a suggestion; they are a necessity.

Take clogged drains, for example—they can lead to water pooling, which places excessive stress on the roofing structure. Ignoring maintenance for these accessories can ramp up repair costs faster than you can say “roof replacement.” Property owners need to ensure these components are not only installed but also prioritized for upkeep.

Moreover, accessory materials can deteriorate over time and may need replacement. Without routine checks, this wear can go unnoticed and result in serious structural damage. Investing in proactive measures for roof accessories not only saves time but protects financial resources as well.

Recognizing the integral role of roof accessories in overall drainage systems can also help prevent larger system failures. Proactivity isn’t just good practice; it’s downright essential for long-term roof health.

Ignoring Weather Event Impacts

Severe weather is a persistent threat to commercial roofs, yet many property owners dismiss its impact. High winds, heavy rain, and extreme temperatures pose significant risks, making a robust response strategy vital.

Consider wind—it can displace roof membranes, while ice dams can accumulate and cause leaks. Understanding local weather patterns and their effects on roofing systems is essential. Unfortunately, many companies fail to adapt their maintenance protocols in light of weather forecasts, resulting in missed opportunities to fortify their roofs.

Post-storm inspections are crucial but often overlooked. Skipping an assessment after adverse weather can allow minor issues to fester and escalate into expensive repairs. Waiting to see if a problem resolves itself is rarely a winning strategy.

Furthermore, investing in weather-resistant materials can significantly reduce vulnerability. Choosing the right roofing systems tailored to local climate conditions is a proactive approach every property owner should embrace—don’t wait for the storm to pass to check for leaks.

Lack of Detailed Record Keeping

A comprehensive maintenance history can dramatically influence a commercial roof’s lifespan. Yet, many property managers fail to maintain thorough records, creating a barrier to effective decision-making.

Regular maintenance logs track roof conditions and repair timelines, allowing property owners to identify trends that may indicate larger issues. Without this vital information, they risk missing patterns that could guide better resource allocation and prevention.

Poor documentation can also complicate warranty claims. Many warranties require regular maintenance records to validate coverage, and neglecting to keep these could expose property owners to unexpected costs. It’s a classic case of “you don’t know what you’ve got until it’s gone.”

Moreover, a meticulous record suggests accountability, aiding conversations with roofing professionals. Detailed maintenance histories equip property owners with the context to discuss specific issues, resulting in more effective solutions down the line.

SECTION 4: ROOT CAUSES

Identifying the root causes of commercial roof damages is not just important—it’s essential for savvy property managers and owners. A staggering 80% of roofing failures spring from design flaws, subpar materials, and inconsistent maintenance practices. Tackling these factors head-on can lead to reduced repair bills and longer-lasting roofs, ultimately protecting valuable investments. This section dives into the primary culprits behind roof failures and underscores the importance of proactive measures.

Poor Initial Roof Design

A roof’s design lays the groundwork for its success or failure. Flaws like inadequate slope lead to water pooling—one of the quickest paths to leaks and structural issues. Some roofs are designed without accounting for local weather patterns, leaving them ill-equipped to handle heavy snow, vicious winds, or brutal heat.

Flat roofs, for instance, that lack effective drainage systems are particularly vulnerable. Without proper drainage, water can accumulate, creating a breeding ground for leaks and, ultimately, costly interior damage. A design that thoughtfully considers local climate and the intended use of the building is critical for sidestepping future headaches.

Design pitfalls can spring from inadequate knowledge of roofing materials and system requirements. Using lightweight materials in areas prone to heavy snowfall is a recipe for potential disaster, like roof collapse. Engaging experienced professionals with a solid understanding of material appropriateness is crucial to prevent these foundational problems.

A strong design doesn’t just think about the immediate; it prioritizes longevity and resilience to avoid being mired in constant repairs. When the design is flawed, property owners inevitably face an uphill battle in maintaining their roofs for years to come.

Substandard Roofing Materials

The temptation to cut corners often leads property owners to choose cheap, substandard roofing materials that can’t hold up over time. In the short term, this may seem cost-effective, but it usually backfires, resulting in higher maintenance expenses and, ultimately, the need for replacement.

Take low-quality membranes, for example. They may degrade under UV exposure faster than you can say “water leak,” leading to moisture infiltration and potential interior damage. While they might appear functional at first glance, they often fall short of industry durability and weather resistance standards.

Subpar materials extend their reach into insulation and energy efficiency as well. Poor insulation doesn’t just expose the roof to damage; it also drives up energy costs, leading to an endless cycle of mounting expenses for the property owner.

Investing in quality roofing materials might feel daunting, but it’s a decision that pays dividends over time. Property owners should prioritize high-performance products rather than defaulting to the lowest upfront cost, ultimately saving themselves from financial pitfalls down the road.

Inconsistent Maintenance Programs

There’s an alarming trend: inconsistent maintenance programs are a leading cause of roof damage. Without regular inspections and ongoing upkeep, small issues can balloon into major problems. Failing to check for minor leaks or wear can lead to serious structural damage and expensive repairs.

How often should one inspect? Industry standards recommend at least two inspections each year, along with additional checks following severe weather. Neglecting these best practices can open the door to unexpected roof failures that leave property owners scrambling.

Moreover, not maintaining clear maintenance logs makes tracking repairs and recurring issues a convoluted process. Documenting maintenance efforts, inspections, and repairs offers invaluable insights into the roof’s condition and lifespan, empowering informed decisions.

The clear objective is to implement a robust maintenance schedule that encompasses routine inspections, timely debris removal, and swift repairs for discovered problems. A comprehensive maintenance strategy can significantly mitigate risks and ensure roofs remain in peak condition throughout their lifecycle.

DATA DRIVEN EVIDENCE

When it comes to commercial roofs, premature failures are a ticking time bomb for property owners, with over half of all roofs not making it through their expected lifespan. Such figures don’t just reflect poor luck; they reveal a pressing need to transition from a fire-fighting mentality to a proactive maintenance strategy. Armed with real statistics on roof longevity, cost breakdowns, and success stories, facility managers can make decisions that protect their investments before it’s too late.

Statistics on Premature Roof Failures

Recent statistics deliver a gut punch: approximately 50% of commercial roofs are replaced prematurely, a reality driven by neglect and inconsistent maintenance. The National Roofing Contractors Association (NRCA) highlights that while weather and debris play significant roles, many of these failures come from a lack of regular preventive inspections. Shadowy, undetected issues can rapidly spiral into hefty repair bills.

Moreover, the NRCA reveals a fascinating nugget—roofs that benefit from routine inspections and maintenance can last up to 25% longer than those left to their own devices. It’s clear that committing to preventive action can drastically enhance a roof’s life span. Addressing minor leaks or localized damages early can prevent the need for catastrophic renovations down the line.

Many property owners underestimate the severity of what may appear to be trivial leaks or damage. What feels like a minor inconvenience today could evolve into a nightmare tomorrow if unmonitored. Regular maintenance is a shield against premature failures, not only preserving the roof’s integrity but also maintaining the building’s overall value.

Dedicating time and resources to consistent inspections translates into substantial savings in the long run. Recognizing and acting on these statistics can empower facility managers to safeguard their properties effectively and budget smarter for future roof care.

Cost Analysis of Preventive vs. Reactive Maintenance

The financial ramifications of roofing decisions are immense, underscoring that preventative care trumps reactive maintenance every time. Research shows a staggering return on investment—every dollar invested in preventive upkeep can save property owners between $5 and $10 down the line. This stark contrast highlights the undeniable value of a proactive approach.

Imagine a standard commercial roof replacement costing around $100,000. If a preventive maintenance plan averages only $10,000 over a decade, the rationale for proactive spending becomes crystal clear compared to potential replacement costs. Statistics consistently demonstrate that investing in maintenance reaps significant financial rewards.

Reactive strategies, on the other hand, often lead to unexpected financial pitfalls. Neglected roofs can suffer extensive damage resulting in exposure to the elements and serious safety risks. Hidden costs associated with emergency repairs, unplanned downtime, and operational interruptions frequently add to the financial burden, which is often minimized or overlooked.

A comprehensive look at total ownership costs reveals that adopting a proactive maintenance mindset not only protects assets but also promotes long-term economic savings. Facility managers who base their budget decisions on these insights are better equipped to strategize effectively for their roofing systems.

Case Studies on Extended Roof Lifespan

Take the example of a retail warehouse that invested in a robust preventive maintenance program. Over eight years, this facility committed to regular inspections and minor repairs, resulting in an astounding 30% extension of the roof’s lifespan and delaying replacement costs that could otherwise reach six figures.

Another standout case involves an industrial facility that embraced a digital tracking system for roof inspections. With this high-tech approach, they could monitor wear and address issues before they snowballed, ultimately adding 20% more years to their roof’s life. This proactive choice drastically reduced their overall roofing expenses.

These stories illustrate a critical point: prioritizing preventive measures not only maximizes roof longevity but also translates into significant financial savings. Each dollar spent on regular maintenance transforms into tangible benefits, minimizing disruptions and allowing for unfettered operations.

Documented outcomes show that businesses embracing preventive practices enjoy fewer emergency repairs and better roof performance. By adopting data-driven maintenance strategies, commercial property owners not only protect their roofing investments but also enhance overall operational efficiency.

SECTION 6: ALTERNATIVE SOLUTIONS

As commercial roofing systems approach their golden years, the specter of severe damage looms larger. A revealing study by the National Roofing Contractors Association shows that over 30% of roofs suffer failures within the first decade. These failures can translate into stomach-churning repair costs and unnecessary operational disruptions. To tackle these challenges head-on, exploring innovative solutions that emphasize proactive maintenance, cutting-edge materials, and integrated maintenance practices is not just beneficial—it’s essential. Implementing these strategies can dramatically extend a roof’s lifespan while ensuring safety and cost-effectiveness for property owners.

Proactive Maintenance Programs

Establishing a proactive maintenance program is a game changer for any commercial roofing strategy. Conducting regular inspections serves as a preemptive strike against minor issues before they balloon into major headaches. Industry data suggests that roofs subjected to at least biannual inspections can reduce repair costs by up to 50%.

Consistent upkeep allows property owners to pinpoint vulnerabilities induced by weather fluctuations, debris accumulation, or even pest populations. Employing a documented maintenance schedule fosters accountability and provides a comprehensive history of roof conditions, invaluable for strategizing repairs or upgrades.

Additional proactive measures—like clearing gutters and removing debris—play a pivotal role in preventing water pooling and maintaining roof integrity. This attention to detail not only supports the roof’s longevity but also its overall structural security.

Integrating technology, such as drone inspections, transforms traditional maintenance routines by offering precise, real-time assessments of roof conditions. This high-tech twist ensures that no potential issue is overlooked, enabling timely interventions.

Advanced Roofing Material Selection

Choosing superior roofing materials is crucial for securing a property’s long-term roofing health. Modern choices, such as thermoplastic polyolefin (TPO) and ethylene propylene diene monomer (EPDM), are engineered for increased durability and enhanced waterproofing properties compared to their conventional counterparts.

These innovative materials also boast improved UV resistance, safeguarding roofs from becoming brittle as they weather the seasons. Additionally, their energy-efficient designs can lead to lower HVAC costs, offering exciting savings alongside robust protection against damage.

Property owners ought to perform a lifecycle cost analysis when selecting roofing materials. Though high-performance options may demand a larger upfront investment, their longevity and reduction in maintenance needs often result in significant long-term savings.

Furthermore, some of these advanced products come with reflective coatings and energy-generating features, contributing to sustainability goals while shielding the roof from the elements. Investing in such materials ensures roofs endure the test of time and climate.

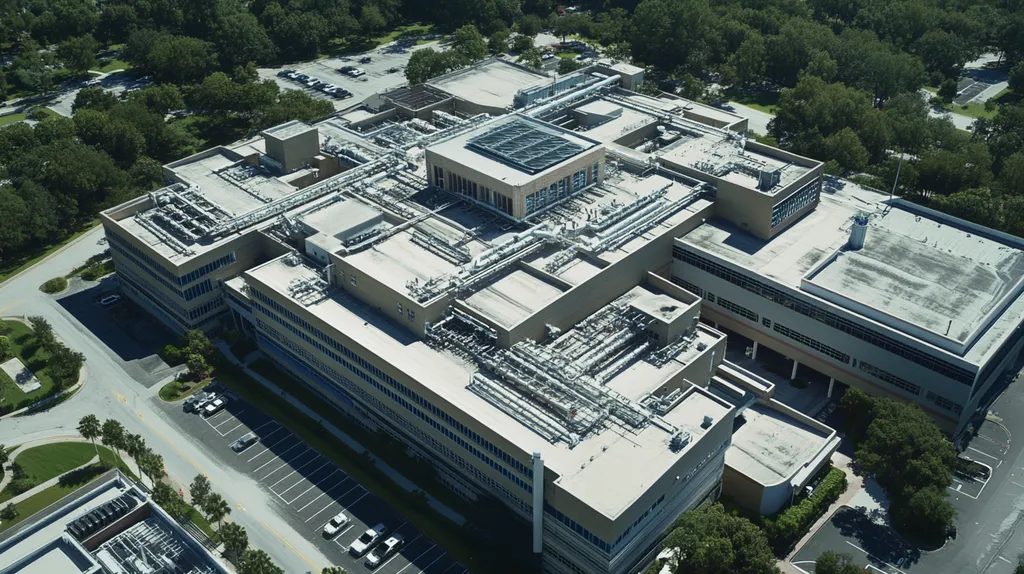

Integrated Roof and Equipment Maintenance

Integrating roof maintenance with the overall upkeep of building equipment is vital for optimizing facility performance. Many roofs serve as the foundation for HVAC units and other mechanical systems, linking their condition directly to that of the roof itself.

When maintenance schedules for equipment coincide with roof inspections, potential hazards can be identified and resolved promptly. For instance, ensuring HVAC units are operating efficiently prevents condensation that can lead to embarrassing leaks.

By crafting a comprehensive maintenance strategy that encompasses both the roof and its supporting equipment, facility managers can significantly diminish the chances of damage. This holistic view fosters streamlined operations and improved asset management.

Moreover, collaboration between roofing contractors and equipment service providers enhances communication and expedites issue resolution, strengthening both the roof’s integrity and the machinery it supports.

The Bottom Line

With 80% of commercial roofs failing prematurely and replacement costs exceeding $250,000, the industry can no longer afford to cling to outdated damage prevention strategies.

Traditional approaches like biannual inspections and reactive repairs consistently fall short against modern challenges, from extreme weather events to aging infrastructure.

The data is clear: proactive maintenance programs can extend roof life by 25% while saving $5-10 for every dollar invested.

Success demands a paradigm shift: integrating advanced materials, comprehensive documentation, and holistic maintenance strategies that address both roofing systems and associated equipment.

The future of commercial roofing lies not in managing damage, but in preventing it through data-driven, systematic approaches that protect both assets and bottom lines.

FREQUENTLY ASKED QUESTIONS

Q. What are the current practices for maintaining a commercial roof?

A. Routine inspections and debris clearance are standard practices for roof maintenance. However, relying solely on these methods can lead to missed issues, especially in today’s extreme weather. Instead, property owners should adopt proactive protocols that include flexible inspection schedules and thorough assessments to identify potential vulnerabilities early.

Q. How do systemic issues affect the longevity of an industrial roof?

A. Systemic issues like inadequate drainage and neglect of crucial areas can drastically undermine roof longevity. These flaws can cause water pooling and promote leaks, leading to costly repairs. Addressing these issues early through regular inspections and comprehensive maintenance strategies is essential for preserving the roof’s integrity.

Q. What are some missed opportunities in commercial roof maintenance?

A. Many property owners overlook vital components like roof accessories during maintenance. Ignoring drains and vents can lead to major problems, including water pooling. Regularly checking and maintaining these accessories not only prevents significant issues but also extends the overall lifespan of the roof.

Q. What root causes contribute to commercial roof damages?

A. Roof failures often stem from poor initial design, substandard materials, and inconsistent maintenance. These foundational flaws can lead to leaks and extensive damage. Identifying and addressing these root causes proactively is crucial for safeguarding your investment and ensuring the roof’s longevity.

Q. What does the data say about premature failures in commercial roofs?

A. Alarmingly, about 50% of commercial roofs fail prematurely, often due to neglect. Those that receive routine maintenance can last significantly longer. Implementing a proactive maintenance approach not only preserves the roof’s integrity but also saves money in the long run.

Q. What alternative solutions exist for commercial roof maintenance?

A. Exploring proactive maintenance programs and advanced roofing materials can substantially enhance roof durability. Technologies like drone inspections provide real-time assessments and can help to address potential issues early. These alternative solutions not only improve longevity but ensure long-term cost savings for property owners.

Q. How can I maximize the lifespan of my industrial roof?

A. Maximizing your roof’s lifespan starts with regular, comprehensive inspections combined with proactive maintenance. Clear debris, check drainage systems, and address any damages immediately. Investing in quality materials and integrating roof upkeep with building systems, like HVAC, also plays a crucial role in maintaining structural integrity.