Welcome to today’s Battle Royale featuring two roofing heavyweights: “Flat Roof Drains” in the east corner versus “Scuppers” in the west!

Tonight’s showdown pits these contenders against each other across six punishing rounds designed to test every aspect of their performance for Proper Drainage on a Commercial Roof.

At stake? Millions in potential costs, decades of building protection, and the critical performance demands of modern commercial and industrial facilities.

Our professional judging panel will evaluate each round on technical merit, real-world performance, and value delivery. After all six rounds, we’ll declare our ultimate champion.

Ladies and gentlemen, facility managers and building owners… it’s time to rumble!

ROUND 1: INITIAL COSTS & INSTALLATION

When it comes to commercial roof drainage, the stakes couldn’t be higher. Water accumulation can lead to structural damage, mold growth, and catastrophic roof failure if not properly managed. Flat roofs require specialized drainage systems since gravity-based flow is limited, making the choice between drains and scuppers a critical decision for long-term building performance. (source: TEMA Roofing Services)

Material Expenses

Internal roof drains represent a significant upfront investment, requiring professional-grade materials and comprehensive plumbing systems. These components include cast iron or copper drain bodies, strainers, clamping rings, and extensive interior piping networks.

Scuppers present a more economical initial investment, primarily consisting of metal fabrication and flashing materials. Their simplified design requires fewer components and minimal specialized materials.

However, the durability and longevity of internal drain materials often justify their higher costs through extended service life and reduced replacement frequency.

Based on material quality and long-term value, internal roof drains claim the “ADVANTAGE” in this category.

Installation Complexity

Internal roof drain installation demands precise coordination between roofing and plumbing trades. The process involves careful placement, proper pitch calculation, and integration with building plumbing systems.

Scupper installation presents a more straightforward process, requiring only exterior wall penetrations and basic sheet metal work. This simplicity reduces the potential for installation errors and minimizes the need for multiple trade coordination.

The streamlined nature of scupper installation translates to lower labor costs and reduced complexity on the job site.

For installation complexity, scuppers hold the clear “ADVANTAGE”.

Project Timeline

Internal drain installation typically extends project timelines due to the complexity of integrating with existing plumbing systems. The process often requires multiple inspections and careful testing before completion.

Scupper installation can usually be completed in a fraction of the time, with fewer dependencies on other building systems. This efficiency minimizes disruption to building operations and occupants.

The faster installation time and reduced coordination requirements make scuppers the more time-efficient choice.

When considering project timeline impact, scuppers earn the “ADVANTAGE”.

ROUND 1 WINNER: Scuppers

ROUND 2: DURABILITY & LIFESPAN

When evaluating commercial roof drainage systems, durability and lifespan directly impact building protection and long-term costs. Studies show that water damage from inadequate drainage accounts for over 40% of commercial roof failures, making system longevity crucial for facility protection.

Gravity drainage systems are recommended for flat or low-slope commercial roofs under 150 square meters per drainage point, while larger roofs benefit from more sophisticated solutions that can achieve significantly higher drainage speeds. (source: Waterproof Magazine)

Material Resilience

Internal roof drains typically feature heavy-duty materials like cast iron or copper that resist corrosion and physical damage. These materials maintain their structural integrity even under extreme temperature fluctuations and constant water exposure.

The drain bodies include protective coatings and reinforced connections that prevent deterioration at critical junctures. Their robust construction allows them to handle high water volumes without degradation.

Scuppers, while effective, often utilize lighter-gauge metals that may warp or corrode over time. Their exposed positioning makes them more vulnerable to environmental wear and impact damage.

For material resilience, internal roof drains claim the clear “ADVANTAGE”.

System Performance

Internal drain systems incorporate multiple safeguards against failure, including primary and secondary drainage paths. Their enclosed design protects critical components from UV exposure and weather damage.

These systems maintain consistent performance through seasonal changes and can be equipped with heating elements to prevent freezing in cold climates. Their integrated design also reduces the risk of water infiltration at connection points.

Scuppers provide simpler but less protected drainage paths. Their open design makes them more susceptible to clogs and ice formation, potentially compromising performance during critical weather events.

In system performance evaluation, internal roof drains earn the “ADVANTAGE”.

Long-term Reliability

Internal roof drains demonstrate superior longevity, often matching or exceeding the lifespan of the roof membrane itself. Their protected location within the building envelope shields them from direct environmental exposure.

Regular maintenance access points and standardized components make these systems easier to inspect and repair when needed. This accessibility helps prevent minor issues from escalating into major problems.

Scuppers, while maintenance-friendly, typically require more frequent repairs or replacement due to their exposed position and simpler construction. Their direct exposure to elements accelerates wear patterns.

For long-term reliability, internal roof drains secure the “ADVANTAGE”.

ROUND 2 WINNER: Flat Roof Drains

ROUND 3: PERFORMANCE FACTORS

The performance of commercial roof drainage systems directly impacts building integrity and maintenance costs. When drainage fails, even a single inch of standing water can add 5.2 pounds of weight per square foot, potentially overwhelming structural design limits. Proper system selection must balance water removal efficiency, maintenance requirements, and climate-specific challenges.

Water Flow Efficiency

Internal drainage systems use gravity and engineered flow paths to quickly remove water from roof surfaces. The drainage system on a commercial building requires internal pipes to connect to the internal drain, enabling efficient water management even during heavy rainfall. (source: Waterproof Magazine)

These systems can be equipped with larger drain openings and carefully calculated pipe sizes to handle peak water volumes. Their design prevents water from accumulating in any single area, distributing the load across multiple drainage points.

Scuppers rely on roof slope and edge positioning to direct water flow. While effective for smaller roof areas, their capacity can be overwhelmed during intense storms, potentially leading to backup and pooling.

For water flow efficiency, internal roof drains claim the clear “ADVANTAGE”.

Maintenance Requirements

Internal roof drains feature protective strainers and debris guards that help prevent clogging. Regular inspection and cleaning are essential to maintain optimal performance, requiring access to both roof-level components and internal piping.

These systems benefit from standardized maintenance protocols but may require specialized equipment or expertise for thorough cleaning and repair. Internal clogs can be more challenging to locate and address.

Scuppers present more straightforward maintenance needs with easily accessible components. Their open design allows for quick visual inspection and simple cleaning procedures using basic tools.

Given the trade-offs between accessibility and complexity, maintenance requirements result in a “TIE”.

Resistance to Ice and Snow

Internal roof drains face significant challenges in cold climates where freezing can disrupt water flow. Even with heating elements, these systems remain vulnerable to ice formation within pipes and around drain openings.

The enclosed nature of internal drains can trap ice and create dangerous backup conditions. This risk requires additional winterization measures and careful monitoring during freeze-thaw cycles.

Scuppers provide natural pathways for ice and snow melt, working with gravity to prevent accumulation. Their exterior mounting position helps prevent internal freezing while allowing ice to clear naturally.

For winter weather performance, scuppers earn the “ADVANTAGE”.

ROUND 3 WINNER: Flat Roof Drains

ROUND 4: MAINTENANCE REQUIREMENTS

The maintenance demands of commercial roof drainage systems directly impact building performance and operational costs. Studies show that poorly maintained drainage systems account for up to 35% of premature roof failures. Property managers must weigh the long-term maintenance commitments between different drainage options to protect their investment and prevent catastrophic water damage.

Inspection Frequency

Internal roof drains require quarterly professional inspections to maintain peak performance. These inspections must evaluate both surface components and internal plumbing connections to identify potential issues before they escalate.

The complex nature of internal drain systems demands specialized knowledge and equipment to properly assess all components. Technicians must verify proper flow rates, check for internal pipe damage, and ensure strainer functionality.

Scuppers benefit from simpler inspection requirements, typically needing only visual checks of the opening and surrounding flashing. Their straightforward design allows maintenance staff to quickly identify and address potential issues.

For inspection requirements, scuppers claim the “ADVANTAGE”.

Cleaning Requirements

Internal roof drains need regular cleaning to prevent debris accumulation in strainers and piping. This process often requires specialized equipment to clear internal blockages and ensure proper flow through the entire system.

Professional cleaning services are typically needed at least twice annually, with additional cleanings required in areas with heavy foliage or during storm seasons. The internal components make thorough cleaning more challenging and time-consuming.

Scuppers require only basic cleaning tools and techniques to maintain proper function. Their open design allows for easy debris removal and quick visual confirmation of successful cleaning.

When considering cleaning requirements, scuppers hold the clear “ADVANTAGE”.

Repair Complexity

Internal drain repairs often involve multiple building systems and require coordination between roofing and plumbing specialists. Problems within the drainage system can be difficult to diagnose and may require extensive investigation.

Component replacement in internal systems frequently demands significant roof membrane disruption and potential interior access. These repairs typically result in longer facility disruption and higher labor costs.

Scupper repairs generally involve straightforward metal work and flashing repairs that can be completed from the exterior. Their simplified design means fewer potential failure points and more straightforward repair procedures.

For repair complexity and accessibility, scuppers secure the “ADVANTAGE”.

ROUND 4 WINNER: Scuppers

ROUND 5: SUSTAINABILITY CREDENTIALS

As environmental regulations tighten and building efficiency standards evolve, the sustainability impact of commercial roof drainage systems demands careful evaluation. Modern drainage solutions must balance water management, material conservation, and energy efficiency to meet growing environmental challenges while protecting building assets. Property owners face increasing pressure to implement systems that minimize environmental impact while maximizing building performance.

Water Management Efficiency

Internal roof drains provide superior control over water flow and distribution, enabling integration with rainwater harvesting systems and controlled discharge rates. These systems can be precisely engineered to handle specific water volumes while preventing overflow during peak events.

The drainage system on a commercial building requires internal pipes to connect to the internal drain, making the system more complex but allowing for better water management and potential reuse opportunities. (source: Waterproof Magazine)

Scuppers offer limited control over water discharge, potentially contributing to site erosion and stormwater management challenges. Their simplified design makes it difficult to implement water conservation strategies or regulated flow rates.

For water management efficiency, internal roof drains claim the “ADVANTAGE”.

Energy Efficiency

Internal roof drains support better insulation continuity across the roof surface, reducing thermal bridging and improving overall building energy performance. Their placement allows for uninterrupted installation of roofing materials and insulation layers.

These systems also facilitate better integration with cool roofing materials and solar installations, as they don’t create obstacles or shadows on the roof surface. The enclosed design helps maintain consistent roof temperatures and reduces heat loss through drainage penetrations.

Scuppers create multiple thermal breaks in parapet walls, potentially compromising building envelope performance. Their placement can interfere with optimal solar panel positioning and reduce usable roof space for energy-efficient installations.

For energy efficiency considerations, internal roof drains earn the “ADVANTAGE”.

Material Longevity

Internal roof drains utilize highly durable materials designed for decades of service, reducing replacement frequency and associated material waste. Their protected location within the building envelope extends component lifespan and minimizes exposure to degrading elements.

These systems typically incorporate recyclable materials like cast iron or copper, supporting end-of-life material recovery. Their standardized designs facilitate component replacement without requiring complete system overhaul.

Scuppers often require more frequent replacement due to environmental exposure, generating additional material waste. Their simpler construction may use less material initially but demands more frequent maintenance and replacement.

For material sustainability, internal roof drains secure the “ADVANTAGE”.

ROUND 5 WINNER: FLAT ROOF DRAINS

ROUND 6: SPECIALIZED APPLICATIONS

Specialized commercial roofing applications demand drainage solutions that go beyond standard installations. Manufacturing facilities, data centers, and distribution warehouses face unique challenges that can make the difference between reliable operations and catastrophic failure. The stakes are particularly high in facilities where water damage could compromise millions in equipment or interrupt critical business operations.

High-Load Environments

Manufacturing facilities and industrial buildings require drainage systems capable of handling extreme loads and chemical exposure. Flat roof drains excel in these environments due to their robust construction and ability to integrate with specialized filtration systems.

Industry-leading manufacturers like Zurn Industries produce specialized drain systems engineered specifically for industrial applications, featuring chemical-resistant materials and reinforced components. Their systems include features like extra-large strainers and chemical-resistant coatings essential for industrial environments. (source: Plumberstar)

Scuppers, while effective in standard applications, often lack the sophisticated features needed for industrial settings. Their simplified design may not adequately handle specialized filtration requirements or chemical exposure common in manufacturing environments.

For high-load industrial applications, flat roof drains claim the clear “ADVANTAGE”.

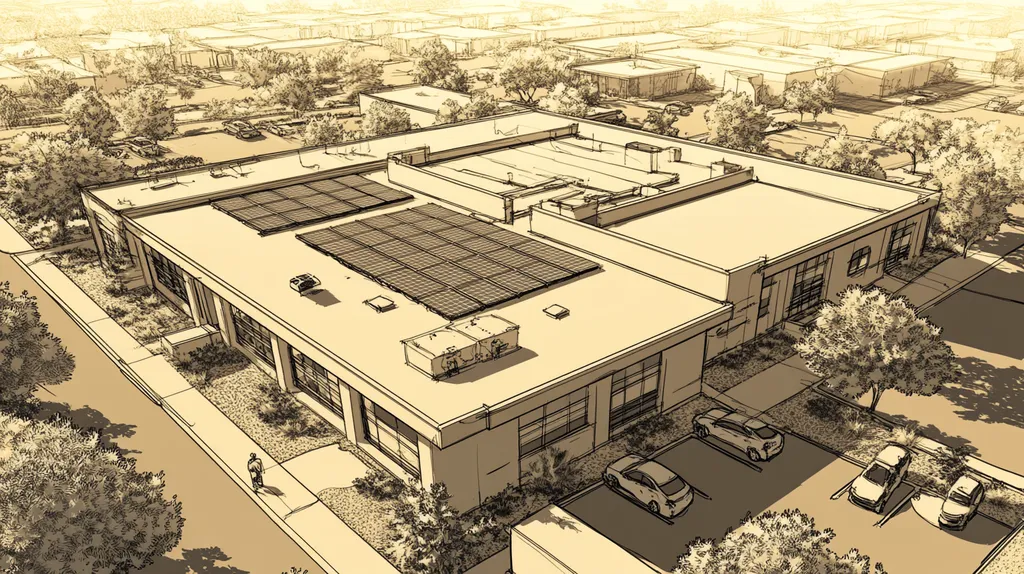

Equipment-Dense Rooftops

Modern commercial rooftops increasingly house critical equipment like HVAC systems, satellite dishes, and solar arrays. Flat roof drains offer superior flexibility in placement, allowing optimal positioning around roof-mounted equipment without compromising drainage efficiency.

These systems can be strategically located to create clear maintenance paths while ensuring complete coverage. Their below-surface design preserves valuable roof space for equipment placement and maintenance access.

Scuppers require specific edge positioning that may conflict with equipment layout needs. Their fixed location requirements can limit equipment placement options and create maintenance accessibility challenges.

For equipment-dense installations, flat roof drains secure the “ADVANTAGE”.

Green Roof Integration

Sustainable building designs increasingly incorporate green roof systems that require specialized drainage considerations. Flat roof drains can be equipped with soil guards and filtration systems specifically designed for vegetative roof applications.

These systems effectively manage both surface and subsurface water movement essential for plant health. Their design allows for proper soil depth while maintaining efficient drainage throughout the growing medium.

Scuppers present significant challenges in green roof applications, potentially creating dry zones near drainage points and complicating proper soil depth maintenance. Their edge-only placement limits effective water distribution through growing medium.

For green roof applications, flat roof drains earn the “ADVANTAGE”.

ROUND 6 WINNER: FLAT ROOF DRAINS

AND THE WINNER IS…

After six grueling rounds of technical evaluation, we have our verdict…

Ladies and gentlemen, with four rounds to two, your NEW COMMERCIAL ROOF DRAINAGE CHAMPION is… FLAT ROOF DRAINS!

The champion dominated the competition through superior durability, unmatched performance in specialized applications, and outstanding sustainability credentials. Its robust construction and versatile design proved decisive in rounds focusing on material resilience, water management, and integration with modern building systems.

But don’t count scuppers out completely! In situations demanding rapid installation, simplified maintenance, or superior cold-weather performance, this seasoned contender still packs a powerful punch. Their straightforward design and lower initial costs make them a strong choice for smaller facilities or retrofit projects with limited budgets.

Remember, folks – every building brings its own unique challenges to the ring. Local climate conditions, structural specifications, and specific facility requirements can all influence the final decision. While tonight’s match provides valuable insights, property owners should always consult qualified roofing professionals who can evaluate their specific situation before making the final call.

In the high-stakes world of commercial roofing, the true victory comes not from following the crowd, but from selecting the drainage solution that best protects your specific facility’s long-term performance and value.

FREQUENTLY ASKED QUESTIONS

Q. What are the initial costs of a commercial roof drainage system?

A. Initial costs for drainage systems vary. Internal drains require significant investment due to complex materials, while scuppers offer a more economical option. In the long run, the robustness of internal drains can justify their higher upfront cost.

Q. How does durability differ in commercial roof systems?

A. Internal roof drains often use heavy-duty materials, enhancing longevity and performance under various conditions. On the other hand, scuppers tend to use lighter materials, making them less durable over time.

Q. Which drainage system is more efficient in water flow for commercial roofs?

A. Internal drainage systems are designed for quick water removal using engineered flow paths, ensuring efficiency during heavy rainfall. Scuppers can be overwhelmed in intense storms, potentially causing pooling.

Q. How often should a commercial roof drainage system be inspected?

A. Internal roof drains should be inspected quarterly by professionals due to their complexity. In contrast, scuppers typically need only visual checks, which simplifies the inspection process.

Q. What is the sustainability of commercial roof drainage options?

A. Internal roof drains promote better water management and utilize durable, recyclable materials. Scuppers often require more frequent replacements, affecting overall sustainability due to higher material waste.

Q. Are there specialized drainage systems for industrial roof applications?

A. Yes, industrial roofs often need specialized drainage systems designed for high loads and chemical exposure. Flat roof drains excel in these environments, integrating essential features for industrial applications.

Q. How do flat roof drains benefit equipment-dense rooftops?

A. Flat roof drains provide flexibility in placement, accommodating critical equipment like HVAC units. Their below-surface design helps maintain roof space for installations without compromising drainage efficiency.