Every year, industrial building owners lose millions of dollars due to misunderstood or poorly managed roof warranties. Industry data shows that 65% of warranty claims are denied due to non-compliance with basic requirements.

For facility managers and property owners, navigating warranty coverage presents a maze of technical specifications, maintenance obligations, and critical deadlines that can make or break protection for their valuable assets.

This comprehensive guide examines common warranty misconceptions, practical implications, and evidence-based strategies to help building owners maximize their warranty coverage while avoiding costly pitfalls.

SECTION 1: COMMON MISCONCEPTIONS

Understanding warranty coverage on industrial roofs is crucial for property owners. Yet, many fall prey to misconceptions that can lead to unexpected costs and repair headaches. Surprisingly, up to 60% of roof failures stem from inadequate maintenance, underscoring the importance of knowing what a warranty actually entails. This section aims to dispel common misunderstandings around warranties, empowering building owners to manage their roofing assets wisely and avoid costly surprises.

Warranty Covers All Roof Components

A widespread belief is that warranties protect every aspect of a roof, covering all components and materials. In reality, most warranties focus on specific elements, like the membrane or particular features. For instance, if flashing or drainage systems fail and aren’t included in the warranty, the property owner may end up facing significant repair costs.

This limitation can be particularly confusing when certain parts of the roofing system are identified as problematic. Understanding what is and isn’t covered in a warranty can significantly influence financial planning. Owners should carefully scrutinize the warranty document to grasp its boundaries clearly.

Moreover, some warranties may only become valid if the roofing system is maintained appropriately. Skipping regular inspections or repairs could void coverage, leaving building owners at risk for expensive replacements.

To avoid these pitfalls, property owners should engage with roofing professionals who can clarify the full extent of their warranty coverage and highlight maintenance responsibilities for components.

Maintenance is Unnecessary with a Warranty

Another prevalent misunderstanding is that having a warranty eliminates the need for maintenance. This belief can be harmful to the lifespan of an industrial roof. In truth, most warranties necessitate routine maintenance, including inspections and documentation of any repairs.

For example, even if a roof comes with a generous 20-year warranty, failure to perform regular upkeep could render that warranty void before its time is up. Industry standards indicate that proper maintenance can extend a roof’s lifespan by up to 50%. Yet, many owners mistakenly treat warranties as “set it and forget it” guarantees, which is far from accurate.

Neglecting proactive maintenance can lead to roof failures that warranties won’t cover. Misunderstanding warranty conditions could burden property managers with hefty repair bills when issues arise.

Informing building owners about the necessity of ongoing maintenance, even when a warranty is in place, can protect their investments and help prevent legal disputes over denied claims due to maintenance non-compliance.

Manufacturer and Workmanship Warranties are Interchangeable

Many property owners mistakenly believe that manufacturer warranties and workmanship warranties serve the same purpose. While both provide protection, they cover different aspects of roofing systems. The manufacturer warranty typically safeguards the performance of materials, whereas the workmanship warranty focuses on the quality of the installation.

This distinction is vital since a superior product poorly installed can lead to failure, leaving property owners with few options if they misinterpret these differences. For example, while high-quality materials might be covered under the manufacturer warranty, the costs to remedy an installation error may not be covered.

Additionally, the terms of workmanship warranties can vary significantly based on the contractor’s practices. Owners should ensure their agreements explicitly outline the scope and duration of both warranty types.

By understanding these differences and securing comprehensive protection through both warranties, property owners can better shield their investments and minimize unexpected expenses in the future.

SECTION 2: PRACTICAL IMPLICATIONS

Grasping the nuances of warranty coverage on industrial roofs is not just useful—it’s essential for building owners. A simple oversight can lead to major financial headaches. For example, if a warranty claim is denied due to exclusions, unexpected repair costs can disrupt budgets and ongoing operations. This section delves into critical areas of warranty coverage that influence roof performance, outline labor and material limitations, and identify essential weather and maintenance exclusions.

Impact on Roof Performance and Lifespan

The terms of a warranty can greatly impact the performance and lifespan of an industrial roof. A comprehensive warranty tends to offer assurance of high-quality materials and installation standards, which contribute to the roof’s durability. In contrast, limited warranties may do little more than cover leaks, ultimately putting the roof at risk.

If a warranty does not cover necessary repairs, building owners might face unplanned expenses, prompting early roof replacements. Regular inspections and maintenance are vital to maintain coverage, as neglecting these tasks can void warranty benefits and lead to significant structural damage.

Warranties that stipulate the need for meticulous maintenance logs can actually help extend the roof’s lifespan when properly observed. Understanding these performance-related factors should be a priority for building owners to protect their investment.

A lack of awareness about these implications can result in costly repairs or premature replacements. Building owners must recognize that failure to address these issues directly affects their budgets and operational stability.

Labor and Material Coverage Limitations

Warranties often include limitations pertaining to labor and materials, which can be confusing for property owners. While some warranties offer coverage for specific defects, they may not encompass all possible issues. This creates a false sense of security regarding full protection.

For instance, a warranty could cover material defects for a decade but offer labor coverage for only a fraction of that time. Consequently, building owners might incur substantial repair costs long before their warranty period expires.

To avoid pitfalls, it’s crucial for building owners to thoroughly read the fine print and seek professional advice when evaluating warranties. Understanding these coverage nuances can transform a potentially costly decision into a smarter investment.

Additionally, certain roofing materials may come with specific restrictions within the warranty. Identifying these details can empower building owners to make informed choices about their roofing systems.

Weather and Maintenance Exclusions

Weather-related damages and maintenance neglect frequently appear as exclusions in industrial roofing warranties. Most warranties specify that they only cover damage from particular weather events, leaving owners vulnerable to issues caused by gradual environmental wear.

Moreover, many warranty agreements require routine maintenance to remain valid. Ignoring these maintenance stipulations can mean that even minor issues turn into significant repair costs that the owner must manage alone.

This underscores the importance of diligence; failure to address these exclusions can place owners in financially difficult situations when it comes time to file a claim.

To reduce potential risks, building owners should work closely with roofing professionals to establish maintenance schedules that align with warranty requirements. This proactive approach can lead to substantial cost savings and improve the overall lifespan of the roof.

SECTION 3: COST OF MISINFORMATION

The stakes are high when it comes to warranty coverage on industrial roofs, and misunderstanding these terms can lead to significant financial burdens for property owners. A survey revealed that nearly 30% of building owners lack knowledge about their roof’s warranty terms, resulting in unexpected costs when claims are denied. It’s vital to understand the ins and outs of warranties to avoid costly oversights. This section explores the financial consequences of misconceptions, the types of consequential damages typically excluded, and how modifications can void existing warranties.

Financial Consequences of Misunderstood Warranties

The repercussions of ignoring warranty specifics can be dire for building owners. Many mistakenly believe that warranties provide blanket protection against all roof-related issues, which is usually not true. For example, if a leak occurs and the property owner hasn’t completed regular maintenance as specified, the warranty could become void, leaving them responsible for costly repairs.

Another common mistake occurs when maintenance activities aren’t adequately documented. Neglecting to keep receipts or service records can lead to denied claims when issues arise. In the absence of this proof, building owners may face significant repair costs, potentially jeopardizing their financial stability.

Furthermore, understanding the limitations of coverage is essential. Many warranties cover only manufacturing defects, not damages caused by environmental factors or inadequate installation. This misconception can lead to unplanned out-of-pocket expenses for repairs that owners wrongly believed were covered.

In summary, being unaware of warranty details can lead to significant repair costs and can jeopardize a property owner’s investment. Knowledge is power when it comes to managing these critical assets.

Consequential Damages Not Covered

It’s a common error for building owners to assume that warranties cover every type of damage. However, most warranties specifically exclude consequential damages, meaning indirect costs associated with roof failures are often not covered. For instance, if a roof leak causes water damage to equipment or inventory, the warranty typically won’t cover these repair expenses.

This gap in coverage can create serious financial challenges. Owners may find themselves responsible for costs associated with business interruptions or lost stock due to roof failures. The actual costs of a roof failure often extend far beyond mere repair expenses, affecting overall business operations.

Additionally, many warranties do not account for third-party damages. If a roof collapse affects neighboring properties, the owner may face liability claims, further complicating the financial landscape. This reality stresses the importance of thoroughly reviewing warranty documents to understand their limitations before issues arise.

Consequently, property owners should be vigilant in recognizing that significant out-of-pocket expenses may result from damages their warranties do not cover, reinforcing the necessity of a comprehensive risk assessment.

Voiding Warranties Through Modifications

Making alterations to an industrial roof can dramatically impact warranty validity. Many owners fail to realize that even minor changes—such as adding equipment—can void existing warranty coverage. Installing heavy HVAC units without notifying the manufacturer can lead to expensive consequences, as this might alter the roof’s design and load-bearing capacity.

These modifications could result in the owner being fully responsible for any subsequent damage. If a claim arises after such changes, insurers may deny it, citing the altered state of the roof as a valid reason.

In addition, attempting DIY repairs can create compliance issues with warranty conditions. Using unapproved repair methods or materials can lead to the immediate voiding of the warranty. This risk highlights the necessity for property owners to consult roofing professionals whenever changes are made.

Ultimately, being aware of warranty stipulations regarding modifications is crucial. Building owners should proceed with caution to ensure that adjustments do not unintentionally jeopardize their warranty protection.

SECTION 4: REALITY CHECK

Grasping the nuances of warranty coverage on industrial roofs is not just beneficial—it’s critical for safeguarding assets. Research shows that over 60% of roofing issues stem from insufficient maintenance and oversight. Without a comprehensive understanding of warranty types and conditions, property owners can find themselves facing steep repair or replacement costs. This section aims to clarify the key issues surrounding warranties, including the various types available, essential manufacturer standards, and critical exclusions to watch out for.

Types of Commercial Roof Warranties

Commercial roofs typically come with two primary types of warranties: manufacturer warranties and workmanship warranties. Manufacturer warranties focus on the roofing materials and their performance. In contrast, workmanship warranties zero in on the quality of the installation.

Each warranty type has distinct coverage periods and specific conditions that must be met for the warranty to be valid. For example, manufacturer warranties may last anywhere from 10 to 30 years, depending on the materials used. Recognizing these differences is essential to prevent coverage gaps.

Some building owners mistakenly assume that having one type of warranty is sufficient. However, optimal protection is achieved when both manufacturer and workmanship warranties are combined. This strategic mix maximizes coverage and minimizes potential liabilities or unexpected repair costs down the line.

Property owners should have thorough discussions with both contractors and manufacturers regarding warranty options before finalizing terms. These discussions clarify the necessary conditions to uphold warranty rights, an essential factor for long-term security.

Manufacturer Inspection Standards and Requirements

Manufacturers often stipulate specific inspection requirements that property owners must follow to maintain warranty validity. These inspections may include initial assessments as well as periodic evaluations throughout the warranty period. Neglecting these inspections can result in denied claims when issues arise.

For instance, a manufacturer may require annual inspections or assessments following severe weather conditions. If damage occurs and an inspection hasn’t been conducted, coverage for repairs may be denied.

To safeguard their investments, property owners need to maintain diligent records of all inspections and maintenance activities. Failure to document these processes can lead to disputes and jeopardize warranty status. Each missed inspection is more than just an oversight; it can result in substantial financial consequences.

Understanding what inspectors are looking for can also guide proactive maintenance. By adhering to manufacturer guidelines, property owners can extend both their roof’s lifespan and their warranty coverage.

Understanding Warranty Minimums and Exclusions

It’s crucial for building owners to have a clear understanding of warranty minimums and exclusions. These stipulations lay out what is covered and what isn’t, narrowing the gap between expectation and reality. Many owners wrongly believe that warranties shield against all types of hazards, which is rarely the case.

Common exclusions typically cover damage arising from negligence, natural disasters, or modifications made without approval from the manufacturer. For example, unauthorized installations can void warranty coverage, leading to unexpected expenses when it’s time to file a claim.

Moreover, many warranty terms require specific maintenance activities to remain valid. This means owners must stay vigilant about required tasks to keep their warranties intact. Ignoring such responsibilities can lead to significant financial repercussions in the event of a roofing failure.

To avoid misunderstandings, property owners should carefully review warranty documents and consult with professionals for clarification. Misinterpretations can result in surprise costs and potential roof failure, making it essential to fully comprehend exclusions as part of responsible ownership.

SECTION 5: EVIDENCE-BASED ALTERNATIVES

Understanding warranty coverage is crucial, yet many property owners overlook essential preventive strategies that can evade costly repairs. Implementing regular rooftop inspections and consistent maintenance significantly enhances a roof’s durability and performance, lowering the risk of unexpected failures. Additionally, selecting a roofing system tailored to specific requirements is vital, as each option has unique strengths and weaknesses. Lastly, keeping thorough documentation is essential for validating claims and tracking repair history. These strategies are instrumental in maximizing the value of roofing investments.

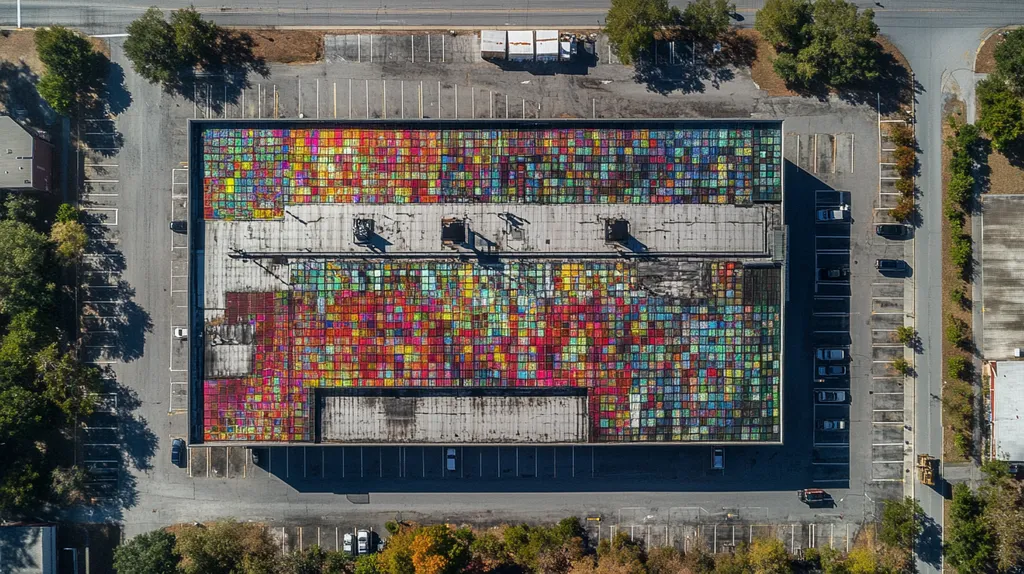

Regular Rooftop Inspections and Maintenance

Regular inspections of industrial roofs are not optional; they are critical for long-term viability. Scheduled maintenance can reduce roof-related issues by over 60%, allowing property owners to catch potential problems, such as leaks or membrane damage, before they escalate into expensive repairs.

A solid maintenance plan typically includes bi-annual inspections, as seasonal weather changes greatly impact roofing materials. For instance, winter storms may cause ice damming, while summer heat can lead to thermal expansion—both damaging if not addressed promptly.

Moreover, documenting inspection results creates a comprehensive maintenance history. This record is indispensable when negotiating warranty claims or securing replacement services. Without proper documentation, claims could be denied, leaving property owners exposed to unexpected costs.

In summary, regular inspections not only protect the roof from deterioration, but also help ensure warranty requirements are met, preserving coverage and enhancing overall asset management.

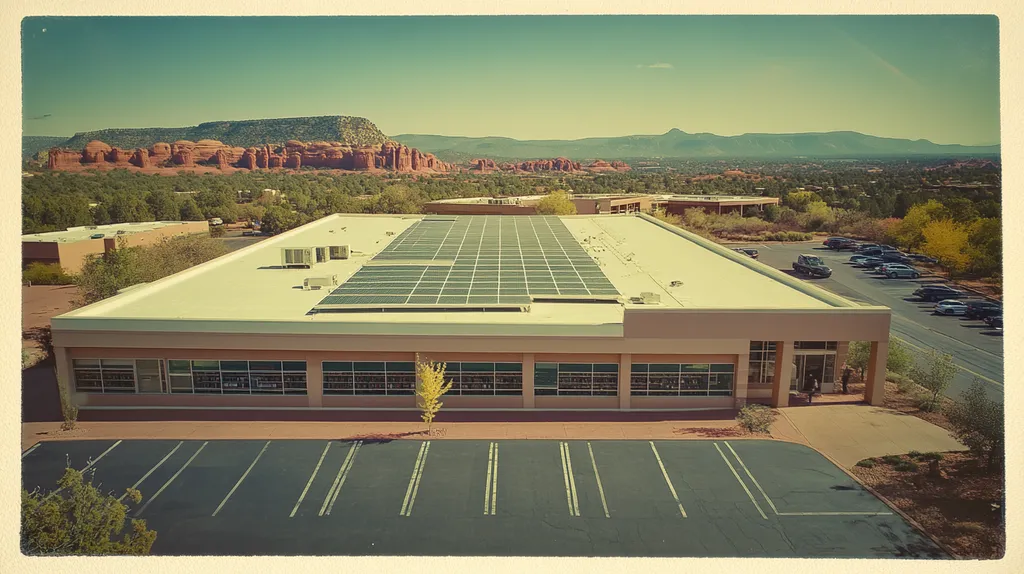

Choosing the Right Roofing System for Your Needs

Selecting the appropriate roofing system can have lasting effects on both performance and warranty applicability. From single-ply membranes to built-up roofs, each type comes with distinct advantages and disadvantages. For example, TPO roofing offers excellent energy efficiency, while EPDM excels in extreme weather conditions.

Familiarity with the specific demands of an industrial property—including load-bearing capacity, climate considerations, and local regulations—can significantly aid property owners in making sound decisions. Investing in a roof that matches operational needs not only lessens maintenance requirements but also extends its lifespan.

Conversely, choosing the wrong roofing system can result in premature failures. A roof that retains heat, for instance, may face accelerated wear due to thermal expansion, which could ultimately void warranties if linked to improper selection.

Therefore, conducting thorough research and consulting with roofing professionals can greatly enhance decision-making and secure optimal performance and warranty coverage.

Importance of Documentation and Records

Effective roof management hinges on maintaining comprehensive documentation and records, an often underestimated aspect of ownership. Accurate records—encompassing warranties, inspection reports, maintenance logs, and repair invoices—streamline the claims process during roofing failures.

Organizing these documents, whether digitally or physically, helps establish the legitimacy of warranty claims. Manufacturers typically require thorough documentation to determine coverage for reported issues. Without adequate records, property owners risk incurring out-of-pocket expenses for repairs that could have fallen under warranty.

Furthermore, maintaining detailed records offers insights into maintenance trends and associated costs, facilitating better budgeting moving forward. Regular reviews of these documents allow for an assessment of the roofing system’s long-term performance.

In conclusion, meticulous documentation not only fortifies warranty support but also serves as a strategic guide for informed decisions regarding future maintenance and upgrades.

SECTION 6: TEST AND VERIFY

The stakes are exceptionally high in industrial roofing. A denied warranty claim due to lack of proper verification can result in steep repair costs and significant operational downtime. Without thorough verification, owners may find themselves unprotected against leaks or even structural failures. It’s essential for building owners and facility managers to understand the entire verification process involved in warranty claims. This section will guide readers through how to effectively verify warranty claims, ensure compliance with manufacturer standards, and conduct comprehensive roof inspections and testing.

Verifying Warranty Claims and Procedures

Verifying warranty claims starts with a deep understanding of the specific terms and conditions outlined by the manufacturer. Many owners may think a cursory review is enough, but this can lead to misunderstandings. Keeping in regular communication with the manufacturer or warranty provider can clarify exactly what is covered and identify the circumstances under which claims could be denied.

Detailed records of all maintenance, repairs, and inspections are crucial in the claim process. Without this thorough documentation, property owners may find it challenging to validate their claims. It’s standard practice to maintain logs of all work performed on the roof, including dates and descriptions of each maintenance task.

Additionally, following any manufacturer-recommended inspections is non-negotiable. Owners should implement a proactive schedule for these inspections to catch issues before they escalate into violations that could jeopardize warranty coverage.

Ultimately, active engagement in the warranty process not only safeguards the investment but also nurtures positive relationships with manufacturers and contractors, ensuring a supportive network for future needs.

Ensuring Compliance with Manufacturer Standards

Compliance with manufacturer standards is paramount for maintaining warranty coverage. Every roofing system has its specific installation and maintenance guidelines provided by the manufacturer. Straying from these guidelines can void warranty protections, putting the investment at risk.

Building owners must ensure that all roofing contractors are well-versed in these standards. Hiring qualified and certified professionals who recognize the nuances of the warranty can save time and prevent complications later. A contractor’s experience with specific roofing materials ensures proper installation and compliance with guidelines.

Moreover, routine compliance checks should be integrated into the facility management process. This includes regularly scheduled training sessions for the maintenance team, focusing on roof care and the importance of adhering to manufacturer specifications.

By consistently completing these tasks, property owners help protect their buildings’ assets and sustain the validity of their warranties over time.

Conducting Thorough Roof Inspections and Testing

Regular roof inspections and rigorous testing are critical for ensuring long-term roof health and maintaining warranty integrity. Best practices recommend conducting at least two comprehensive inspections each year. These proactive assessments can identify minor issues before they escalate into major problems.

During inspections, attention should focus on common vulnerabilities such as seams, flashing, and gutters. A proactive strategy in spotting wear and tear can facilitate timely repairs, strengthening warranty claims when needed. Structural integrity assessments can also unveil potential hidden issues.

Incorporating additional testing methods, like moisture scanning or infrared thermography, enhances understanding of the roof’s condition. These advanced technologies uncover problems that visual inspections might miss, empowering property owners to make more informed decisions.

Having maintenance teams trained to identify signs of wear enables swift action to resolve issues before they hinder business operations or jeopardize warranty status.

The Bottom Line

With over $2 billion lost annually to denied warranty claims in the industrial roofing sector, property owners can no longer afford to misunderstand their coverage.

The evidence shows that 65% of warranty denials stem from preventable issues like inadequate maintenance documentation and non-compliance with manufacturer requirements.

Success lies in treating warranty management as an active process rather than a passive protection plan.

Building owners must commit to regular inspections, maintain detailed records, and ensure all modifications meet manufacturer specifications.

Those who implement these strategies while understanding their warranty limitations will maximize their roof’s lifespan and protect their substantial investment from unnecessary risk.

FREQUENTLY ASKED QUESTIONS

Q. What common misconceptions exist about commercial roof warranties?

A. Many property owners mistakenly believe that warranties cover all roof components. In reality, most are limited to specific elements, such as the membrane. It’s essential to understand what your warranty includes to avoid unexpected repair costs.

Q. How can warranty conditions impact the performance of an industrial roof?

A. Warranty terms can greatly influence your industrial roof’s lifespan. A comprehensive warranty usually ensures quality materials and installation, while limited coverage might only address leaks. Proper maintenance is vital to keeping your warranty valid and extending your roof’s performance.

Q. What are the financial consequences of misunderstanding warranty terms?

A. Misunderstanding warranty terms can lead to surprising repair costs. Many owners don’t realize that regular maintenance documentation is necessary to uphold warranty validity. Without these records, claims can get denied, leaving owners to cover pricey repairs.

Q. What types of warranties are available for a commercial roof?

A. Commercial roofs are usually protected by manufacturer warranties and workmanship warranties. Manufacturer warranties cover material performance, while workmanship warranties focus on installation quality. Understanding these differences helps prevent gaps in coverage.

Q. How important is regular maintenance for industrial roofs?

A. Regular maintenance is crucial for industrial roofs. Scheduled inspections can identify issues early, allowing for timely repairs. This not only prolongs the roof’s life but also ensures that warranty requirements are met, preventing financial surprises.

Q. How can building owners verify their warranty claims effectively?

A. Verifying warranty claims involves understanding the warranty terms and keeping detailed maintenance records. Engage regularly with manufacturers to clarify coverage specifics and follow all recommended inspections to avoid claim denials.

Q. What modifications can void a warranty on a commercial roof?

A. Modifications like adding equipment or making unapproved repairs can void roof warranties. Even small changes can affect warranty coverage, leading to denied claims. Always consult professionals before making alterations to avoid jeopardizing your investment.