Commercial roofs face an increasingly brutal reality: extreme weather events that would have been once-in-a-lifetime disasters now arrive like clockwork, turning “adequate” roofing systems into expensive casualties faster than facility managers can update their insurance policies.

When Hurricane Harvey’s 130-mph winds peeled membranes off buildings like giant Band-Aids, or when Colorado’s softball-sized hail punched through “impact-resistant” materials, one truth emerged crystal clear – the gap between marketing promises and weather-fighting reality can cost millions.

Smart facility managers know that understanding commercial roofing resilience isn’t just about preventing leaks anymore. It’s about building fortress-like protection that keeps operations running while competitors are calling emergency contractors and explaining water damage to very unhappy stakeholders.

SECTION 1: THE BASICS EXPLAINED

Picture this: Mother Nature throws a tantrum with 90-mph winds, marble-sized hail, and torrential rain that would make Noah nervous. Your commercial roof? It’s standing there like a superhero with a cape, protecting millions of dollars in equipment, inventory, and operations below.

But here’s the plot twist – not all commercial roofs are created equal when it comes to weather warfare. Some fold faster than a house of cards in a hurricane, while others laugh in the face of extreme conditions.

Understanding what separates the weather warriors from the wimpy roofs could mean the difference between business as usual and a very expensive headache. Let’s dive into the fascinating world of commercial roofing resilience!

What It Is (In Plain Language)

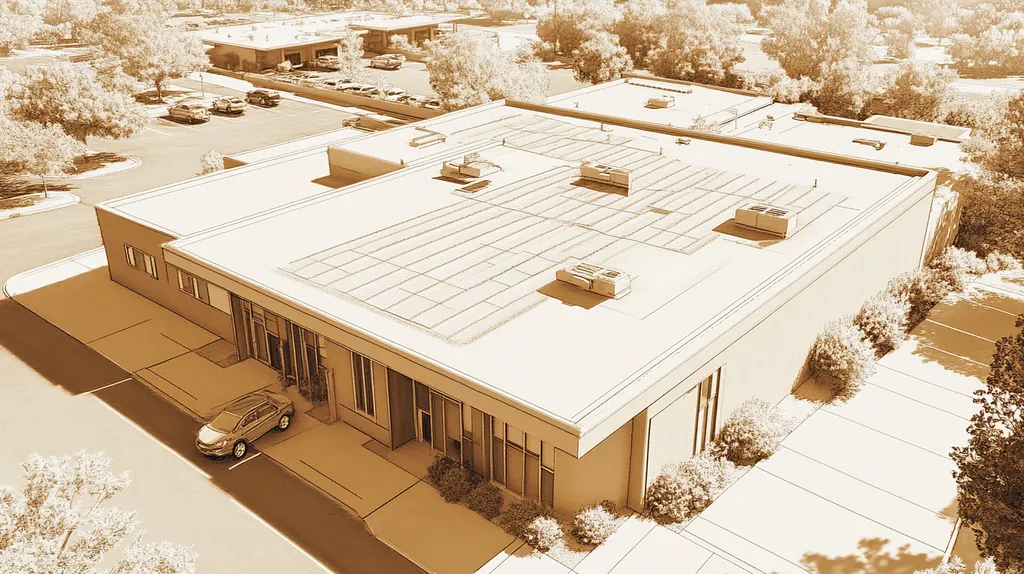

Think of a commercial roof as your building’s ultimate bodyguard – but instead of protecting against paparazzi, it’s fending off nature’s fury. Unlike your house’s steep, shingle-covered slopes, commercial roofs are typically flat or low-sloped giants that stretch across warehouses, factories, and office buildings like protective shields.

These roofing systems come in several exciting varieties! Single-ply membranes work like giant waterproof blankets, while modified bitumen systems layer up like weather-resistant lasagna.

Built-up roofs pile on multiple layers for maximum protection. Each type gets selected based on your local climate’s personality – whether it throws tantrums with tornadoes or sulks with endless snow.

The real magic happens in the layered approach. Modern commercial roofs aren’t just one-trick ponies; they’re sophisticated systems with insulation, waterproof membranes, and protective barriers working together.

This teamwork creates a fortress that doesn’t just keep water out – it manages temperature swings, resists wind uplift, and maintains its cool when the weather gets hot and bothered.

Why It Matters (To Your Building)

When extreme weather crashes the party uninvited, a failing roof can turn your business into an expensive water park – minus the fun. Wind storms love to play “lift the membrane,” exposing your valuable interior to rain, which then goes on a destructive shopping spree through electrical systems and inventory.

The domino effect is brutal: operations shut down, repairs pile up, insurance claims multiply, and your bottom line takes a beating. But wait, there’s more!

Weather-resistant roofs also serve as your building’s climate control headquarters and safety command center. They regulate temperature to keep energy costs from skyrocketing and ensure compliance with safety regulations that protect occupants.

In hail-prone regions, a robust roof prevents costly puncture wounds, while in snow country, it prevents dramatic structural collapses that make headlines for all the wrong reasons. Ignoring weather readiness is like playing Russian roulette with your entire operation.

Smart investment in weather-ready roofing translates into long-term savings, operational stability, and peaceful sleep during storm season – priceless benefits in our increasingly unpredictable climate.

How It Works

Commercial roofs wage weather warfare through an impressive arsenal of materials, engineering wizardry, and installation techniques that would make military strategists proud. High-performance membranes create impenetrable barriers against water infiltration while laughing off wind uplift attempts.

When installed correctly, materials like metal, EPDM, and PVC offer excellent resistance to various weather conditions. Additionally, thermal insulation improves energy efficiency during extreme temperatures (source: Castagra Industrial).

The engineering brilliance continues with flexible designs that accommodate building movements caused by wind loads and temperature changes. This prevents the dreaded cracks and leaks that turn roofs from heroes into zeros.

Mechanical fasteners, adhesives, or ballast systems work like invisible anchors, securing roofing layers so they stay put during nature’s temper tantrums. Meanwhile, drainage systems act as efficient traffic controllers, directing water off flat surfaces before it can pool and cause long-term deterioration.

The secret sauce? Regular inspection and maintenance that spots potential vulnerabilities before they become expensive failures, ensuring your roof’s weather-fighting capabilities stay sharp and ready for action.

SECTION 2: PRACTICAL APPLICATIONS

While most commercial roofs quietly do their jobs during mild weather, extreme conditions separate the champions from the casualties faster than you can say “insurance claim.” Hurricane-force winds, softball-sized hail, and temperature swings that make your building expand and contract like an accordion are putting standard roofing systems through trials they were never designed to handle.

The result? Facilities across the country are discovering that their “adequate” roofs become expensive liabilities when Mother Nature flexes her muscles.

Common Uses & Examples

Manufacturing facilities in Tornado Alley have become masterclasses in extreme weather roofing, featuring mechanically fastened systems that grip buildings like determined barnacles during 100+ mph wind events. These installations use specialized fastener patterns and reinforced membranes that laugh off debris impacts that would puncture standard materials.

Coastal distribution centers showcase another brilliant application – reinforced single-ply membranes with hurricane-rated fastening systems that prevent the dreaded “roof peeling” phenomenon during storm surges. These roofs often incorporate impact-resistant layers that treat flying debris like annoying mosquitoes rather than armor-piercing rounds.

Cold-climate warehouses demonstrate thermal resilience through multi-layer systems designed to handle freeze-thaw cycles that would crack lesser roofs like eggshells. Reflective coatings in desert regions create roofing systems that shrug off 120°F temperatures while keeping energy costs from melting facility budgets.

Retail complexes in hail-prone regions feature impact-resistant materials and specialized drainage systems that handle sudden deluges without turning parking lots into temporary lakes. Each application represents real-world problem-solving that transforms roofs from weather victims into weather victors.

When You Need It Most

The moment weather forecasters start using words like “historic,” “unprecedented,” or “life-threatening,” your roof becomes the star of its own survival movie – and you definitely want it to be the action hero, not the first casualty. Hurricane seasons reveal which roofs have the right stuff when sustained winds turn loose materials into dangerous projectiles.

Sudden temperature plunges create thermal shock scenarios where unprepared roofing materials crack faster than ice cubes hitting hot pavement. Extended heat waves push standard materials past their breaking points, causing premature aging, membrane shrinkage, and seal failures that open buildings to water infiltration.

Ice storms present triple threats – heavy loads, thermal cycling, and ice dam formation that can turn drainage systems into frozen disasters. Multi-day storm events test roofing endurance like marathons, where materials must maintain integrity through prolonged punishment rather than surviving single dramatic moments.

The aftermath periods prove equally critical, as damaged roofs face secondary weather events before repairs can begin. Smart facility managers recognize these vulnerability windows and invest in extreme weather readiness before the forecast turns threatening.

Interactions With Other Systems

Commercial roofs operate as quarterbacks in complex building system playbooks, coordinating with drainage, HVAC, and structural components to create unified weather resistance strategies. When drainage systems work in harmony with properly sloped roofing, they transform potentially devastating water accumulation into controlled, managed flow that protects building integrity.

HVAC integration becomes critical during temperature extremes, as roofing performance directly impacts indoor climate control and energy consumption. Properly installed materials like metal, EPDM, and PVC offer excellent resistance to various weather conditions, while insulation and drainage systems prove critical for maintaining roof integrity during extreme weather events (source: Castagra).

Structural coordination ensures that roofs and building frames work together to handle wind loads, thermal expansion, and snow loads without creating stress points that lead to expensive failures. Insulation systems partner with roofing materials to create thermal barriers that prevent interior temperature fluctuations from compromising operations during weather extremes.

Smart facility managers recognize that penetrations for equipment, vents, and utilities become potential weak points during severe weather, requiring specialized sealing and reinforcement strategies. This systems thinking approach transforms individual components into integrated weather defense networks that protect entire facilities rather than just covering them.

SECTION 3: KEY TERMINOLOGY DECODED

When contractors start throwing around terms like “mil thickness” and “wind uplift ratings,” facility managers often nod politely while secretly wondering if they’re being sold snake oil or genuine protection. This terminology confusion becomes dangerously expensive when extreme weather strikes and reveals that “premium” installations were actually budget-grade materials dressed up in fancy language.

Understanding roofing jargon isn’t just about impressing colleagues at facility management conferences – it’s about making informed decisions that could save your building from catastrophic failure. Let’s decode the essential terms that separate weather-ready roofs from expensive disasters waiting to happen.

Essential Terms Explained

Wind uplift isn’t just meteorology class trivia – it’s the invisible force that turns roofing membranes into expensive kites during storm events. This upward pressure occurs when wind flows over a building and creates negative pressure above the roof, literally trying to suck materials off like a giant vacuum cleaner.

Understanding uplift ratings helps you choose systems that stay put when 80-mph gusts decide to test your roof’s commitment to the building. A roof rated for 90 psf uplift resistance will laugh off storms that would peel lesser materials like banana skins.

Thermal cycling sounds technical, but it’s simply your roof’s daily workout routine as temperatures swing from scorching days to cool nights. Materials expand when heated and contract when cooled, creating stress that can crack membranes and loosen fasteners over time.

Flashing might sound like something inappropriate, but it’s actually your roof’s secret weapon against water infiltration. These metal strips seal joints, penetrations, and transitions where water loves to sneak in during heavy downpours.

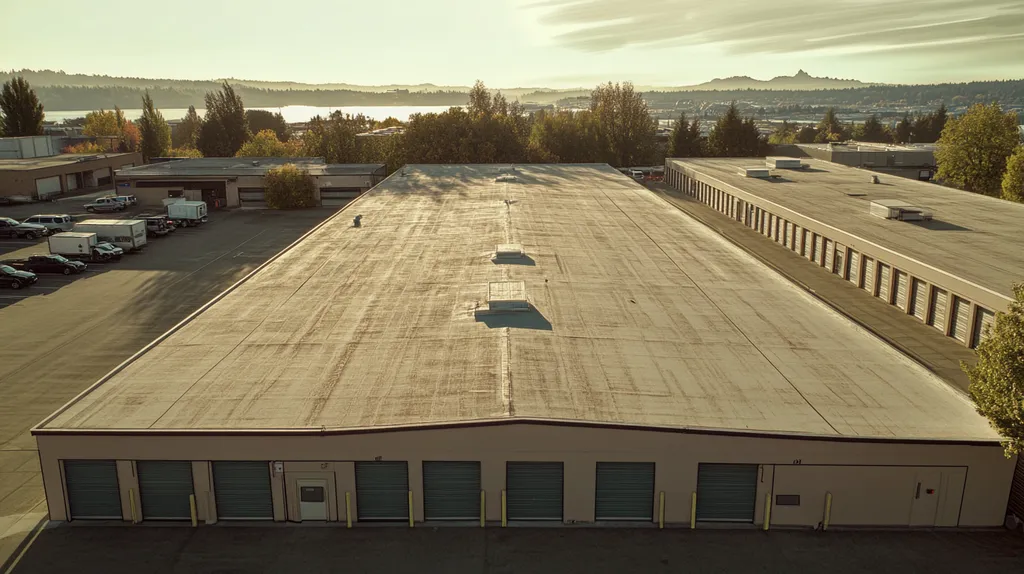

Ponding water transforms flat roof areas into temporary lakes after rainfall, creating weight loads and accelerated deterioration that can turn minor drainage issues into major structural headaches. Proper slope and drainage design prevent these aquatic disasters.

Industry Jargon Translated

Membrane types like TPO, EPDM, and PVC aren’t alphabet soup – they’re different materials with distinct personalities when facing extreme weather. TPO offers excellent heat reflection, EPDM provides outstanding flexibility, while PVC delivers chemical resistance that makes it perfect for industrial environments.

Single-ply membranes, such as EPDM, TPO, and PVC roofing, are particularly effective in climates with intense UV exposure, helping to maintain energy efficiency and reduce cooling costs (source: Solaria Solar & Roofing). Understanding these differences helps you match materials to your specific climate challenges rather than settling for one-size-fits-none solutions.

R-value measures your roof’s resistance to heat flow, functioning like a thermal report card that directly impacts energy bills and indoor comfort. Higher R-values mean better insulation performance and lower HVAC costs during temperature extremes.

Ballasted systems use rocks or pavers as natural anchors, relying on weight rather than adhesives to keep membranes in place. This approach works brilliantly in moderate climates but can become projectile ammunition during severe windstorms.

Modified bitumen combines the flexibility of rubber with the durability of asphalt, creating materials that handle temperature swings better than your building’s thermostat-obsessed tenants. These systems excel in climates where thermal cycling would stress more rigid materials.

Measurement & Units Simplified

PSF (pounds per square foot) ratings tell you how much punishment your roof can absorb before crying uncle to wind loads, snow accumulation, or debris impacts. A 120 psf rating means your roof can handle significantly more abuse than systems rated at 60 psf.

These numbers become critical when local building codes require specific load ratings, or when your facility sits in hurricane alley where flying debris turns rooftops into target practice. Understanding PSF ratings helps you avoid under-engineered systems that fail when you need them most.

Mil measurements describe membrane thickness, where higher numbers mean better puncture resistance against hail, falling branches, and maintenance foot traffic. A 60-mil membrane offers substantially more protection than 45-mil alternatives when weather turns violent.

Wind speed ratings in mph directly correlate to your roof’s survival chances during severe weather events. Systems rated for 110 mph winds will outperform 90 mph alternatives when hurricanes decide to test your facility’s mettle.

Square footage calculations seem straightforward until you factor in slopes, penetrations, and waste allowances that can increase material requirements by 15-20%. Accurate measurements prevent mid-project surprises that blow budgets faster than tornadoes blow off inadequate roofing materials.

SECTION 4: DECISION FACTORS

Picture this nightmare scenario: A facility manager proudly shows off their “budget-friendly” roof installation just months before a Category 3 hurricane turns it into the world’s most expensive confetti. Meanwhile, down the street, a competitor’s building with a properly engineered system rides out the storm like a champ, resuming operations while everyone else is calling contractors.

The brutal truth? Roofing decisions made in comfortable conference rooms get their final grades during nature’s pop quizzes – and there are no make-up exams when extreme weather strikes.

Smart facility managers know that choosing commercial roofing systems isn’t just about comparing price tags and warranty brochures. It’s about understanding how cost, performance, and durability dance together in a complex waltz that determines whether your building becomes a weather warrior or a casualty statistic.

Cost Considerations

The sticker shock of premium weather-resistant roofing makes many facility managers reach for the antacid, but playing the “lowest bid wins” game often creates expensive plot twists when storms roll in. Cheap membranes might save money today, but they become financial black holes when hail punctures them or wind peels them off like giant Band-Aids.

Smart cost analysis looks beyond initial installation to include the lifetime expense equation. A $200,000 premium system that lasts 25 years without major repairs beats a $120,000 bargain roof that needs replacement after the first major storm event.

Insurance companies aren’t stupid – they offer premium discounts for hurricane-rated roofs because they know these systems prevent expensive claims. These savings can offset higher upfront costs while delivering superior protection that keeps businesses running when competitors are mopping up water damage.

Labor complexity adds another wrinkle to cost calculations, as specialized installation crews command higher rates but deliver precision that prevents expensive callbacks. Phasing installations strategically can spread costs over multiple budget cycles while prioritizing critical areas first.

The real cost wisdom? Calculate total ownership expenses including energy savings, maintenance reduction, and business continuity benefits rather than just focusing on the initial check you’ll write.

Performance Trade-offs

Every roofing system has a superhero origin story and a kryptonite weakness, making the selection process feel like casting the perfect weather-fighting squad for your facility. TPO membranes excel at reflecting UV rays but can struggle against baseball-sized hail, while modified bitumen laughs off impact damage but may suffer in extreme heat.

Metal roofing delivers impressive hurricane resistance, with properly installed systems withstanding wind speeds up to 140-180 mph while resisting cracks and splits that plague other materials under stress. However, these steel champions can show surface battle scars from hail impacts, though their structural integrity remains rock-solid.

Reflective coatings create energy-saving heroes that slash cooling costs but may sacrifice some toughness against debris impacts. Heavy built-up systems provide fortress-like protection but require structural analysis to ensure buildings can handle the additional weight load.

Wind uplift ratings become critical selection criteria in hurricane zones, where choosing a system rated for 120 mph over 90 mph could mean the difference between minor repairs and total roof replacement. Geographic threat assessment helps prioritize which performance characteristics matter most for your specific location.

The winning strategy involves honest evaluation of local weather patterns to match roofing strengths with your facility’s biggest vulnerabilities, creating customized defense systems rather than one-size-fits-none compromises.

Lifespan & Durability Factors

Commercial roofs live in a brutal world where they must maintain peak performance through decades of thermal cycling, UV bombardment, and periodic storm battles that would make action heroes retire early. The difference between 20-year and 30-year service life might seem academic until you calculate replacement costs and business disruption.

Durability champions distinguish themselves through superior membrane thickness, reinforced seam construction, and fastener systems engineered to maintain grip during nature’s temper tantrums. These enhanced details prevent the sneaky leaks that start small during wind-driven rain but grow into expensive interior damage over time.

Quality materials resist the slow deterioration that turns yesterday’s weather barriers into tomorrow’s expensive problems. Premium systems maintain flexibility through freeze-thaw cycles while cheaper alternatives become brittle and crack like old rubber bands.

Maintenance requirements vary dramatically between roofing types, with some systems needing annual attention while others cruise for years with minimal care. However, even the most durable materials can’t overcome poor installation practices that create vulnerabilities from day one.

The durability sweet spot balances material investment with expected building service life, ensuring your roof protection matches your facility’s long-term value while delivering consistent performance through whatever weather surprises climate change decides to throw your way.

SECTION 5: COMMON CHALLENGES

When extreme weather decides to test your commercial roof’s mettle, it exposes every shortcut, cheap material, and installation flaw with the precision of a forensic investigator. The heartbreaking reality? Most roofing failures during severe storms weren’t caused by the storm itself – they were disasters waiting to happen, disguised as “functional” roofing systems.

Picture facilities across the country discovering that their “adequate” roofs become expensive liabilities faster than weather alerts can update. Understanding these predictable failure patterns and their telltale warning signs transforms facility managers from reactive victims into proactive protectors.

Frequent Problems & Solutions

Wind uplift turns poorly fastened membranes into expensive kites during storm events, with inadequate attachment systems failing spectacularly when gusts exceed design ratings. The solution involves upgrading to mechanically fastened systems with enhanced fastener patterns that grip buildings like determined barnacles, refusing to let go even when 100+ mph winds throw tantrums.

Hail impacts create puncture wounds that seem minor until the next rainstorm turns them into major leak sources, with standard membranes offering about as much protection as tissue paper against softball-sized ice missiles. Impact-resistant materials and reinforced membrane systems treat hail like annoying mosquito bites rather than armor-piercing rounds.

Drainage disasters create the dreaded ponding water scenario, where flat roof areas become temporary lakes that accelerate deterioration and add dangerous structural loads. Proper slope correction and high-capacity drainage systems transform potential aquatic disasters into controlled water flow that protects building integrity.

Metal, EPDM, and PVC roofing offer excellent resistance to various weather conditions, provided they are installed correctly, making material selection and installation quality equally critical for long-term performance (source: Castagra). The winning strategy combines weather-appropriate materials with installation techniques that prevent these predictable failures from turning storms into expensive disasters.

Warning Signs To Watch For

Membrane bubbling and blistering serve as your roof’s cry for help, indicating trapped moisture that’s creating internal pressure ready to explode during the next temperature swing. These seemingly innocent bumps become catastrophic failure points when thermal cycling turns minor imperfections into major breaches.

Flashing separations around penetrations, equipment, and roof edges create invisible highways for water infiltration that bypass all your expensive waterproofing efforts. During wind-driven rain events, these small gaps become fire hoses directing water exactly where you don’t want it – inside your building.

Interior water stains and mysterious drips reveal that your roof’s protective capabilities have already been compromised, often indicating damage that occurred during previous weather events but went unnoticed. These symptoms typically appear weeks or months after the actual damage occurs, making detective work essential.

Ponding areas that persist more than 48 hours after rainfall signal drainage problems that create accelerated deterioration and weight loads your roof wasn’t designed to handle. These aquatic time bombs become exponentially more dangerous when freeze-thaw cycles or additional storm loads stress already compromised systems.

Preventative Approaches

Climate-specific material selection forms the foundation of effective weather defense, matching roofing system strengths to local threat profiles rather than settling for one-size-fits-none solutions. Hurricane zones demand different strategies than hail country or freeze-thaw regions, making geographic threat assessment essential for intelligent material choices.

Proactive maintenance programs catch minor issues before they become major failures, with scheduled inspections after significant weather events preventing small problems from multiplying into expensive disasters. Professional contractors trained in extreme weather damage recognition spot vulnerabilities that untrained eyes miss completely.

Enhanced fastening systems and reinforced membrane installations create fortress-like attachment that laughs off wind loads that would peel standard systems like banana skins. These upgrades cost more upfront but prevent the catastrophic failures that turn storm seasons into budget nightmares.

Advanced monitoring technologies like thermal imaging and moisture detection systems identify hidden problems before they manifest as visible damage, giving facility managers the intelligence advantage needed to stay ahead of weather-related deterioration. Smart prevention investments deliver exponential returns when extreme weather tests every building’s preparedness.

SECTION 6: NEXT STEPS & RESOURCES

Picture this disaster scenario: A facility manager confidently hands over a million-dollar roofing project to the lowest bidder, armed with nothing but price quotes and glossy brochures. Six months later, when Hurricane Harvey’s younger brother arrives for an unscheduled facility inspection, that “bargain” roof performs about as well as tissue paper in a car wash.

The brutal truth? Most roofing disasters start long before the first storm cloud appears – they begin in conference rooms where the wrong questions get asked and critical standards get ignored. Smart facility managers know that the difference between weather warriors and expensive casualties lies in the homework done before contracts get signed.

Questions To Ask Providers

Smart facility managers grill potential roofing contractors like prosecutors cross-examining suspects, because sweet-talking salespeople often promise hurricane-proof performance while delivering tissue-paper protection. Start with the knockout punch: “Show me three similar projects that survived Category 3 hurricanes without major damage – and provide the facility managers’ contact information.”

Demand specific performance numbers that matter when nature throws tantrums: “What’s your system’s tested wind uplift rating, and how does that compare to our local building code requirements?” Follow up with hail resistance ratings, thermal cycling capabilities, and fastener specifications that separate real protection from marketing fluff.

Don’t let contractors escape without explaining their installation crew’s storm-region experience and specialized certifications. Ask about their emergency response protocols and warranty coverage that actually functions when you need it most – after extreme weather exposes every shortcut and cheap material choice.

Properly installed metal roofs can withstand wind speeds up to 140-180 mph, depending on the material and installation, making contractor expertise absolutely critical for achieving these performance levels rather than just promising them (source: Allied Roofing).

The winning questions focus on measurable performance data, real-world survival stories, and specific installation techniques that transform marketing promises into weather-fighting reality.

Industry Standards & Guidelines

Industry standards function like building DNA – they determine whether your roof develops into a weather warrior or grows up to become an expensive disaster waiting for its first storm test. ASTM D7158 wind resistance standards and UL 2218 impact ratings aren’t boring paperwork; they’re survival benchmarks that separate systems that laugh off extreme weather from those that fold faster than lawn chairs in hurricanes.

The National Roofing Contractors Association (NRCA) guidelines provide the roadmap for installation practices that actually work when wind speeds hit triple digits and hail starts falling like frozen golf balls. These aren’t suggestions from overly cautious engineers – they’re battle-tested requirements developed from analyzing thousands of weather-related failures.

Local building codes add another critical layer, incorporating regional threat assessments that account for your area’s specific weather personalities. Florida’s hurricane requirements differ dramatically from Minnesota’s snow load standards, making geographic compliance essential for intelligent protection strategies.

FEMA guidelines connect federal disaster preparedness wisdom with practical roofing decisions, helping facilities qualify for mitigation grants while building resilience that keeps operations running when competitors are calling emergency contractors. Smart facility managers treat these standards like insurance policies that prevent rather than just compensate for weather disasters.

Further Learning Simplified

The roofing industry evolves faster than weather patterns, with new materials and installation techniques emerging as climate change throws increasingly creative challenges at commercial buildings. Staying current isn’t just professional development – it’s financial survival in an era where yesterday’s adequate protection becomes tomorrow’s expensive liability.

NRCA educational webinars translate complex engineering concepts into practical decision-making tools that help facility managers spot genuine innovations versus repackaged marketing hype. These sessions provide insider intelligence on emerging threats and proven solutions without requiring advanced degrees in materials science.

The Roofing Alliance offers research-based insights that connect laboratory testing with real-world performance, giving facility managers the ammunition needed to challenge contractor claims and verify system capabilities. Their white papers decode the latest climate adaptation strategies in language that budget-conscious executives actually understand.

Online industry platforms provide continuous updates on regulatory changes, material innovations, and installation best practices that keep facility managers ahead of the curve. This knowledge investment pays exponential dividends when extreme weather tests every building’s preparedness level.

Smart learning focuses on translating technical advances into competitive advantages that protect both buildings and bottom lines during nature’s increasingly frequent pop quizzes.

The Bottom Line

When the next extreme weather event strikes your facility, your roof will either be your building’s greatest asset or your most expensive liability – and that fate gets sealed long before the first storm cloud appears.

The facilities that emerge unscathed from hurricane-force winds, softball-sized hail, and catastrophic temperature swings share one critical advantage: they invested in weather-ready roofing systems before nature demanded proof of their protection claims.

Climate change isn’t waiting for budget approvals or convenient timing. Every day spent with inadequate weather protection increases your facility’s vulnerability to the increasingly violent storms that turn “adequate” roofs into expensive disasters.

The choice is stark and immediate: upgrade to extreme weather readiness now, or explain to stakeholders later why your facility became another cautionary tale about the true cost of roofing shortcuts.

FREQUENTLY ASKED QUESTIONS

Q. What makes a commercial roof tough enough for extreme weather?

A. Think of it as a superhero suit made of multiple layers working together! These layers include waterproof membranes, insulation, and protective barriers all designed to resist wind, water, and temperature swings. The real magic happens when quality materials and smart installation combine to create an unshakable fortress over your building.

Q. How do industrial roof systems handle different extreme weather conditions?

A. They adapt like pros! In tornado-prone areas, reinforced fasteners hold strong against fierce winds, while cold climates get multi-layered designs to survive freeze-thaw cycles. Coastal roofs sport impact-resistant membranes to shrug off flying debris. Each solution tackles specific weather challenges, turning ordinary tops into specialized defenders that keep your operations safe.

Q. What commercial roof terms should I know to avoid costly mistakes?

A. Key lingo like “wind uplift rating” tells you how much force your roof can resist before lifting off, while “mil thickness” measures membrane strength against punctures. Knowing terms such as thermal cycling and flashing helps you understand how roofs stay flexible and watertight. Getting these basics means smarter choices and fewer surprises in bad weather.

Q. What factors should facility managers weigh when choosing a commercial roof?

A. It’s about balancing cost, durability, and performance! While budget roofs may save dollars upfront, investing in premium systems can prevent costly storm damage and business interruptions. Location matters too—pick materials rated for your regional threats, like hail or hurricanes, to avoid expensive repairs. Think long-term savings and peace of mind, not just price tags.

Q. What common commercial roof problems threaten weather resistance?

A. Watch for weak fasteners becoming kites in high winds and hail damage turning into leaks. Ponding water after rain can accelerate wear and lead to structural stress. Early signs like membrane bubbling or flashing gaps signal trouble. Spotting these hazards early lets you fix small issues before storms turn them into costly disasters.

Q. What questions should I ask roofing contractors about commercial roofs?

A. Be a roofing detective! Ask for examples of projects surviving Category 3 storms and check their performance stats—wind uplift ratings and hail resistance matter. Don’t forget to dig into their team’s storm-region experience and warranty details. These questions separate true experts from smooth talkers who promise more than they deliver.

Q. How does incorporating green roofing options impact commercial roof weather resistance?

A. Green roofs don’t just look good—they boost weather defense by adding extra insulation and managing stormwater naturally. This added layer reduces temperature swings and eases drainage, preventing ponding water problems. Plus, they help your building stay cool under that blazing sun, cutting energy costs while strengthening the roof’s overall resilience.